JOHN DEERE X300 - WORST LAWN TRACTOR EVERI purchased a John Deere X300 from our local John Deere dealer on

07-17-2013 and was expecting many years of service from said lawn

tractor, however I have surely been very disappointed with the

reliability of this lawn tractor. In fact, this is the

worst lawn

tractor/mower that I have ever owned and I will present my case why I

have come to this opinion and conclusion.

I yearly change the oil

filter, oil, spark plugs, clean or replaced the air filter and the

in-line gas filter (optional) depending on its condition. I also

lubricate aka grease all the jerk fittings and oil at other points per

the manufacturer's manual. Tires and battery have been replaced a

time or two which is rather routine.

The year 2022 was a time for some serious parts replacement to the deck

of which if I am not mistaken had 178.6 hours total run time.

LAWN TRACTOR MAINTENANCE

Today 03-22-2022, the mid-day weather was gorgeous with highs in the

lower 70s and a great day to do the annual maintenance on the John Deere

X300 lawn tractor.

What started out to be routine maintenance, ended up being a

corrective maintenance issue. Yesterday after cutting the front,

side and back yard and having the deck in gear while running water into

the port to clean the deck underneath, I noticed an abnormal sound and

the deck was doing more vibrating that usual with the deck blades in

gear.

While removing the right cutting blade, I noticed a good amount of

movement in the spindle and knew that the bearings were gone. I

went to John Deere aka Quality Equipment in Polkton, NC and purchased a

spindle assembly. When you purchase something with John Deere

green on it, your wallet or plastic will definitely know you have been to

John Deere!

I had never taken the cutting deck off the X300 and viewed a couple

videos on YouTube before starting this project which was a valuable help

and resource.

After disengaging the deck from the lawn tractor, I used a DeWalt 20V

cordless impact Drill Driver model number DCF885B which is

variable speed; 0-2,800 RPM to try and loosen the pulley nut which was

7/8 inches, however the nut would not budge. I then took a propane

torch and heated the nut up and after several seconds with the impact

driver/drill chugging along, the nut finally broke loose. It was

then no problem removing the spindle assembly which was held to the deck by

four (4) bolts.

The old spindle assembly is off and the new one ready to be

installed. I definitely didn't blow or wash the leaves from the

upper cutting deck...........my bad!

New spindle installed and ready for the pulley and pulley nut.

With that out of the way, getting the deck back onto the lawn tractor

took some serious effort, but managed to get it done and tested the unit

out and it ran fine without all the noise and excessive vibration.

I should have replaced the other spindle which will go out soon for

sure, but I am going to "milk"

it as long as I can!

After reading a few internet threads, the deck bearings do not last

that long on some of the John Deere models and I am not talking about

the cheaper ones they sell to Lowe's, etc. for resale.

Most of the time you get what you pay for, but I don't think it fits

current John Deere, whereas I believe their quality has diminished over the

decades trying to

stay competitive with other brands which are getting a Lion's share of

the market.

After the spindle replacement, I changed the oil, oil filter, spark

plugs, cleaned the air filter and greased the fittings.

BECAUSE ITS GREEN, DOESN'T MEAN QUALITY AND SERVICE

Just for the record to validate my above heading, I used a Troy-Bilt

lawn tractor which was around 18 HP with a Kohler engine and 36 inch wide cutting deck for

approximately twenty-five (25) years and did not have any major repairs

or issues, other than cross threading the spark plug which had to be

re-tapped/threaded. The deck spindle bearings were still good when I gave it

to our oldest daughter, of which she used it for a few years and I believe

that was about eight (8) years ago.

The only problem with the machine was the carburetor needed cleaning

and the fuel line needed to be blown out!

PLANNED OBSOLESCENCE

After viewing a couple

videos on why many lawn tractor deck spindle

bearings fail within a few years, it was apparent that they were

manufactured to fail. The reason being, there are grease fittings

on most of the spindle assemblies, however the bearings are sealed and

the applied grease never reaches the inside of the bearing raceway.

The only grease in the bearings is the grease applied during the bearing

manufacturing process.

Here is the definition of planned

obsolescence: Planned obsolescence means

manufacturers deliberately designing products to fail prematurely or

become out-of-date, often to sell another product or an upgrade – a

practice that is barred in some countries.

Web page updated by Bill aka Mickey Porter on 03-22-2022.

DECK SPINDLE TEAR DOWN

We had rain last night early morning (03-24-2022) and too wet to do

anything outside and to keep from getting

"antsy", I decided to tear down the X300 deck spindle, whereas at least one bearing was

completely shot.

Yesterday, I attempted to take the spindle apart to access the

bearings, but wasn't able to do it. There are no YouTube videos

showing the tear down of the John Deere spindle, part number

AM137483; finally figured out the top idler spacer needed to come off. It was

apparently fixed solid to the main shaft; i.e., press fit on the shaft.

I soaked the shaft/heavy washer with Kroll oil overnight and this no

doubt helped!

There was about 1/8 inch clearance between the washer and the spindle

housing and took a flat head screwdriver and worked around the diameter

of the housing and it started to move upward and finally got it removed.

I definitely did the above the hard way, whereas all I had to do was

put a nut on the top threaded spindle and tap it with a hammer and the

spindle will start moving out of the spindle housing. You have to

readjust (back out the nut) to give the shaft clearance space, whereas

the spindle will come out the bottom of the spindle housing.

As depicted by the pixs below, the top bearing was totally destroyed

and somewhat dry indicating there was no grease getting to it.

There was some grease inside the spindle housing and the lower bearing

was still in fairly good shape. I did notice that there was no

seal on the bottom bearing facing the spindle cavity and probably why it

did not fail, of which there was adequate grease in the bearing raceway.

NOTE: John Deere sells the above bearings, whereas the

bottom bearing has the top seal removed and the upper bearing has both

seals in place. No amount of grease you pump will get into the top

bearing and as evidenced will prematurely fail!

A closer look at the bearings, of which the top bearing was totally

destroyed aka shot.

I ordered a couple after market bearings for this spindle and will

drill and tap a weep hole in the upper spindle housing and also remove

the seal on the bearings that is facing inside the spindle housing to

allow grease to get to the bearings. I tested the zerk grease

fitting on the top of the shaft and there was grease getting through two small holes on either

side of the main shaft.

As soon as the bearings arrive, will get the deck spindle put back

together and have a spare unit!

REPLACED SPINDLE BEARINGS

I received the spindle bearings today (03-28-2022) and already

drilled and tapped a weep hole in the spindle housing to ascertain that

the cavity will be full of grease.

I installed the spindle bearings without the usage of a press,

whereas I have a small press to install frets into musical instruments,

but it was not large enough, therefore I tapped the bearings into place

with a small hammer with a brass and a hard plastic head. After

the bearings were installed, I filled up the spindle cavity with high

temperature bearing grease. Pixs below:

I removed one of the bearings seals on each bearing and the

bearings without the grease seal will face inward toward the spindle

cavity to allow grease to get to the bearings.

The bearing is slowly tapped into position.

Spindle housing with the bearings and caps in place along with the

weep hole sealed with a 10-24 bolt.

I will give the spindle a test run using my large drill press to

drive the spindle and see if the grease stays in place. There was

some slop between the main shaft and the inner bearing no doubt due to

wear. If it doesn't work, I have enjoyed taking the spindle

housing apart and installing the bearings even though the bearings cost

$ 15.50 for a set of two.

Web page updated by Bill aka Mickey Porter on 03-28-2022.

REPLACED LEFT SPINDLE

The lawn tractor was making a terrible racket when the mowing deck

was engaged and ordered a John Deere deck spindle assembly from one of

John Deere's vendors via EBay which was a few bucks cheaper than the

closest John Deere Dealer in Polkton, NC. The hours on the JD was

approximately 178 hours.

I replaced the worn out spindle assembly and the top bearing was

totally shot and the ball bearing raceway had given way and the ball

bearings had worn grooves into the spindle spacer rendering the spindle

housing unfit for replacing the bearings.

It didn't take but about 30 minutes, guessing at the time since I now

know the short cuts and easy way of removing the deck, etc. and added a

1/2 inch drive pneumatic impact wrench which was a breeze removing the

spindle housing, blade and pulley nut.

I did notice a couple belt flat groove idler pulleys had excessive play in them

and will order replacements and order a new belt since it is showing

some wear, but still working ok.

After replacing the spindle assembly, I cut the grass in the front

and side yard and the lawn tractor was not too loud when the deck was

engaged and no excessive vibration as before.

Web page updated by Bill aka Mickey Porter on 04-16-2022.

REPLACED TWO DECK FLAT IDLER PULLEYS

On May 11, 2022, I replaced the two flat idler pulleys on the

deck. I have on back order the V-Drive deck pulley. When the

V-Drive pulley arrives at the John Deere outlet in Polkton, NC I

will purchase two of the hard plastic deck wheels which are worn badly.

The deck drive belt is in fairly good shape and will

"milk" it a little

longer............grin if you must!

After installing the two flat deck idler pulleys, it was amazing how

quiet the machine sounded with the blades engaged. The total

operating hours for the X300 was 182 hours.

The only thing that didn't need replacing on the 42 inch Edge deck

was the two spindle drive pulleys.

Basically, I will have rebuilt the deck when the V-Drive deck pulley

arrives and the replacement of the worn deck wheels.

To say the least, "I am not impressed

with the reliability of this John Deere X300 42 inch deck."

Web page updated by Bill aka Mickey Porter on 05-11-2022

REPLACED WORN DECK WHEELS

On May 16, 2022, I replaced the two worn deck wheels and noticed that

the shoulder bolts aka axles were worn badly as well and order some

generic shoulder bolts from EBay.

The shoulder bolts I received, the shoulder portion of the bolt was

about 3/32 inch too long and added a washer between the shoulder bolt

and wheel to the deck frame bracket. I had to drill the washer

hole out to 5/8 inch diameter and the wheels were snug without much

wobble and turned freely.

NOTE: While at the John Deere place in Polkton, NC, I

purchased a belt and picked up the v-drive pulley that was on back

order. I will not change the v-drive pulley unless

the v-drive pulley gets real noisy, wobbly, etc. and/or the drive belt

breaks.

Web page updated by Bill aka Mickey Porter on 05-20-2022.

LAWN TRACTOR TRANSMISSION TROUBLES

Sometime around May 27th, while cutting our yards, the lawn tractor

would barely go forward and reverse and making a horrible metallic

clanking sound and I assumed the transmission was gone. I went on

YouTube and viewed several videos and talked with the John Deere service

department and they said to check the transaxle pump drive pulley that

it might be worn out, of which I did and that was the initial problem.

I went on line an ordered OEM parts; transaxle pump drive pulley and

the transmission cooling fan of which the splines were worn also.

I definitely didn't order them from John Deere since John Deere just

repackages the parts which are made for Tuff Torq!

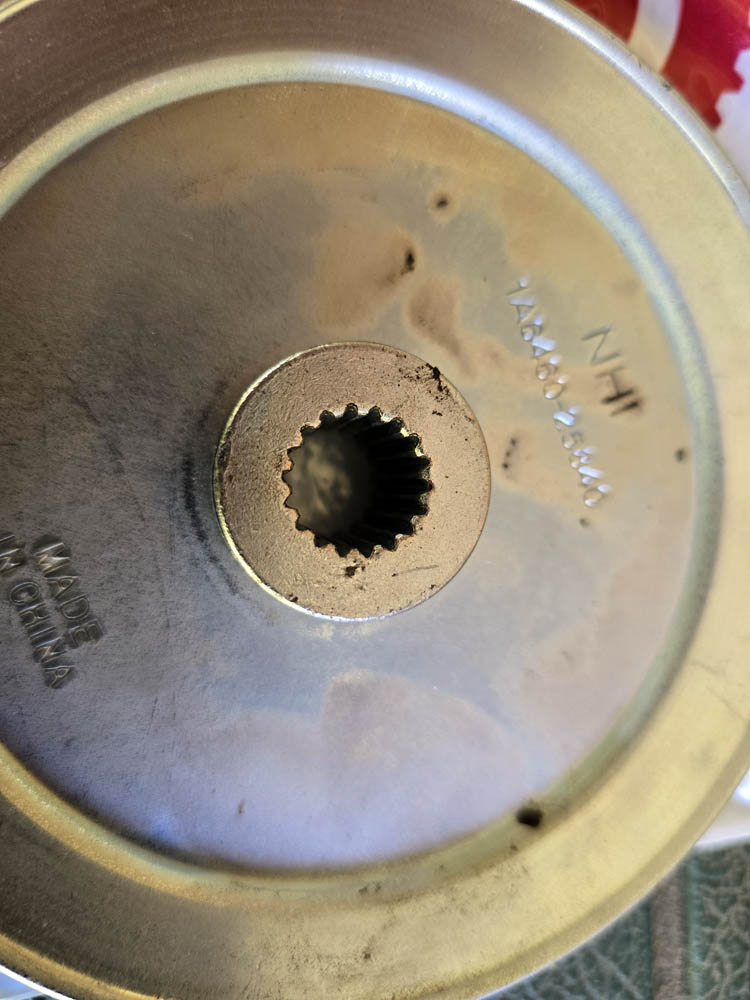

Pix of the original drive pulley and the splines are worn completely

out; only a few on the bottom of the bottom. Looks like a smooth

bore 20 gauge shotgun barrel muzzle, grin if you must!

A big difference in the splines on the new pulley. The hub of the

pulley is made of a softer material than the drive shaft to the

transmission pump since you don't want to have to tear the transmission

down for such a problem.

The fan still has some life left to it, but it was very loose on the

drive shaft and needed to be replaced.

Pix of the replaced drive pulley and transmission cooling fan.

There are plenty of YouTube videos showing how to change these parts

out.

The lawn tractor was field tested going up a few steep hills and

the transmission pulled ok.

TRANSMISSION OIL CHANGE

The oil in the transmission has never been changed and my bad for not

doing more research. Quote John Deere manual,

"The transmission is a sealed component.

No maintenance is required on this transmission. If you suspect

any transmission problems, please contact your authorized dealer."

Since I did not want to remove the transaxle from the lawn tractor, I

elected to do a "poor man's"

oil change, meaning to pump out as much oil as I could from the

transmission, replaced what I removed with new oil and do that a few

times until the oil looks nearly new. I did this three (3) times

and the oil looked good on the 3rd removal. There are several

YouTube videos showing how this is done without removing the transaxle

from the lawn tractor.

At the end of this years grass cutting season,

I plan to remove the transaxle (transmission) from the lawn tractor and

put new oil in the tractor. This procedure will allow you to

nearly remove all the oil that is inside the transmission.

The initial two times of pumping about a quart of oil from the

transmission, the oil was very, very black and the third time, it was

much cleaner looking.

To reiterate, "This is the worst lawn tractor/mower that I have ever

owned!"

Current hour time on this lawn tractor is 226.6 hours!

Web page created by Bill aka Mickey Porter on

06-04-2024.

NOTE: Since replacing the transmission oil on

06-04-2024, I have pumped out and replaced 3 quarts of the oil with

15-50 wgt. oil and so far so good on the transmission continuing to work

properly.

Many have stated on various threads that changing the oil in

the Tuff Torq transaxle is a waste of time, however it has worked in my

case. Whenever, the transaxle does bite the dust, I am thinking

about replacing the K46 transaxle with the K66 transaxle which is a

serious upgrade from the K46 and it will fit the above lawn tractor

frame, etc.

SHEAVE

ASSEMBLY PULLEY BEARING DEFECTIVE

I replaced the sheave pulley

assembly John Deere part number AM135526 on or about 05-10-2022

and it lasted less than two (2) years and five (5) months. I was

cutting grass this afternoon (10-04-2024) and the pulley bearing froze

up and the nut worked its way loose on the pulley allowing the belt to

come loose from the engine drive pulley. The bearings were total

seized in the bearing raceway.

Current hour meter is 238.7 hours, therefore the pulley lasted a

total of 56.7 hours!

Rather than use another one of John

Deere original Chinese made parts, I ordered a generic replacement by

Stens offered by Powermowersalesonline, of which no doubt is Chinese

made also.

This John Deere

X300 lawn tractor has been a total disappointment as documented in this

product review.

Web page

updated by Bill aka Mickey Porter on 10-04-2024.

USPS

Here is the tracking for the order

placed via EBay on October 5, 2024 and our USPS is akin to one that has a

jackass entered into the Kentucky Derby and expects to win the race!

This is a classic example of affirmative action at its best!

Sat, Oct 12

8:14am

Out for Delivery, Expected Delivery by 9:00pm

WADESBORO, NC 28170

Sat, Oct 12

8:03am

Arrived at Post Office

WADESBORO, NC 28170

Sat, Oct 12

8:03am

Estimated delivery date updated to Sat, Oct 12 9:00pm

Sat, Oct 12

6:07am

Departed USPS Facility

GASTONIA, NC 28054

Fri, Oct 11

2:45pm

Arrived at USPS Regional Destination Facility

CHARLOTTE NC DISTRIBUTION CENTER, 28057

Fri, Oct 11

6:48am

Arrived at USPS Facility

GASTONIA, NC 28054

Fri, Oct 11

4:18am

Processing Exception, Regional Weather Delay

Fri, Oct 11

4:03am

In Transit to Next Facility

Fri, Oct 11

1:25am

Departed USPS Facility

PALMETTO, GA 30268

Thu, Oct 10

3:33am

Arrived at USPS Facility

PALMETTO, GA 30268

Thu, Oct 10

1:04am

Processing Exception, Regional Weather Delay

Thu, Oct 10

12:49am

In Transit, Arriving On Time

Wed, Oct 9

11:38pm

Departed USPS Regional Facility

BIRMINGHAM AL DISTRIBUTION CENTER, 35222

Wed, Oct 9

3:21pm

Arrived at USPS Regional Facility

BIRMINGHAM AL DISTRIBUTION CENTER, 35222

Tue, Oct 8

6:22pm

Processing Exception, Regional Weather Delay

Tue, Oct 8

12:00am

In Transit to Next Facility, Arriving On Time

Mon, Oct 7

11:07pm

Arrived at USPS Regional Origin Facility

OPA LOCKA FL DISTRIBUTION CENTER, 33054

Mon, Oct 7

10:07pm

Processing Exception, Regional Weather Delay

Mon, Oct 7

10:07pm

Estimated delivery date updated to Fri, Oct 11

Mon, Oct 7

9:52pm

Accepted at USPS Origin Facility

MIAMI, FL 33189

Mon, Oct 7

9:52pm

Estimated delivery date updated to Tue, Oct 8

Sat, Oct 5

9:32am

SHIPPING LBL CREATED USPS AWAITS ITEM

MIAMI, FL 33189

Sat, Oct 5

7:45am

Tracking number provided

This is not the first time that the USPS Regional Destination Facility

CHARLOTTE NC DISTRIBUTION CENTER, 28057 has received a shipment and then

rerouted a shipment back to the last facility and then finally got the

package sent to my local post office here in Wadesboro, NC. Only in

America is such incompetence tolerated, especially at all levels of

Govt.!

REPLACED SHEAVE ASSEMBLY

The bearings in the above sheave aka idler pulley was smooth as silk.

Hope it will last much longer than the replacement

I got from John Deere in Polkton, NC. This is the third (3rd)

sheave pulley on this lawn tractor.

I removed the deck in order

to replace the pulley and it was no trouble since I now have experience

removing the deck.

Web page updated by Bill aka Mickey Porter on

10-14-2024.

LEAVING ON A SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take this

moment to accept him by Faith into your Life, whereby Salvation will be

attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through faith;

and that not of yourselves: [it is] the gift of God: 9 Not of works, lest

any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for, the

evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by the

word of God.”

Open this

link about faith in the King James Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the Lord

Jesus, and shalt believe in thine heart that God hath raised him from the

dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation, King

James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder of

soul and spirit, and of the joints and marrow, and is a discerner of the

thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of God is

eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory of

God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what doth

the LORD require of thee, but to do justly, and to love mercy, and to walk

humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."