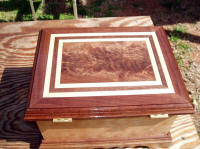

COMPLETED KEEPSAKE HEIRLOOM BOXES

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep

Safety paramount because hand and power tools can

do serious bodily harm and death if not used properly, therefore these pages

are solely for entertainment purposes only from a personal

liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues before going

any further. Safety glasses and hearing protection is a must although

I do forgo the hearing protection many times; my bad!

LETS GET STARTED

After getting

my woodworking table saw sleds calibrated, I finally got around to starting

a custom keepsake heirloom wood box for my bride of forty-seven (47) years. I decided to

use quilted figured maple for the box and walnut for the base and trim with a walnut

lid with a maple, walnut, maple inner band and a nice piece of crotch

figured walnut for the inside panel. I had the crotch walnut air

drying for about 8 years and hopefully it will be stable enough to use.

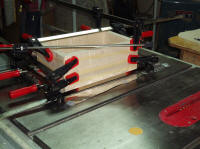

I tested out my crosscut slide using some 3/4 inch birch plywood and it

was pretty close and made a box to contain the

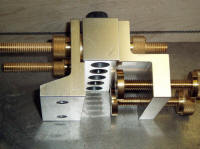

Dowelmax jig system that I

recently purchased to add dowels in all the forty-five degree miter joints since

end grain wood does not glue that well and wanted the extra strength of the

wooden dowels. The Dowelmax system is one of the best woodworking

products I have ever used and totally stoked with its top notch quality and

performance. I will add pixs that I have taken along the way and

didn't photo every detail but there are plenty to view. Click on below

thumbnail pixs for a larger screen view of setting up the sleds and doing

some test runs on the birch plywood and also testing out the Dowelmax

doweling jig.

NOTE: I had pc troubles and lost about all the thumbnail pix

taken for this page and will try and get them restored.

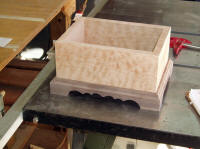

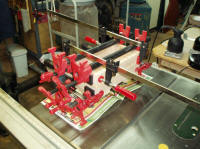

Below is first test box using birch 3/4 inch plywood and using it to

store the awesome Dowelmax jig. I have one Dowelmax set up just to

install the vertical drawer type forty-five degree dowels and another

complete Dowelmax for all the other dowel installation needs:

After testing out the calibration of the sleds of which I found out very

quickly that just using an accurate miter gauge

(Starrett C359) purchased used off EBay to adjust your table

saw blade tilt will get you very close to your target but the real acid test

is when all four (4) miters come together without a visible gap showing and

corners are ninety (90) degrees.

This is a trial and error process until you get it set as perfect as

possible. However, the table saw tilt set screw is not that accurate

since you can torque the setting and a few thousands of an inch from perfect

makes a big difference. Also, the stop set screw is located where

sawdust can easily get onto the blade tilt mechanism inhibiting accuracy and

a dawg to reach to clean.

Next was to surface plane the piece of figured

quilted hard maple down to about 3/4 inch and rip the width to around 4.5

inches and cut the maple to the lengths with a forty-five degree miter on

each end. The miter saw table sled comes in handy since you can use an

adjustable stop to have each side, front and back cut to the same length.

If one length is shorter or longer, you will not have a

"perfect" forty-five (45) degree

miter joint rendering a "perfect"

ninety degree right angle. Since end grain glued is not that strong, I drilled three

holes in each end of the miters to insert wooden dowels for the extra

strength which for this application is probably an overkill but I want this

box to last a very long time for the next generation, etc. I made an

additional stop sleeve for the drill bit to bottom out in the drill chuck because I know that set screws can

and will come loose and destroy a part when critical depth drilling is required

and Murphy's Law

never sleeps.

Everything went real well until the actual glue up of the box of which the

Titebond III glue that I used was too fast setting; e.g., not enough open

glue time and the box ended up being a little out of square of which I tried

to push it into square but the glue had already done its thing and will have to

deal with that later. Since then, I have received a

bottle of

Titebond II extended time glue which is working out great. I

used a 3/16 inch thick piece of plywood for the bottom of the box which

should be strong enough.

After the box was assembled, it was time to start the bottom rails to

function as feet and give some decorative design element to the basic box shape.

I used walnut of which I surface planed to thickness and then ripped to the

required width. I used the Porter-Cable 3.25 HP table mounted router with a molding bit to

make a pleasing shape to the edge of the base trim and also routed a rabbit

groove to the inner edge so the box would recess down into it about 1/4 of an

inch. I didn't do those sequence pixs; guess I was "brain dead" a little;

grin if you must. After getting the profile for the base trim routed, I then

band sawed the scallops out on the bottom edge of the trim and then mitered

each piece to the correct length. I also drilled each corner for a

wooden dowel using the Dowelmax doweling jig and then glued the base trim miters.

After the glue dried, I sanded the band saw

marks out using a Dremel tool with a 3/4 inch diameter drum sander and also a

1.5 inch diameter drum sander on the drill press.

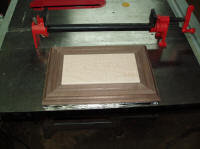

I wanted a walnut trim around the top of the box that extended outward to

the same size as the base trim and sized the walnut and headed to the router

table. I used the same router bit I have used so far for the molding

but changed the orientation of the wood to vertical instead of horizontal.

The same doweling procedure was used for the edge molding miter corners to

add strength to the

miters. I used my forty-five degree crosscut slide to make the miter

(picture frame type cuts) that I use for trimming the ends of my turkey box

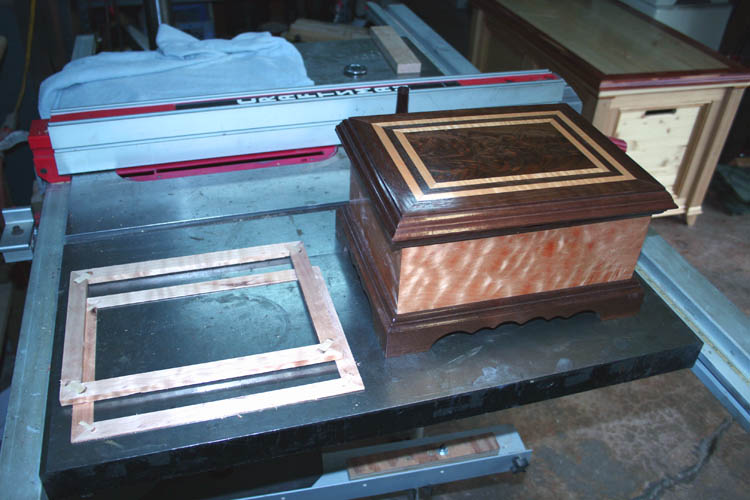

call lids. Below is an achieved pix:

With the above three components finished for the box, whereas the lid being the main focal point for this box and wanted to showcase the figured walnut

crotch wood that I have had on hand for about eight (8) years air drying. I planned

to do a custom turkey box call utilizing this wood but after thinking about how thin the box

call wood would end up, I changed my mind since wood of this type is prone

to become unstable and will splinter and blow out when routed and/or carved

as thin as the soundboards on a turkey box call. I used a piece of walnut

and strips of curly maple wood for the contrasting lamination of the border

around the walnut figured crotch wood. NOTE: This

wood gets its name because the wood is

harvested from the base of the tree or tree trunk that has formed a crotch, two pieces of

wood from the main trunk of the tree which normally leaves a very

distinctive swirl pattern as evidenced by the pixs below. This was a tricky

process getting the center figured walnut crotch wood to size since as I

stated earlier, the box was slightly out of square and had to make

adjustments that would render the miter joints and glue joints pleasing to

the eye, even though not perfect! The walnut crotch wood was

approximately 2 1/4 inches thick and shaped like a large wedge and used one

of my straight cut table saw sleds to get the wood cut to feature the

crotch/swirl pattern. I planed the top and bottom of the wood and then

ripped it in half length wise making two cuts on the table saw with the saw

blade extended to its maximum reach and flipped the piece end over end to

make the final cut rendering two pieces about 7/8 inch thick. Each

piece was then planed down to the same thickness as the walnut border which

was around .730 thousands of an inch. Normally, you would build the

mitered frame around the center piece but I elected to do it the hard way

and cut the crotch to fit as close as I could after the outside frame was

mitered and glued together. I used epoxy to glue the center crotch

wood in place and scored the inner edges deep of both the frame and the center wood

where epoxy would get into each piece and hopefully make a strong bond keep it from moving

around. I later applied some epoxy glue with a walnut colored powder

to fill in a few hairline cracks in the surface of the crotch walnut and

will keep check on it and apply the filler as needed if any cracks reappear.

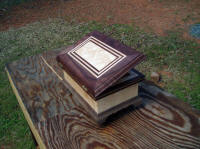

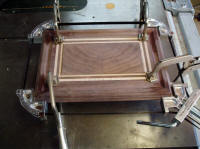

Below is the box with the base and upper molding trim not glued in place:

The base will be stained a darker walnut color since there were some sap wood

in the side and rear piece and the trim below the lid will be stained also.

I want be able to stain the lid due to the contrasting curly maple wood but

it is dark enough to finish natural.

Below is a pix of the lid

with some of the sanding dust blown off, whereas you can see the beautiful

figured swirl/feather pattern of the walnut crotch wood.

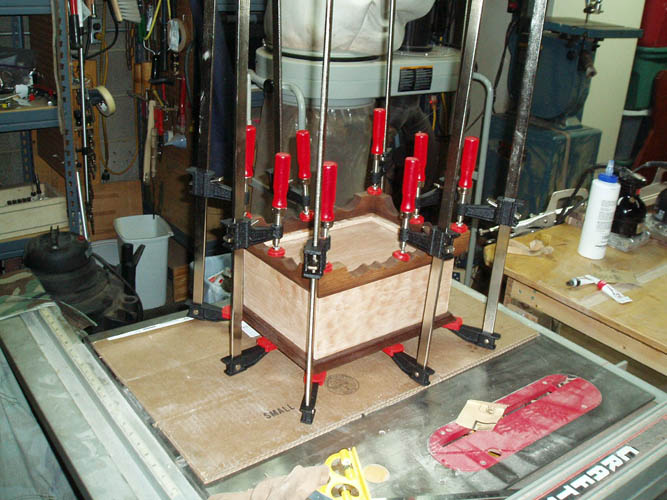

I glued the base and upper trim in place and allowing it to dry as I upload

the pixs. It will then be time to mortise the lid and upper trim of

the box to accept the solid brass hinges. Below pix with the box

upside down while the glue is drying. I am seriously thinking about

inlaying a medallion

I made for my bride and myself back in the middle 1970s that has my

copyrighted script Porter logo inlaid into a round piece of Gabon

ebony

which would look great on the front of the quilted maple box. I believe with a clear coat of finish applied, there will

be very good contrast between the dark and lighter colored woods.

After the finish is applied, I will add a piece of felt to the bottom of the

box and leave the inside wood as is to highlight the quilted maple

grain pattern. The figured walnut crotch wood reminds me of a feather

with the matching north and south swirls similar to a

book matched pattern.

My friend Robert Webster of Hamlet, NC, retired Captain from the NCDOC

stated I needed one more clamp on the above box. You know I had to

grin.

Web published by Bill aka Mickey Porter on 02-27-15.

Today is February 28, 2015 and got the hinges attached to the box and it was

a little difficult trying to route a mortise for them freehand.....I hogged

out one of the mortises, in fact the first one, way too much in length

because I couldn't follow the line I had scribed.....my bad for sure but it

is recoverable and on the inside of the box too. I got a better light

source and was able to get a much better fit between the hinges and the box

upper trim. It would have been easier I do believe, to just use a

chisel and cut the mortises in but I had to do it the easy way which turned

out to be the hard way without a routing jig/template. The upper edge

of the box was a little too narrow to use my small Dremel tool and router

base and had to fabricate a much large platform with enough real-estate to

have room to keep the router flat to the surface. I could have clamped

a large width block to the inside of the box and accomplish the same thing

but sometimes "we can't see the forest for the

trees", grin if you must! Click on the below thumbnail pixs for a larger screen

view:

I plan to use a different procedure on routing mortises for the hinges on my

next box and use the table mounted router with a

"flipping story stick" which aids in setting the

stop blocks for the length of the mortise and also the width of the cut.

This technique is used by Doug Stowe who authored,

Basic Box Making available from Amazon.com

of which my lovely sister presented me with a copy years ago when I started

making custom turkey box calls.

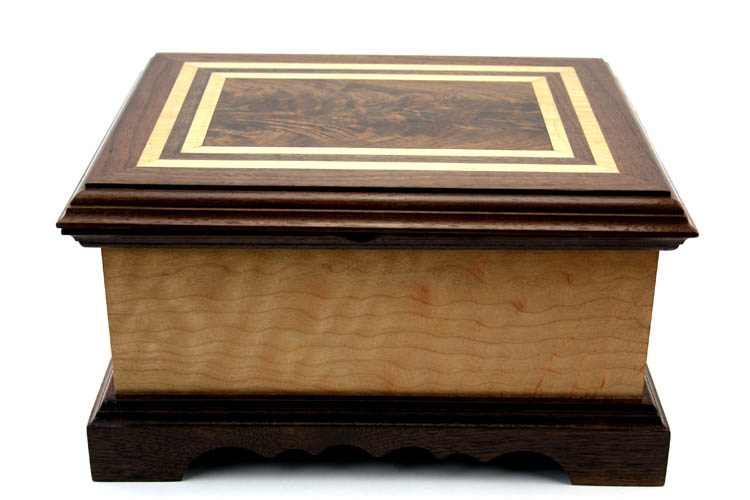

This is what the box looks like ready for a coat of sanding sealer

and a few top coats of lacquer or polyurethane and will apply it when the weather gets warmer

with much less humidity

in the air.

I believe the above Custom Keepsake Box for my bride will really pop when a

clear finish is applied to it and become a cherished heirloom. My

bride is really impressed with this keepsake box and glad I finally got around to

making something special for her with my own two hands. This box was a learning experience and

my next one will be much improved. I already have the sides and bottom

together of a nicely figured curly maple box and plan to use the same base, upper trim and

lid design since I already have enough figured crotch walnut for several

more boxes. I will probably make the upper trim of the box under the

lid a little more bolder in design.

Web published updates by Bill aka Mickey Porter on 02-28-15.

CURLY MAPLE AND WALNUT KEEPSAKE BOX NO. 2

While waiting for the weather to get warmer and dryer, I started another box

using curly maple and walnut trim. Plan to use the same lid design but

with a little thinner width curly maple, walnut, curly maple inside border

and a much bolder upper molding trim. I will add a few pixs along but

will not do an entire photo sequence

since everything is basically the same construction wise. Below is what I have done so

far:

I made the upper molding trim using two different router bits and used one

of the same bits to make the scalloped base molding. Instead of

attaching the molding onto the top of the box, attached it to the sides

which gives the box a lower profile and more pleasing to the eye in the

overall proportion. There are established

formulas for such but didn't

do the research and winging it on this project. Also, 3/4 inch

thickness for the sides is an "overkill"

but I want the box to last a life time and you are not transporting the box

around anyway. The overkill characteristics must be part of my DNA

since that theme has carried over into other areas my entire life....grin if

you must! I might add a drop in removable small tray too. The

lid will overhang the front and sides about 1/4 inch which adds additional

depth to the upper molding trim and also provides a gripping surface to open

the lid without routing a recess in the upper trim molding for that purpose.

The lid components are cut to their final dimensions, holes drilled for the

dowels and ready to sand before the glue up assembly.

I like the wider outside walnut border with the smaller width

maple/walnut/maple laminations which actually yielded a larger inner figured

crotch walnut panel. Below lid pre-fitted before the sanding and

glue-up.

The Titebond II Extended Time glue just about set up too quickly

before getting all the dowels and edges with glue applied and had trouble

getting the parts to come together with the clamps but managed even though

the fit was not as good beforehand. I have to rethink how I want to

glue the inner panel in place since the individual dowels take some time

aligning and you just don't push the pieces together since the miter joints

have dowels at a right angle. You have to rock the sides into place

because of the placement of the dowels and elongate a few of the holes to

aid the process. I might have had the miter

dowels too close to the inside panel and will try them more centered into

the miters on the next box which should give more latitude in aligning all the dowels.

I contacted

Dowelmax and the inventor Jim Lindsay emailed me and stated in this type of

panel, all the dowels need to be aligned in the same

axis

which means I will leave out the dowels in the sides of the inner panel

since there will be no problem with just glue securing the side of the panel

to the border. This will be a tricky procedure and will give it a test

run on the next box.

I have experienced one bad problem on my part and that is dropping the

mitered corners of the various parts and when they make contact with a solid

surface, they nearly "always" land on

the knife edge of the corner leaving a noticeable ding or dent in the wood.

I use the table saw real-estate for a flat working surface which is cramped

up and need to clean off the work table adjacent to the table saw that I use

as an out feed table to hopefully reduce dinging the parts. The past

few days when I am handling a mitered component, I talk to myself saying

something like, "Ok Butter Fingers, watch what

you are doing."

Murphy's Law

never sleeps!

Web published updates by Bill aka Mickey Porter on 03-04-15 and 03-05-15.

Below box with some initial sanding done to the lid, etc.:

After the sanding is done, it will be time to install the

hinges and plan to

test out my table router set-up on some scrap wood and see how it goes

before committing the box and the lid to the router table. I am using

a pair of back flap solid brass hinges which are heavy duty since the lid

has some substantial weight to it and like I normally do, I go a little bit

"overkill" on many things. I try and purchase what I can from

Woodcraft

in Matthews, NC since they have an excellent selection and inventory for the

woodcrafter plus a knowledgeable friendly staff and about a 45 minute drive from our home.

Web published updates by Bill aka Mickey Porter on 03-07-15.

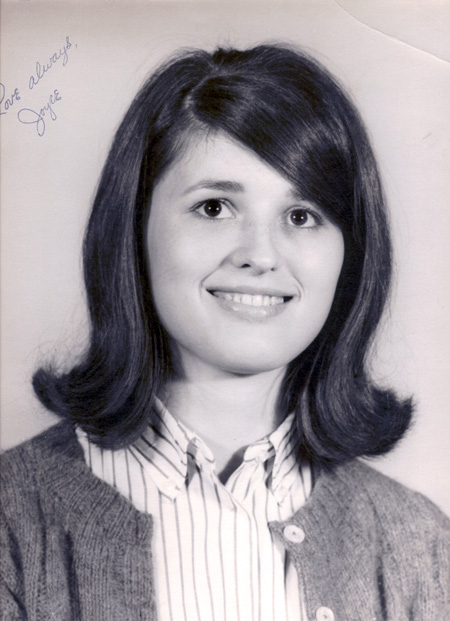

Below is pix of the above box with a special inlay I commissioned David

Nichols,

Custom Pearl Inlay

of Malone, NY do for me. I planned to use

his inlay as a pattern and cut one myself, but he set the bar far too high

for this one and no way I could come close to the quality of work that he

did. I routed a cavity for the inlay and the box is ready for fitting

the hinges and some final sanding before I glue the composite inlay into the

cavity and start spraying some lacquer.

Below is the pix that I emailed David Nichols of my bride to be that was

taken in December 1963 to use as a pattern for the above inlay:

She is still the love of my life after 56 years of marriage and I still call

her my bride!

Web published updates by Bill aka Mickey Porter on 04-17-18, 01-31-2020 and

04-27-2024.

INSTALLING HINGES WITH A "FLIPPING STORY STICK" AND ROUTER TABLE

I mentioned earlier about the procedure that Doug Stowe, author of

Basic Box Making uses to install hinges

using a router table and a gauge called a

"flipping story stick", whereas I wanted to

give it a try and test run the procedure on scrap material before committing

to the special keepsake box I am building for my bride. I will confess

right off, that I was a little more than apprehensive even after a trial test run

because it doesn't take but one mess-up to ruin a project that has come

together pretty good so far.

I will add thumbnail pixs to help manifest how the flipping story stick method works.

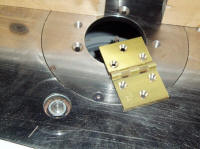

The first thing is to cut a length of material the exact length of your box

and/or lid and using the hinge you plan to use, place it on the story stick

the distance you desire from one end of the stick and scribe around it.

Using your table saw, notch away the area where the hinge will rest and have

the slot tight enough to where the hinge will not fall out; a good snug fit.

After the "flipping story stick" is fabricated, you adjust your router fence for the

correct width of the hinge and using stop blocks that will control the

movement (length of the mortise route for the hinge). I used a solid

carbide spiral 1/4 inch diameter router bit for this purpose. You use your

hinge to adjust the router depth to match your hinge thickness. For

some reason, most of the smaller box type hinges have the outer portion of

the leaf about ten to twelve thousands of an inch thinner than the rear near

the barrel of the hinge. After you calibrate your router table set up

using the fence and stop blocks, you simply do a blind route by having your

box and/or lid against the left stop and lower the box and/or lid down onto

the router bit which in essence is drilling a hole and this will prevent any

chip out and move the lid or box back and forth until the cavity is routed

out which is controlled by the fence and stop blocks. I will

make a set of right angle stop blocks that will locate off the fence miter

track for the next hinge installation. After you

route one side for the box and the lid (if both are the same length), you flip your story stick over and

adjust the stop blocks for the other side of the box and lid. You

finish off the corners using a square corner chisel or a regular chisel.

Click on below thumbnail pixs for a larger screen view and hopefully show

what I am trying to explain:

I didn't take a pix using the corner chisel and regular chisel but it was a

piece of cake at this point with a big relief in the anxiety level since

everything went as planned with no mishaps.....grin if you must!

On this particular box where I have the length of the lid overhanging the

box to give additional depth perception to the custom molding that I

made, I had to use a small piece of wood the correct width to calibrate the

stop blocks for the lid only. Everything came together and fit like a

glove.

To help with in the hinge installation, I used a self-centering

drill guide made just for # 5 and # 6 flat

head screws and adjusted the length of the 7/64 inch bit to where it would

not drill through the outside of the molding since there isn't a whole lot

of extra real estate present.

I used epoxy and some black powdered filler and glued in the custom inlay and

will do a final sand tomorrow before applying a sealer coat and multiple

coats of lacquer and lightly sand down between coats. It is best to

wait at least 24 hours to give the lacquer time to cure, however I have

applied as many as six (6) light coats of thinned lacquer on

musical instruments

in a single day before wet sanding after curing out a couple days to build

up a good base coat of lacquer. I have applied as many as 20 coats of

thinned lacquer to musical instruments with the majority of the finish wet

sanded down before polishing it out to a

mirror finish. A few pixs while the

weather was in the 80s and the wood grain is really beginning to come alive

after a coat of sanding sealer on the curly maple box and started a couple

coats of lacquer on the quilted maple box. Click on thumbnail pixs

below for a larger screen view:

One of my favorite resources for box building is

Mike's Heirloom Boxes

and he builds some beautiful one of a kind custom

heirloom boxes for sale.

Web published updates by Bill aka Mickey Porter on 03-11-15.

STARTING BOX # 3 AND # 4

While waiting for the weather to clear up again and get out of the mid 40s,

where it will be feasible to start spraying more coats of lacquer on the

first two boxes, I started on a couple more boxes. I am using the same

walnut trim design for the base and the trim underneath the lid and using

birds eye maple for box # 3 and added a banjo wood purfling that was used on

Gibson pre-war

Granada banjos referred to as a stitch purfling. Click

on the below thumbnail pixs for a larger screen view:

I finished gluing up the lid components for the birds eye maple box and the

box structure for # 4 which is curly maple. NOTE: I

installed dowels using the

Dowelmax

jig system as before and worked a little quicker. After applying

glue to the dowel holes and mating surfaces, I then installed the dowels and

there was enough open glue time left, whereas this change of procedure

worked out very well.

Web published updates by Bill aka Mickey Porter on 03-19-15.

I decided to make a better clamping system while setting up the router using

the "flipping story stick" and below a few pixs taken. I already had

some extra 5/16 T bolts, threaded knobs and plenty of scrap wood and it didn't take long to

get it going for a test run on routing the hinges on box # 3. At this

stage of box building, you don't want a slip on the router table for sure.

As depicted by the pixs, the box and/or lid is trapped between the right and

left stops and also the fence which controls the width of the route for the

hinge, whereas the right and left stops controls the length of the mortise.

If you are doing more than a single box, this is the way to do it, whereas

you have to make a "flipping story stick" for each different size length box

and/or lid. I had one small mishap installing the hinges. This

lid was about .020 inches thinner that my other boxes since I added the

extra walnut strip which goes next to the birds eye maple center panel and

had to plane the outside lid trim down and didn't adjust the length of the

snappy hinge bit and the 7/64 inch diameter drill bit came through near the

outside of the molding cut which is on the back of the lid but some epoxy

and filler will hide the "boo boo"

enough to "not stick out like a sore thumb".

I had to shorten the four back brass flat head screws about .032 inches.

The fabrication of these boxes require extensive usage of the router table

for all the custom molding and trim used and the simple pivoting fence works

much better and faster than trying to adjust each side of the fence parallel

to the router table top and/or edge. The adjustable fence system that

came with the Bulldog router table was the first thing I removed from it and

drilled a hole through the router table top and the left hand side of the

fence and made a simple "pivoting stick" which is far superior and only have

one adjustment to deal with for fence adjustment.

Web published updates by Bill aka Mickey Porter on 03-24-15.

BOX # 3 READY FOR SANDING SEALER

The past couple days I have managed to get a few hours in on box # 3 and # 4

and a few pixs:

Box # 3 being the birds eye maple, got its final sanding and ready for a

coat of sanding sealer. Box # 4 which is another curly maple and

changed the lid design on it. I added an additional radius on the top

of the lid and also routed a groove for a curly maple raised lid. I

cut the maple lid rabbit portion out on the table saw and added a 3/8 inch

radius to the top edge. The raised lid adds a tremendous amount of

visual perception to the height even though it is only raised about 3/16

inch but looks more like some of the ole time wooden coffin box

lids.....grin if you must! I am still not 100 percent satisfied with

my miter joints after gluing them and loose a little accuracy

of the miter fit during the glue-up process and will have to figure out the best and easiest

way to get a better glue-up. The Dowelmax jig is really getting a

workout on these boxes which have a pile of forty-five (45) degree miter

joints.

Below box # 3 and # 4 pixs below:

I added a 1/4 inch radius to the bottom molding/base of box # 4 and it has a

good visual appeal and plan to use it on the rest of the keepsake boxes I

plan to build. The thickness of the base trim was also increased to

7/8 inch thickness and gives the base a more bolder look which matches the

upper lid trim and lid design with increased visual balance.

Web published updates by Bill aka Mickey Porter on 03-26-15.

MAKING SOME PROGRESS AND A NEW LOOK ON THE BASE DESIGN

I decided to add a couple more router cuts to my standard base trim and

pleased with the new look which more resembles a traditional foot design. Below

is pix of the new base/trim using a 1/4 and 3/8 inch radius router bit in

addition to two other router bits used for the inside rabbit and a standard

Roman Ogee molding bit:

Click on below thumbnail pixs for a larger screen view:

I thought I had cured "Butter Fingers"

from dropping things but dropped lid # 4 and naturally it fell on the

concrete floor and landed on one of the back corners making a nice round

shape of the point instead of the square point. I had to do some

sanding and match the other corner of the lid the same. Guess I need

to continue to remind myself to hang on tight when handling the keepsake box

components when not over the carpet on the workbench!

Box # 4 is ready for the installation of the hinges and waiting on the glue

to cure/dry after gluing the base trim to the bottom of the box. I

plan to spray all four boxes with multiple coats of thinned Mohawk lacquer

when the weather conditions are right since I have to spray outside without

the benefit of a dedicated spray booth. Maybe I can get it done before

the insects get to flying and swarming....grin if you must!

Web published updates by Bill aka Mickey Porter on 03-29-15.

Box # 4 got a coat of sanding sealer today, March 30, 2015:

BOX # 5 BIRDSEYE MAPLE

With box # 4 waiting for the top coats of lacquer along with the other three

boxes which have a few coats of lacquer and sanded down ready for additional

coats, I plan to "fire up" my

Lynx L-300H HVLP 1 quart

spray gun manufactured by CATechnologies and use some left over Mohawk

lacquer from my last

banjo project. I glued up box # 5 which is another birds

eye maple of which I already had the sides, back and front mitered, sanded

and ready for the installation of the dowels using the Dowelmax Classic

doweling jig which is a dream to use. Earlier, I got 5 sets of boxes

cut out and mitered the forty-five (45) degree corners and set them aside

and have three sets of the curly maple left to put together. I haven't

decided on what the lid design will be for box # 5 but might use a raised

walnut center panel and go with my standard walnut, curly maple, walnut and

curly maple outside lid trim design since I have enough already glued up.

Below a few pixs:

In the past when I owned a mail order business for musical parts and

accessories from 1969 through 1978, I manufactured both

metal and wood

components and would do the parts in lots varying in quantity up to 150 or

more units for the larger metal items which helped distribute the set-up cost.

However, with these individual keepsake/heirloom boxes, it is a little more

difficult to do in lots since basically each one is a little different and

would have to standardize the width, height and length of the box which I

did on the last five sets of wood. Curly maple and Birdseye maple is

also somewhat pricy and I have to pay retail cost plus shipping and that is

another determining factor for the box construction. The extremely

hard Northern birds eye maple doesn't want to cut that well especially

on the forty-five (45) degree miters using the sled and even with a new blade it

is easy to "burn" the wood. My standard thin kerf 80 teeth crosscut table saw

blade wanted to wander from a perfect cut and switched over to a general

purpose saw blade with 40 teeth with a full .125 inch kerf which was dull

but worked much better than the 80 teeth crosscut blade. I am having the 40

teeth combination blade re-sharpened, however I am going to order another

combination blade, hopefully one that is a better quality blade,

maybe Forrest, Freud, etc.

I am having a "ton of fun" with

these keepsake/heirloom boxes and I can tell an improvement in my

woodworking skills with each box but I do have a few glitches in my system

of which I am trying to work out and "Work Smarter,

Not Harder" which is open for

debate.....grin if you must!

Web published updates by Bill aka Mickey Porter on

03-30-15.

SPRING WEATHER FINALLY ARRIVED AND IT

FEELS GREAT

The ole cliché about the month of March

"Comes in like a roaring Lion and goes out like a Lamb"

is still pretty much true for this year, although the wind the past couple

days have really been doing its thing. We have a large set of Wind

Chimes hanging from roof overhang over our deck and they are tuned to the

key of G and give off some beautiful music.

Below are few pixs taken as I am cruising along with

these keepsake/heirloom boxes and one of my friends related to me that was a

lot of set-up and jigs for them but I already had over half the slides made

for my custom turkey box calls. My real passion if I can call it that,

is making jigs and fixtures in order to get to the point of producing a

product whether it is in wood or metal when I plan to make more than a few

and the mental challenge is what I enjoy the most. Routine production

of a product is not my "cup

of tea" although I don't necessarily

dislike such which may sound somewhat paradoxical.....grin if you must!

Well, as usual I got side tracked a little and below the pixs I mentioned

above:

I increased the depth of the 3/8 inch radius router cut on the box base trim

and satisfied with the look. It is a little risky routing the radius

after the base trim is fabricated but with the scalloped design, I just

can't route the groove ahead of time before trimming to length since it

would cut into the scalloped design. So far I haven't damaged the

couple bases that I have done this way but as I have stated before, "Murphy's

Law Never Sleeps." Box # 5 is ready to glue the top

trim molding and base along with final sanding everything and a coat of

sanding sealer. The pix of the Dowelmax jig shows the 1/8 inch spacer

in place for the 7/8 inch thick stock that I am using on the border of the

lid with the birds eye maple center raised panel. The miter sled for

the picture frame type cuts is getting a good workout on each box too!

I planned to start spraying the four boxes already completed sans the final

top coats of finish outside but the pine tree pollen is falling now and

might not be a good idea unless I can catch a windless morning, etc., and

get the boxes back inside as quickly as possible. I have one curly

maple box frame ready to glue up and gluing the miters so far is one of the

challenges to keep the corners as perfect as possible since they are cut

pretty accurate but I loose some accuracy during the glue-up process.

I ordered a couple

Merle band clamps featuring special corner

blocks with self adjusting jaws which should help me with the glue process

and on other projects as well. If not, it want be the first time I

have wasted some hard earned cash!

Web published update by Bill aka Mickey Porter on 04-04-15.

BOX # 5 READY FOR SANDING SEALER

The walnut and birds eye raised panel box is ready for a coat of sanding

sealer.

Below, one coat of sanding sealer applied and not buffed or sanded down yet.

04-10-15

The close up pix of the raised panel lid reveals the tight birds eye grain

pattern which should be "beautimous" when finished with clear lacquer.

Web published updates by Bill aka Mickey Porter on 04-07-15.

BOX # 6 CURLY MAPLE WITH BOOK MATCHED WALNUT RAISED LID

Being retired, I get extra fun time in, whereas my bride and I are getting

out much more since the cold weather and the

"flu crud bug" had her staying inside for around 5 weeks

except to get out on each Friday for her weekly hair appointment and a

couple times she wore a mask as a health concern for others. We are

catching up on eating out at our favorite restaurants of which none are

located in our

"One Horse Town" but we enjoy the ride and being out and

about together! I have also managed to get some time in on Box # 6 and

decided to use up the walnut, curly maple, walnut, curly maple lid frame

material I have on hand and do a book matched raised walnut panel. I

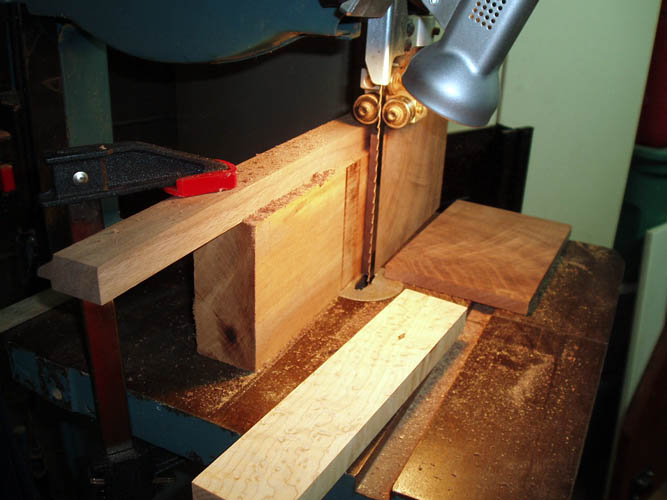

have a couple end pieces of some 3/4 inch thick walnut and ripped the first

piece in half on the table saw but that is a high risk procedure of which

can easily translate into a kick back with possible injury. The second

piece, I exercised more common sense and safety precautions and set up

the Jet 14 inch band saw which has a 1/2 inch width blade with 4 teeth per

inch. I rigged up a taller fence to match the height of the

walnut board which was a little over 4.5 inches x 9.25 inches and it worked

out great. The saw didn't bog down and the finish cut was nearly as

good as if it had been run through the planer or jointer; might be a little

exaggeration but not too much. Pix below of the set up:

I glued the book matched walnut pieces to a 1/2 inch thick birch plywood

panel the same size as the walnut and the glue-up came out great!

Click on below thumbnail pixs for a larger screen view:

The book matched walnut reminds me of the shape of a large bell....grin if

you must! I also got in a couple of the

Merle band clamps

and put

one of them to use immediately. From what

I observed so far, the clamp is doing what it is claimed and designed to

accomplish. I do think the small red plastic self-aligning flexible

jaw inserts

that fit into the right angle jaws are flimsy and puny looking and noticed

they did flex/bend under pressure when I tightened the adjusting screw

mechanism since the edge of the lower lid that makes contact with the

plastic inserts is a little over 1/8 inch in height which isn't a lot of

contact area. I elevated the lid with a piece of 1/2 inch birch

plywood that had a piece of aluminum foil over it so the plastic

flexible jaw inserts would make contact in the center of the self aligning

flexible jaws inserts. I tend to over kill

or over engineer things that I make or design but that is just my own DNA

for sure....another grin is in order. I will take out the removable

self aligning jaw inserts and just use the die cast ninety degree blocks

instead since they really aren't needed for ninety degree clamping. I

will give it a test run after the glue up above has dried.

I have all the components ready to glue up which

includes the upper trim and the lower foot/base trim, whereas the basic box

is already glued up and sanded.

Tomorrow, I will glue the trim and foot/base in

position and final sand the lid and will be ready to attach the hinges.

Box # 7 is another curly maple and have the box frame

and bottom already doweled and glued. Box # 8 has the pieces cut and

dowels drilled but not sanded or glued yet. As soon as the pine tree

pollen gets gone, I should have about all the 8 boxes ready to do some final

spraying lacquer and then to another project or two with plenty of yard work

to get on. I am forgoing turkey hunting season this year and maybe my

friends will harvest a couple birds and I can enjoy some

Wild Turkey Nuggets

or Wild

Turkey Breast Stir Fry or two.

Web published updates by Bill aka Mickey Porter on

04-10-15.

BOXES UPDATE

I got just a little woodworking in today but mostly serviced my Lawn Tractor

changing the oil and filter, sharpened the blades and greased all the

fittings and then got some grass cutting time in. There was plenty of

time in the afternoon for my Bride and I to get some

swinging time

in under the shade of the white oak tree that is beginning to leaf out

nicely.

I got box # 8 curly maple shell in the Merle clamps of which I removed the

plastic self-aligning jaws from the die cast corner brackets and it seems to

work ok. I did a little touch up on the base trim miter joints with a

mixture of Epoxy 330 and some Mohawk powder on box # 6 and will final sand everything

in a day or two. I will also get the upper trim and lower base rail/feet

cut for Box # 7 and think about what lid design I want to do. I have a

couple glue ups left of the walnut, curly maple, walnut and curly maple lid

material; enough for one more lid and will probably do a raised curly maple

lid with it.

I was hoping to have some Wild Turkey today, the two legged kind with wings and

feathers on it and not the bottle version but my hunting buddies went empty

on opening day. I settled for some

cubed venison loin strap and mushroom gravy

and have it simmering as I type......grin if you must! Will serve it

over a bed of sticky rice with

Mary B's Tea Biscuits.

Web published update by Bill aka Mickey Porter on 04-12-15.

MERLE CLAMP USAGE

Below a few pixs of using the Merle clamp for gluing the lower and upper

trim on box # 7 and the clamp works pretty good:

I started on the lid design and decided to use a piece of the walnut left

over from Box # 6 and glue up another book matched raised panel; pix below:

I band sawed the board in half and have a pix of it posted on here earlier.

I glued the edges together and will laminate onto a piece of birch plywood

for a backing and run it through the planer to get it the correct thickness

and then cut all the walnut trim miters to length that already has a 1/4 inch slot

routed into them for accepting the raised panel.

Web published updates by Bill aka Mickey Porter on 04-18-15.

BOX # 7 UPDATE

Click on below thumbnail pixs for a larger screen view:

My bride likes the raised panel insert with the wood grain

"rays" coming down instead of the

orientation on the left which reminds me of turkey tail feathers spread

while in a full strut mode. I didn't take a pix of the raised panel

where I cut the rabbit edge using the table saw. With the figured

wood, there is a less chance for chip or tear out using the tables saw

versus using the router

table. The only thing left to do will be some final sanding and glue

the base trim to the box, install the hinges and it will be ready for a coat

of sanding sealer.

My curly maple supply is fast dwindling and have used the best already.

I believe my Bride's Box # 2 has some of the nicest curly maple and walnut

grain pattern and only befitting that she has the best of the best!

Each box has its own unique elements and I personally like all of them.

Above Box # 7 has a coat of sanding sealer buffed down ready for finish

clear coats when the weather is more conducive; e.g., less humidity and

wind. The book matched walnut raised panel should really pop

when clear coats are applied and buffed/polished out.

Web published updates by Bill aka Mickey Porter on 04-22-15 and 04-26-15.

BOX # 8

Box # 8 will be my final keepsake heirloom box in this series unless I

decide to do other ones in the future. I am currently

"time sharing" between some yard

projects and other things needing to get done and have a couple more wood

working projects down the pike aka

bucket list and hope to get to them

before fall of the year arrives when it will be time to get back into the

ole platform tree stand with the bow and arrow, The Lord willing of course!

My woodworking skills have really improved on this project and need to keep

similar projects on the burner, whereby my eye/hand coordination skills will

stay in focus and in tune.

I haven't decided on what lid design to use, however I do have one walnut

lid molding cut like Box # 5 which has the grooves already routed for a

raised panel and might see if I can do a raised panel with a panel inside

the panel or something a little different.

Web published updates by Bill aka Mickey Porter on 04-26-15 and 05-01-15.

BOX # 8 LID DESIGN

I got a chance to work on box # 8's lid and got the lid completed except

drilling dowels for the forty-five (45) degree miters. I had a piece of

slightly figured walnut 3/4 inch stock long enough for the insert book

matched panel and ripped it in half on the band saw and have enough to do a

couple type insert panels. Pix below of the temporary attachment to an

oak board long and thick enough to go through the thickness planer without

bursting the grain pattern:

I ran out of Scotch one inch width double stick tape and used a small drop

of Titebond II glue in each corner and let it set an hour or more and it

held ok. I have some tape on order and couldn't wait until next

week.....grin if you must! I used the bottom panel of which both have

interesting wood grain patterns to them and came from the same board.

Below a few thumbnail pixs taken and the more or less free hand routing for

the insert "raised type panel" was the difficult part. My antiquated

late 1960s Dremel tool had barely enough power to run the small 1/4 inch

width two fluted carbide tipped flat bottom bit and had to switch over to a

small trim router with a solid carbide spiral bit to finish the job. I

cut the 45 degree corners in using a chisel and it worked out pretty good.

I have to drill for the 3/8 inch diameter dowels using the Dowelmax jig for the forty-five (45) degree

miters and do a finish sand on all the parts and it will be ready for glue up.

I could have accomplished the same visual effect by using a thinner panel

and just gluing it in place on top of the curly maple slightly raised panel

but I had to do it the hard way again which seems to be my regular MOA

(method of operation) on this project....another grin is in order for sure.

Below pix of the semi-finished lid:

Even with the make shift small wood fence on the Dremel router base, it was

difficult to keep the router bit from wandering away from the finish edge

when the router bit encountered the tough curly maple element which is

harder than the non-curly portion, it would dig into the maple panel which

required a lot of sanding to true the inner edge.

If I planed to do more than one box or two of the same identical design, it

would be feasible to make a routing template for both the insert and the

wood panel using a guide bushing but that is a pile of work to get it done

very accurately.

Web published updates by Bill aka Mickey Porter on 05-02-15 and 05-03-15.

LID GLUE UP 05-04-15

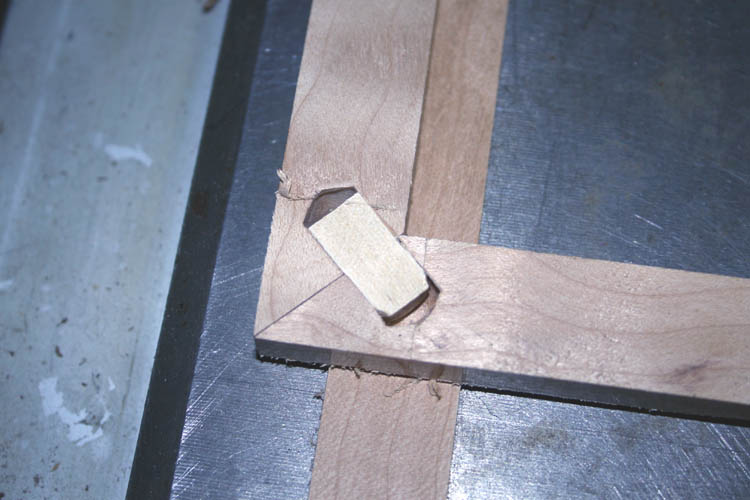

Got a chance to do a little box work this morning and drilled the holes in

the walnut outer miter corners for 3/8 inch dowels, a few pixs below:

I will glue the inner walnut book matched panel in place after I do a final

sanding on the lid. I normally let the Titebond Glue stay clamped

about a day or at least overnight although it sets up much faster than that;

still old school I guess. Got a little yard work accomplished this

morning and the weather is fantastic outside; should be 80 plus degrees

today. A few mornings ago, it was in the lower 40s and our furnace

kicked on to get the chill out of the home.

This keepsake heirloom box(s) project is coming to a close and box # 8 is about

finished. Only thing left is glue in the inner walnut panel in the

routed cavity on the

lid, final sand the box perimeter and upper trim, glue the lower foot trim

assembly in place and install the hinges. A coat of sanding sealer and it will

be time to get out the spray gun and work on all the boxes as if on

production. Some of the boxes already has several coats of finish lacquer on

them but the spray equipment will work a lot faster than the lacquer in the

can and less expensive if I don't count the current cost of the high dollar

lacquer thinner.

Web published updates by Bill aka Mickey Porter on 05-04-15.

ALL BOXES READY FOR FINAL COATS OF LACQUER

A couple days ago, box # 8 was finished and got a coat of Deft sanding

sealer. Yesterday, I sprayed a coat of lacquer on all 8 boxes and this

morning I lightly sanded them down to start the next coat of lacquer.

The ole spray gun, Lynx 300L HVLP hadn't been used since my last

musical

instrument was completed in November 2010 and have been finishing my

turkey box calls with Deft spray can sealer and lacquer which works out ok

for a single box call or half a dozen or so. The spray gun does

provide a much better finish since it can atomize the lacquer particles to a

very fine mist which reduces the orange peel look. These boxes will

not have a finish like on a musical instrument where a dozen or more coats

of finish is applied and then wet sanded down after a good base build up of

lacquer which renders a deep highly reflective finish. Below a few

thumbnail pix taken:

Web published update by Bill aka Mickey Porter on 05-14-15.

UPDATE: Above boxes except box # 1 quilted maple aka my OJT (on

job training) keepsake box given out as Christmas gifts; see this

page.

Web published update by Bill aka Mickey Porter on 01-09-16.

MODIFIED HEIGHT ON BOX # 1

I kept box # 1 of which was the first box in the series of eight (8) boxes that I

made simply because I wasn't happy with the height proportions in

relationship to the length. It wasn't difficult to cut about one inch

from the top of the box underneath the lid but I forgot that I had two small

nails hidden beneath the upper side banding to hold it into alignment while

the glue dried. My freshly sharpened carbide tipped circular saw blade

made a little racket when contacting the steel nails but too late to do

anything about that; guess another sharpening will take place sooner than

expected....grin if you must! Also, I tried to miss the wood dowels

that are installed between the forty-five (45) degree corners of the box

which took two passes on the table saw which wasn't a big deal since the

upper banding hides the connection but I originally was planning on putting

another piece of molding out of walnut that was left over but was too thick

and decided to keep the original banding which already had the lid hinge

openings routed and drilled. The custom made walnut molding wasn't

safely feasible to attempt to trim and common sense took over; imagine that!

Below a couple pixs taken, however I still had my camera white balance set

for an outdoor setting in the manual mode; my bad on this one which changed

the image color:

Below pix of the dowel fitted into one of the corners of the box which is

normally hidden from view:

Web published update by Bill aka Mickey Porter on 03-21-16.

BOX # 1 HAS A NEW HOME

My friend Calvin Jones of Wadesboro, NC liked the above box and purchased it

for a special gift on 04-30-16 and now all eight (8) of the custom heirloom

boxes have homes.

Web published update by Bill aka Mickey Porter on 04-30-16.

LATEST KEEPSAKE BOX

It has been approximately nine (9) years since doing a series of custom

keepsake boxes for our immediate family, brother and sister. I

recently wanted to use up some of my scrap aka unallocated wood and and my

bride liked the design of the Birdseye maple box that she had first dibs on.

My woodworking skills are not as honed as they were nine years ago, however

what few mistakes I make was able to cover them up for the most part.

The lid center insert features Birdseye maple and curly maple which floats

in a groove in the walnut trim frame.

The walnut trim for the base and the

lid was left over from the original boxes completed. I only had to cut

out the scallops and miter the corners to fit the base of the box.

I did not do any sequence pixs since this page annotates

in detail how I made the boxes.

Web page updated by Bill aka Mickey Porter on 06-29-2024.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."