FURNACE MAINTENANCE

I reserved Saturday October 20, 2018 to do routine/preventative maintenance

on our oil furnace.

I am guessing the year 1978, when an outside cooling unit was installed,

Johnny Hildreth added additional return duct work to the plenum, of which

you can see on the upper left side of the furnace. There are two large

additional return vents in the hallway that leads into a chamber in one of

the closets in a small bedroom that ties into the large round duct work in

the above pix to provide adequate air return for the cooling system.

We replaced the outside cooling unit a few years back with a larger Trane

unit and you can see the addition to the plenum on the right side to

accommodate the larger A coil.

The used Thermo Pride Beckett model EASR burner is still working pretty good.

I didn't do any picture taking of the recent preventative maintenance simply because fuel oil and cameras don't mix

well and even with rubber gloves on, it is a fairly nasty job, whereas the

colored diesel fuel oil is very smelly too.

I raised the basement garage door to help get rid of any fuel oil smell

while completing the maintenance. You need plenty of rags or paper

towels and containers to keep fuel contamination down to a minimum. I use an old cake

pan underneath the burner fuel pump to catch fuel oil that drips out from

the fuel line from the fuel pump to the nozzle tube assembly. The

burner motor was oiled with light weight oil designated for such. I

changed an in line oil filter that goes into a General 1A-25 filter housing and the

replacement filter is a 1A-30 filter. I use a recycled stainless steel

Bunomatic coffee maker water reservoir positioned below the fuel filter

housing

to catch fuel oil when changing the filter. I have the filter assembly

inside the basement about 10 feet from the oil burner assembly adjacent the

back wall where the incoming fuel line is located. There

are cut-off valves on each fuel oil above ground tank and a cut-off value at

the fuel pump intake on the burner. The electrode assembly was removed

from the burner and the nozzle was replaced with a Steinen .75H. The electrodes were in

excellent shape being replaced on 11-06-16 and buffed each electrode tip

with 400 grit wet/dry aluminum oxide paper. The ceramic electrode

insulators

along with the holder were cleaned and cleaned the lens of the

cad cell that detects light from the burning flame which is a safety device

and will cut the burner off within forty-five (45) seconds if it doesn't detect a

flame. This keeps fuel oil build up in the brick lined firebox inside

the furnace in the event of non-ignition of the burner. Newer

model primary controllers will shut the burner down much faster which is a

better safety device.

Everything was put back together and gave it a test run and bled the air

from the fuel pump and fuel oil filter housing while the burner was operating.

Apparently many years ago, the wires going from the Honeywell furnace controller

terminals TT to the thermostat control topside were skinned back a

little to allow a jumper lead to be placed across them to start the burner.

If the cad cell does not sense flame, the primary control will shut the burner

down. When servicing the burner, sometimes you have to short out

terminals FF on the primary control to keep it from timing out if it

doesn't sense flame, but this allows fuel to be atomized into the fire box

and should be avoided.

FURNACE MAINTENANCE 2016

Below are some archived pixs from 2016 where I replaced the fuel line tubing

aka gun line from

the fuel pump to the electrode assembly, of which a service man years ago had

rounded the hex shaped brass nut using

channellock pliers. Any service

person with a pair of channellock pliers and an adjustable wrench

turning/tightening hex head bolts needs to

be run off your premises for not using the proper tools. Seems like

those folks want to take all the short cuts and I realize time is money for

them.

I can understand a plumber using a pair of channellock pliers on sink

drains and traps, etc., but that is about my limit for their usage. I definitely

do not want to use a pair of

channellock pliers on any

hex nut that can be eventually destroyed over time, whereby you cannot use a socket or

wrench on it. I have and do use a large pair of channellock pliers on

vehicle oil filters, but prefer the large "socket" type oil filter

wrench using a ratchet.

I keep my furnace small spare parts in a separate "tool box". I don't

have a dedicated nozzle wrench, but use a 3/4 inch open end box wrench and a

5/8 inch socket to remove the nozzle from the nozzle tube assembly.

The electrodes were replaced on 11-06-18 and don't think the nozzle was

replaced since the unit was firing properly after the new electrodes were

installed.

SPARE PARTS

I keep on hand a new spare ignition transformer, new spare blower motor, spare set

of electrodes, spare nozzles, spare cad cells and have an older Thermo

Pride/Beckett OEA burner

assembly for spare parts usage as well. I have a used spare Honeywell

R8184K primary control (now obsolete) for

the burner assembly and a spare new RMB Controls furnace transformer

relay controller 175-100101-10. I

recently ordered a couple Suntec SSC109 strainers for the fuel pump and sure the

strainer

needs cleaning and/or replacing, but since I don't have a spare gasket,

therefore I

will leave as is for now. The fuel pump gasket normally doesn't need replacing,

but Murphy's law

never sleeps. I will change the strainer and/or gasket ASAP.

On 11-13-18, I ordered a spare Suntec fuel pump being a Suntec A1YA7912

which replaced the original fuel pump Suntec A1VA7112. Hopefully, I

should have enough spare parts on hand should anything wear out and/or

malfunction needing to be replaced.

NOTE: I replaced the fuel pump strainer on 11-13-18 and it was

very, very dirty, therefore put a new nozzle in the firing gun tube assembly and

set the electrodes to specifications. I didn't replace the fuel pump

strainer gasket which was in good shape.

I also ordered a Firomatic shutoff valve with a long stem that screws

directly into the 1/4 inch NPT fuel pump upper intake and accommodates a

standard 3/8 inch flare input fitting for the copper fuel line. I will elevate

the fuel line off the floor and secure the copper fuel line to a wall stud adjacent the furnace and get

the fuel line in a position that does not present a safety hazard.

I also keep my spare chain saw parts in the same tool box, of which I need

to purchase another tool box just for my chain saw parts and accessories.

I need to replace the jury rig coupling between the fuel cut-off valve to

the intake of the fuel pump. It was put on there many years ago by a

service man who didn't have the proper fitting is my best guess. I believe I stepped

onto or

bumped into the fuel line and there was later a slow leak. I had to clean up

the mess and tightened the

couplings about as tight as I could in order to get the slow leak stopped.

When the Firomatic shutoff valve arrives, I will install it and will have to

add an additional piece of 3/8 inch copper tubing in order to secure the

fuel line off the floor onto one of the wall stud members which should get

the fuel line out of the way as far as stepping on it, etc. When

Johnny Hildreth and myself installed a new fuel line to the above ground

tanks install, we didn't have much extra tubing on hand if my memory is correct;

although enough to

get the job completed. I might hold off on the installation of

the Firomatic shutoff valve until the end of the heating season, unless

there has to be maintenance done on the furnace. The old saying,

"If it ain't broke, don't fix it"....grin

if you must!

I plan to check the pump pressure and if it is not holding or too low, will

replace the pump at the same time I install the Firomatic shutoff valve.

The furnace air filters are ok. I have two filters in the system that

are aluminum framed and able to wash and dry them with air pressure,

etc. They remove a lot of dust from the air, however they do restrict

the air flow some and replaced them with the 30 day disposable type during

the cooling season to get more air flow.

Hopefully, this old fuel oil system will last another heating season!

FURNACE HISTORY

When we purchased our home in 1989, the furnace used an underground

oil tank, however when the fuel level got down to about 12 inches from the

bottom of the tank, the system would loose its prime due to a single line

supply versus the two line supply which has the return line to the tank from

the fuel pump which automatically primes itself. The tank depth in the ground was the problem being

about level with the basement floor where the furnace is located. I

noticed there was a fill tube (priming tube) installed in the fuel line that

came through the basement wall, but that definitely was a temporary fix to

re-prime the system. Later, I installed a check valve, but that didn't

help out as far as the burner loosing its prime.

I later installed two 260 gallon above ground tanks in tandem which gives

plenty of gravity flow pressure and that eliminated the burner loosing its

prime with a single supply line to the fuel pump on the burner.

I had the original burner motor rewound by Roger Funderburke of Marshville,

NC (now deceased) and a heating system will normally fail at the coldest time of the

year.....grin if you must! We had to use an auxiliary heat

source (Kerosene heaters) and it was still very cold being only able to heat a couple rooms at

the most. Later, the phenolic adapter fitting that went from

the burner motor shaft to the fuel pump broke and it was so outdated, I could not

find a replacement part and the burner assembly was changed out by Johnny

Hildreth, Allen Hildreth and myself on 01-10-98 which is detailed below.

The original furnace Crane Sunnyland heat exchanger is still going

and this is the third burner assembly installed on the furnace. Our

neighbor and friend Johnny Hildreth and his son Allen replaced the original burner with a used

Thermo Pride Beckett model OEA that I purchased around 1995 from

Grover Tarlton

(now deceased) for spare parts. Johnny replaced the burner on 01-10-98

and it definitely was cold for sure. We had to modify the mounting

holes for the air tube flange that secured the burner to the furnace

mounting bracket.

The stack relay thermal switch controls were removed from the flu not being needed with the first

Thermo Pride Beckett replacement burner install on 01-10-98 which used the cad cell

technology for safety. The old stack control unit used a thermo couple

to detect heat and shut the burner down in case the fuel did not ignite.

The last burner was replaced by Marvin Goodwin of Lilesville, NC and

myself in 2012 was a Thermo Pride Beckett model EASR that was

used and it was recycled from the furnace removed from The Mt. Beulah Baptist

Church of which the heat exchanger was bad. I believe Marvin took the old OEA burner with him if I am not

mistaken. I did have some trouble very soon after the install with the cad cell

not sensing the flame

because the burner electrodes and gun tube were dirty and not reflecting

enough

light back to the cad cell of which the cad cell was working fine and would

shut the burner down. The burner that

came from The Mt. Beulah Baptist Church was set up for a two line in ground fuel system and

the by-pass plug was not initially removed from the fuel pump causing the

burner to soot up when we fired it up. It was making a terrible racket

trying to pump fuel, but was restricted by the by-pass plug being installed. We have a single line gravity fed system from the

above ground fuel tanks as stated earlier, therefore the by-pass plug has to

be removed from the lower right fuel intake port. I remembered from years ago, that Johnny Hildreth

had to remove the by-pass plug from the used OEA burner fuel pump that I

obtained from Grover Tarlton sometime around 1995 that he and

Allen installed on 01-10-98. I related that info to Marvin and the burner fired as it should

once the by-pass plug was removed from the lower intake. I am guessing

this caused the accumulation of soot in

the burner tube assembly which later caused the system to shut down.

I obtained a spare Thermo Pride Burner model OEA with an identical Honeywell

R8184K primary control from a furnace that was replaced with a heat pump a few blocks

from our home and swapped out the primary control, but the problem was a dirty

burner tube and electrode gun assembly not reflecting enough light back to the cad

cell. Those older Thermo Pride Beckett burners, OEA and EASR are now obsolete for

sure as well as some of the Honeywell primary controllers. Some service

personnel will paint the inside of the burner tube assembly white in order

to reflect more light back to the cad cell which makes sense.

With newer Beckett burners, the motor is running at 3450 RPM and the

ignition transformer is around 20K volts versus the older 10K volts and 1725

RPM main drive motor, of which the new burners are faster igniting and more efficient.

If I didn't have an array of spare parts for the older burner, I would

upgrade to the new Beckett burner.

I replaced the 3/16 inch diameter x 10 inch length nozzle fuel line aka

gun line on

October 3, 2014, of which the brass fitting to the flame gun tube was

damaged by earlier repairmen using Channel lock pliers. An 8 inch

length nozzle line will work fine, but I could only locate a 10 inch length

which has the brass flare fittings in place. There was other

maintenance done to the burner, but did not have any annotation in the

furnace maintenance file folder.

I installed the third motor for the squirrel cage fan on 06-25-17, of which

is now a 1/3 HP ball bearing motor versus the original 1/4 HP motor with sleeve

bearings. The squirrel cage blower has bronze bearings which gets

oiled a couple times a year with 30 weight motor oil.

Since 2012, I have been able to keep the furnace running and replaced

the ignition transformer on the third aka current used burner assembly since

2012 if my memory is correct.

I keep all my maintenance documentation in a file folder which has a diagram

of the original install of the Crane Sunnyland model upright basement furnace.

NOTE: CRANE stopped making HVAC products in 1968.

Furnace technology sold to Amana.

JOHNNY HILDRETH

Our friend and neighbor

Johnny Hildreth did most of our plumbing

and furnace maintenance until he passed away on 05-25-09. We certainly

do miss this kind and generous neighbor and friend. He taught me how

to maintain our furnace and that has been a big help since the current

generation HVAC men

in our area are lacking experience on the older fuel oil heating systems due to fuel oil

furnaces being replaced with heat

pumps and gas packs. Fuel oil systems are still much in demand in the

Northern cold climate zones with the fuel tank in the basement or underground

due to the sub freezing temperatures. I remember back in the 1970s at

the old home place on White Store Road, it was so cold outside that the

kerosene about froze and was the viscosity of Karo syrup rendering the

main Seigler oil heater practically useless due to not getting enough fuel

to the heating chamber.

When the heat exchanger does give up the ghost, I will no doubt go back with

a Thermo Pride fuel oil similar basement model furnace since we have a split

heating/cooling system in place.

Web page updated by Bill aka Mickey Porter on 10-20-18 with additional pixs

added on 11-06-18 and updates on 11-13-18.

FUEL OIL FURNACE MAINTENANCE

CONTINUED

Our fuel oil furnace the past couple years has been performing really

well and didn't perform and major maintenance, but lubricated the

squirrel cage fan bearings and also the drive motor for the burner.

However, I decided to do a complete routine annual maintenance on the

system; e.g., changing the in-line fuel filter, complete lubrication of

the squirrel cage fan blower bearings, drive motor for the burner,

cleaning the CAD cell lens and cleaning and inspection of the

burner gun.

Above is pix of the in-line General filter system. I have an

ole Bun-a-matic water tank used as an oil catch when removing the base

unit of the General filter housing. There is also an in-line fuel

cut-off valve before the input to the General filter assembly.

I elected to use a different filter replacement for the General fuel

filter.

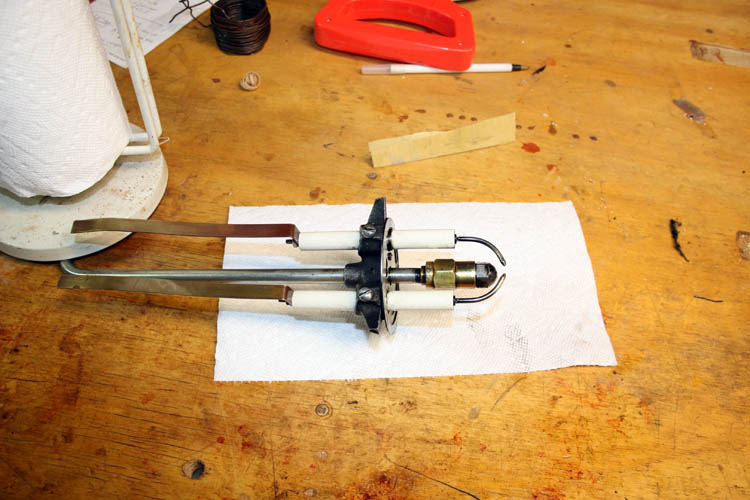

Pix of the old burner.

The fuel line to the "gun" assembly has been disconnected and you can

see the gun with the two brass spring type connectors attached to the

electrodes.

The gun above has been cleaned and soot removed from the ceramic

insulators, electrodes cleaned using 600 grit paper to freshen the tips

of the electrodes. The electrode gap was still properly set and

didn't need to adjust them. The unit has been firing without any

problem and no need to replace the nozzle, however most service

personnel will change the nozzle as part of the maintenance, where

needed or not. There is also a filter inside the nozzle input to

catch any small debris from the fuel oil line and there is also a filter

in the pump. With the in-line fuel filter from the tank, you have

triple protection from debris, etc., and I am sure

most of any particles will be captured before it reaches the burner

assembly.

I put the gun back into the burner and connected the fuel line to the

burner pump, fired the unit up and opened the bleed valve to the fuel pump and let

fuel drain into a catch container and any air that was in the system

will be removed. Remember I opened the General fuel in-line filter

and let the housing fill back up with fuel and there is a small vent

screw on the filter housing just for that purpose also.

I fired the burner up and let it run and checked for fuel leaks and

everything was good. Cleaned up any fuel on the concrete basement

floor and hopefully will be good for another heating system. I

will change the air filter to the unit also and lubricate the squirrel

cage blower bearings again before it is time for the heating system to

come on line.

Web page updated by Bill aka Mickey Porter on 09-24-2023.

CORRECTIVE MAINTENANCE 01-23-2025

Back in the early fall of this year, 2024, I did a Reader's Digest

version of my furnace maintenance since it was running running real well

with no problems and figured it would be OK, my bad!

However, on the early morning of 01-23-2025 at about 4:00 AM my bride and

myself were having trouble sleeping (insomnia)

and got up, whereas she went to the bathroom and then to her recreation room

which has the TV and a lift chair. I noticed right off that the house

was cold and checked the thermostat and it was showing

60 degrees F. and the outside temperature was around

15

degrees F.

I got my clothes on and proceeded to diagnosis the problem and it was

found quickly the burner was no firing at all. I checked the arch

across the terminals of the ignition transformer and it was evident it was

not putting out enough spark. I had a spare Dongan XD-WN208

ignition transformer in reserve and replaced it.

I also removed the gun electrode assembly and cleaned it up and replaced

the nozzle with a new one and cleaned the CAD cell. I think I first

opened up the vent valve to the fuel pump and checked that it was pumping

oil, of which it was.

Everything was put back together and ran the unit and checked for leaks

and it was fine. Probably took an hour to complete and more than an

hour to get the house back up to 72 degrees F. Running good so far at

4:41 PM.

I have a friend getting me another ignition transformer as a back up.

The transformer that was in there was very old and can't remember where I

got it from.

Web page updated by Bill aka Mickey Porter on 01-23-2025.

CORRECTIVE MAINTENANCE 03-13-2025

On or about 03-13-2025, I noticed that the thermostat when reached the

proper setting, the controller unit would shut down and immediately would

come back on again and would cycle several times doing the same thing.

I would have to lower the thermostat setting in order to cut the controller

off which turns off the drive motor and fan to the burner.

Since I had never experienced this problem before, I called Marvin

Goodwin and he came over and changed out the original Sears thermostat.

However, during the night, the unit cycled off and on before and he came

over the next day and put the original thermostat back in and also swapped

out the controller with a new one. I normally keep spare parts for the

furnace on a lower shelf, however I could not locate the spare controller.

After Marvin installed the new controller R8184G 4009, the furnace

is working fine.

I took the liberty to look inside the old controller and the problem

could be any number of things.

Web page updated by Bill aka Mickey Porter on 03-16-2025.

LEAVING ON A SPIRITUAL NOTE

If you do not know Jesus Christ as

your Lord and Savior, please take this moment to accept him by Faith into

your Life, whereby Salvation will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through faith;

and that not of yourselves: [it is] the gift of God: 9 Not of works, lest

any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for, the

evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by the

word of God.”

Open this

link about faith in the King James Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the Lord

Jesus, and shalt believe in thine heart that God hath raised him from the

dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation, King

James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder of

soul and spirit, and of the joints and marrow, and is a discerner of the

thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of God is

eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory of

God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what doth

the LORD require of thee, but to do justly, and to love mercy, and to walk

humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."