MARTHA WASHINGTON SEWING STAND TABLE

I recently received a call from Ms. Nanny Robinson, who allows me to harvest

Wild Persimmons from a tree in her yard, whereas she has an antique magazine

rack/end table in need of repairs. I told her I would come by

in a few days and take a look at it.

I visited with Ms. Robinson and surveyed the scene on the magazine rack which is made from

Honduras Mahogany.

Someone in

the past, did repairs on it which didn't hold. I told Ms.

Robinson it would take a few days, since there would be several gluing

operations, of which I usually let glue dry overnight and/or 24 hours to fully

cure.

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep

Safety paramount because hand and power tools can

do serious bodily harm and death if not used properly, therefore these pages

are solely for entertainment purposes only from a personal

liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues before going

any further. Safety glasses and hearing protection is a must, although

I do forgo the hearing protection many times; my bad!

RECON AKA RESEARCH

I emailed a friend Ralph Coble, owner of

Lord George Anson Antiques here in

Wadesboro, NC and a picture of the antique magazine rack/end table and he

said it was a

Martha Washington Sewing Stand Table.

Above pix of Ralph Coble in front of Lord George Anson Antiques taken on

04-22-17.

GETTING STARTED

I brought the

table stand home and the entire frame on one side was very

loose with some of the support members pulled apart. The main frame

assembly joinery were

tongue and groove, however most of the mortises were

dado slots the entire length of the member.

They were originally glued in place without any brads or dowels to secure

and lock the wood components together, other than the glue itself. At

the turn of the 18th century and earlier, animal hide glue was the glue of

choice; nothing like the high tech modern adhesives of today; e.g.,

cyanoacrylate (super-glue), epoxy, polyurethane, PVA, etc. I use

Titebond Ultimate III (Aliphatic resins) for applications where moisture might be a problem including

exterior applications.

The right hand side of the table stand was

totally separated from the side of the table frame and someone had sanded it down

and tried to glue it back, of which the glue did not hold. The bottom

of the stand table was crudely made and did not fit the grooved slots

either. Also, a couple finish nails were driven into the left side

segmented compartment attempting to keep

the bottom in place.

As evidenced by the pixs, the entire right hand side was totally loose

and the only thing holding it together was the top which has four (4)

countersunk flathead screws on the underside connecting the frame to the top.

The first objective would be to get the frame back into alignment before

attempting to glue the members together.

The plywood bottom was held in place by a couple finish nails and decided

to add a border around the bottom, since there was no way to place a new

piece of plywood in there without trying to unglue the segmented section from the two side

members.

I removed the top and the frame was pulled back together before any glue

was applied, however the segmented section as depicted on the left side in the

pix, would not fit together because someone had removed wood from one of the

members leaving a 3/32 inch gap on the outer perimeter. The inside

joint fitted together much better. There was evidence of glue being applied at

some time not too far back which did not correct the problem. In a

production environment, a jig would be required to properly position and

hold the thirty (30) degree +- segmented pieces tightly together and then the entire

segmented

portion would be later attached to the table.

Someone in the past added hinges to the top leaf portion that covered the

segmented vertical storage "bins." I don't know what the original hardware looked like,

but probably a levered

Soss type hinge.

Below pix:

BOTTOM SHELF

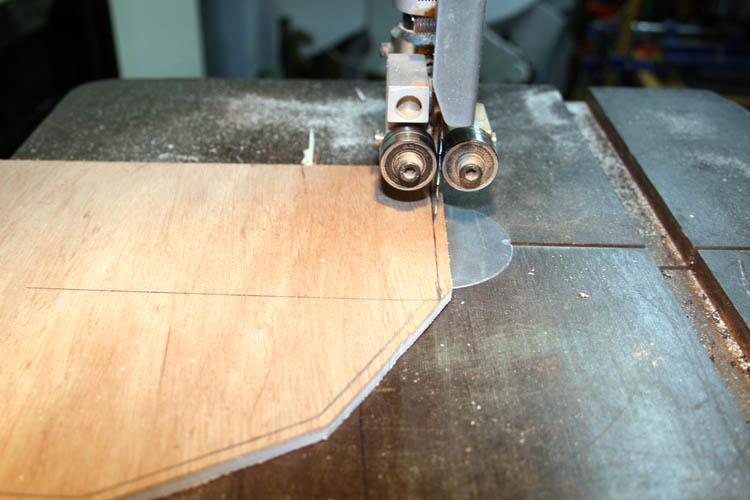

In the pix above, I got the measurements for the bottom of the segmented

section and transferred it to a piece of 3/16 inch plywood. Since the

bottom fits inside of a groove, there was some flexibility in fitting it.

Therefore, I used the table saw and band saw in combination with my 6 x 48

inch belt sanding machine to get a decent fit.

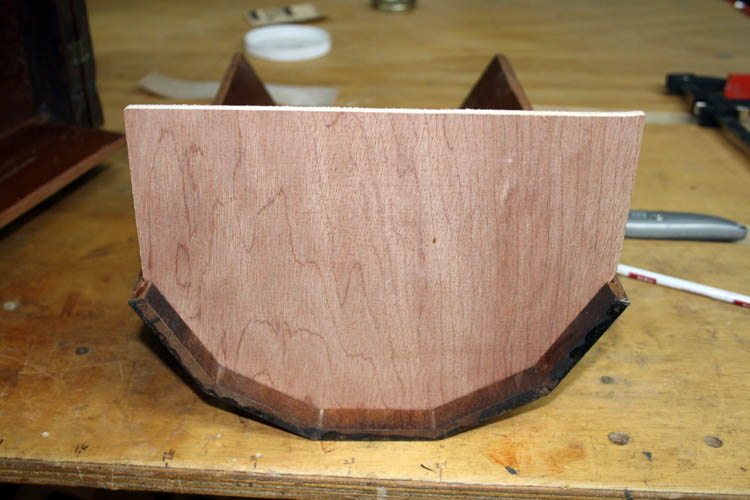

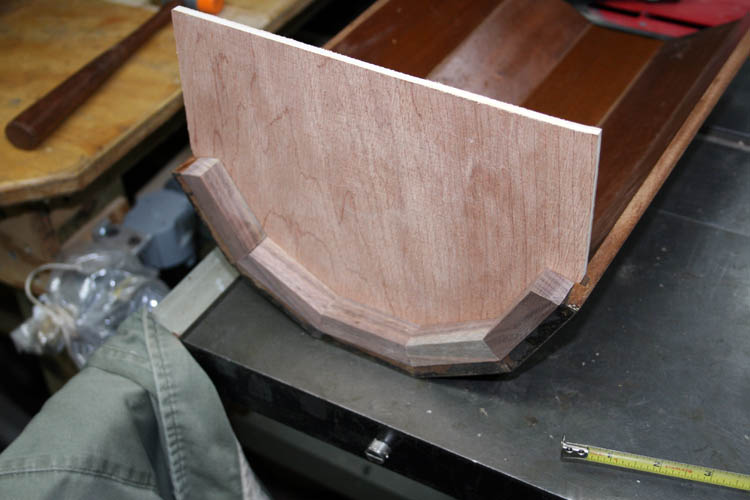

After getting the bottom dry fitted to the segmented vertical section that was

broken from the frame, I started making seven (7) segments for extra

support which were about fourteen (14) degrees at each end.

I also made seven (7) segments for the other side plus a member

for the back end of the bottom. I had some scrap black walnut about

the right size and used the miter chop saw to get the correct angle and

length for each piece. Since, this area is on the bottom, I didn't

worry about a musical instrument grade fit, but it was definitely close

enough for government work....grin if you must!

After the bottom was secured, it was time to do the first glue up for the

frame, which included three side members and gluing back together a section

of the top frame that was severely cracked and just about in two pieces.

Since this piece had been prior refinished and a somewhat butchered repair, the

value was diminished as far as an original antique, therefore I didn't have

a problem with adding the lower segmented supports for the plywood bottom.

This job was a repair and not a full blown historic restoration. A

full restoration would cost more than what the antique value would be.

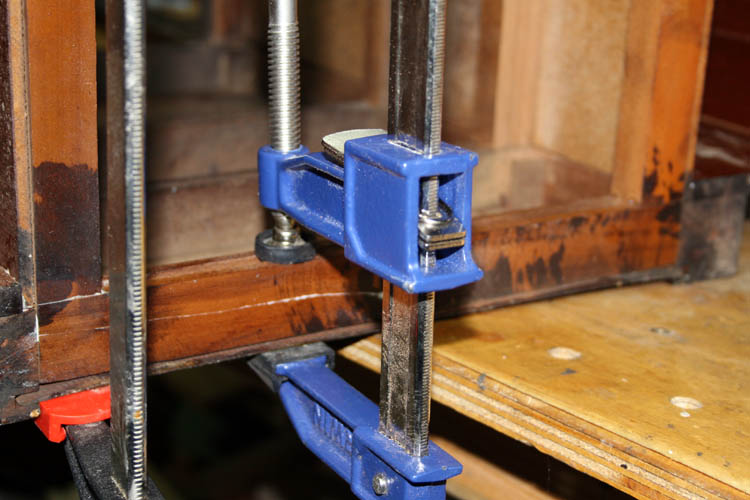

MAIN FRAME GLUE UP

I used Titebond Ultimate III glue and clamps to pull it back together.

FYI, the Titebond glue is actually stronger than the wood itself.

Believe me, I have tested, it that statement is a FACT.

Final clamp added and excess glue wiped off with a damp cloth.

The main frame loose components were placed back into the proper

position, glue applied to both the tongue and groove and clamping pressure

was applied using bar clamps and allowed to cure 24 hours.

LEG REPAIRS

All four legs were made by gluing up two segments of wood together and

turned on a lathe, whereas one of them had a very large crack at the glue

joint which had failed. I used a couple guitar makers wooden cam

clamps to pull the joint back together after working glue into the crack.

SEGMENTED SECTION GLUED TO THE TABLE

The hardest part of this repair was the half round segmented vertical storage section

which had come un-glued in two places. As I stated earlier, someone in

the past had attempted to glue it back together and had sanded down one side

of the segmented section and the outer portion was about 3/32 inch open at

the outer edge. The inside portion of the angle fit fairly good.

I dry fitted the half round segmented vertical section and there was not much room for

clamping. I tried a band clamp but it would not pull both sections

together. One of the sides fit together nearly perfect and a good

strong masking type tape used to hold musical instrument binding/trim around

the top and bottom edges of a guitar would be adequate enough pressure.

The other side would take a little more persuasion with a couple regular

long bar clamps. Since the seam would depend on the strength of the

glue, I drilled a few holes into the segmented vertical section and the

table vertical section to allow glue to get into both pieces of wood for a

better bond. I mixed up a wood filler using fine sawdust, coloring

agent and the Titebond Ultimate III glue for this section to be glued.

My friend Calvin Jones, noticed the aluminum foil in the background as

asked what it was for. I told him, "I used it to cover the new bottom

to prevent the glue from sticking to it, since I wanted it to

free float in the slotted

segmented section." I removed the aluminum foil from the bottom

before I did the final glue up of the segmented pieces to the table

segmented members.

The vertical segmented pieces were about 3/8 inch thick and too thin to

attempt a spline or wood dowels and if attempted, might burst the wood open.

Glue/wood filler mixture and regular Titebond Ultimate III glue on the

right.

The above joint fit together fairly well, but the other side was a "dawg"

to fit.

Tomorrow 04-20-16, I will check the glue up fit and apply additional

homemade filler to the seam where the tape is and let it set an additional

24 hours. I noticed the filler had shrunk some and will get it leveled

up by sanding and then match some stain to the area that had been prior

sanded down by the earlier failed repair attempt.

I glued in the additional segmented pieces for the bottom of the

segmented storage area and applied a dark stain to the new wood bottom and segmented

pieces added and re-installed the top.

I applied a dark walnut stain to the "new construction" members above,

not normally seen.

The segmented vertical side storage bins look pretty good now.

COMPLETED PROJECT

I delivered the Martha Washington Sewing Stand Table to Ms. Robinson and

we installed the three drawers. By the appearance of the drawer

colors, someone had removed the original finish since the

drawers did not match the rest of the sewing stand table.

Nevertheless, it is a lovely piece of historic furniture from the past.

As I stated earlier, a full blown historic restoration would cost more than

what the antique retail value would bring. She asked me what it cost and

I told her it didn't cost her anything. I told her this was payback

for some of those "beautimous"

persimmons harvested from her tree.

We chatted for a long time and she promised to let me take a picture of herself

when she gets prettied up......grin if you must!

It is rewarding to do things for other people and return a kind favor not

expecting anything in return by a simple, "Thank You."

I equate that with, "doing to others as you would have them do unto you!"

Does, the

golden rule sound familiar?

Web published by Bill aka Mickey Porter on 04-19-17, updated on

04-20-17 and 04-22-17.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."