HOT WATER HEATER INSTALLATION

Our electric hot water heater was installed in 1994, therefore is twenty (20) years old and it was installed by our neighbor

Johnny

Hildreth who died in 2009. Johnny was the best neighbor

and friend one could hope for and my bride and myself certainly do miss

him. I have pixs of him at some of our various

Christmas and other

functions that is annotated throughout

this website and I will link to them.It was a week or two ago that I

noticed some water near the base of the hot water heater and it was

evident that it was leaking somewhere around the top heating element and

with the age of the unit, it was time to replace it versus attempting a

repair. This is a 40 gallon capacity hot water heater

manufactured by A. O. Smith and what they refer to as a short model.

I believe it was 44 inches in height and it was elevated on a couple

pieces of square tube and channel iron to bring it up to the desired

height for easier plumbing in.

Above pix of the existing hot water heater and plumbing. I

might have drained water from the tank at least one time in the past,

but not sure.

Here the water leak is visible and I earlier removed the Styrofoam

protector to verify where the leak was coming from.

Normally when it comes to major plumbing repairs, I tear up more

stuff than I fix, grin if you must, but after viewing many YouTube

videos, I ascertained that this project was doable in my humble opinion,

especially with fittings and couplings that do not require soldering.

It has been over forty (40) years since doing any copper pipe soldering

and here in Anson County, North Carolina, there is definitely a shortage

of qualified and certified plumbers and will leave it at that!

GOING BACK IN TIME

Going back in time to the early 1960s, of which I helped wheel barrow

brick and mortar during the summer months for my uncles Doug Coley and

Baxter Bowers, there were several good plumbing contractors and plumbers

in our town of Wadesboro, NC and will mention those that I remember:

Coggin Brothers, Johnny Wagner, Jimmy Ormsby, Johnny Hildreth, Jack and Dorton Gilmore and there were a few others

that I cannot recall at this time. Most of the plumbing was either

copper or black iron pipe and the sewage drains were of cast iron.

Materials used today have definitely changed with PEX replacing

copper lines since it is less expensive, more flexible and easier to

install. PVC definitely has a lion's share in the plumbing

industry and last longer than PEX.

BACK TO THE INSTALL

As with my normal MO, modus operandi,

got side tracked and went on line and found a 40 gallon capacity hot water heater

manufactured by A. O. Smith available at Lowe's in Rockingham, NC , however it was 50 inches in height versus

the 44 inches in height of the old unit. I got the tape measure

out and figured it would fit to the existing plumbing if I leave off the

square tubing and channel iron base supports.

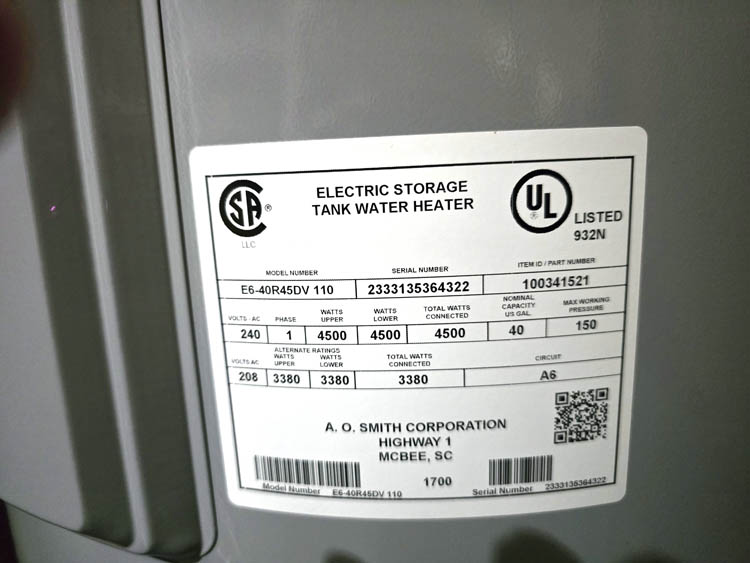

Above pix of info on the replacement hot water heater and below a

close-up pix of the old unit:

There definitely is a lot of soldering on the hot water side of the

hot water heater to bring the connection up to the hot water line.

TOOLS REQUIRED

After getting into the hot water heater replacement, I needed a few

additional things such as nut drivers and a short Phillips # 2

screwdriver and of course some extra lighting. I did use an

electronic voltage tester, but I have not been impressed with them, but

would rather use a volt/ohm meter instead.

LETS GET STARTED

First order of business was to trip the breaker for the 240 volts AC

at the breaker box aka power panel to the hot water heater. I then

closed the incoming water line value to shut the water supply off.

I attached a water hose to the drain outlet on the hot water heater

tank and ran the hose outside under the basement garage door. The

faucets were opened up in the house and the screw was opened up on the

tank valve, however no water came out the hose when the value was

opened. I then used my air compressor to blow air through the

water hose into the tank and then the unit started draining. I

probably took over two (2) hours to drain the tank, due to

sediment deposits on the bottom of the tank near the drain valve which

restricted the water flow from the tank.

Once the water was drained from the tank, I then proceeded to cut the

1/2 inch and 3/4 inch copper lines to the tank and then removed the

power cable to the unit. Since there was a shelf over the hot

water heater, it was close quarters to get a standard pipe tubing cutter

to make a full 360 degree rotation on the 1/2 inch copper line, however it cut the tubing ok.

Both lines were deburred using a Shark Bite deburring tool which is also used

to mark the length of the tubing that goes into the Shark Bite fittings.

Before doing the above, I had to disconnect the dryer and relocated

it out of the way in my basement woodworking shop.

The old hot water heater was removed and I dragged and/or walked the

unit to the basement garage door and placed it outside for later

disposal.

I had earlier marked the hot and cold water line where it needed to

be cut and needed about three (3) inches length of the 3/4 inch copper

tubing to connect from the water supply cut off valve to the Shark Bite

line to the tank which was 12 inches in length. I cut the 3/4 inch

supply line about 2 inches from the elbow in the line.

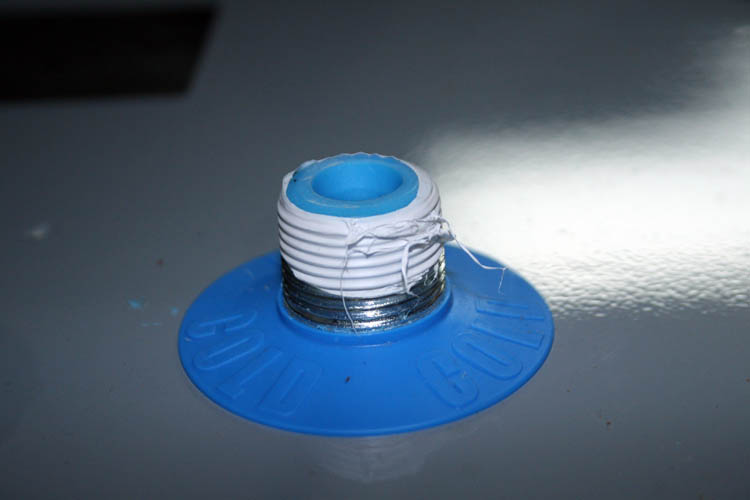

I applied 4 to 5 turns of Teflon tape to the hot water and cold water

FIP connection at the tank.

When applying the Teflon tape, you wind in a clockwise direction.

The Shark Bite Max stainless steel braided water hoses were connected

to the hot and cold water lines and I then turned the main water supply

line on to check for any leaks and there were none. I did notice

that the cold water supply line Shark Bite stainless steel hose did

distort some due to the tight bend to make the connection. If there

is a problem in the future, hopefully not, I will have to go to plan B and get a right angle Shark

Bite fittings for the 3/4 inch cold water supply line to the in line

Shark Bite ball cut off valve which will raise the braided line upward

reducing the tight angle bend at the tank connection.

Next was to connect the 240 volt AC line to the unit using twist lock

connectors and placed the steel cover over the connections.

The in line Shark Bite ball valve was opened and water was allowed to

drain into the hot water heater tank. I left a couple faucets, hot

water side open to purge any air out of the hot water heater as the tank

was being filled with cold water.

As stated earlier, no leaks were detected and the acid test was to

turn the power back on to the unit and check for any leaks since when

the water is heated up, the pressure will build up in the tank. I

ran hot water from a sink to allow cold water to fill back into the hot

water heater tank and allowed the heating elements to do their thing.

So far, there are no leaks and hope the Shark Bite fittings will

perform as they should. I believe I did my part getting the copper

pipes prepared for them and pushing them to the marks made on the copper

tubing. It did take some effort to seat the fittings properly.

Tomorrow, our Lord willing of course, I will connect the dryer back

up and give our utility department a call to come by and pick up the old

hot water heater. Lowe's charges a $ 3.00 disposal fee

for the old tank. I wonder where those funds end up, grin if you

must!

HOT WATER TANK AUTOPSY

I wanted to see how much sediment was in the hot water tank and

decided to cut open a panel out of the bottom section.

My Milwaukee small angle head grinder with a 4.5 inch diameter

friction cut-off wheel was not larger enough to go through the walls of

the tank which had a 2 inch thick insulation. Therefore, I had to

skin aka peel the outer metal cabinet housing and then remove the

insulation giving me access to the actual water tank itself.

As evidenced by the above pix, there was a considerable amount of

sediment deposited in the water tank and that is why the tank drain

valve would not allow water to escape from the tank until I forced air

through the valve cutting loose some of the sediment. The hot

water tank is resting on its side when this pix was taken. The

bottom of the tank is dome or convex shaped for strength and evenly

distributes the weight of the water better. The top of the tank is

also dome or convex shaped.

There is a blue glass coating on the inside of the tank and quote from

the internet: "In 2004, A. O. Smith reaffirmed its mastery of

glass lining technology by introducing patented Blue Diamond™ glass

coating on its best Conservationist® residential water heaters.

Blue Diamond™ provides the ultimate protection… over twice the corrosion

resistance compared to industry-standard glass lining."

The left portion of the inside of the tank is where the valve is in

the tank and you can see the sediment deposited all around the valve.

I turned the water tank upright and drained most of the existing

water out for photographic purposes. I might scoop out most of the

sediment and ascertain how much was left. There was a good amount

that exited when I placed the tank upright and on its side.

CLOSE UP OF SEDIMENT AND MAGNESIUM ANODE ROD

I scooped out the sediment from the tank and found what was left of

the magnesium anode rod.

I didn't measure the amount of sediment, but it is at least a gallon

and found what was left of the magnesium anode rod which was just about

totally eaten away. The rod hangs from the top of the tank and is

a few feet in length.

Close-up pix of the remaining magnesium anode rod.

All the water did not drain from the tank, but most of it did and due

to the restriction of the sediment at the output valve, it took about

two (2) hours to drain the tank which was then manageable even for an

old man, grin if you must!

I did not see a magnesium rod which no doubt was eaten away to help

get rid of some of the calcium deposits.

I think the majority recommend you drain the tank yearly to help

remove the deposited sediments from the tank.

TANK WALL THICKNESS

The tank wall thickness is a little over 3/32 inch thick and showed

no sign of corrosion and this unit was very well made.

DIDN'T DO ENOUGH RESEARCH USING SHARK BITE BRAIDED

STAINLESS STEEL HOSES

I recently reviewed several complaints and issues using the Shark

Bite stainless steel braided hot water heater hoses and there definitely

is a problem with the interior black plastic lining breaking down with

black flakes getting into your hot water supply. In fact, there

is a lawsuit against Home Depot and Reliance Worldwide addressing those issues that is making its way into the

court system as I type.

I went on line and filled out a form at Reliance Worldwide asking if

any changes had been made to the rubber plastic lining in the Shark Bite

braided stainless steel hoses.

I received a reply from Reliance Worldwide, however they did not

address my question, but gave hyperlinks if I wanted to file a claim, of

which I do not!

I plan to replace the Shark Bite hoses with PEX pipe as soon as

possible and will get a refund from Amazon for the Shark Bite stainless steel braided plastic

lined hot water heater hoses.

I guess this is a product of myself being too frugal not wanting to

pay a plumber to

solder copper pipes back in place. Sometimes, I am my own worst

enemy for such things, grin or frown if you must. I need to learn

to solder copper pipes again and get the current updated solder and

flux; old school flux stuff was acid core and 60/40 and corrosive as

evidenced by old copper pipes turning green where the flux was left on

the pipe.

REPLACED HOT WATER HEATER HOSES

I replaced the Shark Bite stainless steel braided hoses with PEX

and had to add the appropriate Shark Bite fittings for the 1/2 inch and

3/4 hex pipe and the 3/4 inch FIP connections to the hot water

heater hot and cold. Prior to making the PEX connections, I turned

the power off to the hot water heater and turned the input cold water

valve off to the hot water heater tank. After the connections were

made, checked for leaks after turning to cold water input valve on and

then tripped the 30 amp. breaker to the on position and purged the hot

water line(s) and checked for leaks and everything looked good, no

leaks. There is some local codes that prohibit placing

PEX directly to the hot water heater, especially if it is a gas unit

and required at least 18 inches or more before adding to PEX.

PS I have an LED light source giving some light to the

dark area.

The cold blue side PEX was about a perfect fit with the

fittings, but the red hot side PEX was not perfectly aligned, but

close enough.

Web page uploaded by Bill aka Mickey Porter on 07-18-2024 and updated

on 07-19-2024, 07-20-2024, 07-22-2024 and 07-25-2024.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."