POTATO AND ONION STORAGE BIN

For nearly five (5) decades, we have stored onions in our refrigerators and most culinary

folks will tell you, it is best to store them in a cool dry place that

allows some air flow around them as well. The same goes for potatoes

too! Onions left in the refrigerator too long will definitely get

mushy. Many, many years ago, farm folks had some type of

root cellar to store such items. My Grandma Coley used an

area underneath the back porch which was shaded and cool to store sweet

potatoes, etc.

I surfed the internet looking for some ideas and free plans to build such a

storage bin and what I decided on was a set of plans (not

free of charge) from

Woodcraft. I ordered the plans which

basically was one large folded sheet of paper 22 x 34 inches with a cover

sheet. I did have a little difficulty in getting the plans locked into

the ole brain; might be a product of maturity. The plans were not

that costly and I didn't have to take out a loan or mortgage our properties

to purchase the plans.....grin if you must. Since the plans are

copyrighted, I will not include a detail photo of them, but linked to the product

above in case you desire to purchase a set. BIN SIZE: 10

inches deep by 15 inches wide by 11 inches tall. OVERALL SIZE:

40 inches tall by 19 inches wide by 12 inches deep.

Pixs below of the finished potato and onion storage bin getting some usage on 05-24-17!

Below, a closer look at the Potato and Onion Storage Bin. I

purposely chose the stain not to match the dining room buffet and the original pine

paneling which is the real wood; 9", 7" and 5 inch width tongue and groove

boards at least 3/4 inch thick. The medium walnut color makes this project

"stand out" from the

surroundings, otherwise it would blend right into the color scheme of the

kitchen and dining room.

I am very pleased with the outcome of this fun woodworking project! I

made one boo boo which I corrected.

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep Safety

paramount because hand and power tools can do serious bodily harm and death

if not used properly, therefore these pages are solely for

entertainment purposes only from

a personal liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues

before going any further. Safety glasses and hearing protection is a must,

although I do forgo the hearing protection many times; my bad!

MATERIALS

The plans called for using 1 inch pine shelving boards which are planed down

to 3/4 inch in thickness that are from 8 to 12 inches in width in clear pine

and high dollar; ranging up to 40 bucks per board 8 feet in length at some

retail locations. As with most woodworking projects, you have to let

the materials acclimate to your workshop storage conditions; e.g., humidity

to stabilize.

The door frames for the storage bin are made from 2 inch width pine boards.

I will check and see what common pine shelving boards that Lowe's in

Rockingham, NC has in stock and will pick through their stuff and find

something decent.

The joinery used is mostly butting the pieces together and held by glue and

some 1 1/4" finish nails. End grain does not glue well, but I guess it

is strong enough for this application with the usage of the finish nails.

This is not the most secure method, whereas cutting dados would change the

length of the inner shelve members, however would be much stronger. In

all probability, I will install wood

dowels in the door frames (stiles

and rails) and the face frame component. You could use

pocket hole screws for the door frames and

the face frame, but I am not a big fan of pocket screws. I might get a

Kreg pocket-hole screw system in the future, but I have managed many decades

without one. The plans do not show a routed edge around

the perimeter of the top and that is another possibility. It is normally my mode of operation, (modus

operandi) MO, to over build something, but I want something to last

and strong as the

Rock of Gibraltar....grin if you must!

Will add pixs and narrative as I work on this project.

Web published by Bill aka Mickey Porter on 04-22-17.

WOOD PROCUREMENT

It was misting rain on 04-24-17 and decided to drive to Lowe's in

Rockingham, NC and check their pine shelving material inventory out and below is a pix

of what I brought home. I got extra pieces, because there is usually a

need for extra, since there were knots on some of the pieces I

purchased. I did pick through what they had on hand and obtained the

best of the best. I normally find a usage for any scrap aka

unallocated materials (as my

friend Frank Schoepf

of Hampstead, MD) calls

left overs from a project and I do keep the ole "pack

rat" theme alive and well.

I put scrap wood stickers between the boards to facilitate acclimating to

my normal/average workshop humidity. I also found a use for the heavy melted

lead spheres.

A close up of the end boards which will have to be trimmed to get rid of

the non useable portions:

I purchased three knobs for the bins and a magnetic latch. I didn't

like what hinges that Lowe's had in stock and will see what H. W. Little Hardware,

Inc. has in stock locally and/or do some internet shopping.

While the wood is stabilizing, I will round up the butt hinges, support

friction arm for the upper storage compartment, appropriate stain and check

my inventory of 15 gauge angled finish nails for the pneumatic nail gun.

I thought I had a gallon or two of

Mohawk nitrocellulose classic instrument

grade lacquer, but only have a few gallons of the reducer, therefore will

order a gallon of the Mohawk brand lacquer. Mohawk, sent me to

one of their distributors for such a small order.

NOTE: I have to add 1 1/4 inch length 15 gauge angled finish nails to

my procurement list. I ordered a gallon of the Mohawk nitrocellulose classic

instrument lacquer from

Klingspor's Woodworking Shop in Hickory, NC

and received it in one day via UPS.

Web published update on 04-27-17.

CUTTING MATERIALS TO SIZE

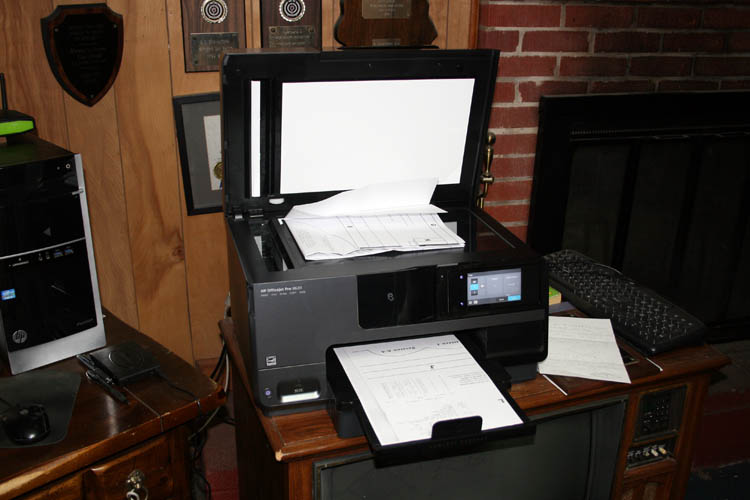

The plans comes with an excellent cutting chart and copied that section

off the plans and placed on a clipboard.

First on the agenda was to cut the 8 feet length boards to a manageable

length since my shop is very crowded and don't have out wings extending from

either side of my table saw to allow working with an 8 ft. length of material which is a

handicap, but I do manage as the need arises. 05-08-17.

Click on thumbnails for a larger screen view:

After getting the material to manageable lengths without much waste, it

was time to use the table saw. I used a rip blade, zero tolerance

insert and fence to get

boards to the proper width as needed.

I used an impromptu crosscut slide I made when constructing a

toy/blanket chest

for our youngest Grandson to handle the 12 inch width boards which are

actually 11 1/4 inches in width. The slide will handle a 24 inch wide

panel and makes it easy to square up

the ends, etc. I squared up to length a couple 10 inch width boards

which are actually 9 1/4 inches in width. I changed the blade to a

crosscut blade.

I used the above smaller crosscut slide to cut the 2 and 3 inch boards

used.

Above pix of the wood cut to the proper width and length and ready to

start a glue up for the top and back member.

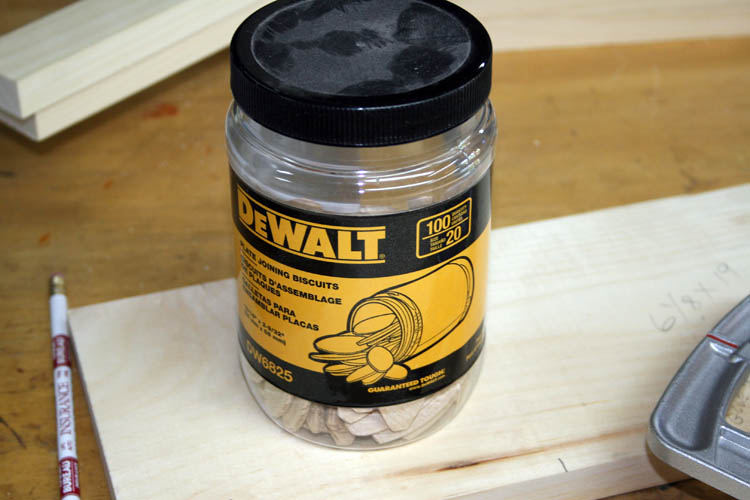

USING BISCUITS FOR THE TOP AND BACK MEMBERS

I got the Porter-Cable biscuit jointer out and used # 20 biscuits and

Titebond Ultimate III glue. The dust collection bag with the biscuit

jointer is worthless, therefore I use the hookup from my Shop Vac.

The plans do not call for the

usage of biscuits or wood dowels in this project; keeping it simple as many

woodworkers do not have a biscuit jointer or a doweling jig/fixture, but you

know my MO by now!

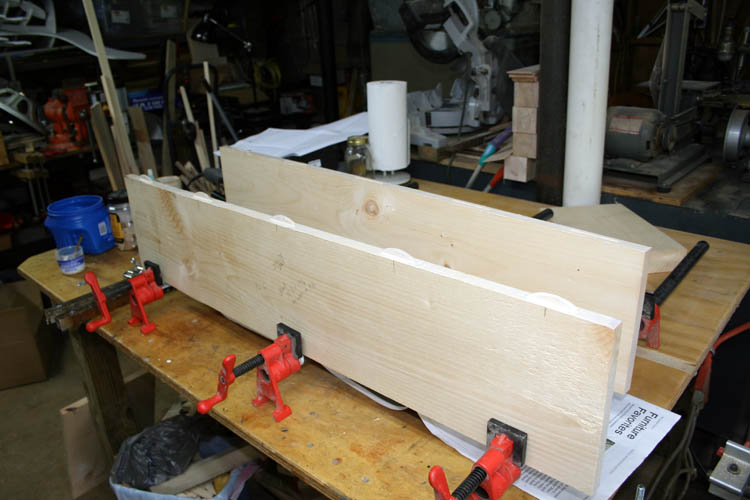

I used three 18 inch length 3/4 inch diameter pipe clamps and a couple 1

inch square aluminum cross brace members to keep the wood from bowing under

pressure. A couple C clamps at the end,

"sealed the deal".....grin if you must!

Tomorrow, I will use the same procedure for the back member, but will use

four 24 inch bar clamps, since my other pipe clamps are at least 5 feet in

length and cramped for room using them on the above outfeed aka work table.

I will also make the cut outs on the side pieces and the front bottom

band.

UNALLOCATED AKA SCRAP MATERIAL

Below pix of some of the scrap aka unallocated material left over that is

to the left of the 5 gallon bucket which also has unallocated material from

other projects....a pack rat for sure!

Web published update by Bill aka Mickey Porter on 05-08-17.

SHOP WORK ON 05-09-17

I removed the clamps from the glue up for top of the storage bin and did

the glue up for the back member.

I used # 20 biscuits and glue for the back member as well.

My 3/4 inch pipe clamps I used for the top member were too short to use

for the back glue-up and I have four that were at least five feet long and

too large to easily maneuver on the table saw outfeed aka work table and

rarely use the five feet clamps. I used the PortaBand saw and shortened the 3/4

inch pipe to manageable lengths......I can purchase addition threaded 3/4 inch

black iron pipe if needed for other projects in the future.

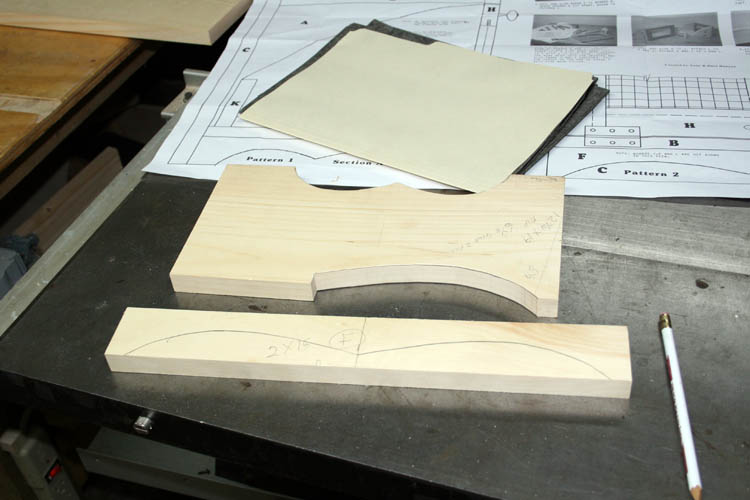

I got around to getting my patterns transferred for the side, front and

the two curved storage bins onto scrap wood and made a wood template in case

I decide to do another one for someone else.

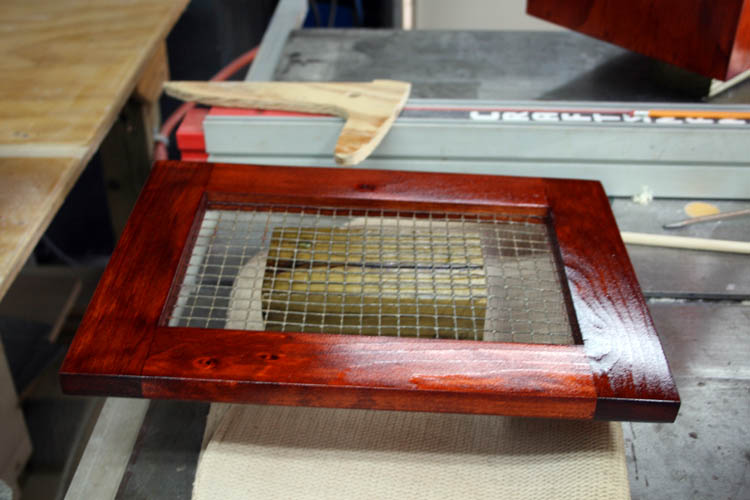

STORAGE BIN DOOR FRONTS, ETC.

The storage bin door fronts use nails and glue for their attachment, but

since I have the Dowel Max dowel system, I like going the extra step for

building something that will last. While it definitely takes more

time, I don't mind doing it. One could use a small biscuit or even

pocket screws, but the pocket screws would be visible on the backside of the storage bin

when you open it, but not from the frontal view.

Also, slots have to be cut into the members to allow for the 1/2 inch

square mesh galvanized wire to fit and the inside edges need to be stained prior

to assembly. I used my router table with a .097 slotting cutter and

set it up where the end of the vertical stiles would not show the slot by

using a couple stop blocks to limit the travel of the slot cut. The

plans call for .125 inch slot, but I have my slotting cutters dedicated for

something else using the .125 inch width slotting cutter. A table saw would work, but

I wanted to stop the slot on the

stiles, otherwise you have to fabricate and glue a filler strip in the

end of the stiles.

I also used dowels in the face frame instead of just

nailing and gluing them to the sides and lower front.

Click on the below thumbnail pixs for a larger screen view:

SHOP WORK ON 05-10-17

I got a chance to work some more on the potato and onion storage bin and

made pretty good time. I did find one boo boo of a part that didn't

fit just right and according to the cutting chart, the part was

correct....misread something somewhere, but able to fix it. The

problem was the orientation of the lower shelf onto the back member......my

bad!

I glued the door frames together with the wire mesh and started

assembling one of the bins, since the other door frame glued last evening

was dry. The 1/2 inch square galvanized wire mesh was at least 25

years old. I purchased it to keep bats out of the attic by closing off

their access through the end gable vents, of which the regular screen wire

had rusted out. I can certainly see a

"pack rat" theme.

Did a trial fit and everything was ok and ready to spread some glue

and fire the nail gun. This nail gun is magazine fed; hope the

Liberals don't outlaw the 100 "round" nail magazine capacity......grin if you must!

After the storage bin was glued and nailed, I sanded the back and the top

using an orbital sander. I have a belt sander but the orbital will do

just fine and I can locate it quicker than the belt sander, since I rarely

use the Porter-Cable 4 x 24 belt sander. On the pine boards, the 4 x

24 belt sander might be too aggressive on the soft wood unless you have a

delicate touch.

With the back and top sanded, I need to cut the detail out on the sides

using a jig saw.

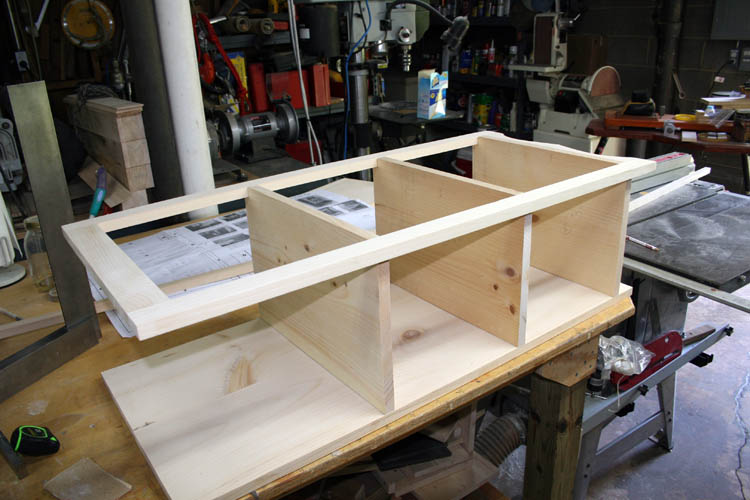

ASSEMBLY TIME

Since the project from now on will be glue and nails, I needed some

alignment marks on both sides of the back in order to get the three shelves

in the proper place and some witness lines to make certain the 1 1/4 inch 15

gauge finish nails will hit the center of the shelves.

I dry fitted the parts and everything looked pretty good and have to figure

out the easiest approach the aligning and nailing the shelves to the back.

The back member was held vertical with the aid of a large 4 inch block

of wood and a bar clamp. The glue was applied to each shelf member and then

nailed from the back side, whereas the witness lines worked great keeping

the nails into the center of the shelves and the shelves centered to the

witness lines.

You about need

Orangutan length arms to reach around to the back side of

the back with the nail gun and keep the shelves aligned. I had to

stand on a steel bottom chair to get the extra reach....a safety hazard for

sure.

ATTACHING THE SIDE MEMBERS

I used the same procedure for marking the sides with a pencil line to center the

nails into the shelves. The Starrett 18 inch machinists square below, is far too heavy for routine

work. I purchased it solely to

calibrate my jigs and fixtures with. I need

to purchase an accurate framing square that is much lighter in weight for

everyday usage!

After the witness lines were drawn, it was time to glue and shoot some

finish nails.

FACE FRAME INSTALLED

I inserted one of the completed storage bins to see what the project looks like

and pleased so far.

I order three pairs of hinges on line from Amazon and still waiting for

them. They were shipped GHL Global and probably coming from China,

etc. I couldn't find what I wanted within 20 +- miles and is the

reason for the internet order which most of the time is extremely fast.

SHOP WORK ON 05-11-17

This morning, I set my router table up with a decorative border bit to

route an edge around the top member of the potato and onion storage bin. The

plans do not call for a border, but I wanted to dress the top

edge up a little; remember my MO?

I like the decorative edge for the top versus the plain edge. It is

best to make several smaller passes instead of trying to remove all the wood

wood with one pass to prevent chip out and reducing the life of the router

bit.

I finished up the other bin by installing the door front to sides, back

and bottom with glue and

nails. I used a couple clamps to help pull the glue line tighter

together before driving home the nails with the pneumatic 15 gauge finish nailer.

I had to laugh at myself; e.g., while gluing and nailing this bin together,

I was hammering away, not realizing the nail magazine was empty. The

piston aka plunger that drives the nails into the wood was still making an

indentation into the wood as if a nail was installed. The reason if

wasn't obvious at first, is because I used a couple bar clamps which held

the parts in place.... ......grin if you must!

TOP INSIDE BORDER INSTALLED

The plans do not call for an inside border underneath the top, whereas

they have the top simply glued and nailed in place. From my personal

experience, end grain wood does not glue well to regular horizontal

orientation grain wood. Also, the top will contract and expand along

the width of the wood, depending on the humidity conditions and the width of

the top. In all probability, there would not be a problem, but might

as well plan for the top width expansion. The top inside border aka

band, will also supply support to the back, side members and face frame to keep them

from bowing in/out at the top. There are many ways to install

expansion brackets, etc., but will go as low tech as possible on this one

without purchasing additional hardware.

With the inside border installed, I will elongate the screw holes in the

border to allow for width wood expansion of the top and install the wood

screws from the bottom side of the border into the top.

Since the inner border will not be seen, I didn't use my dedicated miter

sled for the table saw to cut the angles, but used my cut-off saw which just

gets you close. It was calibrated for a hopper jig/fixture and left it

as it was set which is not a perfect forty-five degree calibration. I

will re-calibrate it at some point in time!

I plan to round up some pine colored wood filler this afternoon, fill all

the nails holes and tomorrow, start some sanding with the orbital sander and

finish up using a couple Porter-Cable Speed Bloc Palm sanders progressing up

to about 220 grit sandpaper. Sanding is good

personal therapy, but you have to contend with the dust generated and

the cleanup.

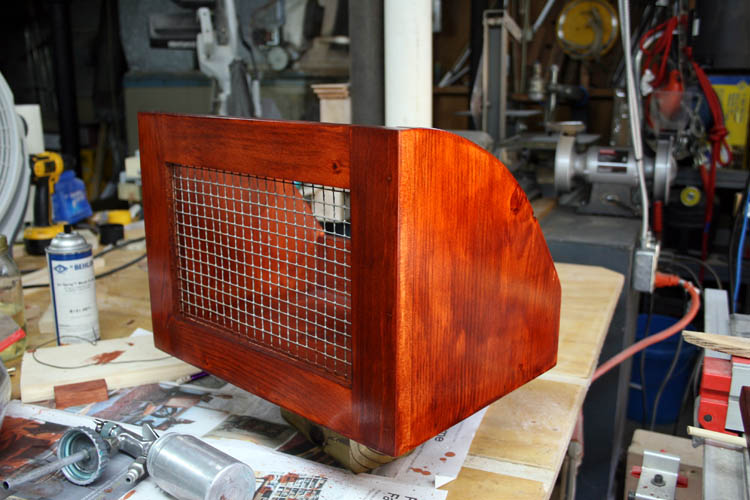

APPLYING STAIN

With the sanding completed, I applied a medium brown walnut alcohol based

stain, product name Behlen Master Solar-Lux, which is non-grain raising.

This product is compatible with using nitrocellulose lacquer, of which I

plan to use. Many States including California has strict regulations

on using a high VOC (volatile organic

compound) type lacquer such as the nitrocellulose, but water based

lacquers do not give the same results in my humble opinion. This is

speaking from my musical instrument finishing experience going back to the

late 1960s and continue to use that type of lacquer today when needed.

The inside of the potato bin, back and bottom will not be too visible,

but went ahead and applied stain to those areas. I also applied stain

to the top, which will be installed after the final finish. I went

back later and blended the stain more evenly on the sides of the main frame.

Above pix with the stain still fairly wet.

I need to install the wood support for the magnetic latch for the upper

door before spraying the sanding sealer and final top coats of lacquer.

The door hinges have not arrived yet and still have to obtain some type of

door support for the top compartment door.

After the glue dried overnight, I applied a coat of stain to the wood

support

for the magnetic latch.

In a few days, I will spray

a "wet" coat of Mohawk sanding sealer and then start applying a few finish

coats of the nitrocellulose musical lacquer. Updated 05-13-17.

FINISHING

My basement woodworking shop is too small to spray finishing materials

aka lacquer and without an exhaust system and/or spray booth, therefore I must spray

finishing materials outside, of which is not the ideal situation, but manage

nevertheless.

I have a link

which describes my finishing methods and will not re-invent the wheel on

this one, but will give a few highlights as I go along. I don't use my

spray gun regular enough to be proficient with it, but I do get by.

I will install a roofing nail in each corner of the base of the potato

and onion storage bin to keep the bottom off the surface I have the base

resting on. I will drill a pilot hole about the same diameter as the

roofing nail to keep from splitting the wood. I will remove the nails

after the project is finished.

Lynx L-300H HVLP spray gun with lacquer reducer

and sanding sealer. Using 1 qt. pressurized can.

Top of the potato and onion storage bin with a coat of sealer and ready for a light sanding and then to the

lacquer. The knots give the top some character.

Above, the door frame for the top shelf compartment.

Storage cabinet/bin upside down and storage bins below.

This afternoon, I will lightly sand the components down with a Scotch-Brite pad, remove the sanding dust and apply at least one

or two top coats of Mohawk brand nitrocellulose musical grade lacquer.

Web published update by Bill aka Mickey Porter on 05-15-17.

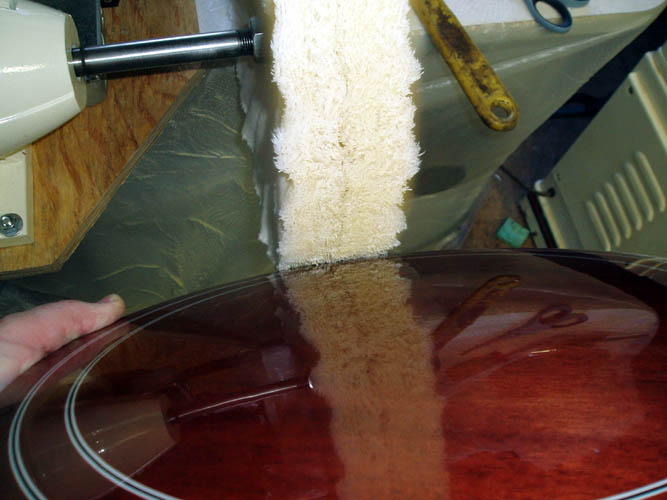

FINISHED FINISHING - NO PUN INTENDED

I put my last coat of finish on this project today, being May 19, 2007.

I have to keep reminding myself this is a furniture type project and

not a musical instrument that

requires about twenty (20) coats of lacquer, of which most of that type of

finish is wet sanded down to get rid of the so called orange peel effect and

then polished and buffed out to a literal "mirror

finish." See the banjo resonator pix posted below to

get my meaning of a mirror finish:

I had to re-order the hinges for the potato and onion storage bin the

third time, due to vendors too slow in their delivery and/or processing.

I ordered the last three pairs from Woodcraft, Inc. and they created the shipping label

on the 19th and ready for UPS to pick it up. Below pixs

of the parts waiting for the final assembly.

The above top has a lot of dings in it, but is Lowe's

"Top Choice" wood,

grin if you must. Nevertheless, it has plenty of character due to the

dings and knots present.

The top storage door.

I kept the basement shop door up and a large fan blowing out the

finishing vapors while the parts were curing out some. Luckily, I

didn't have any insects making a permanent home on the wet lacquer.

While waiting for the hinges to arrive, I will elongate holes in the top

inner band for attachment of the top with screws from underneath, of which will allow for any width

expansion due to changing humidity conditions. Tomorrow, I will see if

I can locate a friction latch for the top door to limit its travel to a

horizontal position when opened. I will install the magnetic latch to

the top door when I install the hinges.

This project is winding down and look forward to placing it in the

kitchen/dinning room beside the buffet and start

"field testing" it out with

some potatoes and onions. Probably store hamburger and hot dog rolls,

etc., in the top compartment, whereas regular loaf bread is stored in our

roll top bread box on top of the refrigerator. I normally keep New

York and/or Jewish Rye Bread in/or both our refrigerators.

I have to do some serious vacuuming and dust removal before my next

woodworking project!

Web published update by Bill aka Mickey Porter on 05-19-17.

WAITING FOR THE HINGES

Hinges were received and installed on 05-24-17, pixs below. I used

a scratch awl and a 3/32 inch bit in a portable hand drill. The pine

wood was soft enough that the drill was used very little.

The 3/32 inch diameter pilot hole will definitely reduce the risk of

bursting out the edge of the wood.

Installed the friction lid spport.

This has been another one of my fun woodworking projects and still

thinking about doing a curly maple coffee table when I can locate the proper

thickness and length wood required.

TOTAL COST OF THIS PROJECT