CZ 452 AMERICAN LEFT HAND .22 CALIBER RIMFIRE RIFLE

REVIEWAfter getting all the accuracy from a

Savage Mark

II BTVLSS which has taken a couple years of trying everything, I

finally decided to purchase a CZ 452 American .22 caliber rimfire rifle in a

left hand model. Initially, the CZ 452 American left hand was my first choice but no one

could deliver one in a timely manner and went with the Savage Mark II

BTVLSS. The Savage Mark II BTVLSS is a dang good squirrel gun but leaves a lot to be

desired for when punching holes in paper. I did everything to it

except pour molten lead or concrete into the void spaces in the factory stock to

replace all the missing wood......grin if you must! So here goes

another rimfire odyssey..........

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep Safety

paramount because hand and power tools can do serious bodily harm and death

if not used properly, therefore these pages are solely for

entertainment purposes only from

a personal liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues

before going any further. Safety glasses and hearing protection is a must,

although I do forgo the hearing protection many times; my bad!

GETTING STARTED

I placed an order with our local pawn and gun Village

Pawn & Gun Shop LLC and they were able to get me one this time

from one of their wholesalers Davidson's Guns aka gallery of guns in Prescott, Arizona and I

received the rifle on 12-17-15. Their price was pretty much in line with

most of the retailers selling that firearm via the internet but they are

still scarce as a hen's tooth to find at times....the demand far exceeds

the supply since the 452 is being phased out and

reborn as a

455 of which I personally do not like some of the changes; e.g., barrel

tenon held

in place with two set screws versus the screw in barrel. Those changes

in my humble opinion are not to produce a better quality rimfire rifle but

to reduce their manufacturing cost. The long term will determine if it

is an effective strategy for them since consumers ultimately control the

demand.

I will add pixs along the way to document what is being done to this

rifle.

The first order of business is to acquire a

Basix Trigger and

a pair of BKL

scope rings for

it via the internet and do some test firing before I have the barrel

threaded for my suppressor. Pillar blocks and bedding will be next on

the list but wanted to shoot it prior to the installation of pillar blocks

and glass bedding to have a reference point or standard to

start from as far as the initial accuracy.

My first impression of the gun was; it is well made, excellent metal to

wood fit, nicely polished blue steel, machining on the exterior of bolt and receiver was

very good. You get the feel that this rifle is a high powered rifle

instead of a rimfire. The cheapest looking component on the CZ 452 American is

the trigger guard which is a single piece of flat stamped

sheet steel that is formed

with an additional flat stamped plate for the trigger sandwiched between the

trigger guard and the stock. It will definitely be replaced with an aftermarket one that is machined

from a solid billet of steel and one is currently on backorder. As stated above, the trigger guard will be the

replaced as soon as

DIP has them in stock again.

When I removed the action/barrel from the stock, the rear action screw was

tightened to 30 inch pounds and a Gorilla was on the assembly line who had an extra serving of

bananas for breakfast must have tightened it as the

front action screw took only 18 inch pounds to release it. There was

also an indentation several thousands of an inch deep into the rear stock at

the receiver tang caused by the extra torque. When I

replaced the action back into the stock, I set both actions screws at 18 inch

pounds and realized why the rear one was pulled down so tight. There

was a slight binding between the barrel and the last inch or two of the

stock forend and they tightened the rear action screw down to apparently pull

the barrel up off the stock. Someone at the factory had placed an ink

mark on the wood stock near the forend where it was binding and apparently

didn't go back and remove any wood but left the action torque as I found it

which is a good guesstimate.

Web published by Bill aka Mickey Porter on 12-18-15 and updated on

12-24-15.

RIFLE BASIX TRIGGER INSTALL 12-25-15

With some down time today after Christmas, I installed the Rifle Basix

Trigger assembly. You will need a Dremel type tool, a small pointed

abrasive stone, epoxy cement, drive pin punch and a small brass head hammer to

complete the job. Inserted a few sequence pixs below and not to

re-invent the wheel, scanned the rifle Basix, Inc.

instruction sheet

for the CZ 452 Bolt Action Rimfire Rifle.

Above is what you receive along with the instruction sheet.

The forward pin on the trigger assembly has a small dimple punched into

each end to keep the pin from sliding out of the trigger requiring you to

grind away enough material to allow it to be punched out. It will be necessary to secure

the new pin

with a dab of epoxy glue. A .098 diameter slotted spring pin or

roll pin would work just as well in my humble opinion. I let the J-B Weld set up for a few hours

and adjusted the trigger pull to around 1 lb. 7 oz., however it will easily

go down to 12 ounces but not pass my bump test for the trigger and sear

engagement.

I did notice when inserting the set-screw into the trigger for the

trigger spring adjustment, it was an extremely tight fit; much tighter than most

other similar applications. I don't know what the torque was but it

was difficult to turn with the small Allen wrench supplied and the set-screw was

definitely not crossed threaded either!

While I had the receiver and barrel removed from the stock, I used 80

grit abrasive paper and sanded down the portion of the stock forward of the

receiver since it had the slight bind on the right hand side of the wood stock

when the action screws were at 18 inch pounds of pressure. After

testing, I will later come back and seal the stock.

I planned to install the BKL # 276 rings for the

Bushnell 6x18x50mm Banner model scope

but the mounts were way to high since the barrel has a good taper to it past

the receiver and it was just too high for my personal taste. I will

acquire a smaller height set of rings ASAP. The BKL # 276 High

rings were

approx. .980 inches from the bottom of the scope tube to the bottom of the

dovetail ring base. The dovetail groove machined into the receiver of

the CZ 452 American is a

standard 3/8 inch dovetail versus the 11mm metric dovetail that is on the 455 and

other 452s, etc. The CZ 452 American dovetail measures .500 inches

across the top of the dovetail and the CZ 452 trainer measures .433 across

the top of the dovetail and many scope rings will fit both receivers.

NOTE: I went ahead and installed the BKL # 276 rings and

will see if "they grow on me" as

far as liking them since I am antsy to go ahead and give this rifle a test

ride.......grin if you must! The extra height of the rings may be

necessary for the bolt handle to clear the rear scope ocular lens housing

and will find out if a lower scope ring will work. Nope, they didn't

grow on me!

I plan to test fire the rifle with various brands of subsonic ammo to

ascertain if the rifle is worth the extra expense to have the barrel threaded for

my suppressor and possibly have it pillar blocked and glass bedded at the

same time if needed.

I took a few pixs of the stock and there is plenty of wood real-estate that surrounds

the receiver making it a good candidate for pillar blocks and glass bedding.

You definitely can see quality engineering in the construction of this

rifle.

Remember, Christ is the Reason for the Season

but he is also the reason for every day of our lives and he deserves our

praise, honor and glory in all things!

Merry Christmas and a Happy New Year!

Web published updates by Bill aka Mickey Porter on 12-25-15.

CHANGED HORSES IN MIDSTREAM

I initially decided to transport the CZ 452 to a

gunsmith

in Blanche, NC for

the barrel threading but

changed my plans and will ship the

barrel/receiver to Accurate Ordnance, LLC

in Winder, GA to have the barrel threaded. I had them thread the

barrel of my Savage Mark II BTVLSS a couple years ago

and very pleased with their First Class All-American work. I saved the

shipping box I made which was an overkill to say the least and got the

barrel/receiver boxed up this evening and ready for the USPS tomorrow

morning.

I emailed Accurate Ordnance and they still remembered the overkill on the

shipping box and we got a grin out of that for sure. Below a few

thumbnails taken:

NOTE: The hyperlink to Accurate Ordnance, LLC was removed,

due to the website no longer active or their contact links and/or telephone

number.

Quoted from Marks Facebook page January 2, 2020: "We

want to sincerely thank everyone who has supported and encouraged us the

last few (9+) years. We greatly appreciate you. Unfortunately,

we have decided to close the shop. I am dealing with a parent in

Hospice care and my attention needs to be elsewhere at the moment.

Jason is retaining the CNC lathe and tooling with intentions of setting up a

new shop. We'll make sure the word gets out there when that happens.

We're contacting the few remaining customers with projects to make

arrangements to make sure they are satisfied. So, if you are one of

those customers, please be patient and I promise we'll reach out to you.

We appreciate everyone's understanding and wish you and your families a

happy and blessed New Year.

Mark Kuczka"

Web page updated by Bill aka Mickey Porter on 07-07-2020.

Our weather lately has not been conducive to doing any serious rimfire

rifle testing due to an abnormal wet and windy winter so far and a few more

weeks of waiting will not make much difference anyway.

When I receive the barrel/action back from Accurate Ordnance, LLC, I will

start test firing and then go to plan B if I think the action needs pillar

blocks and glass bedding of which it might not. The stock has enough

room to install my own fabricated 1/2 inch diameter

pillar blocks for both the rear and

forward action bolts but the forward pillar will need to be reshaped for the

magazine well housing screw and the forward portion of the sear. I am not impressed with the

lamp tubing type pillar block installation

but they apparently work fine.

My friend Robert Webster of Hamlet, NC traded for a

CZ 452 trainer and he shoots excellent 50 yard

groups using both cheap

(Winchester Wildcat) ammo and

mid-range priced ammo like the Wolf Match Target along with several other

brands of low to mid priced ammo. He only lightened the trigger pull

on his CZ 452 Trainer and it made

a big difference in his grouping.

Web published update by Bill aka Mickey Porter on 12-29-15.

USPS MANIFESTED THE ACHILLES' HEEL IN THE RIFLE BASIX

TRIGGER

I got an email from Mark Kuczka at Accurate Ordnance, LLC in Winder, GA

on 01-04-16 and the

subject line simply stated, "Ouch".

I opened the attachment and a picture of the wood shipping box they opened with the trigger

now in two (2) separate pieces. Pix below:

I never would have believed a part could get broken in that wood shipping

box but I was totally wrong. Apparently, the box was thrown a good distance

at some point in transport allowing it to stop suddenly and the

kinetic energy generated allowed the entire barrel and receiver

assembly to move

rearward and/or forward inside the box slamming the trigger into the wood cutout wall, whereby breaking the trigger at its weakest area.

There should have been adequate padding on each end and all around the

receiver/barrel assembly to prevent such a mishap but definitely wasn't the case.

Maybe the same Gorilla that applied torque to the rear action screw at the CZ

factory assembly line is also

working part time for the USPS here in the USA.

Murphy's Law

never sleeps; "Anything that can go wrong

will go wrong!"

The next time I ship a barrel/receiver out, it will

be in a four-point

restraint system.......grin if you must!

PLAN "B" FOR THE TRIGGER REPLACEMENT

When I receive the barrel/receiver assembly back

from Accurate Ordnance, LLC after threading for the suppressor, I will

probably install the original CZ trigger and lighten the spring tension by

either replacing the spring with a weaker one and/or cut a couple coils off

the original trigger spring. The Rifle Basix trigger has very little

material on the sides of the trigger where the hole is drilled and tapped

for the weight adjustment set-screw and definitely is this trigger's

Achilles' heel

as evidenced by the picture above.

I called our local Post Office and will file a claim in the morning for

the cost of a replacement trigger.

My Savage Mark II BTVLSS might have a

voodoo doll that looks like my CZ 452

American and sticking pins in it to keep me from using the new

rifle......grin if you must!

Web published update by Bill aka Mickey Porter on 01-04-16.

USPS CLAIM FILED FOR DAMAGED TRIGGER

NOTE: Filed the claim online since the

USPS no longer uses

the older hand written PS Form 1000 per our local Post Master of which I

believe he didn't want to get involved with the paper work which is fine by

me since a few clicks of the mouse and uploading a couple supporting

documents is all that it took. The USPS website has provisions to mail

you a form if you do not have access to on-line filling which sounds like an

oxymoron! If you can access their website, you most certainly can file

the claim on line. Only in America! 01-05-16.

I checked online on 01-26-16 and noticed the USPS denied my claim on

01-21-16 and awaiting a letter for their reason for the denial. The

USPS has over a 100 billion dollar debt

of which 87 billion in unfunded liabilities for postal retiree health and

pension benefits and other deferred payments overdue. I can see why

they don't want to reimburse me $ 91.00 dollars for the damaged

part.....again, Only in America! The internet and email has

drastically cut into their revenue from the sale of stamps, etc. and they

might end up like the

Pony Express in due time.

Web published update by Bill aka Mickey Porter on 01-06-16 and 01-26-16.

DENIAL LETTER RECEIVED FROM USPS ON 01-27-16

I received a letter on 01-27-16 from the USPS Domestic Claims Accounting

Services which stated, "Based on our investigation, your claim has been

denied because the parcel contained prohibited items. The US Postal

Service prohibits mailing of certain types of items including, but not

limited to, alcoholic beverages, certain firearms, and hazardous substances.

Pistols, revolvers, and other firearms capable of being concealed on a

person can only be mailed between authorized dealers as stated in 18 USC

1715. The responsibility for mailability rests with the mailer, not

the US Postal Service.

If you wish to appeal this decision, send a copy of this letter and a

written appeal focusing on the basis of the claim denial within 30 days from

the date of this letter".....

I submitted an appeal on line and uploaded the following pix:

I attempted to explain that this item does not fit the criteria of 18 USC

1715 and is not a pistol, revolver or other firearm capable of being

concealed on a person and the above receiver and barrel length is 27.75

inches in length. Also, an individual is allowed to ship a rifle

or shotgun to a registered firearms dealer per their own

mailability rules section 432.3g.

Hopefully, they will understand that this is a rifle without a bolt and

stock and could only be used as a club.....another grin is in order!

Web published update by Bill aka Mickey Porter on 01-27-16.

RECEIVED CHECK FROM USPS ON 02-17-16

The US Postal Service finally approved my claim for the broken Rifle

Basix trigger and I received a check in the mail on 02-17-16 and I

definitely will not purchase another Rifle Basix trigger for sure. I

never did hear anything back from Rifle Basix as to their poor quality

trigger and that is some lousy customer service for sure! All their

fancy advertising is just hype and reminds me of the dung left behind by a

bull in a pasture.

BOLT DISASSEMBLY AND OBSERVATIONS

With some down time on my hands waiting on the barrel to get threaded, I

disassembled the bolt. There are many videos on YouTube showing you

how to take the bolt down which is very simple.

I was a little surprised at all the tooling marks on the firing pin aka

striker and decided

to do a semi-polish on the high spots using 600 wet and dry automotive

paper. It looked like someone with a coarse mill

bastard file fabricated the firing pin by hand......grin if you must! Below a couple pixs of the bolt parts:

Below is a close up of the firing pin aka striker showing the tooling marks:

The above pix of the firing pin after using the 600 grit paper....it

would take a lot of work to polish this firing pin out and there might be

too much slop (clearance) when you got through with it. I read one thread where

the writer said it would smooth out after shooting it but I am guessing it

would take a few million rounds to do that.....grin if you must!

Above firing pin aka striker after I polished it with a small buffing

wheel with red rouge using the Dremel tool. I only wanted to polish

the high spots and not to attempt to remove the deeper tooling marks to

prevent unwanted slop (clearance) between the firing pin and the bolt housing. I

have a large

buffer/wheels and various grades of buffing compound for wood

working projects but didn't want to drag it out and set it up.

Other than the tooling mark issue which apparently isn't a big deal since

my friends rifle has about the same tooling marks on his CZ 452 Trainer and

his shoots great. This is a very well made bolt and the firing pin doesn't

travel that far anyway. The exterior of the bolt is machined and

polished pretty good. It is imperative that you

do not change the

angle or alter the shape of the sear engagement area on the sear and the

trigger to sear engagement not depicted in the above pix.

I only lightly polished that area.

Web published updates by Bill aka Mickey Porter on 01-08-16.

RECEIVED BARREL/RECEIVER ASSEMBLY FROM ACCURATE

ORDNANCE 01-19-16

I received the barrel/receiver assembly back from Accurate Ordnance today

and got a chance to check out the broken Rifle Basix trigger to ascertain

why it broke so easily inside of the wooden shipping box. I super

glued the Rifle Basix trigger back together in order to get a few

measurements with the Brown & Sharp caliper and it was easy to understand

why the trigger broke at its

Achilles' heel area. The

trigger width was .250 with a .200 whole drilled in it to contain the lower

portion of the trigger spring and the hole was drilled way off center.

One side measured around .013 to .015 and the other thicker side measured

.035 inches. As the ole cliché, "A

picture is worth a thousand words", see below:

If this is state of the art CNC machining, I will stick with the old way

of doing machine work. I know I can freehand drill without a drill

fixture more accurate than what was done on this trigger and can certainly

do much better on the drill press. I sent an email to

sales@riflebasix.com about

their trigger weakness but have not heard anything back from them and

emailed them this latest close-up pix which speaks for itself. I

did not

ask Rifle Basix for a refund, since I filed a claim with our Snail Mail

System aka USPS but wanted them to be aware of their

poor quality control as

evidenced by the above pix. Their

service after the sale leaves a

lot to be desired! In my case, there is NO

CUSTOMER SERVICE!

UPDATE: On July 3, 2020, I was

teaching our youngest Grandson Xander McKnight Gonzales to shoot the .22

caliber

rimfire rifle and the next day created a

page for him and happened to open the CZ 452 American page and noticed the

broken Rifle Basix trigger pix and out of the blue sent the pix to the sales

link at Rifle Basix. I wasn't expecting a response, but Jeff of Rifle

Basix replied to my email and wanted my telephone number of which I sent it

to him today 07-06-2020. He called me and I missed his call and he

called back and apologized for not responding way back then. Jeff

offered to replace the trigger, but I didn't want to take the rifle apart

again since it has been shooting very well. Jeff said,

"If there was

any of their products I needed to let him know, which he would send at no

charge." I thanked Jeff and did have a little fun during our

conversation and told Jeff, I thought Rifle Basix was under the Federal

witness protection program and we both got a good grin out of that.

Web page updated by Bill aka Mickey Porter on 07-06-2020.

The trigger is made using

Metal Injection Molding technology (MIM)

by the granular look of the metal composition and also the thin horizontal

line visible on the part indicative of some type of mold used in the casting

process. This trigger is definitely not CNC machined from a solid

billet of steel in my humble opinion and any CNC machining is on the upper

portion of the trigger where it attaches to the receiver/sear! I definitely will not use

another Rifle Basix trigger for this CZ rifle. There is nothing wrong

with MIM parts, since the majority of small parts on many firearms are using

MIM parts along with other product manufacturers to reduce manufacturing

costs.

Accurate Ordnance removed the sear from the receiver and it was a dawg to

get the ball bearing on top of the spring and everything aligned to install

the pin that secured it in place. After a few tries, everything came

together and glad I had the shipping box underneath the receiver to catch

the small ball bearing when I didn't get everything aligned just

right.....grin if you must!

INSTALLED ORIGINAL CZ TRIGGER WITH A DIFFERENT SPRING

I reinstalled the original CZ factory

trigger and replaced the spring with a weaker one from

YoDave

Products (second lightest one) with the trigger breaking

at around 12 ounces to one pound and passed my bump test. You have a

couple options if you just want to change the spring and not the trigger.

You can use a Williams ACE Hardware

# 144 spring or a

Fastenal Product compression spring # 161A

which will give you between 10 to 13 ounce trigger pull or their 162A

compression spring which is a little heaver. My shooting buddy Robert

Webster of Hamlet, NC did the Intel on the Fastenal springs and he is

currently using the # 162 spring in his CZ Trainer. He used the # 162C

which is 1.75 inches in length and cut it to one inch length since the vendor did not have the 162A in

stock which is the same spring but is one inch in length.

I got the barrel/receiver

back onto the stock and replaced the action screws with new ones from

DIP

that has a # 20 torx head on them. I installed a set of

BKL-263-MD medium

height double strap scope rings and mounted a Bushnell 6 x 18 x 50mm Banner

model scope which has the heavy duplex cross hairs for hunting but will give

it a workout on the target at 52 yards. There was enough clearance

between the barrel and the objective diameter to allow usage of the scope

cover.

I will post a pix of the rifle tomorrow with the suppressor installed and

if the wind is not too brisk, will start test firing some subsonic rounds.

Web published update by Bill aka Mickey Porter on 01-19-16

RIFLE READY FOR TEST FIRING

I shot the CZ some this morning but the wind was too brisk and variable

and only getting some trigger time in. I would not want to disrespect

the rifle by posting those groups fired, however I did get a good 5

shot group cluster at 52 yards when the wind was in a brief static state....grin if you must! My

front

rest is far to wide for the narrow forend stock and unable to

pull the side "ears" in close enough and will have to improvise

something to take up the slack as I was getting right to left forend movement.

The front rest is fine for the

wider forend of the Savage Mark II BTVLSS.

I ordered a

Protektor # 1 small owl ear front bag for

my

Sinclair heavy varmint BR windage LH front

rest that fits a

regular width (narrow) hunting rifle which should be the ticket. The

stock sling studs were removed which are not needed at this time.

I am looking forward to shooting this rifle when the climate conditions

are much better whereas I can get a more reliable accuracy test. This

is a far superior made rifle than my

Savage Mark

II BTVLSS and if it shoots better right out of the box, that will

definitely be an extra bonus.

My goal for this rifle is to make head shots

on squirrels at 50 yards; one shot one kill and hopefully, be able to get

some decent 5 shot cluster groups a little more regular than what the Savage

Mark II BTVLSS delivers.

Web published update by Bill aka Mickey Porter on 01-20-16 and 01-26-16.

MODIFIED SINCLAIR REST TO SECURE THE PROTEKTOR FRONT BAG

I received the Protektor # 1 small owl ear front bag and removed the

existing Edgewood sand bag that was secured to the windage top with two

horizontal bars and 4 8-32 screws. I had to drill and tap two holes for the 8-32

screws that was on the Sinclair windage plate since two of the holes were

usable. The small owl front bag had four

leather tabs with brass grommets but there wasn't enough room between the

top windage plate and lower plate on the Sinclair windage top to tie it down and it is

now secured with

four 8-32 screws. Below a couple pixs:

The CZ 452 American forend fits the small owl ear sand bag like a glove. I will

obtain some talcum powder to slick the bag up a little.

I fired a few test rounds but it was extremely windy and will do some

serious testing in the future when the weather is more conducive.

Web published update by Bill aka Mickey Porter on 01-27-16.

POABOY ONE PIECE GUN REST

I have my version of the

poaboy one

piece gun rest that is ready for test firing:

Web published update by Bill aka Mickey Porter on 01-28-16, 02-14-16 and

02-19-16.

ADDED SINCLAIR FOREND BENCHREST ADAPTER

I added a Sinclair

forend benchrest adapter to the CZ 452 American and it

works real well. I shot a few groups but the wind is still too

variable to do any serious grouping. Pix below of adapter:

Web published update by Bill aka Mickey Porter on 02-19-16.

UPDATE TO THE BENCHREST ADAPTER

I later removed the Sinclair benchrest adapter and put the Protektor # 1

small Owl bag back on the rest. I couldn't tell any difference as far

as accuracy and the Protektor # 1 small Owl bag is far more versatile than

the Sinclair benchrest adapter set-up and works far better than the Edgewood

sand bag that came with the Sinclair benchrest.

CZ ACCURACY TESTING ON HOLD AT THIS TIME

Due to starting a

woodworking project for our youngest Grandson Xander McKnight

Gonzales I started on 02-19-16, I put the CZ project on hold at this time.

Also, the weather conditions hasn't been great for doing any serious rimfire

shooting.

Hopefully, I will get back in the mood to get some testing done but I

already have seen the CZ is a keeper.

Web published update by Bill aka Mickey Porter on 03-12-16.

TRIGGER GUARD ARRIVED ON 04-23-16

The aftermarket DI Products Steel Trigger guard Item Number 19030 came in

on 04-23-16 and installed it the next day. The trigger guard is very

impressive, not like the factory piece of junk that came on the rifle.

It took four (4) months to get the trigger guard but well worth the long

wait!

The DI Products steel trigger guard is made from a solid billet of steel

and not like the stamped and bent one from the factory which uses two pieces

of stamped steel.

The CZ factory could have done much better on their trigger guard but had

to go and cheapen it up with that stamped piece of metal that came on the

rifle.

Web published update by Bill aka Mickey Porter on 04-25-16.

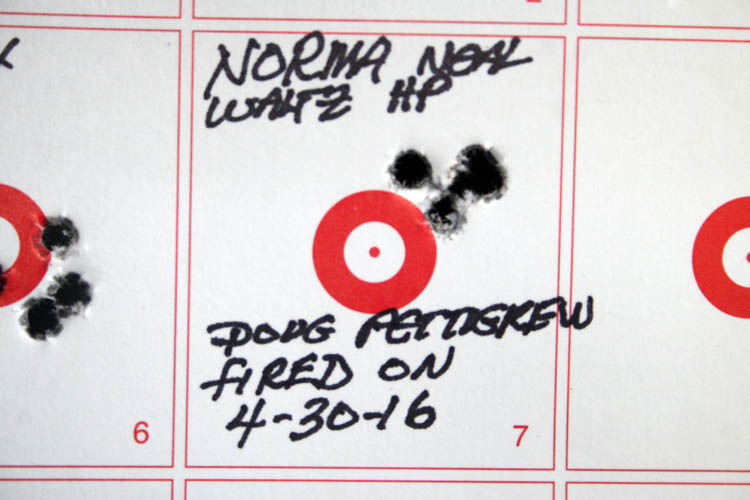

NORMA USA TAC-22 HOLLOW POINTED BULLETS TEST FIRED AT

52 YARDS

The past couple weeks, finally got around to running some Norma USA

Tac-22 bullets through the

Neal Waltz die and my No. 1 Brother-in-Law,

Douglas Pettigrew test fired a few of them this afternoon at 52 yards.

Below is a pix of the target he fired using my left-hand CZ 452 American

rifle and shot a 5-shot group better than I did with my own gun. I

have my shooting benchrest positioned for left hand shooting only and Doug

fired the gun standing up leaning over the rear of the benchrest looking

through the scope...grin if you must.

The NORMA USA TAC-22 rimfire ammo before resizing is: OAL

.969 inches and the bullet driving band diameter is .223 inches in diameter.

After resizing in the Neal Waltz Die: OAL .946

inches with .225 bullet driving band diameter:

I fired several rounds to get the point of aim established shooting

Eley Subsonic Hollow Points bullets which are about 50 feet per second

slower than the Norma USA Tac-22 at around 1100 feet per second. Any of

the above rounds fired so far through the CZ 452 American left-hand is deadly

medicine for Mr. Squirrel at 52 yards. The Norma USA Tac-22 ammo prints high and to

the right of the Eley Subsonic HP bullets which will still harvest a

squirrel. A simple POA (Point of Aim) scope adjustment is all

that is needed.

Web published update by Bill aka Mickey Porter on 04-30-16.

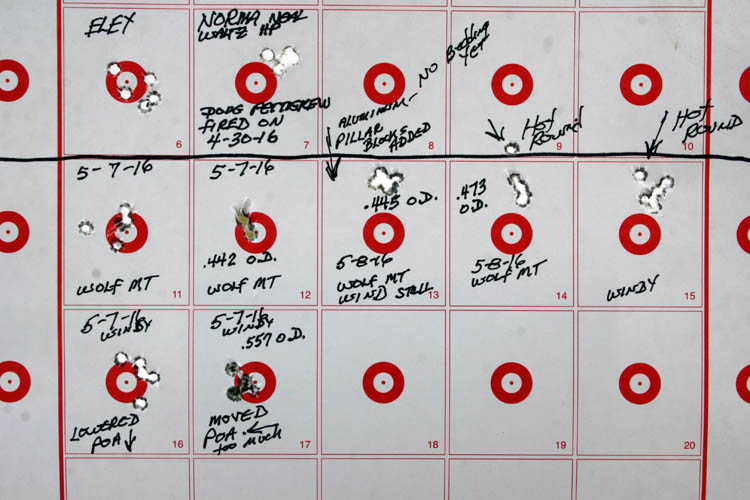

FABRICATED AND INSTALLED PILLAR BLOCKS 05-07-16

With some of my domesticated projects behind me, it was time to get back

on the CZ rifle project of which it was shooting some decent groups early

Saturday morning 05-07-15. However, I decided to install pillar

blocks and had already done internet searching of what others had done to their CZ

rimfire rifles. Most were using thin walled threaded lamp tubing and

other similar tubing so they would not have to enlarge the existing receiver

actions screw holes in the stock. I am sure they work great but I like

something that has more substance to it than the lamp tubing....that is just

my nature as I have been over building stuff my entire life; faulty

DNA I

guess.

I decided to go with the much heavier walled T6 aluminum tubing that was

.500 inches in diameter with a .125 wall thickness which would be just right

for the diameter of the action screws. Commercial pillar blocks are

designed for larger platform rifles and most require a .625 diameter cavity

for them to rest in which is a little more than needed on the CZ in my

humble opinion.

The front action screw on the CZ 452 American has only space between the

stock and receiver and a pillar block would definitely be advantageous for

that one. The rear action lug that is attached to the receiver by

means of a dovetail did not actually touch the wood on my CZ 452 American

and there was a small space between the bottom of the action lug and wood.

The tang or rear portion of the receiver was touching the flat portion of

the stock along with the side radius of the receiver.

Above pix shows the space between the bottom of the receiver and the wood

stock but there is adequate wood real-estate for a heavy pillar block.

Again, plenty of wood real-estate for a pillar block.

SURVEYING THE SCENE

Unless you just enjoy tinkering and messing with things with a good

success ratio on your projects and somewhat mechanically inclined, it is best to leave pillar blocks and glass bedding to the

pros. Those that do this on a regular basis can make it look extremely

simple of which it is not rocket science but it is very easy to mess up

without proper planning and enough tools and supplies to get it done right.

I started off by measuring the length needed for the front and rear

pillar blocks and they were as follows: 1) Front pillar length 1.130

inches,

2) Rear pillar length .808 inches and that depends entirely on the height of your stock which can

vary from stock to stock. I used .005 masking tape at different places

on the stock/receiver fit prior to measuring the length needed for the

pillars. The ideal machinery would be a

lathe and a milling machine but do not own either and used a hack saw, 1

inch belt sander, dial calipers, 6 inch x 48 inch vertical belt sander and

Dremel tool with a cut-off friction wheel to get where I needed to be with

their length and shape. I cut grooves in the perimeter of the pillar

blocks for better glue adhesion. The flat portion removed from each

side of the forward pillar is to give clearance for the sear and the

magazine well housing.

Click on thumbnail pixs for a larger screen view:

STOCK FIXTURE FOR THE DRILL PRESS

I looked at both vises I have to align the stock action screw holes up

with the drill press chuck center and decided to make a simple fixture to

secure the stock while enlarging the two existing action screw holes to 9/16

inches in diameter.

This will allow 1/32 inch all around the pillar block for the epoxy aka mud

to adhere. There are special pilot drill bits just for this specific task but they are

expensive. Some of them will allow you to use a hand drill but I don't

think I am ready to do this job with a hand drill because

Murphy's Law

never sleeps!

I built a very simple fixture to position the stock action screw holes in

line with my drill press chuck. The existing action screw holes were

.363 inches in diameter and used a # J drill bit which is .358 inches in

diameter to center the holes under the drill press. The fixture was

fabricated using a scrap piece of 1 inch thick pine board panel and a couple

5/16 threaded T-nuts, fender washer, 5/16 inch treaded rod and nut. If

I were doing many pillar block installations, I would design a much better

and more versatile fixture for the drill press.

Click on below thumbnail pixs for a larger screen view:

The pixs above shows the fixture in operation. The holes in this

stock was pretty vertical as referenced from the upper portion of the stock

and if not, you would need to adjust your drill press table for vertical

alignment. The stock was secured to the fixture with the usage of the

threaded rod that came up through the cut-out for the magazine well opening

allowing you to reposition the fixture to drill both holes to a 9/16 inch

diameter using a brad point drill bit.

Below pix of the pillar blocks attached to the rifle prior to installing

them using

Devcon 10110. Verify that your bolt can be installed and

removed from the receiver with the pillar blocks in place prior to

installing them into the stock. I didn't do this and it came back to

haunt me after the pillar blocks were installed into the stock; more about

that later on. The pillar blocks were installed in the wood

stock without removing the trigger assembly or the magazine housing, however

they were removed before I glass bedded the receiver.

I cut some pretty hefty grooves in the pillar blocks to aid in the Devon

plastic steel putty aka

mud adhering to them and also scored the inside walls of the holes in the

stock for the same purpose. You can see why the front pillar block is

ground down due to the closeness of the trigger sear block which contains

the ball bearing and sear spring and the magazine well

housing. The sear block will pivot on the front sear pin when the trigger is

pulled.

MIXING THE DEVCON PLASTIC STEEL PUTTY AND PILLAR

INSTALLATION

The Devcon product 10110 requires a ratio of 2.5:1 of the resin to the

harder. I had placed .005 thickness masking tape around the stock where

the receiver will rest to give me that much clearance to make certain the

pillar blocks will be making full contact with the receiver and the trigger

guard aka floor plate versus the stock. I believe all the pixs below were taken after

the pillars were installed and cleaned up.

The installation of the pillar blocks went without a glitch and test

fired the rifle the next day and getting some good one hole 5-shot cluster

groups at 52 yards depending on the luck of the

draw of the ammo and the wind conditions, however the rifle was shooting good one hole clusters before the

pillar blocks were installed but not as tight and as often.

My biorhythms were doing pretty good but after the pillar block

installation and test firing, everything went down hill from then on.

Seems like everything I touched, I either dropped it or knocked it

over....not the best of days to say the least...that is when you need to

take a break, get away from the task at hand and come back at a later time or day!

GLASS BEDDING THE RECEIVER

Prior to glass bedding the receiver, I took the trigger group assembly

and the magazine well from the receiver and used plumber's putty to fill up

any area that might cause an epoxy lock-up between the receiver and the stock.

I used the Dremel tool with a 3/4 inch diameter sanding drum to rough up and

remove some material from the stock where the receiver/barrel makes contact.

I also used a solid carbide cutter to score the stock for additional epoxy

adhesion which no doubt is an overkill on my part but I have seen good epoxy

not adhere to a slick smooth service from my musical instrument making days

and roughing the area up has worked the best for better adhesion. After all the prep work, etc., I mixed up the Devcon 10110 and I believe it

was much thicker than the last time I used it and on the box, the

instructions were to use before 12-09-2018 which is well within that time

frame but the containers had been opened and last used on/or about

01-28-2014 prior to the pillar installation above. I noticed that the white hardener did not mix as smooth as

it should with the resin and did not spread well. I did not spread enough under the

barrel where it tapers down from the receiver which needs support and maybe

to help diminish barrel vibrations and harmonics. A good

shelf-life estimate after the product is opened is at least

one year but

couldn't find anything definitive as to once the product is opened. I

have used Epoxy 330 that was over 30 years old still unopened and it worked

as good as the day when I purchased it. Back then, I purchased glues

in quantity and apparently shelf-life wasn't an issue since the glue was

used up fairly rapidly.

With the rear action lug totally surrounded by the epoxy mud, you can

only remove the action/barrel by pulling on it vertically. Initially,

I had to install a longer action bolt 1/2 x 20tpi and give the bolt a few

good whacks with a small musical

fret hammer using the brass head portion to free

the receiver from the bedding. I was apparently

"brain dead" since I could have inserted a wood dowel

in the receiver and used it to get some additional leverage to remove the

action from the stock. The receiver to wood stock fit like a glove

around the rear action lug with no horizontal or side to side slop.

Several have commented on different rimfire threads that the rear receiver

lug in the dovetail could move around and it is possible depending on how

tight the lug is mounted into the dovetail slot. The bedding around

the lug should solve any potential problem in that area.

I must say that I had the most trouble trying to get the small steel ball

bearing between the spring in the sear to the receiver. I was all

thumbs with my dexterity gone South for sure with the ball bearing going

airborne like a rocket through the air and luckily did not

hit the concrete floor and wander off into obscurity. I am guessing it took

me a good 30 to 45 minutes and I don't have a clue as to how many times I

put the ball bearing in place to have it come out before I could align and drive the

pin through the trigger frame and the sear. I know I didn't have the

barrel/receiver supported in the proper orientation to make it easier. It just wasn't one of

those days but I kept going until I got it right. I saw one set of

instructions from DIProducts using a metal pin to wedge and/or hold the ball

bearing inside the sear but it didn't work for me.

BALL BEARING SUPER GLUE INSTALLATION METHOD

NOTE: My Brother-in-Law purchased a CZ 452 American and I

sent it to Accurate Ordnance, LLC to have them thread the barrel. When

I received the receiver/barrel back, I installed the trigger group and after

several tries of trying to get the sear installed with the same difficulty I

had as above, the idea of using Super Glue to hold the ball bearing in place

against the spring of which I tried it and it worked flawless.

Installed the spring/ball bearing on the first try after my Super Glue

technique. Everything worked as it should with the sear. Many

use a heavy grease between the ball bearing and the last coil of the spring

to help hold it in place. The factory uses this method since grease is

inside the spring at the end adjacent the ball bearing.

The finished job doesn't look too bad, but under the hood, it could use a

make over! In all probability, I will go back at a later date and apply a skim coat of

epoxy to the areas that needs it more or less just for eye appeal. This

definitely was not one of my better jobs, but it is fixable!

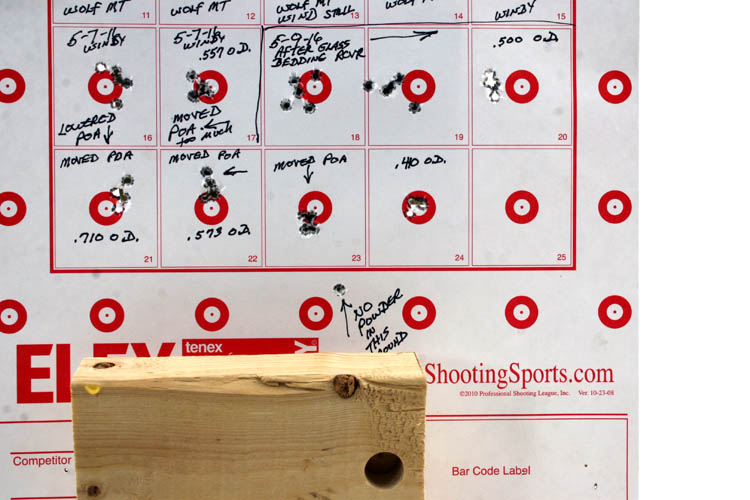

After the clean-up on the stock and action, the wind was fairly calm and

shot about 35 rounds. The first ten (10) rounds were horrible and

thought I had surely messed the rifle up and have to go back and grind the

glass bedding from the stock and start over. After the first ten rounds were fired, the

rifle started holding it's POA and was pleased to see it come around with

the Wolf Match Target ammo. The Wolf MT ammo is good but you will

still get an occasional flyer.

Target # 23 had one round that printed extremely low and the muzzle

report was hardly audible with the suppressor. I moved the point of

aim (POA) up after firing target # 23 and as evidenced by the 5-shot group

fired on target # 24, the CZ 452 left-hand American is coming around.

Web published update by Bill aka Mickey Porter on 05-09-16.

COULD NOT REMOVE THE BOLT FROM THE RECEIVER

I fired a few rounds on the morning of 05-10-16 but the wind was a little

too much, nevertheless, all the rounds fired would easily harvest a squirrel

with a head shot

at 52 yards. This CZ 452 American left-hand is a keeper for sure!

l decided to run a few patches through the bore to remove some powder

residue and noticed I could not remove the bolt from the receiver. I

removed the barrel/receiver from the stock and the bolt could be removed by

depressing the trigger which causes the rear of the sear to move downward

leaving an exit path for the bolt out of the receiver.

CORRECTED THE PROBLEM

I had to regrind the

flat

upper portion of the forward stock pillar block that faces the sear to allow the sear to pivot

downward enough

where the sear inside the bolt would travel downward far enough

to allow the bolt to pass over it and allow the bolt to move to the rear. This probably took at least an

hour of small grinding increments and putting the barrel/receiver back onto the stock and

moving the bolt rearward while depressing the trigger until it would release.

It is best to check the bolt operation with the pillar blocks in place on

the receiver before installing the pillar blocks into the stock.

I test fired at least four rounds at the target outside perimeter bullseye

which are used as a sighter or fowler in a match and 3 of

the 4 were inside the white portion of each individual bullseye shot at which is

around .375 inches in diameter.

Web published update by Bill aka Mickey Porter on 05-10-16 and 06-08-16.

WE WHOOPED 'EM AGAIN JOSEY 11-01-16

The ole CZ has been sitting idle for the most part since the summer

months and time to bring her out again to harvest a few squirrels for a

fried squirrel

and gravy meal.

The past week or two, I have fired some Wolf Match Target rounds through

it and not pleased with the grouping. The Weaver T35 scope was

replaced with a Bushnell Banner 6 x 18 x 50mm scope which is still an

overkill for squirrel hunting but I am prone to do things like that. I tried a few Norma TAC-22, SK

Standard Plus and were getting some hot and weak rounds. With the

suppressor, it is very easy to hear a hot or weak round fired in comparison to a

regular velocity round and printing on the target is the visual aid. I have a chronograph, but didn't want to set

it up which removes any doubt about bullet velocity and helps eliminate some

of the shooter error equation. I like to use the ole saying, "I

couldn't hit a bull in the butt with a base fiddle" to

describe my shooting the past couple weeks as evidenced by the adjacent

targets fired........grin

if you must! I am not sure the Bushnell Banner scope accurately tracks

when going from 6 to 18 power, but it shouldn't be that far off. I

think the wind and bullet variable velocity is the culprit in my humble

opinion.

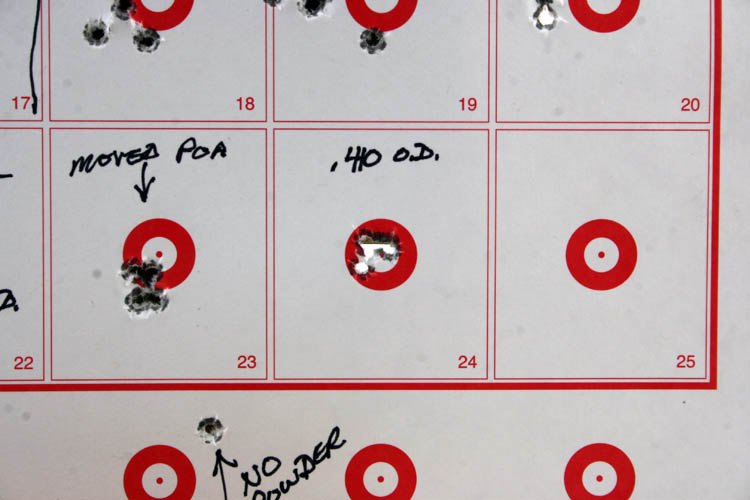

My friend Robert Webster, retired Captain NCDPS from Hamlet, NC came over

today, whereas he shoots right handed and my

shooting bench

is set up for left hand shooting only, because of the way I have it

positioned and anchored since I shoot left handed. My shooting bench

is ambidextrous, but to reiterate, I have it positioned solely for left handed shooting.

Robert can shoot extremely well either handed and after firing several five

shot groups at 52 yards, he said, "It ain't the rifle, get ready to weep."

The wind was fairly calm and I checked Robert's fired groups and he was

right; the gun is shooting fine. He used one of the lines from the

movie, The Outlaw Josey Wales, "We whooped 'em

again Josey" and we both got a good grin going out of that

one. After Robert shot a couple excellent groups, I fired a 5 shot

group that wasn't bad either, but not as tight as Robert's last group fired, of which I

put the calipers on the groups later.

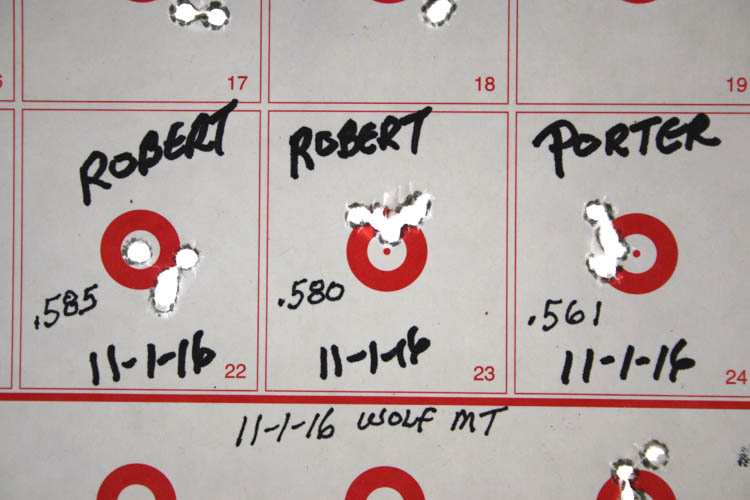

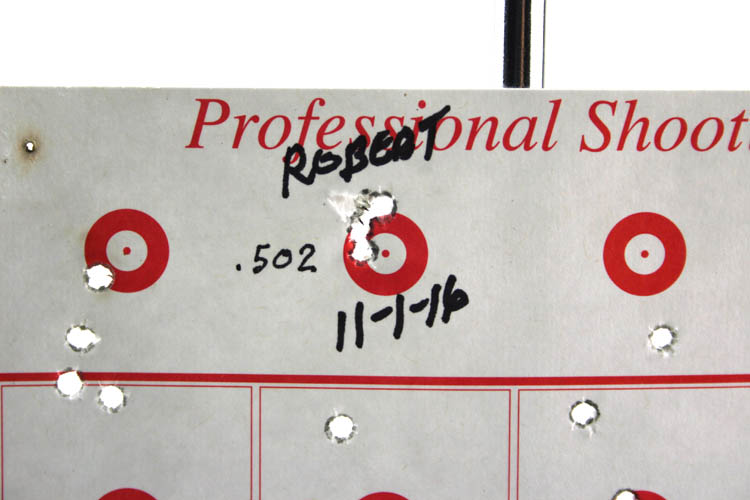

Below pixs of the groups fired outside diameter:

There was just a little wind, but it didn't seem to affect the bullets

much today. I moved the scope 2 clicks up and 2 clicks left after

target # 22 was fired. The Bushnell Banner scope has 1/4 MOA.

Lloyds of London would be in trouble if they issued life insurance

polices on squirrels around here!

Robert said that I need to fix the shooting bench where a right hander

could shoot and I told him, "If I did, I would have to

sell you my gun."

Some of the ammo fired lately, had a few hot and weak rounds in there and we

both say, "With a good gun, ammunition is the key!

My short story titled,

Biorhythms might shed some light on my shooting; got to have an

excuse, right?

Web published update by Bill aka Mickey Porter on 11-01-16.

A PICTURE IS WORTH A THOUSAND WORDS

Above squirrel taken at 50 yards and Yes, the eye was the aiming point!

Web published update by Bill aka Mickey Porter on 11-08-16.

SQUIRRELS VISITING DEER FEEDING AREA 11-09-16

Below a few pixs of a couple unlucky squirrels that ventured into my deer

feeding area while I had the little rimfire rifle close by just for the

squirrels:

Very little meat wasted with these type of heat shots!

Both squirrels taken at 50 yards. The CZ USA 452 American is

definitely some serious medicine for harvesting those bushy tails!

The Wolf Match Target 40 grain bullets modified to a hollow point

using the Neal Waltz

die is awesome.

In summary, I can't say for

sure that the glass bedding and pillow blocks added much if any accuracy to

this rifle, but it definitely did not hurt any either. As stated

earlier, ammunition is the key factor for accuracy with this rifle and most

other rifles as well.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take this

moment to accept him by Faith into your Life, whereby Salvation will be

attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through faith;

and that not of yourselves: [it is] the gift of God: 9 Not of works, lest

any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for, the

evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by the

word of God.”

Open this

link about faith in the King James Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the Lord

Jesus, and shalt believe in thine heart that God hath raised him from the

dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation, King

James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder of

soul and spirit, and of the joints and marrow, and is a discerner of the

thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of God is

eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory of

God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what doth

the LORD require of thee, but to do justly, and to love mercy, and to walk

humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."