SAVAGE MARK II BTVLSS .22 CAL. RIFLE REVIEWThis rimfire rifle is one of the WORST NEW GUNS that I have ever owned as

far as accuracy right out of the box! For those that have purchased

this rifle and it shoots like a dream, you probably have one that should be

sold as "One of a Thousand" like

the ole

Winchester 73 movie starring Jimmy Stewart!

As I have posted many, many times on this website,

"Most of the time, you get what you pay for."

MODIFICATION WARNING DISCLAIMER

The below information in its entirety is for

ENTERTAINMENT PURPOSES ONLY

from a personal liability standpoint and

do not try this at home. Modifications to firearms and

ammunition can cause

serious bodily injury and ultimate death. The below modifications to the

Accu-Trigger will certainly void your Savage product warranty and relieve

Savage of all liabilities in the event of an accidental discharge brought

about by such modification and/or trigger replacement.

Please read the

Legal Stuff

page for additional information concerning liability issues before

going any further.

I have owned my share of .22 caliber rimfire rifles since 1957 when I was eleven

(11) years old and still have an ole Winchester model 67 single shot rifle

that looks like it has been through a hay bailing machine but it still

shoots true.

FIRST BOLT ACTION .22 CALIBER RIMFIRE

My first bolt action repeating .22 caliber rimfire rifle was a Sears

and Roebuck

J.C. Higgins model that I

paid 20 dollars for in the 1960s if memory is correct and had a cheap Revelation

3 power

scope on it which I believe cost $4.00 dollars....grin if you must. I

truly believe that was the most accurate repeating rifle that I have owned to

date. That rifle was manufactured for Sears and Roebuck by Springfield

Armory and the manufacturing process was on the money that day for sure.

That rifle would consistently shoot a hole in a hole at 30 yards and it was

no trouble to shoot squirrels through the eyes with that rifle and you certainly

didn't waste any meat in the process with head shots like that. As a

young lad, I traded squirrels, rabbits

and live opossums at a local grocery store and gas

station for ammunition and always kept plenty of ammo on hand to hunt with

and most importantly at that time, shoot, shoot and do some more

shooting.........it was awesome fun to target shoot and just "plink:" with

the rimfire rifles. My Mom and Grandma had a difficult time keeping

clothes pins on the clothes line because we used them for target

practice.............grin if you must!

After returning home from a two year tour of duty over seas

Morocco,

Africa in 1967 while in the US Navy, the little Sears and Roebuck repeating

rifle had accumulated a lot of rust and pits and later traded it off for

another firearm of which I can't remember what type. I replaced it

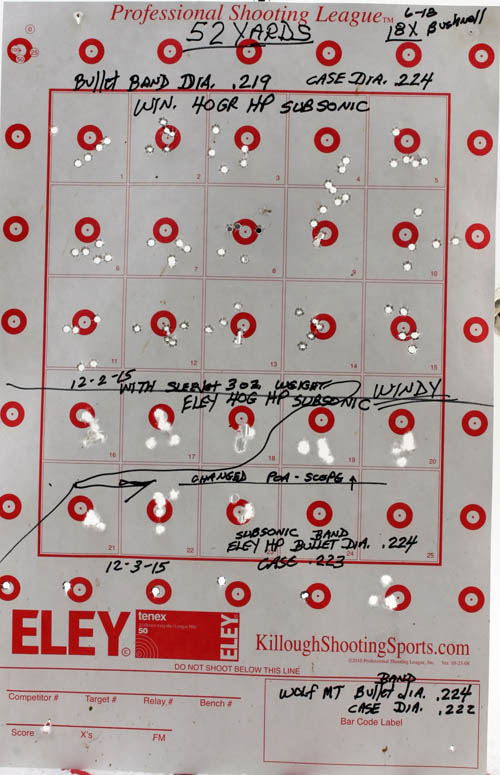

with a couple high dollar Browning semi-autos which were horrible as far as

getting a good group. I traded for a couple of the infamous Marlin 39A

gold trigger level action rifles and those that I shot would not allow you

to shoot a squirrel in the head; the accuracy was that bad even though they

are reported to be super accurate lever action .22 cal. rimfire rifles.

I finally purchased a Remington 541-S and it shot like a dream; a hole in a

hole at 30 yards after I found what ammo it liked; CCI 40 grain Mini

Group LR. However, the Sears bolt action wasn't that finicky about

different types of .22 caliber ammunition and I shot mostly .22 cal. shorts,

Winchester and Remington since most shots at small game were less than 20

yards. I have also owned a couple Remington model Nylon 66 semi-autos

which shot very accurate at less than 20 yards and used one to perform

aerial trick shots with great success.

TRICK SHOOTING

Back in the 1980s, I purchased .22 cal. rimfire ammunition by

the 5000 round case and could duplicate aerial shots the pros were doing

with the Remington Nylon 66 rimfire rifle except draw pictures of which I

never did attempt to do any of it. Most of those shooting target

drawing like the Indian Chief profile with the rimfire rifle was done at

less than 15 feet which just didn't appeal to me.

Above pix from the internet and identical to the one I was shooting back

then.

My friend Stewart Callahan of Polkton, NC who also worked at the Anson

Correctional Facility, whereas, we would ramble around shooting firearms and

one particular day in the mid 1980s, he witnessed me shoot 10 out of 10 hand

thrown aerial targets which were dried out black walnuts. Normally, I

could hit about 7 or 8 out of 10, of which I would shoot the Remington Nylon

model 66 .22 caliber LR left handed and throw the walnuts at about a sixty

(60) degree angle upward with my right hand out a fair distance and then

shoot the walnut as it was descending. I believe it was all about

timing and the Nylon 66 rifle was pointing where I was looking when it was

shouldered.

I traded that Remington Nylon 66 to Ram's Sporting Goods in Rockingham,

NC for a Browning semi-automatic .22 caliber rifle and Stewart Callahan

purchased it from them for 150 bucks and he still has the rifle to my

knowledge.

I have seen shooters who would throw a target overhead (vertical) and

shoot it when it momentarily stopped and then make the shot, however I

learned to shoot what I call intercept being more or less instinctive

shooing. I have shot dimes out of the air, but definitely could not

hit them every time.....grin if you must!

Those days of trick aka fun shooting are long gone as with my

youth and thankful for each and every day that God allows. I give God,

the Praise, Honor and Glory in all things through Jesus Christ our Lord and

Savior!

WINCHESTER MODEL 67

As with most things from the past, our hindsight is 20/20 for sure.

The only rimfire rifle remaining from the past is the Winchester model 67 of

which doesn't have any holes drilled for a scope mount and/or grooves milled

into the receiver section for the same. A good little gun for open

iron sight shooting but with the product of maturity and the date on my

birth certificate, my rifle shooting days with iron sights are long gone and

definitely have to rely on the usage of optics.

The last few years, I got a hankering again to do some .22 caliber rimfire shooting

(going back to my youth days) since the ammunition is fairly cheap but after checking around this year, I found that

the .22 cal. rimfire ammunition was extremely scarce to purchase due to the

consumer

political panic buying brought

about by the current political administrations continued attempt to rid

America of all firearms.

I surmise when you live in a gated community with armed security guards

24/7,

you are not concerned about getting mugged or the threat of experiencing a home

invasion.......

All types of handgun and rifle ammunition is not available

like it once was and the gun shops, etc. are price

gouging the consumer very

badly due to the shortage of rimfire ammunition and all types of handgun and

rifle ammunition although ammunition in .45 ACP and .40 cal. are

beginning to appear on the retailers shelves once again. I ordered a CZ USA

left hand 452 model .22 caliber rimfire rifle but no one could deliver

it in a timely manner and after doing some internet searches, it was found that the Savage Mark

II BTV was a fairly accurate .22 caliber rifle for the price.

SAVAGE MARK II BTVLSS .22 CAL. RIMFIRE RIFLE

I ordered the Savage Mark II BTVLSS in left hand with a stainless bull

barrel and a laminated thumbhole wood stock and was impressed with the

rifle right out of the box as far as looks goes. Their signature accu-trigger was not that

bad either but a little heavier than I remember from shooting the Remington

541-S and had some creep and

grind to it. This Mark II BTVLSS will shoot decent groups at 20 yards

using

CCI .22 cal short CB bullets but it was very hard to get a consistent

group out to 50 yards due to the inconsistency in the loading of the shorts

and these bullets are designed for the gallery and indoor shooting.

My

ultimate goal for this rifle or any other rimfire rifle is to be able to

make clean head shot kills on squirrels out to 50 yards; one shot, one kill!

It should be noted that I am certainly no gunsmith or have

had any gunsmith

training, however I was an armorer for the NC Department of Correction the

last 15 years of my employment but that basically was changing worn out parts replacing with factory

ones and some adjustments would have to be made with various tools, fixtures and

equipment to bring the weapon back to the factory specifications.

I was a Factory Certified Armorer for Smith & Wesson, Ruger and Remington

and an armorer is NO gunsmith!

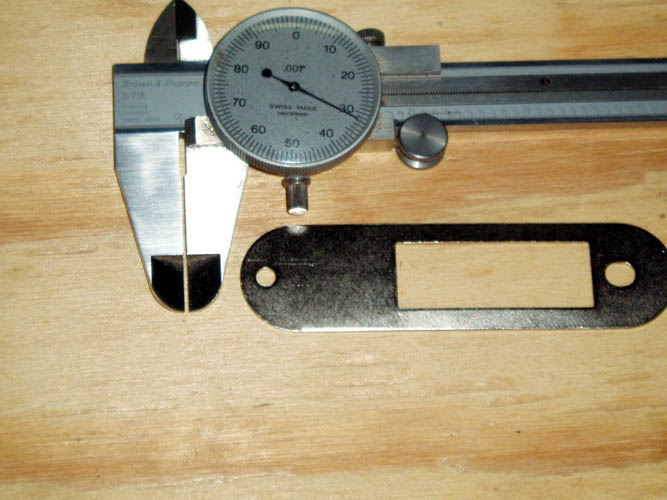

Upon further checking, the magazine retaining

plate aka (floor plate) that

holds the action to the stock with the larger 5/32 inch hex bolt was very thin; .032 inches thick and would

bend easily when you tightened the 5/32 Allen bolt (stock

assembly screw) down on it. The factory

recommends approximately 18 inch pounds but I don't have a torque wrench and

even snug will bend the thin metal plate. That magazine retaining aka floor

plate is a piece of junk. I ordered an aftermarket stainless steel

magazine retaining aka floor plate from

DIProducts,

Inc. that is a full 1/8 inch thick and it definitely doesn't move

at all when you tighten down on the forward stock assembly screw. Pix below

of the rifle before surgery:

Below are a few pictures and didn't do a sequence shoot since this was

impromptu and I get that way many times...another grin is

in order:

As you can see from the pixs above, the floor plate is super thin and it

will bend with very little pressure exerted. Eighteen inch pounds will

definitely distort it badly!

After removing the barrel/action from the stock, I secured the stock in

my

Tipton

Gun Vise while using a small air die grinder with a flat

base and .032 inch diameter solid carbide two fluted router bit which made

quick work of cutting away the extra material to have the .125 inch thick

DI Products, Inc. magazine retaining aka floor plate to seat flush. The stock at the edge of

the floor plate has a slight radius on the outer most edge but didn't want to

go any deeper for a full flush at those edges. Pixs below:

From the above pix, you can see that they left a tab at each mounting

screw/bolt about 1/32 inch above the rest of the stock that was routed for

the floor plate and they could have just as easily routed it full flush....makes one

wonder why they did it that way.

In the pix above, I removed the extra wood on the left side of the floor

plate cavity and later went back and routed the entire cavity to a depth of

.125 inches to match the thickness of the after market stainless magazine

retaining aka floor plate.

The after market magazine retaining aka floor plate routed fairly flush

with the stock and does not give when applying pressure on the forward stock

assembly screw

on the left. The wood screw installed on the right doesn't effect the

action but merely holds the magazine retaining plate in place when the bolt on the left is

removed along with the stock assembly screw on the trigger guard. Savage recommends tightening the left

stock assembly screw to

approximately 18 inch pounds of pressure along with the forward screw on the

trigger guard. As soon as I purchase a

torque screwdriver set,

(Wheeler Firearms Accurizing Torque Wrench), I will

adjust the stock assembly screws to find the sweet spot

for accuracy!

Below pixs of the air die grinder used to remove the excess wood.

You can see the excess router bit protruding beyond the base which does the

stock removal. I could not locate my

MagEyes 2x magnifier and this

route/inlet job was freehand all the way just with my State eye plan glasses

which leaves much to be desired for close work:

Since installing the after market DI Products, Inc. magazine retainer aka

floor plate, the rifle is shooting much more consistent and will post some

actual groups fired when time permits.

I checked the trigger pull with a Lyman Digital gauge and the

average trigger pull was 2 lbs. 5.8 oz

and one went all

the way up to 2 pounds 15.9 oz. and to get a consistent reading you have to

pull parallel with the bore. Before dry firing the rifle, I inserted a

fired shell casing into the chamber to absorb the firing pin impact onto the

brass instead of allowing the shoulder of the firing pin to strike against the barrel,

although with the recessed rim headspace, it might not make contact with the barrel

but it is better to be safe than sorry.

It is imperative that you place the trigger gage on the trigger for a

straight back pull and parallel to the stock, otherwise you will get

inconsistent readings and most will register on the high side and this

carries over into the actual shooting as well. Finger placement is

critical with the accu-trigger since it is very easy to place the

accu-trigger safety blade into a binding position against the slot in the

trigger due to the "slop" in the design. Click on below thumbnails pixs for a larger screen view:

I decided to torque the stock assembly screws to the recommended 18 inch pounds

per manufacturers recommendation, however when I applied more than 10 inch

pounds of torque, I noticed that the receiver bolt had a little

bind in it directly

behind the bolt handle. For such a large diameter barrel, the receiver

appears to be made from a piece of stainless steel pipe or tubing and doubt

it was made from a solid billet of steel. The more I look closely at

this rifle, the cheaper made it looks! The thumbhole laminated stock has a ton of

excess material removed where the entire receiver beds to the stock and the

action bolt lugs that are screwed into the barrel which accept the action

bolts do not contact the stock, only the lower radius portion of the

receiver contacts the inside radius portion of the stock and at the forward portion of the

receiver where the barrel attaches to the receiver and at the rear of the safety

which is probably the reason for the bolt to bind with higher inch pounds of torque applied

on the two action screws that are forward of the trigger guard. It

would make more sense to me to have the stock assembly screws at the forward and rear

portion of the receiver like most of the high powered rifles to evenly

balance out the pressure over the entire length of the receiver itself.

I noticed that the factory had applied just enough torque to the stock

assembly screws to where the thin magazine retaining aka floor plate that held the

forward stock assembly screw did not bend although they recommend 18 inch pounds and if much torque is applied to their factory magazine

retaining plate (forward stock assembly screw), it will certainly bend as I stated earlier. There

just isn't enough material left in the thumbhole laminated stock to install

a forward full bedding pillar but I am sure it can be done and will research

it and

have a qualified gunsmith look into it for me. Both the forward and

rear action lug isn't making contact with the stock at all. When you

are tightening the forward and rear action assembly bolt/screw, you are only

pulling the receiver down into stock.

THIS IS TOTALLY UNACCEPTABLE AND VERY POOR ENGINEERING

AND WORKMANSHIP EVEN FOR A RIMFIRE

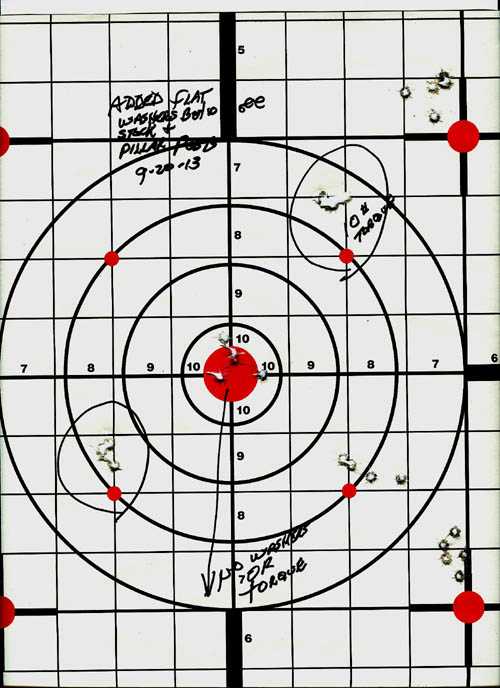

UPDATE: On 09-20-13, I checked the distance between the

forward receiver

action stud that the stock assembly bolt/screw screws into and it was about

.040 inches from making contact with the lower portion of the stock with the

receiver flush against the stock. I found a piece of metal bracket

that was a little over .040 inches in thickness which had an elongated slot

at one end and a regular hole punched in the other end and reground one end

to match the radius of the stock and cut both ends of the bracket off and it

worked nearly perfect in the wood stock taking up the slack or gap between

the receiver action stud and was able to torque it at 10 inch pounds

and the bolt did not bind hardly at all. I had to add about .118

inches of spacers between the rear receiver action stud to take up the gap

between the stud and the stock. My

"rube snorkel" shooting rest I am

using is not the steadiest and fired a few 5 shot round groups to see what

the before and after was and I was impressed even with my poor shooting at

20 yards. Below is a scan of the target:

A couple of the groups had all the bullet holes touching and still

shooting the CCI .22 cal. short CB ammunition which isn't that accurate due

to some of the rounds apparently loaded very weakly and they are not

consistent in velocity just by the sound of the report and also the lag in

bullet travel time to the target which is 370 feet per second or more slower than

the speed of sound. With the sun shinning at the proper angle,

I can actually see the bullet come into my line of sight through the scope and then

see the

drop of the bullet into the target at 50 yards.......710 feet per second is

pretty slow for a bullet!

I continued to ascertain why the bolt wanted to bind slightly and the

distance between the rear action stud and the stock cutout was

more than the front distance and added a lock washer over the thin metal

bracket I used to take up the slack and it worked out great. I applied

about 18 inch pounds of torque to both stock assembly screws and the bolt moved like

silk through the receiver and that solved the problem. A first class bedding job would be more

professional but you can't see the washers between the action studs and the

stock so will leave it as is for the time being. I test fired it again

at 50 yards and three of the 5 rounds fired were touching making one hole

and not bad for the inconsistent ammunition.

Below is initial grouping at 20 yards using CCI .22 cal. short CB

ammunition rated at 710 fps and not too bad since I have not shot many

target rounds in the past few decades. The rifle has

promise for sure but my ole Winchester model 67 single shot will group

better than this with open sights:

So far, I am not satisfied with the performance (shooting wise) of the Savage Mark II

BTVLSS .22 caliber rifle chambered for .22 Long Rifle but it is feeding the

.22 cal. short ammo without much difficulty. Upon slow extraction, I tilt

the rifle to the left to keep the short shell casing from getting lodged

behind the area of the detachable box magazine. However, you can cycle

the action rapidly and it ejects the spent short shell casing without a problem

and a long rifle or long shell casing

will eject fine either slow or fast cycled.

I might install a short bi-pod on the stock in the very near future to

add to the coolness of the rifle.

I did order and receive a bore guide # 175 machined from a solid delrin

rod from

Possum Hollow Products, Inc. which fit the receiver perfectly..........an

awesome first class all American precision manufactured product. Pixs

below:

I have since updated my Kleen-Bore one piece stainless steel coated

cleaning rod to a

Pro-Shot

highly polished one piece stainless steel rod.

When I get a chance to really dial the rifle in, I will post additional

target groups fired. I am sure the rifle will fire the long rifle

ammunition with much greater accuracy but enjoying the low signature report

of the shorts.

Web published by Bill aka Mickey Porter on 09-09-13 with updated pixs

added on 09-20-13.

INGREDIENTS FOR A SQUIRREL STEW

Since our annual squirrel season came in, I have ten (10) or eleven squirrels

ready for a Squirrel Stew.

There were several squirrels consuming my shelled deer corn this afternoon

and had a chance to "nail" a couple of them at about 50 yards.

Web published updated pix by Bill aka Mickey Porter on 11-25-13.

SAVAGE MARK II UPDATE 12-29-13

I ordered Capt. Robert Webster, retired NCDPS a 1/8 inch thick

replacement Bottom metal plate for his Mark II blue bull barrel rifle and we

installed it this afternoon. We also fired a couple 20 yard distance 5-shot groups

using CCI .22 cal. Short CB rounds and both our groups were pretty good.

Robert did an internet search while here and reviewed several ways to drop

the poundage on the Accu-trigger since his trigger pull was registering 3

lbs. 14 oz. although the gun is advertised to go down to 2.5 lbs. of which

his was adjusted at the lowest setting.

Robert shot the smallest 5-shot group on the right which was about 1/4 x 1/2

inch....awesome for shooting off a poor rest. Robert had his rifle

dialed in for the .22 cal. long rifle sub-sonic loads which are inherently

more accurate but I am opting for the much quieter muzzle report at the

moment but will later test fire the different brands of long rifle

ammunition to ascertain which brand will yield the most accurate and

consistent grouping. My rifle is dialed in for the CCI .22 cal. Short

CB rounds with the POA (point of aim) pretty close to centered whereas

Robert's POA is one inch lower with the Long Rifle sub-sonic rounds. I

certainly don't plan to purchase any of the high dollar Eley Tenex, Aquila,

Lapua or

other extremely costly target rounds since I am convinced this rifle will group

accurate enough for my small game plinking and informal target shooting with

the CCI .22 cal. Short CB rounds but I do plan to take it to the next level

when my silencer application gets ATF approval.

Robert and I finally decided not to remove any coils from the main spring on the

trigger since it has a right angle bend on the larger coil spring end that

rests into a hole in the trigger group housing to keep the spring in place and

it would be difficult to cut the spring and then try and bend the tempered spring

back at a 90 degree angle without heating the spring which could ruin the

temper of the spring. We viewed one

video clip that ground off part of the trigger base than contained the

terminal end of the spring which would accomplish the same thing.

While Robert was getting his trigger housing removed and taken down, I stated,

"If it don't work, you ain't messing

with mine".......Robert

looked at me and we both grinned like a possum

eating persimmons and he said

"I was

thinking out loud." The spring's terminal has a much smaller diameter

and is housed in a hole that has screw treads which allows you to move the

compound wound spring up and down to increase or decease the trigger tension

and the removal of additional metal from the top of the trigger support area should not

effect anything else and still give you the capability to increase the

spring tension if necessary.

The only tools needed was a flat base abrasive wheel, a small router

(Dremel), small flat screwdriver, flat Bastard file and Allen wrench set of which I had the

items. Once the trigger assembly was removed from the receiver, the trigger

was removed from the trigger group housing by removing an E clip and pushing

the retaining pin out. The trigger was secured

in a flat drill press vise and clamped to my table saw metal table for

additional support. Click on below thumbnail pixs for a larger screen

view:

The height of the trigger area that supported the lower portion of the

spring before grinding on Roberts trigger was .303 inches and reduced to .228 after

grinding (about two coils strength reduction) yielding a 2 lb. 3 oz. trigger pull and very smooth. Robert

ground my trigger down and he sounded like a Dentist

on Steroids and had sparks flying everywhere since he

bolstered his confidence level after grinding the first one down. We both got a

good grin off that for sure. Each of us fired a 5-shot group afterwards but the

wind was blowing pretty fast and we didn't shoot as tight a group due to the

wind.

We are very pleased with the reduction in the trigger poundage on both

our rifles and with

the right combination of ammunition and a much steadier professional type

bench rest both front and rear, I am expecting some decent groups at 50 yards.

A RIFLE THAT COULD BE MUCH BETTER

With the price of the Savage rifles, Savage could do a much better fit

between the action and the stock since programmable CNC routers do all the work

capable of hitting their programmable mark within a few thousands of an inch and also

replace the Elcheapo bottom plate which is a piece of junk. I would be

shooting the CZ USA Model 452 .22 cal. rifle but no one could supply one in a

left hand model in a timely manner although they are advertised for sale but on back

order. However, accuracy reports place both rifles about the same but

the CZ USA doesn't have the stock and trigger issues above or not reported

anyway. Those that

have "tricked out" their Mark II

have very positive things to say about them as far as accuracy goes. I

have looked at the possibility of putting pillar blocks in the stock but the

main problem is with the forward action lug, the stock is hogged out

to where there is barely enough wood and the only real contact was between

the outside of the receiver and the forward portion that is away from the

hogged out area which has already compressed several thousands of an inch.

Placing a pillar block at the trigger guard would not be that much of a

problem since there is enough wood but you would not want to use a standard

1/2 inch diameter pillar block either and more or less around 3/8 inch

diameter which would still allow you to make metal to metal contact from the

receiver. I am researching what others have done to the BTV stock as

far as bedding and pillar blocks with mixed opinions at the moment.

I am somewhat pleased with the Savage Mark II BTVLSS and believe it is

going to make a serious squirrel gun once I get myself dialed in to the rifle with

the right amount of "perfect practice makes

perfect." I know what you are thinking, Practice

makes Perfect but if you practice something wrong, you will be proficient at

doing something wrong, therefore "Perfect

Practice Makes Perfect."

Web published update on 12-29-13 by Bill aka Mickey Porter.

STILL TINKERING WITH THE ACCU-TRIGGER 12-30-13

Being retired, I do have the opportunity to do fun things more often and

decided to take the trigger pull down a little further on the Savage Mark II.

Pretty much the same thing as described above but used the flat Bastard file

instead of the Dremel tool and stone. Below a few pixs to document the

event:

I was pleased with the results getting the trigger pull to average

1 lb. 11.8 oz. and it really felt light

but still had a little grind and creep and will test fire it this afternoon. I checked the safety

mechanism and also tried to disengage the sear by hitting/jarring the rifle

stock pretty good with the safety in the off position and the sear would not

release and that is definitely what I wanted to know.

As evidenced by the above picture, I filed the rear trigger portion down

that houses the trigger main tension spring to a little over .2035 inches

from the .228 that it was ground down to yesterday. The original

factory height of the rear trigger portion was .303 inches with around .100

inches removed. I plan to leave the trigger as is and concentrate on

improving my shooting technique. Below the best 5-shot group fired at

20 yards with the action bolts aka stock assembly screws at 18 inch lbs. of torque. I was throwing

rounds all over the place this afternoon and passing some blame on the

ammunition....grin if you must! Below group .435 outside

to outside (.213 center to center) and will harvest small game but I plan to do much better with a

more stable front and rear rest/bag. The below group is what I desire

at 50 yards but it is going to be tough to do with this rifle for sure:

Many years of not doing any target shooting and plinking, other than

firing a few rounds each year to harvest venison for the freezer and an

occasional squirrel or rabbit harvested with the little Winchester model 67

open sights, time and age appears to have taken it's toll which might

not be a valid excuse. I am certainly having fun trying to get where I

can shoot much better without spending a ton of money on a special race gun

just for plinking with a rimfire rifle again.

As good as the Savage Mark II BTVLSS is, my ole Remington 541-S and the

1960s Sears & Roebuck made by Springfield (which I no longer own either) would definitely

out group this

rimfire rifle. However, it just might be the shooter in this case

having consumed too many barrels of leaded coffee aka Ole Joe, Java, etc. over the

decades and on the NC

State Eye Plan Glasses and not the rifle........grin

if you must!

Web published update on 12-30-13 by Bill aka Mickey Porter.

I shot a few of the CCI .22 cal. Short CB rounds 01-04-14 at 20 yards and

no steady rest yet, however I moved the scope power down to 9X and that took

some of my perceivable movement

and shake out...............way too much leaded coffee today.

I have a

Sinclair Heavy Varmint AP Windage Rest Left-Hand # 749-013-852WS and a

Protektor B. B. Leather 55AC Rabbit Ear Loaf Rear Bag on order and this

should improve my shooting since the rifle is moving and not steady with the

Rube Goldberg homemade stuff I am currently using. I have viewed

several permanent and portable

shooting bench rest tables and plan to construct a

heavy duty one and hopefully remove as many of the variables, whereby

concentrating on improving my shooting. Both items are on

back order and hope they will be delivered before too much longer.

Check my portable

shooting bench out that I built and waiting on the weather to dry out

and apply a coat of oil stain on it.

My goal is to be able to make consistently clean head shots on squirrels

out to 50 yards (if necessary) and don't think it will be a problem since I have nailed

quite a few of them already at that distance but not with every shot and blame

the ammo and mostly the shooter's current skill level but I guarantee you, it

will get much, much better.

If the rifle will not do that, it will make someone a good boat anchor

for sure and will have to spend some serious upgrade bucks but I have not given up

yet on this project and "The Jury Is Still Out." I

have vented verbally and physically before with products that did not meet

my expectations that the factory didn't correct after phone calls and

emails. Below is pix of an 800 dollar PSE Mach6 bow that was their

"flagship" bow in the mid 1990s and I solved the problem, even though

unorthodox and to the extreme:

Read my short story titled

Murphy's Law.

I believe the above action voided the warranty on that

bow!

Web published update on 01-11-14 by Bill aka Mickey Porter.

REAR PILLAR BLOCK INSTALLATION 01-23-14

After surfing the web and looking at what others have done to their

Savage Mark II BTVLSS and other Savage similar model .22 caliber rimfire rifles, I

decided to go with just pillar block bedding the rear action lug to start with.

The problems I noted on others that have pillar bedded their Savage Mark II rifles, the

front pillar block installation has not held and there just isn't enough

room in the stock to surround the pillar 360 degrees, only about 270 degrees

at the most which is not good. The Savage stock that I have is

probably one of the worst that I have seen as far as having receiver

to wood stock contact.......the stock is just hogged out far too much.

It looks like their

CNC router got a mutant virus or

hired a starved beaver who went crazy chewing up the wood stock blank not knowing when to stop

gulping down and slinging wood chips.

As noted in this short story, I had already placed .118 thousands of inch

spacers between the rear receiver barrel stud that terminates the action screw

aka stock assembly screw so

there would be contact between the receiver stud and the stock which worked

ok but wanted to fix something permanent that would not allow the wood to do

any serious compression. The front receiver action lug required around

.040 thousands of an inch to make contact with what wood there was between

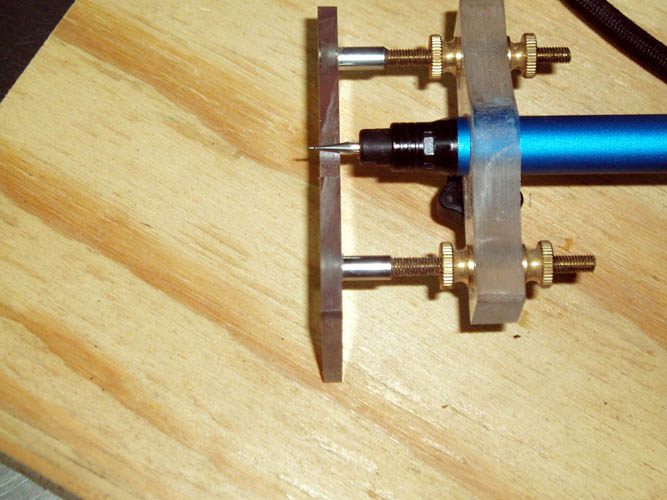

the stock and the magazine aka floor plate. I found an old Waverly routing guide for a

Dremel tool that had not been used since the year 2000 and decided to

recycle it since it had two posts that were .375 inches in diameter and

drilled and tapped for a 1/4 x 20 bolt and the head was plenty long enough

to grind down to the exact length required to fill the above space between

the rear receiver action stud and stock. The action screws are .212 in

diameter and

1.25 inches in length and will fit through the 1/4 x 20 tpi inside

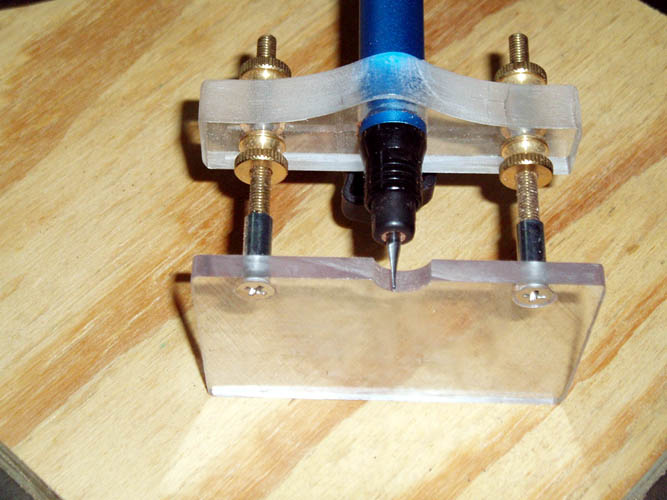

diameter of the brass bushing with some clearance. Pix below of the router jig

cannibalized.

NOTE: This is not the actual Dremel router

jig I cannibalized but one from Stew Mac's website since I didn't take a pix

of mine before the cannibalization.

Pix below of the Stewart MacDonald router jig for the standard Dremel

tool from their on-line catalog:

Below pix of my Stew Mac router jig after cannibalization. The base portion

was in my Dremel accessory case:

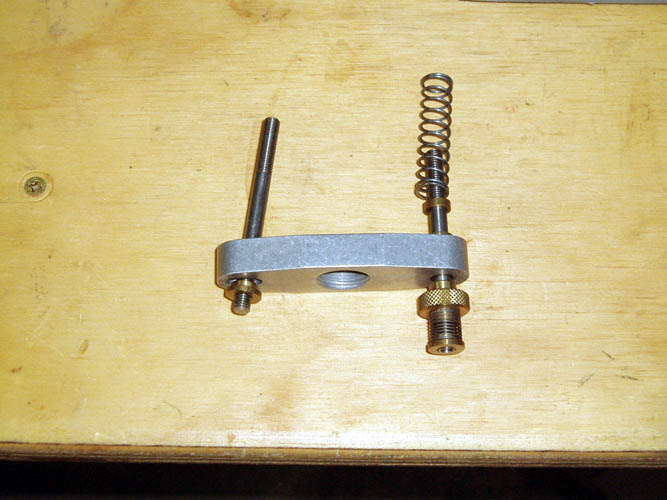

Robert Webster and I bedded his rear action screw and the space between

his stock and receiver rear stud was .215 thousands of an inch and used an

additional flat stainless steel spacer which we probably didn't need,

although it would help disperse the tension created. Pix below of his

spacer and brass bushing aka pillar block. Since there will be metal

to metal contact between the receiver rear action stud, the brass bushing

aka pillar block and the metal trigger guard, the brass will hold up fine.

Don't believe any exotic metals needed here! Pix below of Robert

Webster's Mark II BTV stock with the spacer and brass pillar block

installed:

Robert and his Savage Mark II BTV were the guinea pigs on the pillow

block bedding and didn't take any sequence pixs. That afternoon, I decided to

go ahead and pillar block my rifle and took the time to take some sequence

pixs. The first order of business was removing the barrel/action and trigger

guard. I used a .250 diameter drill bit to align the stock with the

chuck and then drilled out the rear action screw hole to .375 inches in

diameter. The head of the brass bushing was ground down to .120

thousands of an inch plus or minus and then placed into the stock and scribed around

the back side of the bushing flush with the stock that was recessed for the trigger guard.

I cut the bushing to length and then ground score lines around the outside

perimeter of the bushing to help the epoxy adhere a little better. The receiver and

barrel was placed back onto the stock for a trial fit and everything looked

good. I waxed the rear action screw and the trigger guard that will make

contact with the bottom of the brass bushing aka "pillar block" to prevent a

lock-up. Epoxy aka JB Weld was placed on the bushing and placed back into

the stock and cleaned any excess epoxy from the trigger guard area and

reinstalled the trigger guard and both action screws applying 18 inch pounds

of torque to them. It probably would have been better to secure the

barrel/receiver to the stock after tightening the action screws just enough

to have everything aligned and use only rubber bands to hold in place until

the JB Weld cured out. This procedure would prevent any torque to the

receiver to the pillar blocks. Click on sequence thumbnail pixs below for a larger

screen view:

After the J B Weld epoxy sets up overnight, will check and see how it groups but the weather

has been very windy, cold, blusterous and not conducive to do any serious shooting but

will fire a few rounds anyway in the afternoon. Nope, changed my mind!

Robert Webster and I plan to epoxy aka glass bed the forward portion of the

receiver and about an inch or so of the barrel since that basically is the

only part of the receiver action that is making any serious contact with the

wood stock and the stock portion that is making contact with the receiver

is minimal. The forward receiver action stud with the wood hogged out

underneath and around the stock assembly action screw hole is the weak link and the bedding should

reinforce and stabilize this weak area. There is a few thousands of an inch depression in the wood stock

from the front portion of the receiver when we received those rifles since

there was a gap between the forward action lug and rear receiver action lug and the

receiver was pulled down hard into the stock and bending the thin

magazine aka floor plate which we corrected that. Only a small amount

at the rear tang side wall of the receiver makes contact with the stock any I think it might be free

floating a few thousands of an inch or two since we added the spacers,

whereas the side of the receiver makes minimum contact with the wood stock.

As the ole saying goes, "The proof is in the taste of the pudding" and in

this case, the shot group will be the taste test!

NOTE: It would have been much easier and more precision if I

had a metal turning lathe of which I haven't owned one in years and also a

milling machine, therefore had to use what basic machinery and tools at

hand. Standard adjustable pillar blocks available at Brownells and

other suppliers are .500 inches in diameter and a little large in my opinion

for this project since there isn't much wood on the Mark II BTV stocks,

especially for the forward stock assembly screw.

I ordered Devcon Plastic Steel Putty # 10110 to do the receiver bedding and

it should be here within a few business days.

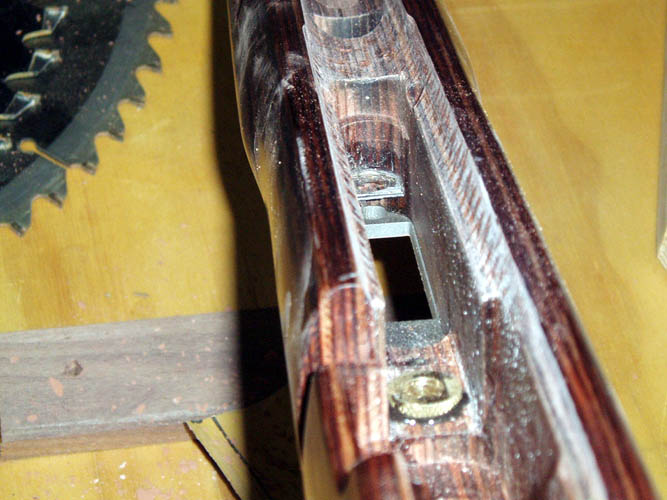

PREP WORK PRIOR TO BEDDING THE RECEIVER 01-24-14

In the meantime, I went ahead and prepped the rifle for the receiver

bedding job. I roughed up the areas of the stock that makes contact

with the receiver with the Dremel tool and checked that I have adequate

clearance between the barrel and the stock. Below a few pixs taken:

As evidenced by the above pix, the receiver makes very little contact

with the wood stock, only the perimeter of the receiver; nothing like the

receiver of a Remington 700, etc.

You can see the depression/indentation in the wood stock in the above pix of the most

forward part of the receiver that makes contact on the lower portion of the

receiver. The wood stock even though laminated is very soft and easily

compressed.

I removed a small amount of wood from the sides of the stock that makes

contact with the receiver to help the Devcon "mud" adhere better.

I smoothed up the upper edge with a round wooden dowel and 100 grit

sandpaper. In the close-up pix below, you

can also see the forward action screw (stock assembly screw) area

below the washer that is totally void of wood to

give 100 percent support for the receiver action stud. This is about

as bad as it gets. There is simply not enough room to properly install a

forward pillar block surrounded with 100 percent wood contact, maybe 50

percent

contact only! There might be 3/16 inch forward ledge that

supports the lug with the area to the right nothing but space! I will

install a hollow spacer to fit between the fabricated metal washer that sits

on what wood there is to support the receiver action lug prior to bedding

the receiver.

The video clips and threads that I have viewed showing adding a pillar

block to this rifle for the forward action screw has failed because there is

not enough wood to totally contain and surround the standard 1/2 inch

diameter pillar block.

WHERE'S THE WOOD?

I get extremely irritated every time I see

how much excess wood was removed from this stock. The only reason I can

think of Savage using such a stock design is because of the magazine wells forward slant design

needing the extra room but that is no

excuse. It would

have been better to have a straight magazine well

with complete wood

contacting the forward receiver lug allowing for a standard pillar block

installation. For this reason only, I definitely would not purchase such

a piece of junk if I had to do it over again! Looks pretty on the

outside but a different animal when you open the paper bag. I realize

this is a 400 dollar plus rifle, but I certainly did expect more bang for

the buck than this poorly and ill fitted stock.

The little Dremel tool is on its last leg of usage with the ball bearings

beginning to cry out...Help Me, Help Me........only been used off an on

since the late 1960s and have repaired it a couple times. I think the

new ones have sleeve bronze bushings instead of sealed ball bearings.

Below pixs of getting a hollow filler spacer put in place below the front

receiver action lug.........as I have stated many times already, there just

isn't enough room to put a regular size pillar block for the forward action

screw and this should work filling the gap between the wood and the magazine

aka floor plate. I continued to cannibalize parts from the router base

and drilled out a thumbscrew that was within a few thousands of being the

perfect thickness. I drilled a hole larger than the action screw for

clearance and it is smaller than the hole in the magazine plate. I cut

the brass spacer in half using the Dremel tool with a friction cut-off wheel.

I used a drill bit and wrapped with a couple turns of Teflon tape for a

tight fit and inserted it through the hole in the magazine plate through the

existing hole the factory drilled through the wood stock and the steel

custom washer I had installed earlier to make contact between the receiver

front action lug to the wood stock. I then mixed up some JB weld epoxy

and filled the gap and inserted the half brass bushing since that was all

that would fit in the hogged out factory cut wood stock. After the

epoxy cures overnight, I will hopefully be able to remove the drill bit

inserted.....grin if you must!

Click on the below thumbnail sequence pixs for a larger screen view:

NOTE: Some of the thumbnail pixs were deleted and not

recoverable.

Below are pixs of the barrel and action both top and bottom view and you

can see there isn't much of the lower portion of the receiver that actually

makes contact with the wood stock, only the lower outside portion only and a

small amount of forward section where the barrel joins the receiver.

After the JB Weld cured overnight, I placed the barrel/action back onto

the stock and tightened the stock assembly screws to 18 inch pounds and I

had clearance between the entire receiver and barrel, of which I have

adequate room for the Devcon Plastic Steel Putty to fill in the area between

the receiver/stock and also about an inch or more of the barrel at the

receiver end for additional support and stabilization.

Like I have said many, many times on this website, "Most of the time,

you get what you pay for." Should have spent a few thousand

bucks and got a real .22 caliber rimfire tack driving rifle, but then again,

I would not have had so much fun messing with this rifle...............grin if you

must!

Web published updates on 01-23-14 and 01-24-14 by Bill aka Mickey Porter.

RECEIVER BEDDING 01-28-14

I received the

Devcon Plastic Steel Putty # 10110 yesterday and decided

to bed the receiver this morning since the weather prophets are calling for

ice and snow this afternoon with a winter advisory warning until 9AM

tomorrow and a good day to stay inside where it is warm and dry. I started by cleaning the wood stock again with Naphtha and

a Q-Tip and let it dry; very minimal amount of Naphtha. The metal parts that make contact with the

stock was waxed with a coat of Kiwi Neutral Shoe Polish and then buffed it

down some with a paper towel. Plumber's Putty was applied around the

areas that could possibly cause a lock up and it took several times of

trimming excess putty off so the action would make contact with the wood

stock and not have any Plumber's Putty contacting the wood stock that will

have the bedding compound applied. I then cleaned the wood stock again

and let it dry a few minutes and applied another light coat of Kiwi shoe

polish to the barrel/ receiver. The Naphtha dries very fast and in the

meantime, mixed up a small amount of the Devcon Plastic Steel Putty using a

2.5/1 ratio of the putty to hardener. I mixed the steel putty thoroughly and applied

it sparingly to the stock areas making contact with the barrel/receiver and most of the bedding material

was underneath the

front portion of the receiver lug area and a good one inch of the barrel. As

evidenced by the pixs taken below, there is very little metal to wood

contact with this stock.

I placed the barrel/action carefully back onto the stock and everything

aligned very well and pressed the action in place of which the Devcon

bedding material oozed out and then torque the action screws to 18 inch pounds pressure

and excess bedding material was observed all around the action which is desired. There

was good free floating barrel clearance and cleaned the excess bedding

material that had oozed out between the receiver and stock. There

should be stress free bedding between the action and stock. Some will

allow the bedding material to get partially hardened depending on the cure time

before they start removing the excess bedding material. I used

many Q-Tips and a light application of Hoppe's # 9 solvent to the tip of the

Q-Tips which worked

exceptionally well. Having worked with epoxy for many years with

musical instruments, you have to clean the excess up quickly depending on

the specific application.

The

acid test

will be tomorrow when I "remove" the barrel/receiver from the

stock and hopefully there will be no mechanical lock-up. My friend Robert Webster

who is the next candidate to bed his Savage Mark II rifle, said that we could always use a

hammer and chisel if necessary to remove the barrel/receiver from the wood

stock and we both got a good grin off that statement for sure.

We also laughed out loud since I was the

guinea pig this time on the receiver

bedding.

NOTE: Thumbnail pixs were deleted and not recoverable!

I drilled a one inch diameter hole in a scrap piece of 2 x 4; clamped in

a vise and inserted the rifle barrel to allow the Devcon Plastic Steel Putty

to cure out

with the rifle inverted in case the putty decided to gravitate of which I

don't think so due to the consistency of it. The pot life is about 45

minutes at 75 degrees F. and fully cures in 24 hours.

As soon as the weather is agreeable, I plan to test fire some subsonic

LR ammunition and see how the rifle groups at 50 yards and will post the

results in the near future. I don't have any of the

"good stuff" ammunition yet, but will test what brands

of ammo I do have.

Web published update on 01-28-14 by Bill aka Mickey Porter

RECEIVER BEDDING CONTINUED 01-29-14

I was a little antsy with anticipation waiting for the Devcon Plastic

Steel Putty to fully

cure and sometime mid-morning I loosened the stock assembly screws aka

action screws and had a little difficulty in getting the barrel/receiver

from the stock. There was a small mechanical lock-up where the barrel

adjoins the receiver but persuaded it to break free. Everything looked

good and the Devcon putty set up solid as steel..........no pun intended..........grin if

you must!

It took a good amount of time to fully remove the Plumber's Putty from

the receiver and dressed up a few rough edges on the lower part of the

inside of the stock with a rasp. I plan to reseal the inside of the

stock with sealer to help prevent any moisture absorption. There is a

glove fit between the stock and action and the Devon liquid steel putty

didn't show any evidence of shrinkage that I could visually see.

NOTE: Thumbnail pixs were deleted and not recoverable!

When the weather breaks, I plan to do some test firing and will post the

results here. I am well pleased with the outcome of this bedding job

which was my first but have done much musical instrument inlaying of mother

of pearl, etc. many decades ago so did have a little similar experience

although this was a whole new ball game for sure. I certainly wouldn't feel bad

paying a top notch gunsmith to bed an action for me considering what could

easily turn into a very bad experience if not done properly.

NOTE: On 01-30-14, I removed the Plumber's Putty from the

hole drilled in the stock that is located about 1 inch forward of the

receiver that had the Devcon "mud" applied..........don't have any clue why

the hole is drilled there other than stock weight reduction. I cleaned

and roughed up the area inside the hole with a small router bit in the

Dremel tool and filled the cavity with J B Weld epoxy and let it cure out.

NOTE: 03-25-14 I got the ole Dremel tool out and ground the

portion of the Devcon Steel bedding that is about 1.25 inches ahead of the

receiver bedding area to full float the barrel. Below is a pix of the

barrel full floated. I test fired it on 04-01-14 and it did group

better, however I had a problem with loose base mounts to the receiver but

full floating is the way to go. Prior shooting data with the scope

base mounts compromised earlier will be more reliable in future test firing.

In the above pix, you can see the Devcon Plastic Steel Putty between the

barrel/action and stock which is what I was after.

Next on the list will be to watch my friend Robert Webster bed his Savage

and see him "sweat" and "squirm" a little.

Robert came over this afternoon around 4ish and we started bedding his

Savage Mark II. It was fun to rib him about taking a good shooting

rifle and the possibility of messing it up turning it into a boat anchor..........we both grinned out loud.

NOTE: Thumbnail pixs deleted and not recoverable!

It didn't take too long to have the rifle ready for the Devcon "mud" and

after a clean-up, the rifle was placed in the holder in the vise to cure out

until tomorrow afternoon. I told Robert that was when the fun begins

and hopefully want have to beat the receiver loose from the stock with his

proverbial "hammer and chisel", payback is sweet!

Also mentioned the usage of a oxy/acetylene

torch to add to his own personal anxiety..............I know that was

bad!

Robert was not able to come over today and I went ahead and removed the

barrel/receiver from the bedding which did take a little effort and cleaned

everything up and it is ready to test fire.

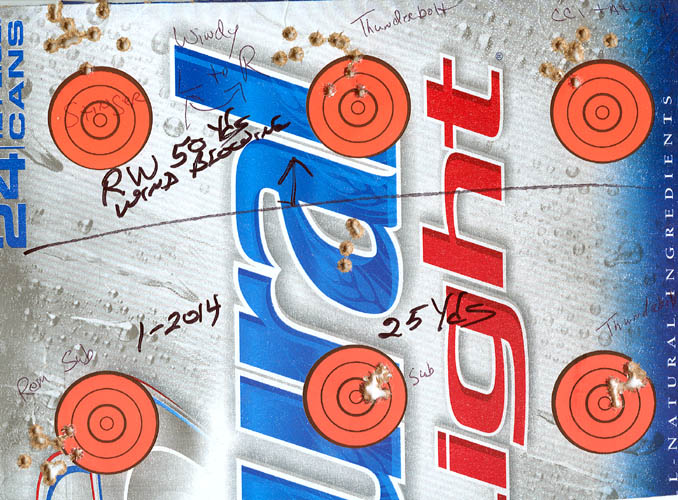

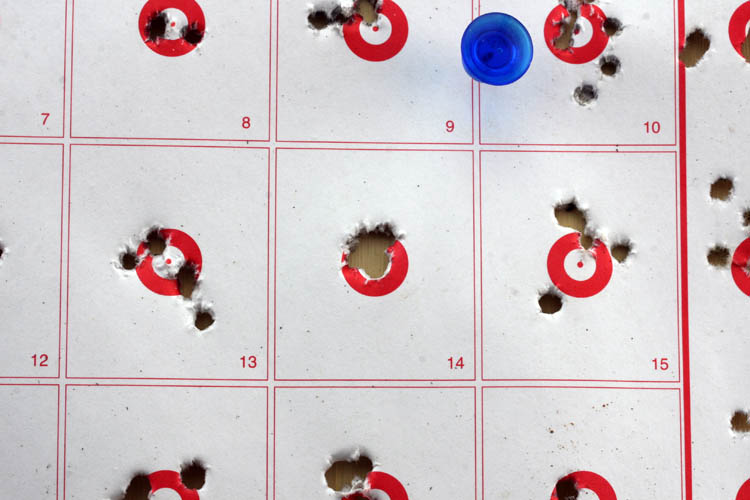

Robert saved a few informal targets that he fired last week at 50 yards

in very windy conditions and will run this one through the pace and see if

it shoots any better after the bedding. Pixs below of target fired at

50 yards before the receiver

bedding in very windy conditions with a east to west wind with the 50 yard

groups also to the left of point of aim. The bullseye diameter

below is 1.375 inches:

CZ 452 TRAINER SHOOTING RINGS AROUND THE SAVAGE MARK II

One of our friends Don Edwards aka Big Daddy Don purchased a CZ USA model

452 Trainer today and they both fired it off a Lead Sled rest at 48 yards

and the CZ 452 out grouped Robert's Savage Mark II BTV right out of the box

with nothing done to it. We both agreed that Big Daddy Don is one

lucky dude and still has his former boss Rick Jackson in his back pocket.

Don's nickname at work was Teflon Don because nothing would stick to him!

I plan to test fire my Savage BTVLSS on 02-01-14 if the conditions are

right and hopefully will shoot a decent group at 50 yards or at least one

good enough to make consistent head shots on squirrels at that distance.

GROUPS FIRED AFTER PILLAR BLOCKED & BEDDING

NOTE: On 01-31-14, Robert Webster sent me a pix from his

cell phone of a couple 5-shot groups he fired at 48 yards from his Savage Mark II BTV

using CCI Standard Velocity 40 grain ammunition. Looks like the receiver bedding

worked out very well in this rifle. I do believe he will be able to make head shots on

squirrels at 50 yards without a problem with plenty of room to spare.

He said there was a little wind but not too much. There is a big

different between the before and after pillar blocks and receiver bedding

and the group tightened up tremendously. You can cover those groups up

with a dime and I asked Robert why he used a penny instead and he said the

penny photographed better than the dime. Pix below:

PS I have noticed that on Robert's target backers, he is

using empty Bud Natural Light Beer cardboard cases which seems like a lot of

beer being consumed there. Robert said he got the empty boxes from the

VFW and places a brick in the bottom of them to keep the target backer in

place and put the bullseye stickers on them. I expect I had the same

look on my face when I told the Lady at the ABC store I was purchasing using

some good Bourbon to make home made

Vanilla Extract. That's my story and

I am sticking to it. Grin if you must!. Recycling

is the word of the day!

Well, it looks like the pressure is on yours truly now to see if my

Savage Mark II BTVLSS will hang in there with them after the pillar block

and receiver bedding job. I got the missing

parts in this afternoon for my

Sinclair rest and will shoot a few 5

shot groups tomorrow and see if the pillar block and receiver bedding did

the rifle any good. The jury is still out on this one.

Web published updates on 01-31-14 by Bill aka Mickey Porter

PORTER'S MARK II BTVLSS FIRED AT 50 YARDS

02-01-14

Got a chance to shoot a few rounds through the rifle this morning and not

the best of conditions.........had a little wind and it was below freezing.

Well, the jury finally came in with the verdict for this rifle and I believe

it is a keeper. Below target fired using CCI Standard Velocity

ammunition with a 40 grain solid lead nose bullet:

NOTE: Thumbnail pixs deleted and not recoverable!

The bottom group is around .600 inches outside diameter and had some

wiggle on the bench rest but not bad. I later found that I had not

tightened down on the fine vertical adjustment knob enough. This rifle is definitely capable of

making a head shot on

a squirrel at 50 yards if I do my part of which was my main goal and plan for this rifle.

When the weather conditions are more agreeable, I plan to test fire half a

dozen or more different brands of ammo to ascertain which one the rifle prefers

and hopefully my shooting skills will improve also.

MODIFICATION TO THE ACCU-TRIGGER

One last modification after doing the above test firing was

removing the accu-trigger blade and spring from the

trigger group assembly which made the trigger much more crisp. I checked that the safety was still

working fine and put the safety in the fire position and hit the side of the

stock hard to see if it would jar loose the sear/trigger engagement and it did

not. The best mechanical safety device when a live round is loaded is

to have the bolt

out-of-battery, meaning lift the bolt

upwards and the weapon will not fire even with the safety in the off

position, of course I do utilize the mechanical safety at all times until

ready to fire and keep the weapon's muzzle pointed in a safe

direction at all times!

The accu-trigger blade protrudes about 3/16 inch forward of the trigger

and when I touch the "blade" to engage the trigger, I start the trigger squeezing process which

makes for a long trigger pull. If you don't engage the trigger

properly with trigger finger

pad centered between the first joint to the tip of your finger and pull the trigger back

in a straight line motion, there is a good amount of resistance felt by the

side to side friction of the "safety blade" against the slotted trigger that has a slot cut

into it for the blade to travel. Some shooters employ the usage of the

tip of the finger only but it takes more effort and will result in a

straight line rear trigger movement; it works for some and some it doesn't I have never owned a rifle

with this type of trigger and personally don't favor it although it is an

extra safety feature allowing you to adjust the trigger poundage safely down far

below what most manufacturers recommended trigger pull which is pretty heavy

for liability reasons which is understandable.

My early 1980s Remington Model 700 chambered for .270 Winchester

came with a stock Timney adjustable trigger and will safely go down to about 38

ozs. Anything less than that, the sear will release from the

trigger upon closing the bolt very hard which is a very dangerous situation.

When I first began testing out different hand loads to find the best

grouping, I took the trigger adjustment down below 38 ozs. and it was a

shocker when I closed the bolt on a live round and it went Boom!

I checked the trigger pull poundage on the BTVLSS and it averaged out to 1 lb.

7.7 ozs. which is about where I want it for hunting. I am

looking at a

Basix Sav-Rat trigger replacement at the

moment but will keep test firing this rifle before doing anything else to

it. With some practice, I am certain I can make one ragged hole

grouping at 50 yards with this rifle which is now a

KEEPER!

TRIGGER ASSEMBLY HOUSING EXCESSIVE CLEARANCE

Robert Webster was the brain storm on removing the "blade" from the

accu-trigger and I had not noticed as much side to side play but there was a

good .030 to .040 clearance between the trigger assembly housing and the

width of the trigger. Removing the accu-trigger blade portion did not

create this problem but it was more evident with the blade removed from the

trigger. After surveying the scene it was obvious that the trigger

housing was fabricated from flat steel and bent into shape. The base

of the trigger housing is secured to the receiver with two 1/4 x 20 tpi bolt/lugs and the

sides of the trigger assembly housing are held in position with three pins

that have E clips. As already stated, there was at least .030 inches

of "gap" between the width of the trigger and the trigger assembly housing and you

could pinch or squeeze in on the trigger housing and see how much slack or gap

was present.

I used a feeler gauge to ascertain what thickness washer was needed and

placed a .030 thickness washer underneath the E clip that held the trigger

in place within the housing. Click on below thumbnail pixs of the

trigger assembly with the washer in place that removed the trigger side to

side movement:

The flat washer worked like a charm and no need to place it inside the

trigger housing which might create additional friction increasing the

trigger pull. There is still a few thousands of an inch clearance

between the trigger and the trigger housing assembly which is necessary to

prevent any increased friction. A couple .015 inch thickness Teflon spaces could be used

inside the trigger assembly housing to reduce any possible trigger/housing friction but don't think it is necessary. I

checked the trigger pull poundage and it dropped down to 1 lb. 4.8 ozs.,

a reduction of 2.9 ozs. with the accu-trigger "blade" removed and the slack

out of the trigger housing. The trigger is very crisp with no

perceivable felt creep or grinding at all.

PUTTING THE PROVERBIAL CART BEFORE THE HORSE

As mentioned earlier on this page, I have an

ATF form 4 pending approval

since August, 2013 to own a suppressor for this rifle and decided to ship the barrel to Accurate Ordnance, LLC

in Winder, GA on 02-07-14 to machine 1/2 x 28 threads on the barrel

and also purchase a custom stainless steel barrel thread protector. This is not the first or

probably the last time that I have put the

proverbial cart before the horse

and guess that is just part of my DNA makeup. Below pix of an overkill

on the shipping box I made from scrap lumber:

If the USPS damages the barrel/receiver that is also bubble wrapped in

this shipping box, there has to be some humongous rough handling going on.

To be on the safe side, I purchased 300 bucks worth of extra insurance which

should cover the cost of a new barrel/receiver if bent in case you do

not want

to shoot around and from behind a tree or something..........grin if you

must! I have observed how personnel load luggage onto a plane and it is

down right scary to watch them actually throw the luggage and packages and a miracle anything arrives without damage and

I am sure there is no finesse either with other carriers with such tight

production schedules! Updated on 02-08-14

THREADED BARREL AND BARREL THREAD PROTECTOR RECEIVED

02-26-14

I received my receiver/barrel back today from Accurate Ordnance, LLC and

Jason Nixon did a First Class All American job threading the barrel to 1/2 x 28 tpi

and the custom stainless steel knurled thread protector. I put the

trigger group assembly back onto the receiver and the receiver/barrel slipped

right into

the bedded stock like a glove with no problem. I got a chance to fire

a quick 5 shot group of CCI .22 cal short CB rounds at 20 yards before dark without a solid rear rest and

four of the five shots made one ragged hole and the other one was a little

high, whereas the muzzle report was much louder indicating a hot round.

A few pixs taken:

The barrel outside diameter was large enough (.801) that the original crown

remained intact with plenty of room to spare. I like the way Jason

angled/flared (chamfer) the forward portion of the thread protector and extended it out

further from the muzzle crown for additional protection. Now to

continue the long wait for the suppressor which I hope is within a couple

months away.

I highly recommend the services of Accurate Ordnance, LLC in Wintre,

Georgia.

NOTE: The hyperlink to Accurate Ordnance, LLC was removed,

due to the website no longer active or their contact links and/or telephone

number.

Quoted from Marks Facebook page January 2, 2020: "We

want to sincerely thank everyone who has supported and encouraged us the

last few (9+) years. We greatly appreciate you. Unfortunately,

we have decided to close the shop. I am dealing with a parent in

Hospice care and my attention needs to be elsewhere at the moment.

Jason is retaining the CNC lathe and tooling with intentions of setting up a

new shop. We'll make sure the word gets out there when that happens.

We're contacting the few remaining customers with projects to make

arrangements to make sure they are satisfied. So, if you are one of

those customers, please be patient and I promise we'll reach out to you.

We appreciate everyone's understanding and wish you and your families a

happy and blessed New Year.

Mark Kuczka"

Web page updated by Bill aka Mickey Porter on 07-07-2020.

When the weather breaks, I plan to spend several days on the range test

firing different brands of .22 cal. long rifle ammunition to ascertain what this

rifle likes to digest the best. In the lower priced ammo, CCI Standard Velocity

does very well. As I stated earlier, my goal for this rifle was to

have an excellent squirrel gun capable of making clean head shots out to 50

yards and this rifle will easily do that. I don't expect it to perform

like a well tuned multi-thousand dollar competitive benchrest rifle in the

10.5 pound class with 1/4 minute of angle or less accuracy with the fore end

resting on a grand plus front rest, but I do plan to

squeeze all the accuracy from this rifle that I can...............grin if

you must!

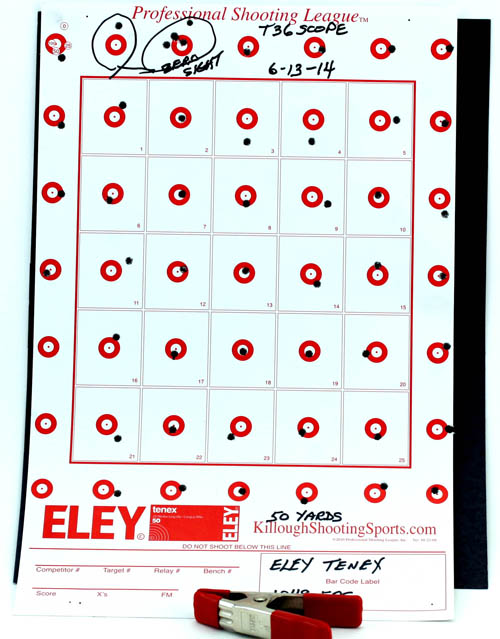

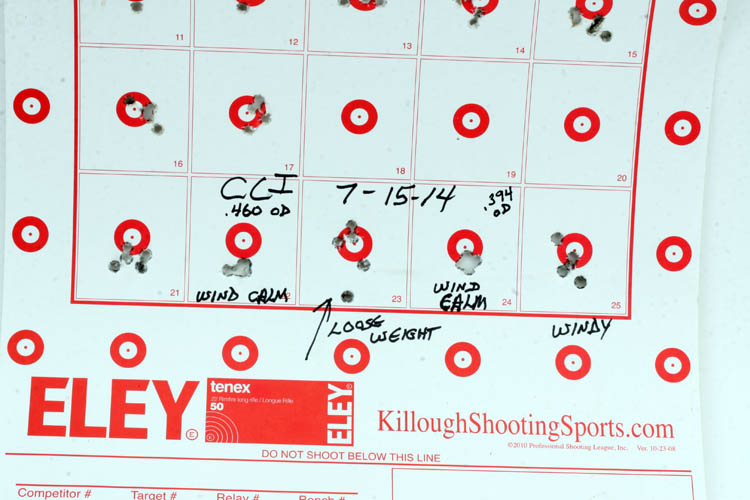

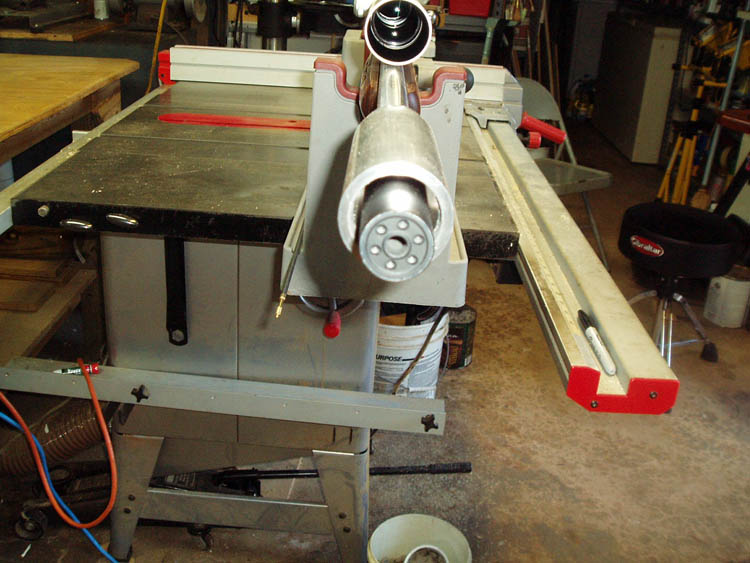

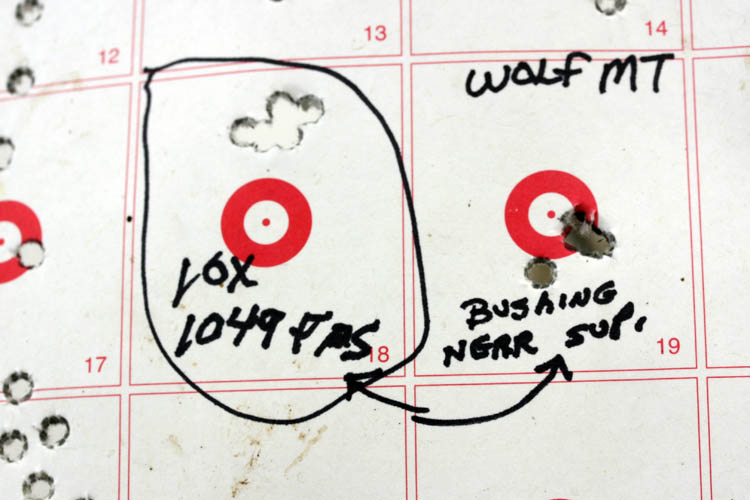

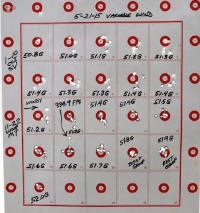

RANGE TIME 03-01-14

The weather finally gave way from the cold, rain, sleet and snow for a

while and got a chance to load my gear and head down to Cason's Oldfield and fired some practice rounds. It was still windy with

a cross wind of about 5 to 15 miles per hour and gusting at times but

managed to get some trigger time in nevertheless. Below a few pixs of

my set-up:

Fifty (50) yards does look a far piece but the Weaver T36 scope

brings the 7/8 inch outside diameter bullseye right up into your face for a much better

view!

The home made

portable shooting bench is very stable in combination with

the Sinclair front rest and the Protector rear bag. The wind was just

too much to get reliable test results for the different brands of ammunition

but the higher velocity ammunition did a little better than the standard

velocity which might not be the normal. I fired several groups last

month using the CCI Standard Velocity ammo and got decent groups but not so

today..........all brands of ammo except Eley Match grade did horrible and

the Eley was not that great either and hopefully will get out there very

soon when the wind calms down. The month of March is usually one of

our windiest months in this neck of North Carolina with the ole saying, "March

comes

in like a roaring Lion and goes out like a Lamb."

Using a Weaver T36 scope and target distance of 50 yards with the smaller

bulls eye outside

diameter 15/16 inch. I also switched to a Bushnell Banner 6-18X and

shot some of the targets as I was getting a good amount of heat mirage

during the mid day. Click on below target thumbnail scans for a

larger screen view:

There is no question the

Eley Match ammunition is superior to anything I fired

today. "Most of the time, you get what you pay for."

I plan to test fire Standard Plus, Norma USA TAC-22 and Eley Tenex in the near

future.

I got an excellent 5 shot group on 02-01-14 using CCI Standard Velocity

ammo, however the wind was very calm. The Eley Match grade ammunition

definitely did better today and the wind didn't affect it as bad as the

other brands of ammo. I did notice that some of the ammo that I

applied the home made lube consisting of beeswax, Crisco and Ballistol, the

groups were a little tighter. I plan to shoot in the near future when the wind is very

calm and try several other brands of subsonic ammunition for comparison.

Any of the cheaper ammunition tested above would take a squirrel's head

out at 50 yards when zeroed for that brand of ammo and that is my goal.

Many shooters on a budget will sort the cheaper bulk ammunition by rim

thickness and also by weight in hopes of getting rid of the occasional

flyer. Web published update on 03-01-14.

Eley ammunition still groups the best although the windy conditions is

not a true test of the accuracy potential of each brand of ammunition fired

in this rifle.

Hopefully, I will get a good windless day and get more reliable consistent

results.

The Norma USA TAC-22 ammunition grouped fairly well as did the Standard Plus considering the gusting

wind. I fired a couple good groups of Federal Auto Match Grade ammo

when the wind was calm and plan to check the rim thickness of different bulk

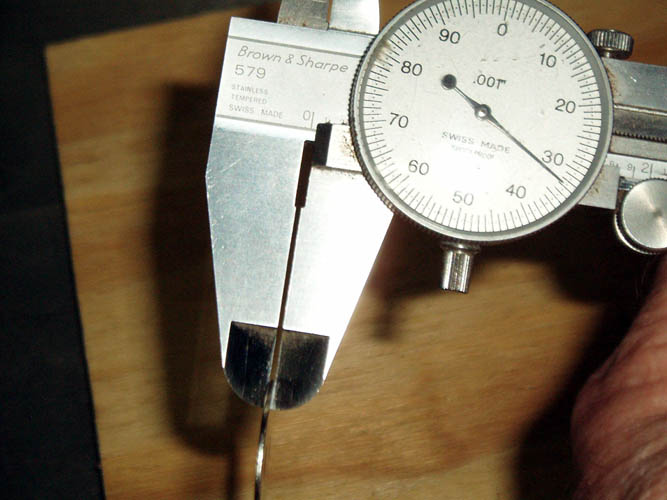

brands of ammunition I have on hand as soon as my dial indicator comes in. I already had a rim

thickness tool to help make it a little easier. Also, the home made

beeswax/tallow lube

shows some promise already and plan to add additional beeswax to the home

made lube

since the beeswax/tallow mixture softened up when the temperature got up around 70

degrees. I used about a 1/3 ratio of the beeswax to tallow and will

increase the beeswax to 50 percent and see how it works out.

I was hoping for better accuracy results with the cheaper ammunition but

so far this gun doesn't shoot the bulk ammunition that well. A tack

driver this rifle certainly is not, but a good squirrel gun

out to fifty (50) yards which was my original goal.

HOME MADE BULLET LUBE

It appears that the better grades of target ammunition has a generous

amount of lube (greasy to the touch) and Eley is reported to use a

combination of pure beeswax and

tallow

of which their formula and application process is naturally a trade

secret! I have already tried beeswax and Crisco

shortening and there is some improvement on bullet accuracy but as most have

said, "You can't take a bad bullet and make a good bullet, but you can take

a good bullet and make it better" with lubrication. I purchased five

plus pounds of beef scraps/trimmings to render the tallow which is nothing

but the fat.

Lard is the same thing but it is from Mr.

PIG. I didn't do any sequence pixs since the only thing you do is cut

the meat up into small chunks and place in a large pot on low/medium head

and stir it around every 15 minutes or so until all the grease (tallow) is

rendered which takes about two hours. I strained the cooked meat trimmings

and grease through several layers

of cheese cloth over a colander into another pot after it had cooled a few

minutes. The tallow came out amber color while still liquefied and

when it cooled down it was an ivory color. The tallow will keep

refrigerated for at least a year. Five plus pounds of beef fat

trimmings rendered about a pint of pure tallow which will lube a sizeable

amount of rimfire ammunition. I plan to start out with

a 50/50 mixture of beeswax and tallow and melt it to the smoking point

before dipping the bullet tip into the hot home made bullet lube allowing

the excess to run off. Both products have a fairly low flash point,

therefore extreme caution must be used and not allow the mixture to get too

hot. Pix of the rendered tallow and brick of beeswax:

Web published update on 03-04-14

REDNECK STOCK FOREND BENCHREST ADAPTER

With some time on my hands, I decided to make a three (3) inch wide x 7.5

inch length flat stock forend benchrest adapter

mimicking a standard flat benchrest rifle stock, whereas the Savage

thumbhole stock is about 2 inches in width at the sling stud with a radius on the bottom

and the width increases a good 3/16 inch as well. The Savage stock already had two

forward stock studs for a sling swivel and bi-pod and used the two 3/16 inch

diameter holes without having to drill any extra holes into the stock.

My antique worn out

rasps and surform tools got a good workout on this little

project, however I removed the bulk of the material with a 3/4 inch diameter

two fluted flat bottom carbide tipped router bit installed in a 3 1/4 HP

Porter-Cable router mounted to a Bulldog router table. For the most

part, this project was old school with no special jigs or duplicating

devices which would have been great! I varied the depth

of the router cut and staggered each successive cut and

got the convex curvature in the ball park before using the rough toothed rasp and Stanley Surform to blend

the concave curvature/radius. The adapter added about .875 inches

overall thickness increase to the existing stock. I didn't take any

sequence pixs and below a few thumbnails of the project getting its first

coat of

Formby's Tung Oil finish and pixs installed

on the rifle stock:

NOTE: Thumbnail pixs deleted and not recoverable!

I need to find a piece of cushion rubber type gasket material to place between

the stock and this stock forend adapter since I didn't get a perfect one to

one fit between the two parts but it doesn't look too

Reneckish.........grin if you must! I didn't take any

serious amount of extra time with the forend adapter as far as sanding it down to a super

fine finish but

left the 100 grit belt sander grit marks on the forward and rear portion of

the adapter. I did smooth out the flat and side portion a little but

again, still didn't take any serious time with this project. If it works out,

I will find an appropriate cushion material to install between the adapter

and the stock and replace the impromptu cut pieces of felt which is all I could

locate in my shop on quick notice. I removed the sandbag from the

Sinclair benchrest AP windage top and this stock forend benchrest adapter

slides like silk back and forth with no wobble or cant which should increase

my shooting accuracy. However, I placed the sandbag back onto the

windage top and there was enough room for the three (3) inch wide adapter

and flattened the sand out and squeezed the ears of the sandbag in which

made good firm contact with the lower side portion of the forend adapter

keeping it snug and flat. Next on my list will be more range testing to

ascertain how this impromptu Redneck Stock Forend Benchrest Adapter

performs. Web published updates on 03-06-14.

NOTE: I did a Goggle search and found that

Sinclair makes a similar forend adapter for

Sporter rifles being more high tech than my wooden version and there's is

adjustable for different stock widths. Oh, Well; I wouldn't have

had all the fun with the sawdust and wood chips flying around

either......grin if you must!

I removed the redneck home made benchrest forend adapter since I plan to

squirrel hunt without it and the curvature was cut free hand and had trouble

getting a perfect vertical alignment with it since it was skewed to one side

making my scope crosshairs canted as well even though the scope was square

with the rifle. When I have the time and think about a better way to

carve the radius more accurate, I might give it another try.

ROOKIE MISTAKE FOUND ON 03-12-14

After firing the Savage on 03-11-14, I was not too impressed with the

grouping and the next day while removing the scope, I noticed that the rear

scope dovetail base mount was "loose as a goose." It was so loose that

when you moved it back and forth it would actually make a rattling sound.

I checked the front mount and it was only finger tight. This was

probably the first new rifle that I have ever purchased that had the scope

base mounts already installed on them from the factory and you guessed it,

assumed they were tight. I removed the mounts, cleaned the threads on

the rifle receiver, screw threads and applied blue

Locktite Threadlock Blue 242 to them and

applied 15 inch pounds of torque. I would have liked to gone higher in

torque but was afraid that I would strip the threads or break the heads off

the little 4-40 tpi screws.

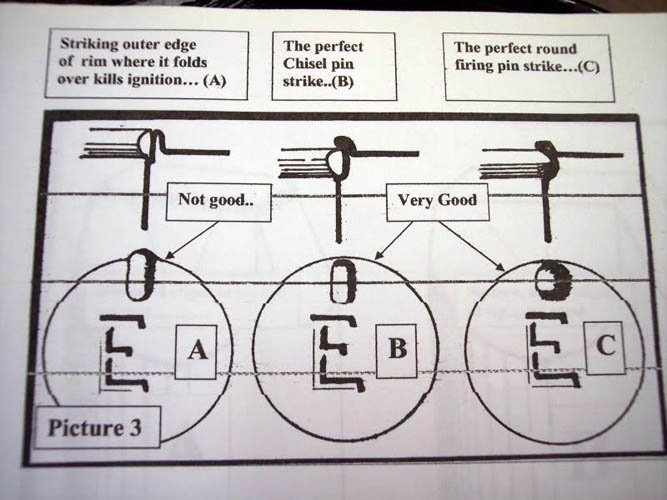

THE ART OF RIMFIRE ACCURACY BOOK BY BILL CALFEE

While doing much internet research on rimfire rifles and accuracy, I ran

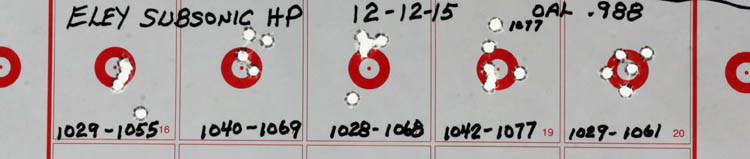

into some old threads that Bill Calfee had responded to a couple years back