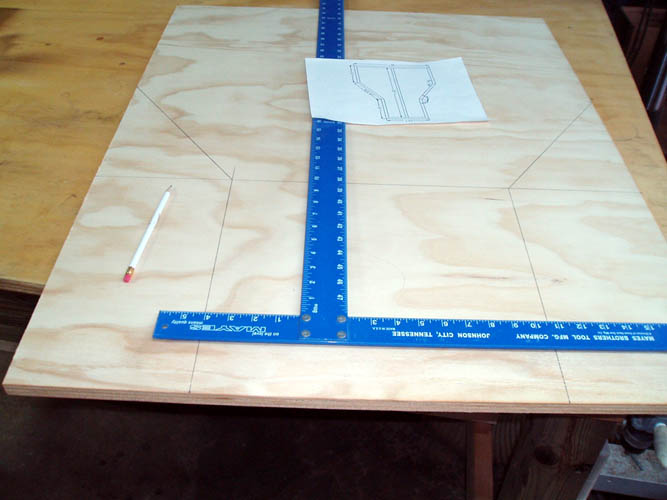

Below, the layout on the piece of plywood ready to cut the side pieces.

The blue aluminum drywall square isn't square but more or less used the long

blade as a straight edge.

.

.

My next step was to cut the sides and used the table saw to make a couple

of the cuts but forgot that the table saw blade is 10 inches in diameter and

when you flip the material over, you have a different cut on the underside

and went to plan B and finished the cuts with a jig saw which was freehand

and not as accurate as the table saw:

After sawing both pieces of the bench top to shape, glued

(sandwiched) together using Titebond Original glue and secured with 1 1/4

inch length drywall screws inserted from the bottom piece of plywood in conjunction

with the bolts that hold the leg pipe coupling and flanges, I started

construction on the couplings.

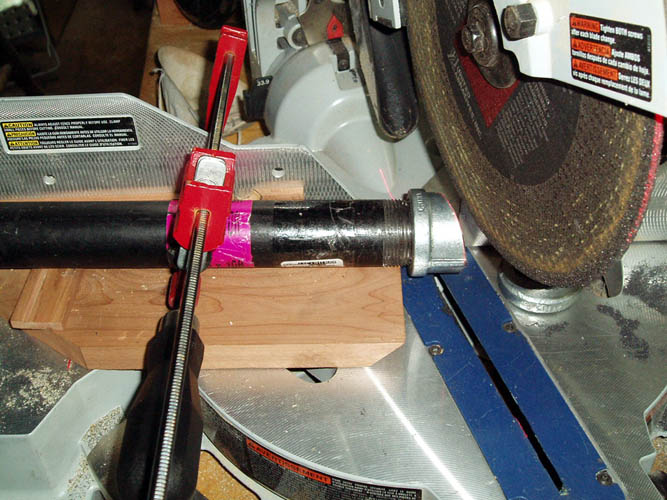

I decided to use my miter saw with a fiber reinforced metal cutting blade

since it would be more accurate in my hands than my PortaBand metal cutting

saw freehand. I secured the 1 1/4 inch coupling to one of the pipe legs;

adjusted the saw to 18 degrees and secured it in place with a Bar clamp.

The laser line really helps getting the pipe coupling centered since each

pipe coupling will yield two (2) complete units. I used three pipe

couplings which yielded six pieces; enough for another portable shooting

bench for my number one Brother-in-Law Douglas Pettigrew of Reidsville, NC. After cutting the 18 degree angle, I de-burred the edges. Pix below:

After cutting the couplings at an 18 degree angle and de-burred, I

took them to my friends John Hyatt and Rodney Caudle in Polkton, NC who

manufactures a top of the line Traditions grill and large competition

type grill/smokers; telephone 704-219-9433 of which I plan to do a

short story in the future of their operation when the weather is conductive.

They sheared the required 4 inch square metal flange plate and welded

the couplings to the plates. Notice that the front two leg plates have

the coupling welded diagonally outward where the legs will be orientated

similar to a tripod configuration which is for stability. Pixs below of the finished welded

couplings/plates: Click on thumbnails for a larger screen view:

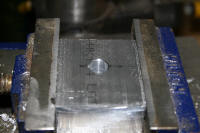

After wire brushing and degreasing the couplings/flange, four 21/64

inch mounting holes were drilled in each flange. I marked and center

punched each flange and used a countersink, 5/8 inch diameter x 120 degrees

as a starting pilot for a standard 118 degree drill bit which will align

itself in the 120 degree tapered hole.

When using countersinks and other short shanked drilling bits, etc., most

of the time you have to re-position your drill press table height due to the

shortness of the countersink which is a pain in the rear if you have a

project that requires precision drilling of which this one did not, you

loose accuracy big time by having to lower the table to accommodate a

standard jobber length drill bit, etc. You can use a locator pin in

your drill press to aid in such realignment but it is time consuming. It

certainly is easier to use a special 1/2 inch diameter holder for the

tool/bit which eliminates having to re-adjust the drill press table height. Below, pix of the countersink holder

which is 3.5 inches in length and precision made by Pat Warner of Escondido,

CA.

NOTE: Pat no longer supplies the countersink holders. I

used a little "Mickey Mouse" Harbor Freight table top drill press since this

project doesn't require any precision and heavy drilling.

NOTE: Pat Warner passed away on July 28, 2017. I met

Pat in 2008

and have several of his books and products. He was First Class

All-American all the way! Updated on 11-16-17.

After the 120 degree countersink, I then bored the holes to 21/64 inches

without having to re-adjust the drill press table height:

A coat of black paint and ready to install the couplings/flanges.

The glue was allowed to dry overnight and the following morning, I used a

DeWalt 1.5 HP router and a 1/2 inch diameter 2 inch length fluted carbide

bit to clean the edges of the two pieces of plywood that were glued together.

I used an aluminum straight edge to guide the edge of the router base

against to maintain a straight line cut. The guide was 2.75 inches

from the edge of the wood which was the necessary width for my router base

to the edge of the router bit. Pixs below:

After cleaning up the edges of the plywood with the router, I used a block

of wood and a small Stanley hand finish trim saw to cut a forty-five (45) degree angle off each

bench top corner to have it a little more ergonomically designed.

Below pix of the bench with the floor flanges I used instead of the couplings of which I

went back later and changed out to the couplings welded to the flat plate at

an 18 degree angle to maximize the stability. This

bench is solid as a rock:

I rounded over the top edge of the shooting bench using a 1/2 inch radius

two flute carbide router bit which had a ball bearing on the base to follow the

edge of the wood. I didn't route the bottom of the bench top but used

an orbital sander to round over and break the sharp edge. I was amazed

that the sheet of plywood didn't have any void or hollow places around the

edge of the plywood which is the norm rather than the abnormal as such as in

the case.

Below pixs of the portable shooting bench with a coat of

Cabot;

product Australian

Timber Oil in a Mahogany Flame color # 3459.

The underside of the plywood looks like

Rosie the Riveter from WWII factories worked on this piece of plywood

with screws instead of rivets.........grin if you must!; pixs below:

NOTE: I used floor flanges for the leg supports originally

and angled them away from the center of the bench with spacers but this is

not the best way to do it. Using the 18 degree angled welded couplings

is the correct way to do it and provides more stability. I had to rotate the coupling flange to align with

the holes in the bench that I had drilled earlier and then marked and

drilled the holes in this set of coupling flanges which is the hard way to

do it. It is best to do it right the first time. To quote Fred

Bear from one of his Archery Books, "Anything worth doing, is worth

doing right" and my

Grandma Coley used the same phrase back in

the 1930s when teaching her daughters to make dresses per my Aunt Mollie

Coley Bowers.

This is a very stable and steady portable shooting bench with plenty of real estate on the top for a

right hand or left hand shooter. You can transport this shooting bench

in the trunk of a car or SUV if desired; all you need to do is unscrew the legs. The total cost of this portable

shooting bench was in the neighborhood of $ 75.00 if you can do the cutting

and welding of the coupling/flange yourself and will cost more depending if you have to

"farm out" the welding. You cannot purchase a portable

shooting bench this stable for that amount of money either and will spend

upwards of $ 600.00 to get a

portable shooting bench this steady

commercially. I used stainless steel bolts and that was an additional

15 bucks for sure. The beauty part of a tri-pod shooting bench is the

self-leveling aspect of the design and the rear leg doesn't inhibit you from

acquiring a comfortable shooting position. I have a

Gibraltar softy throne adjustable stool on order to go with the above

portable shooting bench. I looked at the five leg

Sinclair adjustable stool but didn't like the large platform of the legs

which might take some getting use to and a transportation issue since it

definitely isn't compact. Both adjustable shooting stools had very

good reviews and "six of one and half a dozen of

another."

I will plug or cap the pipe open ends to prevent the legs from sinking

down into loose dirt, sand, etc. I will probably cut a matching

18 degree angle on each leg so the legs perimeter will maintain 100 percent contact

with the floor/ground.

My Number One Brother-in-Law, Douglas Pettigrew of Reidsville, NC liked

the looks of this portable shooting bench and the next time I am at Lowe's

in Rockingham, NC, I will purchased the pipe, etc. and start

building one for him.

My Gibraltar softy throne adjustable stool came in and expecting my

Sinclair rest to arrive on Tuesday and it will be time to do some more

testing with the rimfire.

Web published on 01-10-14 by Bill aka Mickey Porter with updated pixs on

01-19-14.

My

Sinclair Heavy Varmint AP Windage Rest

Left-Hand # 749-013-852WS came in on 01-21-14, however the oversized

scalloped hand wheel and thrust bearing plate which controls the fine elevation adjustment were

missing, rendering the rest practically unusable. I called Sinclair and

they will ship the missing parts out. Below pix of what I received:

The little

Hoppe's gun rest I have used for decades

looks like a toy compared to this rest.

Web published update on 01-22-14 by Bill aka Mickey Porter.

DOUGLAS PETTIGREW'S PORTABLE SHOOTING BENCH

Douglas Pettigrew my Number One Brother-in-Law that I call Brother Doug,

liked the above portable shooting bench and decided to make him one for his

birthday but couldn't get the plywood locally and finally started the

project since I had some plywood left over from a couple sheets of exterior

that was used for our yard parties. I cut it into smaller sections for

storage under my table saw out feed table and had just about enough plywood

left over from the portable shooting bench that I made for myself.

Below is a pix of his portable shooting bench while in the white:

After some sanding, I applied a coat of walnut stain and finished with

Minwax Indoor/Outdoor Helmsman Spar Urethane Clear Satin over a coat of Spar Varnish, using left over finishing

materials I had on hand in the shop.......grin if you must! Below is a

pix of Doug with his early Christmas gift on his deck in Reidsville, NC.

Doug, SusieQ, my bride and I loaded up in SusieQ's vehicle and went to

Danville, VA for lunch of which we had a

wonderful meal and some great

fellowship:

Doug has a shooting lane at the end of his deck out into the woods and will use

his portable

shooting bench for hunting and target shooting.

Web published updates by Bill aka Mickey Porter on 10-31-14.

LOW TECH POABOY ONE PIECE SHOOTING REST 02-02-16

Several days ago, my rimfire shooting friend Robert Webster of Hamlet, NC

was doing an analysis of some of his rimfire targets fired and noticed that

his targets on the left side of the

PSL target, his groups were to the left

of center. The targets fired to the right of center, the groups were

to the right and the light bulb came on for him. We both have been

discussing the possibility of making a home made one piece shooting rest

utilizing what materials we have on hand and not trying to reinvent the

wheel.

Below is my version off his

Gun Turret Model aka

POABOY one piece shooting rest under construction:

I installed a heavy duty steel piano type hinge on the front of the rest to allow

for fine tune elevation and also there is a 1/2 inch diameter smooth bolt

through the hinged walnut that allows for the entire one piece rest to rotate for

windage. I haven't installed the fine tune adjusters for the windage

and elevation yet due to awaiting on some aluminum bar stock and a 1/2 inch

x 20 tpi threaded rod to arrive. The Sinclair rest has both those features incorporated

into it but will only have the front bag aligned to the center of the base

and rear bag and use the coarse vertical adjustment only to level and center the rifle

on the target backstop. There will be a

spring installed underneath the base of the one piece rest pulling tension

against the right side fine tune windage adjuster since I shoot left handed.

The spring will be easier to install versus fabricating a custom spring loaded plunger. There will be an elevation screw adjuster for fine tune elevation adjustment

located in front of the rear sand bag on the center line of the rest.

Both adjusters will be operated with my right hand and will not require much

movement. I am using Bakelite material underneath the front and rear

of the rest to reduce friction and will locate a small thin thrust bearing.

This one piece shooting rest should remove some of the shooting error

caused by the improper alignment of the rear bag in relationship to the

front bag since it is very easy to torque either one which can cause flyers

other than faulty ammo and other variables too many to list.

To reiterate, I have a piece of stainless steel threaded rod 1/2 x 20 tpi coming and

also some 1 x 2 inch T6 6061 aluminum bar stock to fabricate the fine tune windage

adjuster and the elevation fine tune adjuster. I modified an ole

aluminum archery stabilizer rod not used anymore by sawing the weighted section into two

pieces and drill and tapped it for the 1/2 x 20 tpi stainless steel

rod which will work for the adjuster knobs. Using a

Portable Band Saw leaves a lot to be

desired trying to make a square and plumb cut;

recycle is the word for today! I sold my small South

Bend 3 ft. bed lathe a good many years ago and it would

definitely come in handy now.

This shooting rest will basically remain where it is presently located

but you can move it depending on whether you have any Gorilla DNA or have

eaten your Wheaties on a regular basis. The Sinclair rest is easily removed from

the one piece base by removing three hex head bolts that are screwed into Tee Nuts

mounted underneath the plywood base plate. The rear sand bag is not

permanently attached to

the base but only "hemmed" in by the walnut molding frame.

The fine

tune elevation adjuster would still work but the fine tune windage adjuster

utilizes the portable shooting bench for its operation in conjunction with

the spring. The entire one piece rest base plate is secured to the

portable shooting bench with a 1/2 inch diameter bolt used as the pivot point.

I might later install a bronze sleeve bushing but I doubt the rest will ever

wear enough to present a problem.

I will post additional pixs when I get the fine tuner adjusters

fabricated and installed and hope to catch the wind calm enough to do some

testing with the

CZ 452 American left-hand rifle.

Web published update by Bill aka Mickey Porter on 02-02-16.

THE LARGEST 1/2 INCH DIAMETER THREADED ROD I HAVE EVER

SEEN

UPS delivered the threaded rod I recently ordered from

Zoro on line

(EBay) and

noticed that the UPS driver Phillip had the package on his shoulder as if it

were heavy. One end of the threaded rod was protruding from the

cardboard shipping box and that threaded rod was large enough in diameter to support

the base of the Eiffel Tower. We both got a big grin going when I told

him I had ordered a 1/2 inch diameter threaded rod. The person that

picked and packed that item must be on the Blue Cross Blue Shield of NC State Eye Plan for sure or

missed their recent eye exam appointment. Below a couple pix

of the threaded rod with my tape measure for size comparison:

I called Zoro and advised them they shipped a 2 inch diameter threaded

rod instead of a 1/2 inch diameter threaded rod and they did not show

another 1/2-20 x 36 inch length stainless steel threaded rod in their inventory and requested a refund. The packing list showed the right part number of

which the weight was 1.592 lbs. I am supposed to get a return

authorization via email to have UPS pick up the humongous size threaded rod

for return.

I will have to go to plan B and locate another 1/2 threaded stainless

steel rod or locate a regular UNF threaded bolt to make do until a stainless

one is located.

There is always some excitement to be had with some of the projects I

find myself into....grin if you must!

On 02-04-16, my friend Robert Webster of Hamlet, NC found a piece of 1/2

- 20 x 3 feet length of threaded regular steel rod at the Hamlet Hardware

Inc. and below a couple pix of the size comparison between the 2 inch rod

versus the 1/2 inch diameter rod. I have the recycled/fabricated knobs

on the ends of the 1/2 inch threaded rod.

I am still grinning about the rod Zoro shipped. BTW, I weighed it

on a scale and it was about 23 pounds in weight........another grin is in

order.

The aluminum alloy T6 6061 1 x 2 inch x 12 inch length bar stock came in

this afternoon and got a chance to fabricate the fine tune adjusters for the

windage and the elevation. I have to locate a piece of stainless steel

angle to place a pad in front of the windage adjustment screw and also

obtain a heavier return spring to keep tension on the windage adjuster.

Click on below thumbnail pixs taken for a larger screen view:

A spring will be purchased tomorrow and/or swap the ones I have that came

from Tractor Supply since they are not strong enough. The rest will

get a good test early tomorrow if the weather permits.

Robert Webster offered some regular angle for the windage adjuster

pressure pad but I told him I wanted to use stainless steel instead. He

said that I was more hard headed than himself and his Grand Daddy use to

say, "Save your breath to cool your grits"........that

is a classic for sure!

I plan to apply a coat of maple stain to the plywood top and brush a

clear coat of polyurethane over the stain around Spring when the weather is

warm and less humid.

A special thank you to my shooting buddy Robert Webster for planting the

seed for the one piece shooting rest and who knows what the next project

will be!

Web published update by Bill aka Mickey Porter on 02-04-16.

ADDING BRONZE BUSHING AND WINDAGE PRESSURE PAD

It has been far too windy to seriously test the one piece shooting rest

out for accuracy and did fire some rounds off to get some trigger time in

and not a valid test due to the conditions.

I am still waiting on one of my friends to get me a piece of 2 inch

stainless steel angle x 2 inches in length x .125 inches in thickness for

the windage pressure pad and decided to install a bronze bushing in the rest

and also the table to reduce friction. I plan to locate a

pressure sensitive Teflon pad to install under the front of the rest where

it hinges to help reduce friction in that area. The rear of the

shooting rest will be slightly elevated off the shooting bench using the

fine tune vertical adjuster which has a hard slick phenolic pad underneath

the elevation screw contact area and will reduce friction without inhibiting

overall stability.

I removed the hinged walnut from the one piece rest base whereby I could

utilize the drill press to enlarge the .500 inch diameter hole to .625

inches for the bronze bushing. I used a 1/2 inch piece of

poplar wood dowel rod to align the 1/2 inch hole drilled with the drill

press and clamped the drill press vise down when it was centered with the

drill chuck. I removed the 1/2 inch dowel and inserted a 5/8 inch

diameter forstner drill bit and drilled the existing 1/2 inch diameter hole.

The bronze bushing was just a little over .625 inches in diameter and was a

good press fit in the 5/8 inch diameter hole drilled.

I did not do a complete sequence pixs of what I did but below are a few

thumbnails of the bushing installed in the one piece shooting rest and also

the portable shooting bench.

I used the Dremel tool and a small cut-off friction wheel to cut the

bronze bushing to length and ground it to the proper final length using a 1

inch x 42 inch bench mounted belt sander with an aluminum oxide 220 grit belt.

This bushing length was not that critical and a few thousands < minus total

length was what I opted for. My ole small South Bend lathe would have

been ideal for cutting the bushing to length. The owner of the lathe

is not using it and he said he would sell it back to me and might take him

up on the offer.

I glued a 1/2 inch diameter poplar wood dowel rod into the existing 1/2

inch diameter hole in the portable shooting bench to allow the 5/8 inch

diameter forstner drill bit tip to have something to center with. I

used a couple small right angle squares to get a visual aid to help keep the

hand held portable drill aligned.

I will probably add a small low profile thrust bearing between the one piece

shooting rest and portable shooting bench at the pivot point which should

reduce friction there since the Sinclair rest is at least 17 pounds in

weight. I could have made a wood Tee support for the forward rest but

used what I already had in the way of a front rest.....a high dollar front rest to

not use the fine tune adjusters on it....grin if you must!

One of my friends should have the stainless steel 2 inch angle for me

tomorrow and will install the pressure pad adjacent the fine tune windage

screw adjustment. 02-07-16.

NOTE: I installed the stainless steel pressure pad on

02-09-16. I wasn't thinking ahead since I had to route the top of the

platform to

depth to fit the 1/4 inch thick stainless steel angle bracket of which I

asked for .125 inch thickness but "beggars" can't be too choosy. All

my routers had too large a foot print on the base to get the left hand

portion of the bracket routed out because of the walnut home made molding

already glued in place.....put the cart before

the horse on that one! I used a chisel to get about 1/3

of the wood portion cut out not accessible by the router.

LOW TECH POABOY ONE PIECE SHOOTING REST ABOUT READY TO

FIELD TEST

My next iteration of this low tech poaboy one piece shooting rest (if there

is a need) will probably be in T6 6061 aluminum flat bar

stock; totally portable

and independent of my portable shooting bench.

Web published update by Bill aka Mickey Porter on 02-14-16.

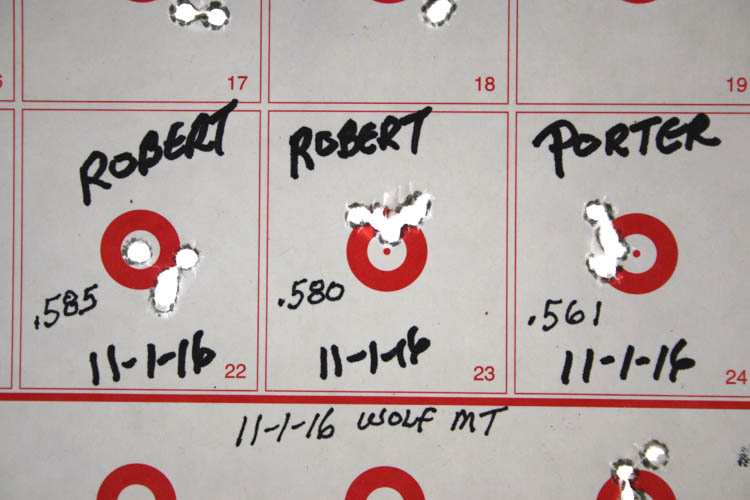

The above groups at 52 yards and will take a squirrel out all day long!

FINE TUNE WINDAGE ADJUSTER MODIFICATION

I wanted to take out some of the slack (movement) in the threaded bolt

windage fine tuner adjuster and drill and tapped a hole for a 5/16-24 tpi

spring loaded

plunger button that was used on my archery equipment back in

the mid 1980s. The plunger button came with several different

thickness springs and used the heaviest one which worked out perfect!

The plunger has a Delrin type replaceable tip and the plunger housing also has an

adjustment weight set screw that increases the tension on the inner shaft

(plunger) if

needed. I also repositioned the main body of the adjuster where the

1/2 inch threaded rod will contact

the center of the stainless steel pressure pad strictly for eye appeal.

Since there is an arch to the movement of the one piece shooting rest when

adjusting windage, the threaded rod contact at the pressure pad will move

in a slight East to West direction depending on which way you rotate the one

piece shooting rest. A steel split nut installed inside the aluminum

block for the stainless steel threaded rod to move through would work just

as well requiring a pressure set-screw to tighten the split

nut for any slack present:......six of one and half a dozen of another!

NOTE: The above fine tune windage adjuster has at least five

(5) times the windage adjustment needed for target shooting like the

PSL

and

ARA targets at 50 yards and with the extra

windage movement available, allows for a wide angle coverage of one of my

favorite squirrel hunting locations. This fine tune windage adjuster has two

(2) recycled archery components; Berger style plunger button and PSE stabilizer rod

weight. There just might be a little bit of an

overkill on the fine tune windage adjuster but that is

my nature. This has been a very fun and laid back project.

I am waiting on the weather conditions to get better before I start

burning up some ammo with the

CZ 452 American left hand rimfire rifle.

Web published update by Bill aka Mickey Porter on 02-14-16.

WEATHER CONDITIONS VERY WINDY AND VARIABLE

I can't seem to catch a good day yet to do some serious test firing but

fired a few rounds in the wind and just getting some trigger time in only.

I added a Sinclair

forend benchrest adapter to the stock of the CZ 452 American and

took the sand bag off the Sinclair rest windage top and it works pretty good.

You loose some "man points" on

the pretty aqua blue color base though. The adapter is very easy to

set-up requiring only one screw supplied that fits like a glove in the

existing stock sling stud hole. The UHMW base material is

"slippery as an eel" and rides

effortless on the rest platform.

Web published update by Bill aka Mickey Porter on 02-18-16.

HARVESTING SQUIRRELS

When our annual squirrel season rolled around, I removed the Sinclair

forend benchrest adapter and went back to the leather and sand bag front

rest support. I disconnected the heavy spring return at the rear of

the benchrest where I can quickly move from right to left without having to

use the fine tune windage adjuster. When target shooting only, I

connect the spring back up. Seems like I keep changing things up, but

this set-up will no doubt remain the same for a while.....grin if you must.

Check out my

squirrel skinning 101 and

rabbit skinning 101 pages.

Web page updated by Bill aka Mickey Porter on 02-06-18.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."