DRILL FIXTURE

Over the decades, I have made and had manufactured numerous drill fixtures for

musical

instrument parts and accessories,

climbing tree stands,

turkey box calls and some that I can't

remember exactly what they were for. I made a drill fixture for my Pop

many years ago for his yard/porch swings chain eye bolt connection to the

swing arms, but he enjoyed doing

things his own way!

If you have multiple accurate holes to

drill, a drill fixture with hardened

steel drill bushings is the way to go. There are a couple schools of

thought on the best way to locate the drill bushings in reference to chip removal, but drilling into wood you have a little

more latitude than with metal.

I am at least eleven (11) years behind in making this type of drill

fixture for the DeStaCo 225U toggle clamps I have installed on various fixtures for

different woodworking operations, turkey box calls, etc. On my

napkin holder

project, I used four (4) DeStaCo 225U horizontal toggle clamps for pattern

routing the foot profile and the front opening of the napkin holder which

saved a tremendous amount of sanding. I also used a couple of the

DeStaCo 225U clamps on my

serving tray hopper fixture.

What prompted this latest drill fixture to drill mounting holes in wood

for the DeStaCo 225U type horizontal toggle clamps and/or look alike

(clone) clamps

was the recent

mortise jig I built using a

design

created by router guru Pat Warner who took using a router to the ultimate

level of perfection in my humble opinion. I have several of Pat

Warner's books, CDs, instructional materials and products he offered for

sale on his

website. I met Pat during a visit

with our Son, Bill, Jr. and his family in Vista, CA in

2008

and had Bill drive me to Pat's home and workshop in Escondido, CA and was a fantastic

and educational visit.

I snapped a quick picture of Pat catching him off guard, of which I will link

here.

Pat died on July 28, 2017 and is certainly missed by his family and loved

ones, the woodworking community and myself as well. Pat Warner was a

perfectionist for sure and produced First Class All-American made products!

His work was flawless to say the least.

HH225D CLAMPS

I recently modified the

mortise jig and needed to make several spacer blocks to go

underneath the DeStaCo 225U horizontal toggle clamps, however I replaced the

DeStaCo 225U clamps with a look alike clamp sold by the toggle clamp store

on

line, of which has a little different mounting hole layout on the

longitudinal axis, but their

HH225D clamps are much smoother with less

binding action in my humble

opinion and have a longer adjustable spindle hold down. Their HH225D

will be my go to horizontal toggle clamp in the future; not to mention they

are at least 1/2 or more in cost cheaper and the quality is as good or

better than the DeStaCo 225U in my humble opinion. The toggle clamp

store provides excellent fast service as well.

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep Safety

paramount because hand and power tools can do serious bodily harm and death

if not used properly, therefore these pages are solely for

entertainment purposes only from

a personal liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues

before going any further. Safety glasses and hearing protection is a

must, however many times I forgo the usage of hearing protection; my bad!

MATERIALS NEEDED

I had a piece of scrap aka unallocated aluminum bar stock that was 1 x 2

x 8 +- inches and ordered four (4) hardened steel drill bushings: 1/4 inch

I.D. and 13/32 inch O.D. x 3/4 inch length.

I used my smaller bench drill press to drill the holes into the aluminum

bar stock, however one of the holes was too far off center to use without

"buggering" one of the holes in

the clamp base and had to

regroup and start over. I transferred the layout pattern fairly

accurate as far as you can go scribing a reference line using a dial caliper

which should be accurate enough for the hole pattern for the clamp, but

something went a miss somewhere.

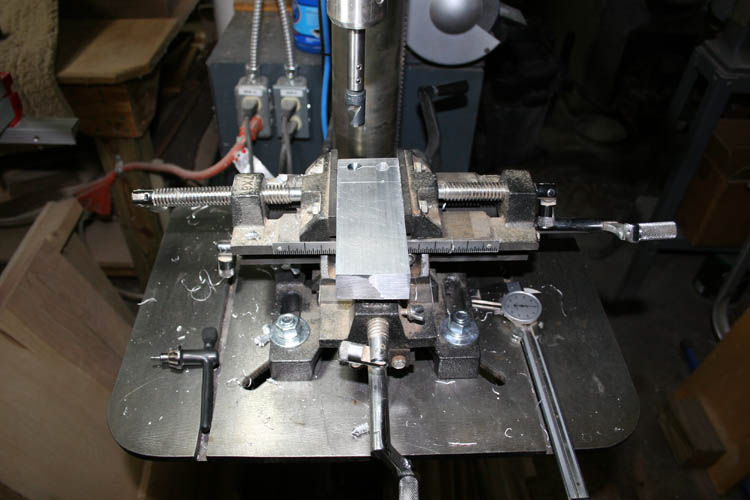

I decided to use my larger floor model drill press and an x-y table which

should secure the bar stock and position the drill press chuck centered where

I needed to drill.

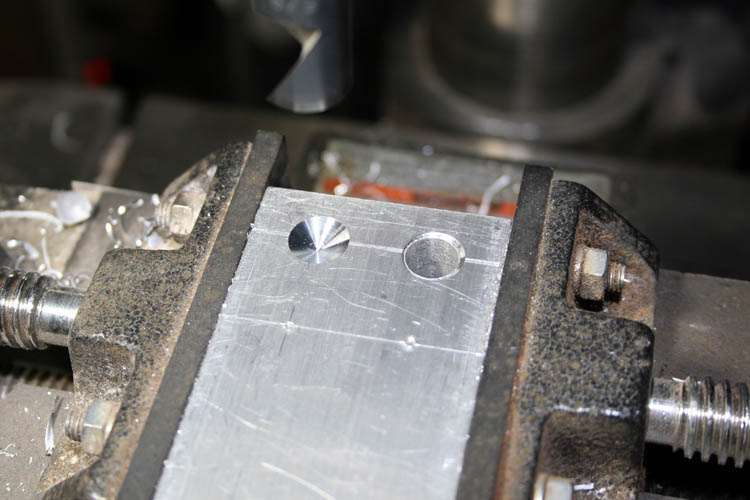

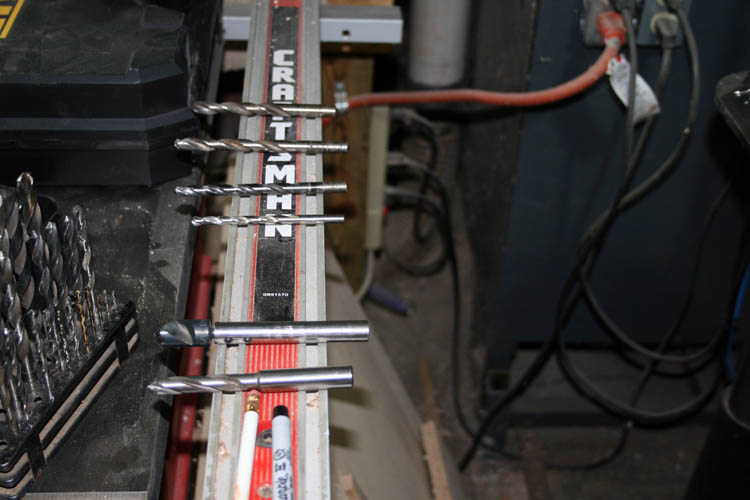

I used a drill for drilling into plastic that had a very sharp point to

index the table into position and centered the aluminum bar stock where the

hole was to go. I used a 120 degree countersink and several other

drill bits working my way to the final drill size of 13/32" which is around

.4062 inches for each hole with some run out by the quill/chuck.

A milling machine with digital read out would be the ticket for this

drilling operation. Afterwards, I found that my drill press table was

not completely square with the drill which is definitely human error on my

part. Not out of square enough to ruin the project though!

There was six (6) drill bit changes for each hole, 24 total....whew!

Blue layout dye would definitely be an asset for seeing your scribed

lines, but too frugal to order some just for this project.

I used a small cheap Harbor Freight arbor press to seat the drill

bushings which were .406 inches in diameter. I didn't have a reamer to

open the 13/32 hole up, but the little press got the bushings in with a good

amount of brute force applied. I used this little press to seat frets

in musical

instruments.

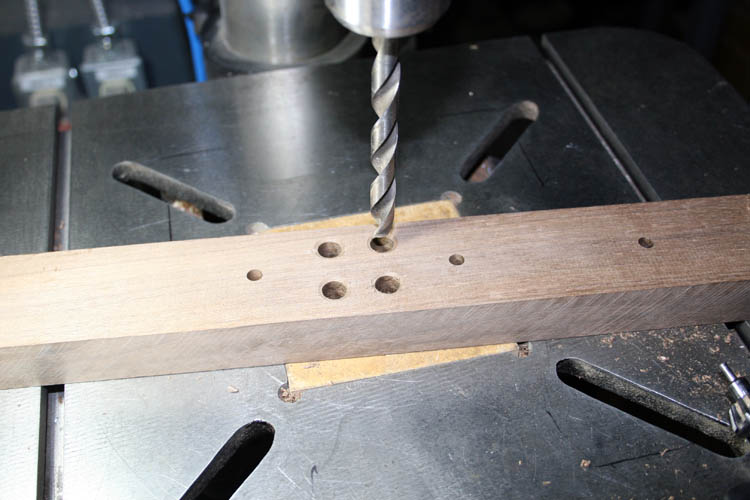

I went as low tech as I could as far as using the drill fixture SN 71.

Pix below:

Just clamp the fixture in place and drill away!

I drilled some test holes in scrap material and they were close enough

for Gov. work.

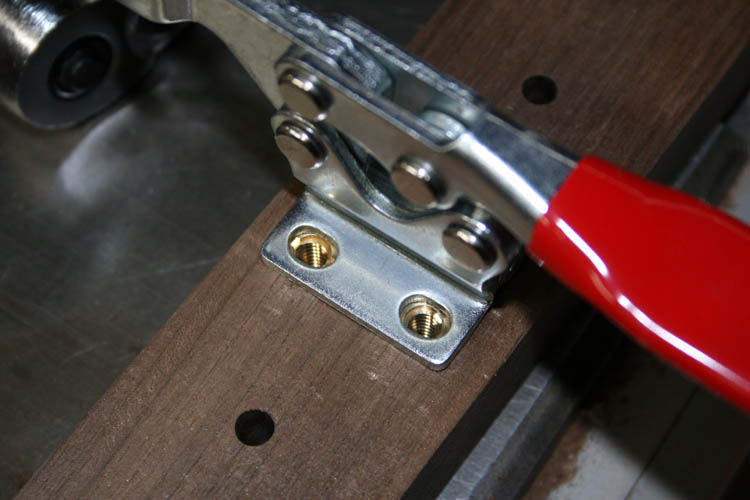

The above pix is the bottom side of the material edge guide that will

have the toggle clamps affixed to.

Mortise jig with the new walnut edge guide member in position for a test fit.

I removed the edge guide clamp member from the Plexiglas platform and then holes were drilled into the member using the drill fixture

and a battery operated drill with a 1/4 inch dia. drill bit. I used a

couple Irwin SP11 vise grip clamps to hold the drill fixture into position

onto the edge guide member.

The walnut guide/clamp member is attached to the mortise jig Plexiglas

platform that holds the

toggle clamps were drilled using the above drill jig and the 1/4 inch

diameter holes were enlarged to 23/64 inch using three different drill bits.

EZ LOK brass threaded inserts were screwed into position.

A 1/4 inch diameter drill bit was used to center the drill press chuck, wood

clamped to the drill press table at each end and then the hole was enlarged

to 25/64 inch. Each of the eight (8) holes were enlarged using the

same locator/drill technique.

Once all eight (8) holes were drilled to 25/64 inch, the EZ LOK brass threaded inserts for 1/4 x 20 bolts were ratcheted into the holes drilled.

The inserts were "tighter than two coats of paint."

The stainless steel flat head socket cap Allen screws can easily be

removed when adding spacer blocks underneath the toggle clamps for

holding down thicker stock. Of course you need longer mounting screws

too. I originally set the DeStaCo 225U clamps for 3 inch maximum

thickness stock and used a couple pieces of 15/16 inch thick scrap material

as spacers between the toggle clamp spindle hold down and the square stock I

was about to mortise.

The flat head socket cap Allen screws works much better than a hex head

bolt and does not have interference with the sides of the clamp.

Mortise jig with the new walnut guide member in position for a test fit.

There was plenty of aluminum shavings from the drilling operation.

MORTISE JIG AFTER THE MODIFICATION

The next fixture/jig that I make, it will be easy to drill accurate

mounting holes for screws and/or holes for the EZ LOK 1/4 x 20 brass threaded

bushings.

Web published by Bill aka Mickey Porter on 03-11-19.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."