This page will take you down memory lane with

pictures and narrative type comments, weaving together bits and pieces of

information as it relates to some of my early research and development

of GIBSON MASTERTONE PRE-WAR BANJOS,

a more or less autobiography leading up to the present time.

Verification documents, references and drawings are included and hopefully

all inferences and opinions by myself will be correctly noted. As

with many things from the past, one must extrapolate using the best

available data to hopefully obtain valid and reliable conclusions which is

not an exact science.

I am sure there are some errors present since I am relying on personal events of

nearly 50 years ago and memory is not infallible. I have made

corrections and

additions as necessary to provide the most accurate information. My

initial purpose for this page was to give credence to my wood working

experience and there was a natural overlap into other areas. I

don't consider myself an expert at anything simply because I have

never found one particular area to hold my interest and devotion, but for a

certain length of time, whereas many are able to find their own particular

profession, hobby and passion to become a Master at it. However, I have never been afraid to try a new challenge and task and do think outside the box which many times

is considered unorthodox. I like the statement that Anthony Hopkins

used in the movie "The Edge", "What one man can do,

another can do." With that

said, there are many

individuals that have

nurtured their God given talents that sets the standard for the rest of us

pretty high.

I do believe and practice,

"anything worth doing, is worth doing right!"

I have featured special and

talented friends and family that have helped and

inspired me and in no way all inclusive in this section and other pages

throughout this website.

I give God our Creator, through Jesus Christ our Lord

and Savior, the Praise, Honor and Glory in all things!

Our "Pop"

William Porter taught us the value and respect of the great

outdoors

and we shared many memorable days hunting cottontail rabbits with all breeds of hounds and later had to use the small beagles because of the increase in

the Whitetail deer population. Pop loved woodworking and made a great

porch/yard swing with the correct seat and back angle curve and used

"old world techniques" such as a draw knife, chisel, etc. to

fabricate his swings. Some of my earliest wood working projects

got its start from "Pop" who taught me how to make a rabbit box,

rabbit trap or rabbit gun, which ever you choose to call them. I made

"Pop" several drill fixtures with

hardened drill bushings over the years but he loved the ole way of doing

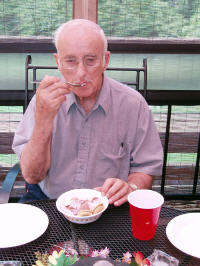

things. Pix of our Dad taken in the early to mid 1960s with my dog Brownie. Pop passed away on August 10, 2007 after a

long battle with heart disease and inserted is the last pix I took of

him on July 4, 2007 while enjoying some ice cream and cookies at our home.

My sister sent me pix of his school days in 1934. Pop had a continuous

testimony for Jesus Christ, loved his Church and fellow man and he witnessed

to us and those in the hospital room hours prior to his death. He was

an honest hardworking man devoted to his wife and family and is greatly

missed, but not forgotten!

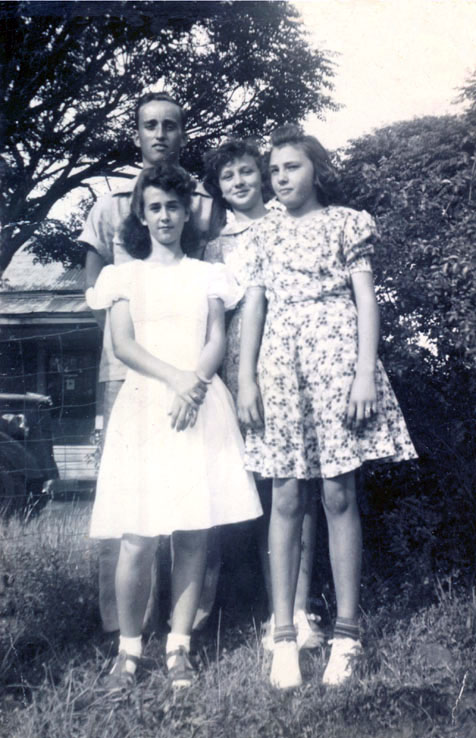

Above four pixs of our "Pop" William Porter

taken between 1934 and July 4, 2007.

Above is a checkerboard table in my

Man Cave in our basement that I

built for our Pop around 1962 or 1963 in the Industrial Arts aka Shop Class

at the Wadesboro High School. David Kephart (now deceased) was our

shop teacher who was an excellent woodworker, craftsman and teacher.

The table had plenty of usage over the years by Pop and anyone who

challenged him to a game of checkers. This checkerboard table was made

long before the veneered checkerboard tops were available through the wood

working suppliers and constructed from solid walnut and poplar, however the

tapered legs were made from glued up walnut 4/4 stock. Table has a

small drawer underneath and visible from the other side to store the

checkers. The flash from the little digital camera "washed" out much

of the detail; the corner squares are from white poplar and the adjoining

wood is dark walnut but the pix bleached the color out at that camera angle

and doesn't do justice to what the table looks like. The table could use a

make over; e.g., sanding and refinishing, but I plan to leave it as

is. Pop was an excellent player and I rarely won a game of checkers

with him since he could see about 3 more moves ahead of you all the time,

however I won the first game ever played on this table. After the

passing of our Pop and Mom, I received the checkerboard table and a custom

inlaid Buck folding hunter knife that I also did for him. I certainly

do miss them both! Posted update by Bill aka Mickey Porter on

03-11-2023.

There is a special Love for one's Mother of which it is

hard to find words to convey that message, but I certainly let her know that

I loved her and have no regrets in that area. Like our "Pop", she was

a hard working woman and loved our Dad and her children dearly and did the

best she could by us and lead us in the right direction. She had a

beautiful strong Alto voice and shared her God given talent that was

nurtured early on with singing and music lessons proved by a prominent

Wadesboro resident. Mom shared her singing in many services in

and around Anson County. NC and will be greatly missed, but not forgotten!

Like our "Pop", Mom had a continuous testimony for Jesus

Christ and did her part witnessing the great Love that Jesus Christ has for

us all and how to obtain Salvation.

She suffered greatly the past seven (7) weeks and was a

cancer survivor of about four years and finally succumbed to congestive

heart failure. During her much suffering, when asked how she was

doing, she would answer, "I am trying"

attempting to maintain a positive attitude and outlook. Throughout the

years, during the many trials and tribulations that came her way which is a

part of Life, she would say,

"And this too

shall pass" of which it does given time and with the Lord's

Grace and Mercy that is available to all of us. Below a few pixs:

The above pix was taken sometime around 1941 with our

Pop in the background of which was Love at first sight when he met our "to

be Mom", grin if you must! Mom is the young Lady on the front right

and her Mother dressed her like a little girl for sure. One of her

sisters Molly Bowers is in the background and Rose Thomas is on the front left.

Pix of my Mom taken in 1946 holding yours truly.

My friends said this was about the best I have ever looked! Grin if

you must.

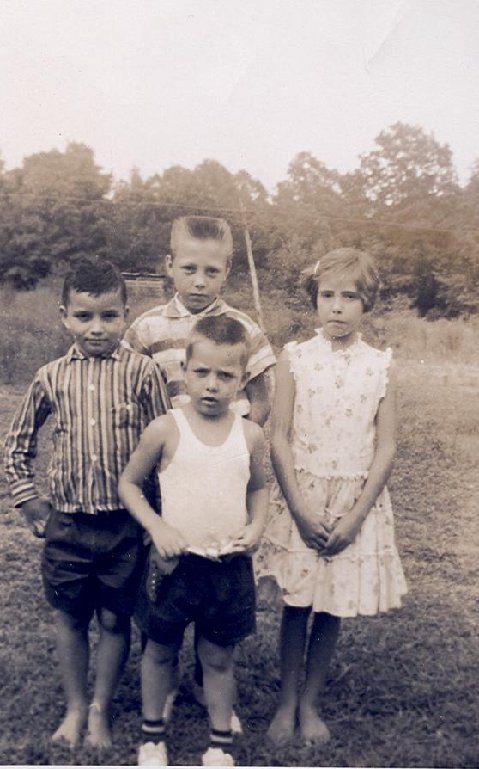

A pix taken in the mid 1950s of the Porter kids

left to right; Allen, Mickey, Joe, front row (deceased) and Sue. Back

during the early black and white westerns on TV, our younger brother Joe

would ride his horse which was a stick that he had fashioned reins (string) tied to

it and he would make all the sound effects and motions of a horse raring up

and would slap the side of his leg while he was "riding" his horse.

How he was able to run with that stick between his legs dragging the ground

behind him and not getting tripped up was unbelievable. He would tie

that stick up to a hitching post just like it was a real horse at the end of his ride.

Back in the 1950s kids created their own toys and

invented games to

entertain themselves and others. I have made my share of sling shots

using automobile tire rubber, old shoe leather tongues and forked prongs

with dogwood being my favorite. It was nothing to roll an old tire

around and if one was large enough, get inside and roll down a hill.

Old tin lard can lids and large coffee can lids would be nailed to a piece of wood and rolled around

like a wheel. Tarzan vine swings were used across small creeks and

branches and sometimes would give way with a crash to the ground, but we

were tough back in those days. About every young boy had a pocket

knife and a Barlow was the standard and whittled and carved many whistles

and objects. Don't remember any kid in our neighbor that intentionally

cut another kid with his pocket knife and we were allowed to carry our

pocket knives to school! Kids also built home made wagons, go carts;

made skate boards and push scooters from metal skates and that was long

before the synthetic poly wheel commercial skate boards. Home made

bows and arrows and the Biblical type David sling has thrown many rocks with

varying degrees of accuracy. The girls would make "play houses" by

clearing off the ground and using pine straw to make the room dividers and

rocks and other objects to simulate the furniture, etc. Making home kites or

using store bought ones which required you to make a long tail to help

stabilize it so it would stay aloft. Those days are long gone! Today, kids have digital technology

devices to occupy their minds and I believe has diminished their personal

creativity.....grin if you must! Times has really changed and I

certainly do miss Brother Joe! Pix added 10-24-12.

Another early pix of Mom and Pop.

Another one of my favorite pixs of Mom and Pop taken in

1978 with Ray Newton in the background.

Pix of my Sister Susan Pettigrew and our Mom.

I have an audio file in .mp3 format about 4 Mb of

Mom singing

Pearly White City around 1998 at a funeral. Click on Pearly White

City hyperlink to open the file.

I have an audio file in .mp3 format about 4 Mb of Mom

singing

I Cannot Fail The Lord recorded on April

17, 1983 at the Wadesboro Church of God. Ralph Henry Coble is playing

the Organ and Carolyn Griffin is playing the piano. Click on I Cannot

Fail The Lord hyperlink to open the file.

The above picture of my Grandma with her first

son Joe of which I have the large framed hand colored photograph in our

home. I lived with Grandma as far back as I can remember and stayed there until 1964 when I enlisted with

the US Navy. My Mom and Dad lived next door to us and countless times

after the passing of Grandma, Mom would say, "I know you loved her more than

me" of which I never gave an answer. I believe she knew the

answer!

As with most of us in our youth, we didn't realize how

smart and wise the "older generation" were

until some years later when we entered the normal struggle of life and the

light bulb finally came on. Grandma was a very giving person who

had a dozen or more rental properties that provided her income and many, many

families left owing her much money over the years, but she didn't have the

heart to immediately evict them as most property owners would do, but allowed them to

stay on until they moved.

I learned a lot of life's valuable lessons from her

over the years, but didn't fully understand the tremendous value and

magnitude of those lessons until after she departed this earth to be Jesus

Christ

our Lord and Savior!

I have a short story titled

Memories From The Past

which goes into some detail about her life and there is an audio file I made

of her in the early 1970s with her singing which is linked on the same page.

Click on the hyperlink

for additional information. I still Love and miss her dearly!

US NAVY BOOT CAMP

After graduating from the Wadesboro High School in

1964, I was interested in obtaining employment with the North Carolina

Wildlife Resources Commission as a Wildlife Enforcement Officer, but that door was never opened and decided to join the US Navy to get some life skills training and as

they advertise, "To see the world."

I did Basic Training aka Boot Camp at Great Lakes, Illinois and

that lasted for twelve (12) grueling long weeks. That training was definitely a

wake up call and not the relaxed training our current military boot camp folks go

through, except the Marine Corps.

I was offered a voluntary medical discharge because of

a .22 caliber gun shot wound received in the left leg ankle in 1960, but

refused the voluntary medical discharge!

I still remember the fire control training where we as

a team would put out fires simulating fire conditions on a ship with real

fires burning and in close quarters. The gas mask training was as real

as it gets too where we went into a closed room and tear gas was released

and we had to remove our gas masks and recite our name and service number.

Yes, it definitely brought tears to your eyes, but not as painful as the OC

pepper spray training with the NCDOC/NCDPS I have went

through.

I was in excellent physical

condition, having worked

out regularly with weights the last two years of high school, but the hours

of marching and drilling would drain your energy level quickly.

Before enlisting in the US Navy, my Pop told me not to

volunteer for anything as he was a Navy man himself during WWII.

SERVICE WEEK DUTY

About half way or so into our boot camp

training, we had to do two weeks of duty called

service week that encompassed all kind of duties like mess hall,

building janitorial service, grounds maintenance, etc. Our unit was assembled and the instructors

would call out looking for volunteers that had training in areas such as truck

driving, water fowl hunting experience and a bunch of hands immediately

were raised. I remember my Pop told me not to volunteer for anything.

The majority of the volunteer jobs were already picked by the eager volunteers

raising their hands and there were only a few of us left. They finally

asked for a volunteer that had typing experience to work as a

typist at the battalion

headquarters. I thought about what Pop told me again and those truck

driving volunteer jobs turned out to be sailors pushing wheel barrows and

the water fowl hunters were assigned to pick up cigarette ducks from various

locations. However, I surmised that I believe this job might be

legitimate and slowly raised my hand with a lot of anxiety. The Drill Instructor told me to

report to battalion headquarters for duty the same day. The typist job

turned out great, whereas I didn't have to report for duty until 0800 hours

each day and went by the mess hall each morning and got the Battalion Officers donuts/cake,

etc. that was waiting on them. I typed cover sheets for manuals, etc., and got off duty each day

around 1530 aka 3:30 PM to 4:00 PM and got off on Friday around noon and was off for the

entire weekend. That gave me a chance to catch up on getting all my

uniforms squared away, brass buckles polished, shoes spit shinned and things in order and do some studying for upcoming

written exams.

Those mess hall workers had to report to duty at around 0330 hours each

morning and didn't get back to the barracks until around 10 PM or later and worked

the entire weekend as well.

The Battalion Commanding Officer asked me if I would

like to finish out my training there as a permanent service week, but I

declined the offer wanting to attend classes and graduate with my regular company

No. 365. They

liked my job performance and gave me a letter of commendation for my

service record.

I lucked out on that two week service week duty

assignment and my

two years of typing in high school paid off as I cruised right along on the

ole manual typewriter.

LIBERTY WHILE IN BOOT CAMP

I can't remember what week of training we were on, but

we finally got a day of liberty and several of us took a train to visit

Milwaukee, Wisconsin. The country side was beautiful with rolling hills and

when we got downtown in Milwaukee, I ordered

a good size steak at a busy restaurant which might have been a T-bone, but not

sure. It wasn't the greatest cut of meat as I remember and definitely a break from

the mess hall chow.

Our group made it back to base in time and I believe we

got one other liberty while in boot camp, but can't recall where I went.

RADIOMAN SCHOOL BAINBRIDGE, MD.

After Basic Training, I was assigned to Radioman Class

A School

in Bainbridge, MD. which lasted at least six months. I received some

excellent electronic training to be used later on in the private sector and it was a tough course

having taken only one advanced math class while in high school. Most

Radioman jobs were of the clerical administrative nature, rather than hands

on electronics repair, unless you went to some of the specialized schools;

e.g., Class B and C Radioman schools, teletype repair, etc. The

Radioman RM rate is more or less and operator job and not a technical rate

per se.

IBM PUNCH CARDS

Getting side tracked a little which is my normal MO,

(modus operandi) while in Radioman School I met an individual who had worked for the Naval

Bureau of Personnel and he explained to me how the IBM punch cards worked

for selecting your duty stations/assignments. That acquired inside

knowledge worked to my advantage and I was able to basically get the

areas of duty that I wanted.

WATCHED MY FIRST THEATER MOVIE

Aside from attending daily classes, I didn't go

off base hardly at all, but watched movies on the weekend at our base theater. Prior

to my enlistment in the US Navy, I had never been to a movie theater and

remember watching the 1963 movie The Pink Panther with Peter Sellers; a riot

for sure! Our local Wadesboro Church of God frowned on attending movie

theaters as sinful activity. After watching the movie, I just could not

make the correlation to that activity being sinful, however I do realize certain types of movies

would definitely fall into that category. A large number of our class lived within driving distance of

Bainbridge, MD and would go home for the weekend, but it was too far from

Wadesboro, NC to try and ride a bus which would not leave much time to visit

home folks at all.

CHARLOTTE, NC TO NEW YORK

My parents took me to Charlotte, NC and boarded a plane

headed for New York JFK International Airport.

ROTA, SPAIN

As stated below, my next duty assignment was in Sidi

Yahya, Morocco, whereas several of us had duty assignments and the

flight was from New York JFK International Airport to Naval Station in Rota,

Spain where we stayed a week or two in a holding company.

GIBRALTAR

Several of us were then transported on a small twin

engine air plane (mail plane) to Gibraltar and if I am not mistaken, spent

the night there and the next morning flew to Rabat, Morocco.

From Rabat, Morocco, we traveled by bus to Sidi Yahya

riding with the locals and that was an experience for sure!

MOROCCO, AFRICA

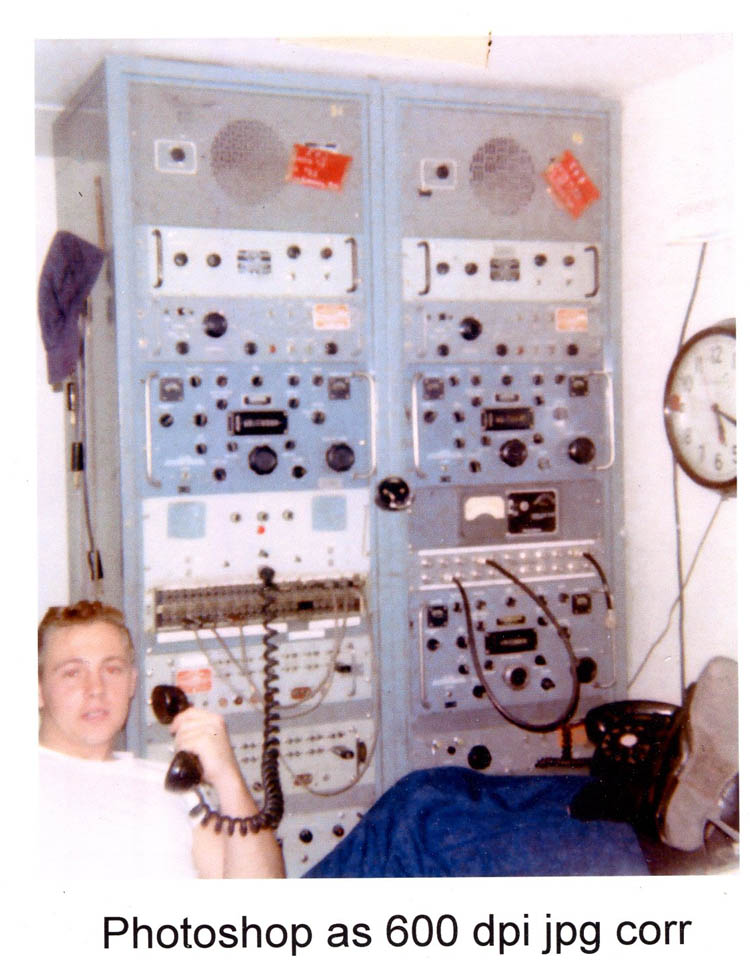

My next duty assignment was at a Naval Communications

Station at Sidi Yahya, Morocco, Africa which was not to far from the old

Port Lyautey,

however our facility was about 20 miles East from Kenitra near

Sidi Yahya. I was there for two years and

advanced to Radioman Second Class E5 Petty Officer in 1966 if my memory is correct.

Here is a

link with a couple photos, etc. The

base at Sidi Yahya was handed over to the Moroccans in 1977. There is an alternate

spelling for Sidi Yahya being Sidi Yahia.

Our primary mission was to provide communications

support with

the ships (Sixth Fleet) in the Mediterranean Sea and submarines in said area. Most of our

communications were via secure cryptic HF circuits. Our transmitter

site was about 60 miles away near

Bouknadel, Morocco which maintained a million

watt very low frequency transmitter of 17.8 KHz for cryptic transmissions to

submarines. Two infamous

research ships (go ahead and grin on this statement) that frequented the

Mediterranean Sea, being the

USS Pueblo and the

USNS Valdez which required 100 percent

communications with them. There were a total of five (5) of those type

ships which included the

USS Liberty that came through the Mediterranean Sea, but the three mentioned above

are the ones that stuck in my memory bank. I am not sure if the other

two (research ships) were assigned to the Mediterranean Sea for duty. It was very stressful since the

USSR would

scan the HF spectrum looking for our signature multiplex incoming signals

and would place bagpipe type

jamming signals on top of the main carrier frequency in an effort to distort our

communications. I was a shift supervisor for a year at this facility

and planted the seed for myself never wanting to be a supervisor

again. I am a hands on person and rather do the job myself, rather

than direct someone to do it. This tour of duty counted as sea duty and while there

participated with some advanced communications skills & equipment and got a

final top secret crypto security clearance, which wasn't required at the

particular area I was assigned to, only a Secret security clearance. The

Navy wanted me to extend my

enlistment another two years to participate at the specialized

communications facilities; one was there in Sidi Yahya which was located

between our Communications Receiver Site Facility referred to as

Special Projects and the Main Base which

had all the support

functions; mess hall, message center, crypto center, barracks, dependent

housing, special

services, motor pool, etc. I believe there were only five (5) of those

Special Projects type duty stations on the globe, but I declined the offer. When I

signed up for the program, you did not have to obligate the two extra years

of enlistment and this rule was changed while they did the background

security check which rendered my Final Top Secret Crypto Security

Clearance. I was told that a couple security personnel from Norfolk,

Virginia came to my home town and stayed a couple weeks doing the background

check, but I don't know that for sure. A Top Secret Security clearance

does require face to face contact interviews in addition to an extensive

background search.

I was selected from our Receiver site facility to participate in a

special project when King Hassan II made a trip to Washington, DC via an

Italian ocean liner and we set up a mobile ComSta in his private villa there in

Rabat. I did an internet search, but could not find a record of the

event. However, I still remember the ship being the

SS Raffaello which was an Italian ocean liner. I believe

their radio call sign was IBLO if my memory is correct. We had

a fleet of mobile trailers of which one contained an

FRT40

transmitter (40 Kilowatts) which took up the entire mobile trailer,

but not sure; it could have been the FRT39 (35 Kilowatts of power). We also had a trailer with

our receiving equipment, a message center and the support equipment needed

such as a generator trailer, fuel tank trailer, etc. We

were treated very well to say the least. Our special unit received a

commendation from the US Navy and the Moroccan Govt., if my memory is

correct.

At the Naval Communications Station were

housed the Naval Security Group

NSG which were comprised mostly of

Communications Technicians later renamed

Cryptologic Technicians

in 1976

and hyperlinked

here with their webpage with info from that era.

Their duty station work complex was located in the same building complex

(receiver site) as the Radiomen and basically, we had

no contact with each other due to security issues and protocols. There

were miles and miles of

rhombic full wave length antennas suspended

by very high large diameter wooden power poles mounted on concrete pillars.

There were also parabolic antennas, microwave antennas and a microwave

system to our main ComSta. The US Marine

Corps provided perimeter security for this building complex and the entire

base.

Above pix to left is a famous Church landmark there in

Kenitra, ocean side restaurant complex, laundry day at barracks and pix of

some shore base HF receivers. I used Niagara starch on the blue work

uniform pants and shirts, prior to ironing them as evidenced by them standing vertical. Later,

we had a Moroccan named Abdullah (pretty common name) that was our barracks janitor contracted to

do all of our laundry at a fair price too. It didn't take long in the

hot sun to dry your laundry either.

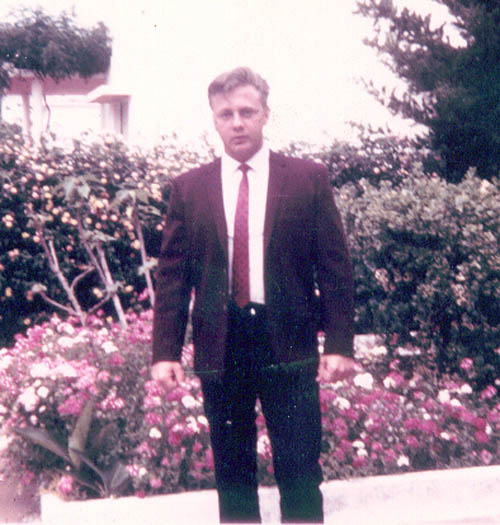

The pix to the far right below is Bill Porter & HC Morris in

Morocco, Africa 1966 (winter) on some R & R while in the U.S. Navy stationed about 20 miles inland

from Kenitra at a Receiving Station near Sidi Slimane and Sidi Yahya. HC is

from Cheraw, SC and retired from the US Postal Service. HC,

myself and others at our facility had

many adventures in Casablanca, Tangier, Rabat, Fez or

Marrakech, but can't remember which one Fez or Marrakech or both!

NOTE: Due to the

cold war

and other reasons which will manifest itself is

some of the hyperlinks provided, we were

required to wear a sports coat and tie to get off the base and our hair was

not cut short to give the appearance that we were military! There were

many foreign spies operating in the cities that we frequented while on

liberty aka R & R and we were trained to be on the lookout for them by their

mannerisms and of course any would be probing questions. For the most part, we didn't travel alone.

Our base had a sales representative and tailor from London, England that

would take our measurements and have whatever particular suit we wanted made

and shipped to our base. He was able to make on site alterations if needed.

I purchased three piece suits and sports jackets made of

Worsted wool,

Sharkskin,

Cashmere wool,

Herringbone Wool,

Harris Tweed, etc., but it didn't take, but a few years to out grow them

from the good food my future

bride provided!

Below a few pixs taken between August 1965 and July

1967 while in Morocco.

H. C. Morris, Cheraw, SC with Bill Porter, pix on the right.

Nov1966.jpg)

The above pix is one of my brides favorites. Taken at the Sidi Yahya

Communications Station (receiver site) in Morocco, Africa in November 1966; a letter from

home, no doubt from my future

bride to be, cup of Java and one of my

favorite magazines, Fur-Fish-Game. We used

Morse code as a novelty to communicate with the main ComSta to

keep in practice in case we ever had to use Morse code.

HEART FELT EXPERIENCE

Most of the things we as young sailors did while on R & R and not

fully committed to our

Lord Jesus Christ, does not lend itself to print and have no desire to do so. However, there was

one memorable event that happened sometime in 1966 while several of us from

our duty station were on liberty aka R & R in Kenitra, Morocco for a couple days

and met two young ladies from Canada employed by the Peace Corps.

Their names were Pam Mitchell from Toronto and Sheila Katz from Ontario.

Our hearts went out to them as only our Lord Jesus Christ can motivate and

inspire via His Holy Spirit and was evident they could use some help, whereas we treated them to a wonderful meal and

a bond of friendship and fellowship was immediately established.

Everything they owned was in their back packs which didn't look to overly

bulky either. We were perfect gentlemen and before they departed on their Peace Corps mission there in Morocco, we swapped

addresses with Pam and Sheila and we went aside and took up money from each of us and gave it to

them to help them on their journey since the Peace Corps definitely was not

a money making job; more or less for the experience and dedication of

helping people. It was one of the most gratifying wonderful feeling and

humanitarian experience of my tour of duty in Morocco. Pam and Sheila would send a

yearly card to my address at Grandma Coley's home on Maple Lane, Wadesboro, NC when they ended their

tour of duty with the Peace Corps and they never forgot the kindness we showed them.

I lost contact with them many decades back sometime around 1975 when Grandma's old home

place was sold and trust Pam Mitchell and Sheila Katz are still alive

and doing well!

PICTURE EDITING BEFORE PHOTOSHOP

My

bride did some editing on the pixs below

that were taken in Morocco, Africa with a pair of scissors and

made a collogue out of them...wonder what else was in those

pictures?..........grin if you must!

NOTE: The above background pix from August 1967

probably taken at Mehdia Beach, Morocco was badly

damaged by the acetate sleeve it was stored in. I ran it through

PhotoShop CS2 and cloned out some of the damaged pixels which were very dark

black spots on the photograph. As I stated above, my bride made a

collogue out of it by adding some pixs I had of myself with other persons in

the pix, of which she edited out with a pair of scissors....another grin is in

order. I worked out with weights as evidenced by the background pix.

I believe the photo was taken in mid 1966; however it wasn't developed

until August 1967 after I returned back to the USA from Morocco, Africa.

The

Six Day Arab Israeli War happened while I

was stationed in Morocco and communications was at a buzz for sure.

I am thankful that our Lord Jesus Christ extends his

grace and mercy to all of us and provides His Devine protection!

TF-140 NAVAL AIR STATION NORFOLK, VA.

My next duty assignment was the

Manned Spacecraft

Recovery Force Atlantic TF-140 which was at the Naval Air Station in Norfolk,

Virginia from July 1967 to Aug. 1968.

I was initially assigned to the message center while a

crypto room was being installed at the TF-140 building complex. After

the construction was shortly completed, my main duty at TF-140 was in charge of our facility crypto

room (only

personnel

in our section with a top secret crypto security clearance) to my knowledge and my

responsibility of getting the documents

decrypted, printed and routed

to the proper personnel. All that technology is obsolete and

declassified now, being replaced with on-line crypto

machines and systems in place due to the advancements in computers and of

course satellite communications.

APOLLO 4

I participated in the

Apollo 4 launch on Nov. 9, 1967 at Cape Canaveral,

Florida. Our team flew down TAD status a week before the launch

for specific tasks and we stayed in a motel there in Coco Beach, Fla. I don't remember

how long we stayed after the launch, but it was good to get back to Virginia

and be able to come home on the weekend to see my bride to be!

Pix taken at NASA Cape Canaveral, Fla. and

Mickey Porter at Coco Beach, Fla.

MARRIAGE

My grade school sweet heart,

Joyce Adcock and myself eloped and were

married on January 22, 1968 and did not tell anyone we were married until I had an apartment

rented for us in

Ocean View, Norfolk, Virginia which was not

very far from my duty station. She is still the love of my

life after 56 years of marriage and is my best friend as well! I can

not imagine life without her, our 3 children and 6 grand children!

I

first observed my bride

to be at the Wadesboro Church of God on August 11, 1957 as the entire

Adcock

Klan (ten of them) came into the sanctuary and

it was love at first sight both ways. She was dark tanned from the

sun, had a yellow dress on and long braided pigtails. A baby doll for

sure and still is!

First two pixs on the left taken at our wedding in

Chesterfield, SC and the right two pixs of my bride taken in March 1968 at Ocean

View, Norfolk, Virginia.

WORLD BOOK ENCYCLOPEDIA SALESMAN

One of the things I vividly remember, was all the sales

people that crawled out from under the rocks trying to sell World Book

Encyclopedias, etc. They would get your address from the utility

companies when you had your power turned on. I posted a sign on our front door alerting those sales

folks that I worked various shift hours and do not knock on the door

unless it was an emergency or military related, but

that didn't slow them down.

A friend of mine from our duty station in Morocco,

Kenneth J. Connors

left in the photo hyperlink who was assigned a ship there in Norfolk, Virginia

came by for a visit when one of the salesmen knocked at the door, whereas

the salesman paid no attention to the sign I had posted. This guy was

selling World Book Encyclopedias and had a slight speech impediment. I

decided to have some fun with him and let him pull out every sales poster he

had of which sometimes he would pull them out and show them upside down and

of course we cracked a pretty good grin at his expense. I led the guy to believe I

was very interested and going to purchase a set of the encyclopedias.

When he brought out the

sales contract and ink pen, I told him, I wasn't buying a set and reminded him at the

beginning I was not purchasing a set of World Book Encyclopedias. I

thought he was going to cry for a moment and he sarcastically said, well, if

it is going to take bread off your table and I told him purchasing a set

would not take bread off our table. It was hilarious to watch him try

and get all the sales brochures and posters back into his brief case and he

departed with some of the posters hanging outside his brief case.

My friend Kenneth J, Connors from Kalispell, Montana and myself had a good

laugh off the guy. I know it was a little mean to do such, but

sometimes you have to "break someone from

sucking eggs."

That guy didn't give up, but sent someone else over and

he was sent on his way as well! I realize those folks were just trying

to make a living, but not every sales potential is a

blue fin sucker either;

gullible for you non southern folks.

Being a newly wed couple, World Book Encyclopedias was

definitely not on our agenda, however years later when our kids were in

school, we did purchase a set.

Modern technology has made the World Book, Encyclopedia

Britannica, many magazines and some newspapers going digital.

BACK TO THE TF-140 NAVAL AIR STATION

NORFOLK, VA.

It was January 23, 1968 when the North Koreans captured the

USS Pueblo and of course

plan B went into effect for secure encrypted communications, not aware that the

Walker Spy

Ring was doing serious damage to our cryptic communications by

handing over copies of current code keys to the Russians. Open the

above USS Pueblo hyperlink which details now

declassified information as far as cryptic equipment

inventory on board the USS Pueblo.

On May 22, 1968, the

USS Scorpion went missing and was later

located with all types of speculation as to what caused the accident.

I did four (4) years in the US Navy and was never

assigned a ship; imagine that! Remember the IBM punch

cards.......grin if you must!

My enlistment in the US Navy provided valuable job

skills training for later usage and an accelerated course in growing to

manhood very fast. However, most of my communications training and

skills were only applicable in an active duty military environment and/or

Defense Contractor type employment. The electronics training was later put

to usage with the North Carolina Telephone Company and passed the FCC

First

Class Radiotelephone Operator License exam on the first try in Norfolk,

Virginia in 1969.

HYPERLINKS SUBJECT TO PUBLIC DOMAIN

NOTE: All references to my military career

as far as communications, etc., are now declassified

as noted by some of the hyperlinks related to the USS Pueblo, USNS

Valdez, USS Liberty, Sidi Yahya and subject to public domain.

Upon honorably discharged from the US Navy on August 3, 1968, my

Uncle J. Mack Coley (now deceased) being Quail hunting friends and Masonic member

with Jack Miller, (now deceased) Vice President of the Outside Plant Operations for the North

Carolina Telephone Company, Matthews, NC, set up an interview with Bob Presson, (now

deceased) Manager of

the NC Telephone Company in Marshville, NC for a job interview.

Talk about a one of a kind job interview, Bob Presson

wasn't aware ahead of time of the interview for a Radio Equipment Engineer

position/job which consisted of installing and repairing two way radios,

base stations and mobile telephones, parts ordering and inventory for the entire telephone company which

spread from Matthews, NC to Pinebluff, NC. This was a hands on job,

not sitting behind a desk with a slide rule, predating the invention of the

personal computer. The

transistor was invented in 1947 and the

silicon chip was invented in 1961 and the US

Navy was heavy into the solid state circuits after WWII with the new technology replacing many vacuum tube

applications, however large transmitters still required those monster vacuum

tubes and power hungry power supplies. All the transmitters and

transceivers within the N.C. Telephone Company still had power amplifier

vacuum tubes, however most of the receiver portion were all solid state.

Bob Presson and only one other person, Ralph Starnes

(both now deceased) within the

North Carolina Telephone Company had an FCC Second Class Radiotelephone Operator License which was

required to adjust said equipment; e.g., power output, frequency, modulation

for the two way radios, mobile telephones and the three (3) microwave

stations located at Marshville, Wadesboro and Norwood, NC.

Bob Presson told Jack Miller, "He thought he was doing a pretty good job of

maintaining the radio equipment." After the interview and being hired

for the job, all three of us went down into the basement where the radio

repair shop was located and you could hardly walk through the door for all

the two way radios and mobile telephone equipment needing repairs.

Within, the three month "trial period", I repaired all

the defective units except one which was later repaired. I maintained

that job until 1972, whereas I trained my replacement Bobby Simpson (now

deceased) of New

Salem, NC, who worked under the FCC license of Bob Presson and I transferred to

my home town Wadesboro, NC working on inside office equipment specializing on Microwave, multiplex equipment, ITT, Stromberg Carlson,

Viacom, Motorola, RCA, GE and special circuits requiring modems and

switching equipment until 1975. At the same time, I was running my musical

instrument repair mail order business and attended the local Community

College until 1978 studying business. I earned a two year degree in Business Administration

and Industrial Management. While working with the NC

Telephone Company, I maintained an Amateur Radio Advanced Class "Ham"

license call sign WB4GAN and kept a 300 ft. long wire antenna and

Collins

KWM2A transceiver at our radio repair and installation facility

which was relocated in the rear of a large warehouse complex offering much

more room and at ground level. I chatted and Morse code with folks all over the world

during down time and kept a banjo and Dobro close by too. I was also a member

of the Navy

MARS program call sign N0KOU.

I worked under Bob Presson's

Second Class Radiotelephone License for about six (6) months and went to

Norfolk, VA in 1969 to the FCC licensing facility and passed the Second

Class Radiotelephone License. I went back to Norfolk, VA about six

months later and passed the

First Class Radiotelephone License.

The FCC revamped all their commercial licenses and changed the

First Class Radiotelephone License to a General Radiotelephone License

(General Radiotelephone Certificate). The FCC later issued lifetime

licenses instead of having to renew every five (5) years.

I still have a

current FCC Commercial Radiotelephone Operator License which collects dust

and guess too much of a good thing (electronics) can burn one out.

UNFORGETTABLE REPAIR

EXPERIENCE

Sometime before 1972 when I

transferred to Wadesboro, NC office of the North Carolina Telephone Company,

I had a very unforgettable repair experience of which I will try and

explain. The two way radio base station in the Wadesboro office had a

trouble in the receiver section that was allowing garbled noise to enter of

which the system had a private line feature which would only allow

transmitters that possessed a very low cycle tone riding on the main carrier

frequency to unlock a circuit in the receiver allowing that transmitter to

be heard.

I checked the entire receiver

section circuitry and could not find any voltage or resistance check that

was out of tolerance. I was under a tremendous amount of pressure

since we did not have a spare or back up transmitter/receive for the entire

two way radio system. Also, the President of the Company's office was

located in this building also adding additional pressure.

After a long hard day of trouble

shooting trying to ascertain the problem and fix it, of which didn't happen

that day, I remember during the night dreaming about the checks that I had

made during the day and what I am going to tell you, had to come from God's

Holy Spirit. While in the dream I was directed by an unseen hand to

the exact problem which was a power supply

electrolytic capacitor as the source of the

problem. The next day, I checked that capacitor and had a replacement

one in stock and took the replacement capacitor and touched the leads from

it to the capacitor in the circuit and the problem immediately cleared up.

Apparently the electrolytic

capacitor had dried up and without an oscilloscope to see that the power

supply DC voltage had an AC ripple in it, it was about impossible to locate.

Anyone that doesn't believe God

works on our behalf is a

fool which the Bible refers to

non-believers.

I was the only employee with the

NC Telephone Company that had

a

First Class Radiotelephone Operator License which allowed you to operate and

maintain TV, AM, Microwave and FM broadcast transmitters as well as two-way radios and mobile

telephones in the private sector. The FCC years later,

changed both the First and Second Class Radiotelephone Operator License to a

General Radiotelephone Operator License

(GROL) which later was lifetime, whereas the

others had to be renewed every 5 years.

One of my friends who is/was a PC

and IT guru stated, "that license might

buy you a cup of coffee today"...we

both got a good grin out of that statement!

During the summer of 1974 and

until July 1975 (guesstimate on the dates), our

section worked seven days a week for several months and I remember one pay

check which had 80 hours regular time and 79 hours overtime. We

installed inside office switching and multiplex equipment on the weekends

that would have normally been contracted out. I was burned out with

the job and decided to go full time with my musical repair business, which

was still doing fairly well in 1975 even with the recession of 1973 - 1975

coming to a halt.

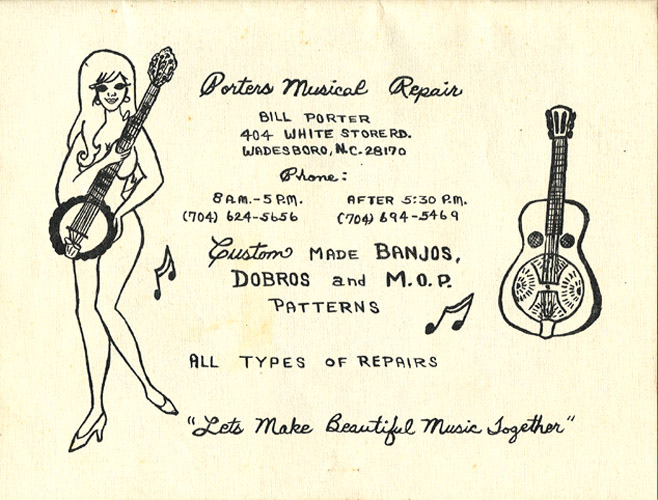

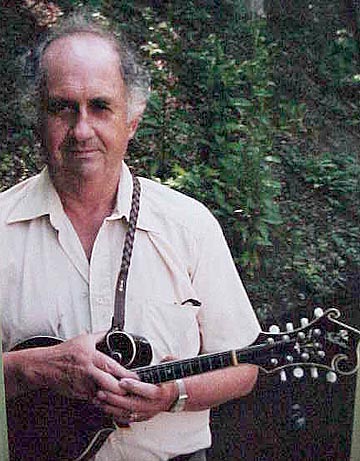

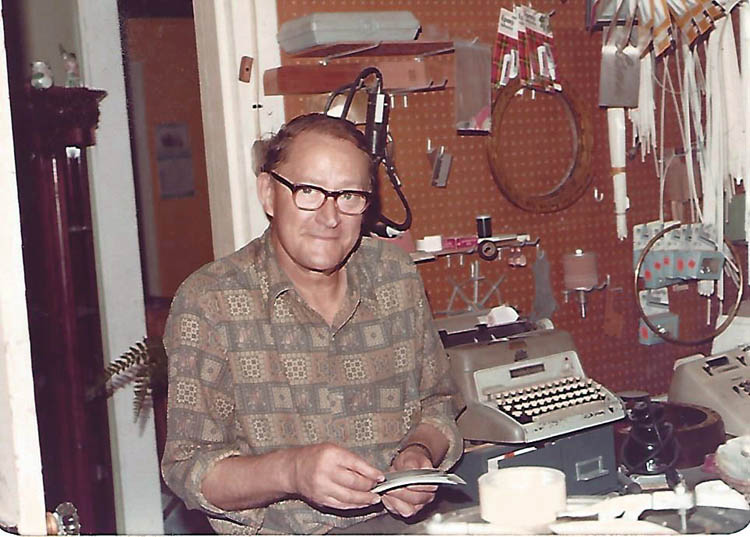

William M. Porter

"still

kicking", is no stranger to woodworking and custom made

products having owned and operated a mail order business from 1969 thru 1978

under the business names of Porter’s Musical Repair and Porter

Banjo Company, however I started acquiring the data and Intel collecting

process much earlier. In addition to supplying factory replacement parts for banjos, mandolins

and guitars, I custom made mother of pearl and abalone pearl

inlay patterns

for prewar vintage instruments specializing in Gibson Mastertone

reproduction and conversion work and various stages of completion of banjo

necks, resonators, fingerboards, peghead and metal fabricated parts. I have

supplied mother of pearl, abalone inlay patterns and specialty

components to Gibson (inlay

patterns only via Carlton Pease), Martin (snowflake inlays via Mike Longworth), NBN,

GTR, Dobro, OMI (Rudy and Ed Dopyera), Custom Shops and Instrument Builders; e.g.,

John Monteleone,

Louis Stiver, Mandolin Brothers,

Frank Neat,

CE Ward, Bill Sullivan,

Jim Yarboro,

Bob Shoe,

Rural Yarborough,

Jennings Chestnut,

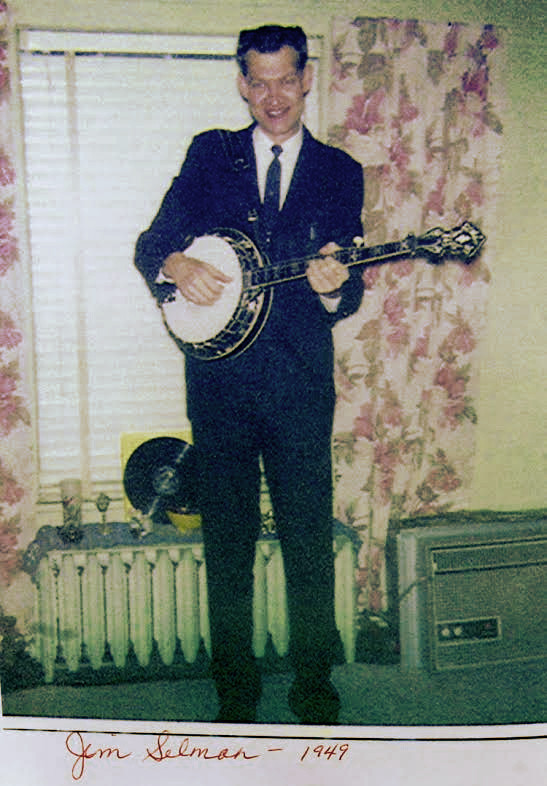

Jim Selman,

Dave Kennedy,

Harold Chriscoe,

Paul Tester,

Tom Morgan via Paul Tester,

Bill Gibson, John Janzegers,

Paul Sasser,

Frederick L. Snyder, Wilburn and Brons Hasty,

Bob Campbell,

Andy Boarman,

Joseph F. Wallo,

David Musselwhite,

etc., all over the United States and several countries. I still have

an old card file index of the mail order customers, however many are now

deceased.

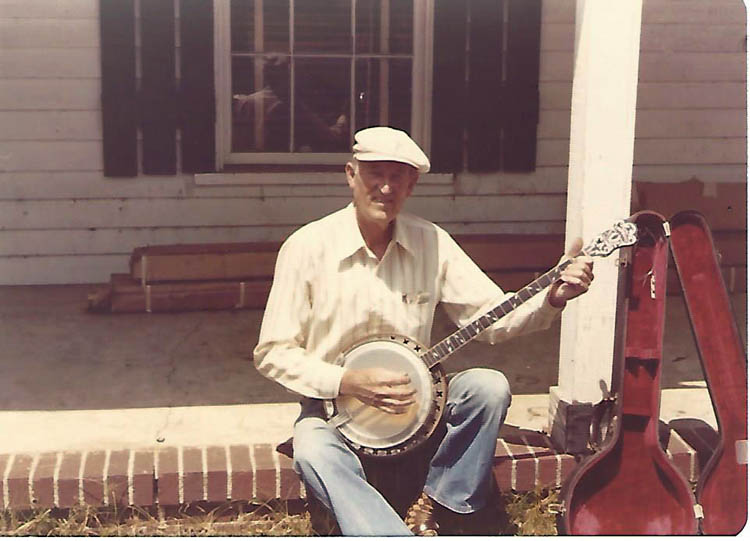

THE OLD TIMERS CLUB

Back in the early to mid 1970s, I played with a group

called the Old Timers Club consisting of

Adzie Martin on the fiddle, Shuman

Lear, guitar and lead singer,

Brutus Gale on banjo and Bill aka Mickey

Porter on Dobro, of which all were retired (except Bill Porter) for a number of years, maybe a

decade or more. We would meet on Saturday morning at Shuman Lear's

store at the junction of Old Lilesville Road and Highway 52S in Wadesboro,

NC. The style of playing (Piedmont style) was ole timey all the way; no bluegrass!

This style was indicative of music played here in Anson County, NC back

during the 1920s through the 1940s with the banjos being picked with two

fingers versus three. We would also play at the local nursing home and it was a

tremendous amount of joy, whereas many of the

residents didn't have family members that visited them for whatever reason.

God gives us many blessings throughout our lives and I thank God through Jesus Christ our Lord

and Savior for each and every day that He allows.

Shuman Lear's Brother David played fiddle with several

groups and a pix of him is with the Dewitt Wheless

group back in the mid 1930s, further on down in this bio.

Bill Porter picking Dobro in 1975 with

"The Ole Timer's Club".

Bill Porter picking Dobro in 1975 with

"The Ole Timer's Club".

Here is a

link to a 31 minute recording from a reel to reel tape, then to

cassette and then digitized to .mp3 file which

is around 37.5 Megabytes in size, therefore right click on the link and

save

as instead of streaming. The audio is not that great since it was

recorded in Shuman Lear's Store next to Highway 52 South with regular

traffic coming by and customers coming into the store for small purchases,

etc.

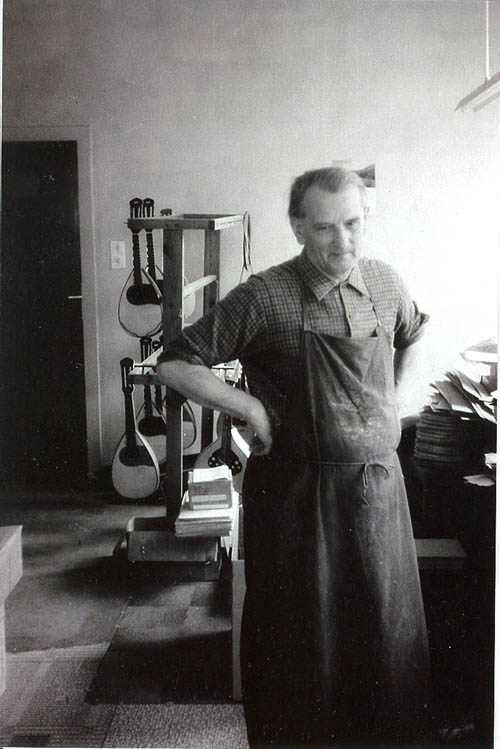

SHOP PIXS AND INFO

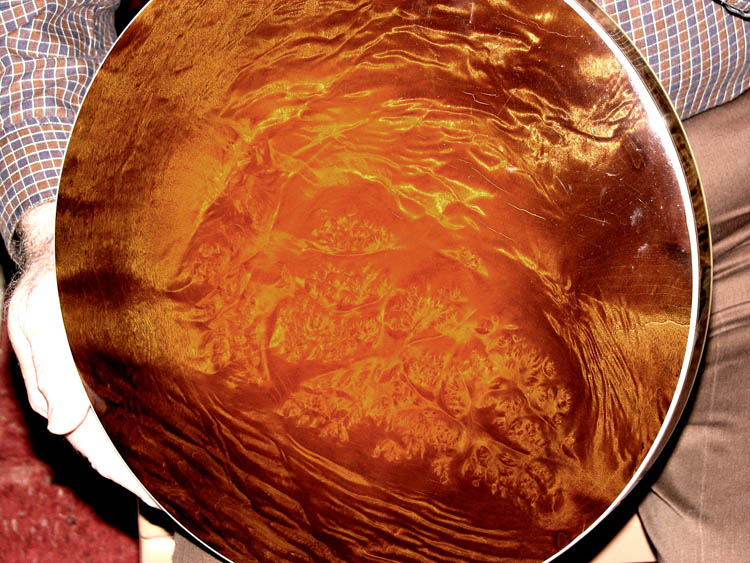

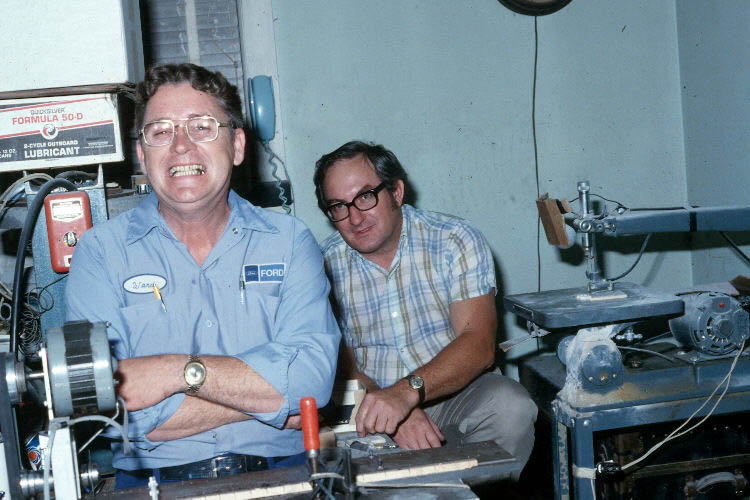

The above pixs around 1977 and compressing 3 to 5

plys of veneers to

form a curly maple Granada resonator back for a banjo

and adjacent pix of some burl walnut resonator backs for #5 Deluxe

resonators. Press was custom made using a steel channel frame and

a 20 ton manual hydraulic press with heating elements on both upper and lower

molds. The molds were made from aluminum truck pistons that were melted

down and sand cast with final truing of both pieces on a tape feed NC lathe.

Harold Chriscoe of Seagrove, NC purchased the above resonator press with

over 400 pieces of 15 inch square 1/16 inch thick extra nice curly and bird's

eye Northern hard maple veneer and Gibson original type 1/10 inch

poplar for the center core of the resonator backs sometime around 1980.

Harold let Doug Hutchins have the resonator mold and raw

materials of which he is not using the press, but has it in storage. John Bowles of Advance, NC ended up with the matching curly

maple side pieces if I am not mistaken since they were thick enough to use

for violin and mandolin sides. Very few craftsman today

fabricate a resonator back and sides identical to pre-war Gibson's.

Several custom banjo makers "cheated" a little on the resonator

sidewall construction which is acceptable by using multiple style laminations

instead of the Gibson style of construction. To basically get the same

Gibson look alike or clone results, a 14 to 15 inch diameter 1/2 inch wall

thickness hard maple drum hoop could be used without any steam bending and you cut it

down to the required size with a band saw and cut the proper length lap

taper (scarf joint) of which saved a good amount of time and did not require a lathe

turning operation, only a table router set-up. Back in the early 1970s, the

drum bent hard maple wood head hoops were very cheap and

readily available about 25 miles from my shop. The center poplar

lamination was mimicked by using a 3/32 to 1/8 inch veneered panel which had a

heavy poplar core and was easily bent to shape without steam and the outer

face lamination was glued in place with contact cement and/or hide glue,

etc.

My custom made sidewall press consisted of an outside diameter

steel mold/ring and the center compression element that featured a three jaw lathe chuck with three special

shaped cauls to contact the inner lamination. The three jaw chuck

applied enough pressure to compress the plys.

NOTE:

Frank Neat of Russell Springs,

Kentucky recently obtained the above resonator mold/press and the side wall press

from Doug Hutchins and also the Kennedy "Jellyroll" prototype

wood rim machine that I used for a few years. Updated on

05-31-10 by Bill aka Mickey Porter.

There is night and day difference between volume and

tone when swapping around resonators on some banjos that have the top

tension hoop and others as well. Gibson in later years (post-war) used

glue in thin flexible membrane sheets placed between the resonator back

laminations that were activated by the usage of high frequencies reducing the

amount of cure or dry time! I personally prefer the old style of

construction as they seem to sound better to me! I don't think there

is a cure for

Psychological Bias

which I probably have too!

A few more pixs from the musical instrument making

days: Sheet brass .063 thickness was die stamped to fabricate a metal

flange for early

Gibson tube and plate banjos. Mr. Lomb of

Waverly in NY

purchased sheet brass and brass tubing for me direct from the mill and had

it drop shipped and saved me a pile of money on raw material cost. I

still remember the empty coffee sacks and Jewish newspaper they used to wrap

and send small parts like

pre-war replica banjo hook nuts, etc., and they knew how to be conservative and

frugal. Some of the best nickel plating on my tube and plate flanges

were out sourced to them and the copper and gold plating was done in High

Point, NC. Old timers like Mr. Lomb are a thing of the past when it

comes to helping someone get started in business!

Insufficient capital

is the main failure of a small business.

Tone hole die set in action.

Tone hole die set in action.

The plate

portion of the tube and plate flange aka two piece flange required a 60 ton press to stamp the OD/ID and was “farmed” out

to a metal stamping company in Charlotte, NC of which I owned the large die

stamping set and the

rest of the stamping was done in house using a small 5 ton mechanical

press with an indexing fixture. I went through three (3) manufactured

tone hole die sets to finally get one manufactured that was a perfect match for the

original tone holes in the plate and that die set was produced with an

optical grinding system directly from a black and white photo of an actual

size tone hole. Parts were then "out sourced" and

nickel and/or copper/gold plated. A few years later, Gibson Musical

Instruments decided to produce the tube and plate flange again due to

increased demand. That part had not been manufactured by Gibson since

the late 1920’s, however their new tube was much thinner walled than the

original and they milled more off the back side of the tube for the plate to rest

against and many broke where they were silver soldered together. The

multi-ply plywood wood rim that Jasper Wood Products supplied them was equally as bad

and would not support the tension exerted between the flange and the tension

hoop, pulling the bead portion of the wood rim upward and on some banjos a

complete separation. Horrible indeed! It is very sad not to

be able to produce a replica of a part that you originally made and

attribute that to the "Corporate Greed Of America"

mentality! Out sourcing parts is fine if the quality is there,

however the bottom line on a spread sheet is the culprit most of the time!

The tube portion of the tube and plate

flange aka two piece flange required a bender with

special spiral tooling to transform a ten (10) foot section of 3/8" diameter

heavy wall (.095 +- .005 inches) brass tubing into a helical coil rendering 3 complete units and it took seven other fixtures including silver soldering and a

lathe operation. My tube and plate flange was identical

to the original 1925 parts or at least the pre-war original I used as a

pattern since there were a couple different ID for the tubes no doubt a

product of tooling changes/wear, etc. of which was a very

small variance.

Many have asked what model bender did I use to roll the

tubes and it was a

Di-Acro Model 2 or Model 3 Hand Operated Metal Working

Bender; can't remember which. When I started manufacturing

climbing tree stands for deer hunters around 1986, I had a larger

version of the bender made; farmed out the lathe parts and assembled the

bender myself. Later, I purchased a Di-Acro Model 4 bender with

factory tooling for the

tree stands since I needed a much tighter radius

bend without distorting the tube diameter and a larger/heavier bending capacity for

special applications.

Those benders were/are expensive and worked great with the

proper tooling. Updated 06-23-18.

PORTER FLAMING CLAW BANJO

While manufacturing the pre-war tube and plate flange,

I made a prototype plate (circa 1975) for the tube and plate flange and used a copyrighted design from my "flaming Claw"

inlay

pattern and below is pix of the plate portion of the "Flaming Claw" tube and plate flange.

The tone holes (which resemble the

Cape

Buffalo's Horns) were cut using a jewelers saw blade and was very

laborious. I had intentions of making my Porter Flaming Claw

Prewartone banjo, but

the inlay and parts business kept me at bay and traded the below one of a kind plate to Jim

Yarboro of Gun Barrel City, Texas and he installed it on one of his Noble

banjos.

Jim Yarboro built me a Porter Flaming Claw banjo using

inlays that I had cut and inlaid around 1975 in trade for a fret saw

machine, display trailer and other things when I went out of business in

1978 of which I think the trade was made around 1979; a guess at the best on

the date. That banjo featured special binding custom made by Jim that

consisted of black/white wire twisted together and embedded in some type of

epoxy material and was a very unique binding for the neck and resonator.

I traded and/or sold the banjo to Harold Chriscoe of Seagrove, NC. I

later got the flaming claw plate back from Jim in 2004 and might put it on a

banjo one of these days. The tone hole pattern is beautiful and the

proper size for sound projections from the resonator for the tube and plate

flange since the standard Gibson tube and plate flange banjo sits higher out

of the resonator which would normally lower the resonant frequency, but the

aperture (opening) between the bottom of the wood rim is increased which

accounts for a slightly higher resonant frequency which seems contradictory,

but the acoustics speaks for itself. My flaming claw tone holes might

be

slightly overall smaller than the pre-war Gibson tone holes which I believe lowers

the resonant frequency similar to the one piece flange set-up. The

aperture between the wood rim and the resonator has the same effect as

enlarging or reducing the size of the sound holes of other acoustic

instruments. Bill Sullivan (deceased) of First Quality after seeing

the flaming claw flange and plating it for Jim Yarboro, wanted to manufacture

his own plate flange with my tone hole pattern, but it was copyrighted even

though Jim Yarboro had the only one made, Jim Yarboro would not allow Bill

to manufacture it. I purposely did not stamp every other hook

hole larger on this plate like the pre-war ones since it is to my

understanding the plate aka flange could be removed by removing half of the

nuts if one wanted to play the banjo in open back fashion. However, I

did stamp every other hook hole larger on the pre-war replica plates I

manufactured. Pix below:

Above pix of my Flaming Claw pot assembly which will be

serial number 001FC with a Cox maple wood rim, Gibson USA Kulesh flat head tone ring

# 7236,

Porter Flaming Claw two piece flange, Huber Mahogany resonator and a Porter Custom Flaming Claw neck also in

Mahogany....See my banjo construction

home page for details. Finished banjo pixs below:

Banjo completed in late November 2010 and is

"one of a kind." I

plan to add a custom "Flaming Claw" armrest later. Never got

around to the armrest.....grin if you must!

I retired the above banjo to its case in January 2017

and started playing my custom build resonator guitar in our

Church and

other Church

functions.

The above banjo was brokered (sold) by my friend David

Musselwhite, Jonestown, PA in December 2021.

Web page updated by Bill aka Mickey Porter on 03-28-18

and 12-23-2021.

Around 1976, I started inlaying an engraved mother of

pearl PREWARTONE block at the 15th fret to the

fingerboards of my Flaming Claw banjo and used the

logo PREWARTONE on my banjo

strings and received a US Trademark Reg. No 1,044,105 on July 20, 1976 for

PREWARTONE.

I never did go into production with the banjo, because I could not keep up

with the custom inlay and parts sales. The parts and inlay business

was really booming after the movie Deliverance came out in 1972 featuring

the instrumental "Dueling Banjos", but sales started really

dropping fast before the end of 1977 due to the 1973 - 1975

recession we had. I had a lot invested in tooling,

whereas Japan started turning out "imitation" parts,

accessories, inlaid Gibson style fingerboards/pegheads, banjos and

reproduction stuff like

crazy. Japan supplied a tube and plate Gibson copy flange retail priced

cheaper than my raw material cost for my own replica two piece flange!

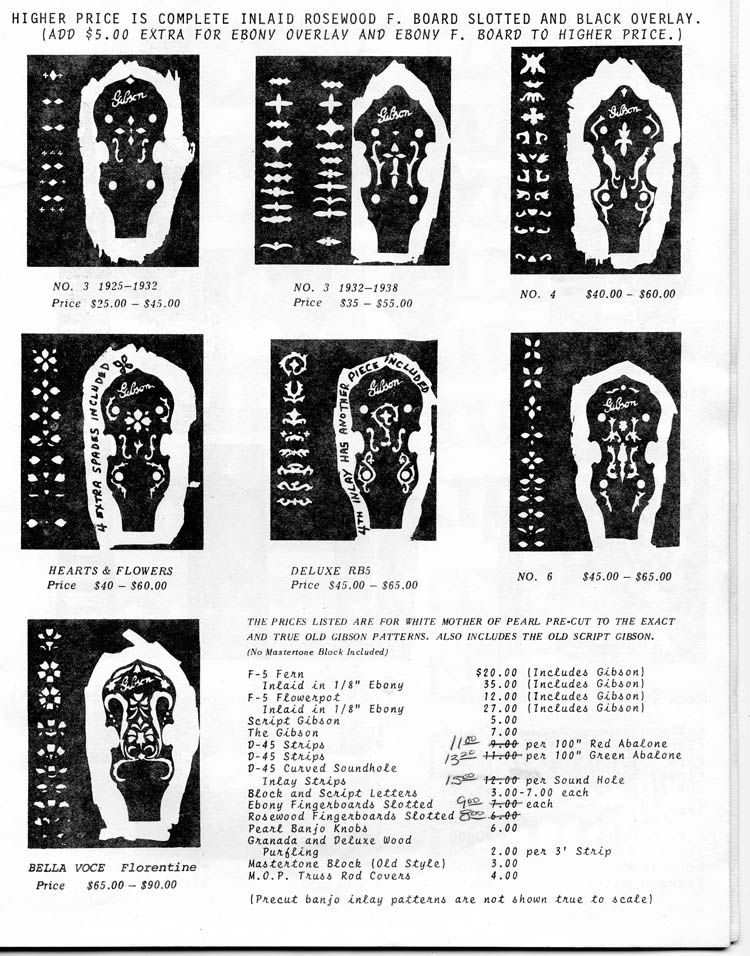

MAIL ORDER CATALOGUE

Pix above of my 1970's catalog mailed out and hard to

believe the price of a Gibson flat head tone ring which retailed for $33.00. A saying from one of my Ole Timer's

Club friends Brutus

Gale, "That was back when a dollar was big as a bed sheet"

which was a fairly accurate statement; a little before the inflation

of the mid to late seventies kicked in.

MINIMUM WAGE 1970

When I started my musical instrument repair service,

the minimum wage was $ 1.60 per hour and made some decent money from cutting

and selling pre-cut and inlaid patterns, mostly pre-war Gibson banjo

patterns which were in demand. See my

inlay patterns

page which details the time taken to cut 29 patterns of various Gibson

pre-war banjo mother of pearl patterns which averaged out to a little over

32 minutes per pattern.

I find it hard to believe

today that one could keep so many things going, but when you are in your

early twenties, the energy and enthusiasm level has to be at a maxim

as compared to the senior citizen status now....grin on that statement.

It was an excellent experience and did meet and make a lot of friends over the years!

The above address (now a vacant field) and telephone numbers are

obsolete.

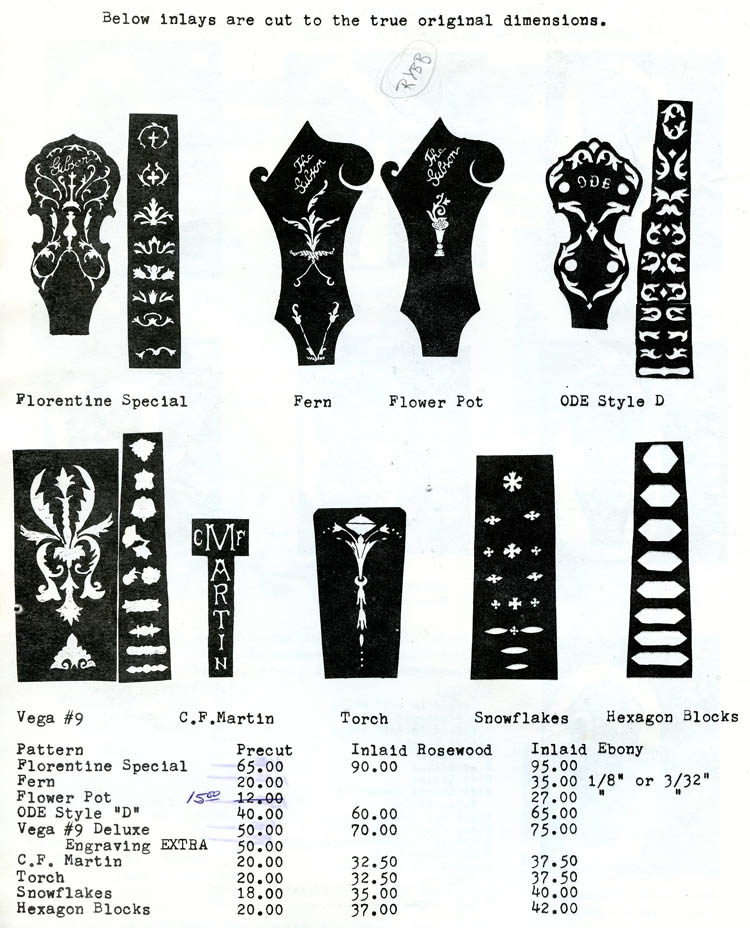

1970 INLAY PRICES FROM THE ABOVE

CATALOG

Below a scan of the inlay prices in the early to mid

1970s; inflation has certainly took its toll..........grin if you must!

Above pixs of inlay patterns were hand drawn and

definitely not true to scale! Check out my

inlay patterns

page for pixs of actual cut inlays by yours truly.

I would grin when people came from various parts of the

USA to visit and purchase parts thinking I was an old man.......grin if you

must! I was in my 20's at that time and now 78 as of 03-18-2024!

During my mail order business days, I purchased metal

standard stock banjo, mandolin and guitar components directly from

manufacturers that supplied Gibson and other musical instrument

manufacturers like; Kluson, Waverly, Grover, Zaharoff,

Bird's Eye Maple, Schaller, Harris Ltd., etc. and

was able to sell at a minimum of 20 percent below retail price (MSRP) and items

manufactured in West Germany (specialty items) such as wood purflings,

bindings, etc. , a sizeable mark-up was possible before the devaluation of

the dollar took place. Ebony back in those days was jet black with

very little white streaks and the wonderful Brazilian rosewood before the

trade embargo!

I had Mr. Lomb of

Waverly Musical Products in NY to manufacture the old style banjo

nuts for me and was probably the first one to offer those old style long hex

nuts to banjo builders via mail order. All Waverly had to do was make

a special set of cams for their machines and the rest is history.

StewMac offered the same banjo nuts when they procured Waverly Musical

Products in the mid 1970s or later.

MOTHER OF PEARL

Pix

of several banjo fingerboards and pegheads being inlaid with mother of

pearl. Mother of pearl price in the early 1970’s was around $35.00 per

pound. Now the price is over $400.00 per pound. In the 1970's,

Porter was considered

"The Source" for accurate Pre-War reproduction

inlay patterns. I normally kept about 20 sets of pre-cut inlay

patterns for each standard pattern on hand and inlaid in the Gibson pre-war

style by cutting a hole through the peghead and fingerboard material.

With many pre-cut inlay pieces on hand, I was able to choose an individual

inlay piece that matched the pre-cut hole in the peghead and fingerboard

with a high degree of precision. Gibson and their vendors stacked up a dozen or more

peghead veneers and pegged them together and cut through all of the veneers

using a German made marquetry saw using a large #6 jewelers saw blade. If

your saw is accurate enough and you don't force feed/cut the material, the

piece on the bottom of the stack will match the original pattern very close.

Inlays produced today using the high technology CNC machines are far

more accurate and precise, but lack the individual artistic touch and

variation in design that the Gibson pre-war instruments posses.

Post-war CNC and/or rotary machine production inlays emulating Gibson patterns

from the early to mid 1970s from their vendor(s) look like they are cut using a cookie cutter,

e.g., RB800,

meaning each individual piece is exactly like the other without the old

style square saw cut backs into the design which gives it character and eye appeal.

It is to my understanding that Mar Pearl did a good bit

of inlaying Gibson's fingerboards and pegheads during the 1970s. I

have personally talked with David E. Markle (now deceased) and he designed

all the machinery used to route the inlays and pockets for the inlay work he

did for Gibson. He was running about 10 custom built routers that had

all the whistles and bells and I believe used a cam system to produce

identical inlays that used more or less an outside profile......long before

the CNC stuff. He also dusted his own diamond wire for cutting

inlays to use on his own diamond wire machine...he was at the top of the

inlay game back then for production stuff.

Gibson and/or their pre-war pearl vendors used poplar wood (heavy veneer) at least 1/10 inch as a backing for

their Mother of Pearl and Abalone inlays and it not only gave support to the

material, but used as a means to maneuver the material into the

jewelers saw blade. I have seen a few tenor/plectrum necks

cannibalized for the inlays that had mahogany used as backing for the mother

of pearl inlays, but this is rare! The German made marquetry saws Gibson used for

their pre-war inlays has long since been out of production and the new

machines are not as accurate in my humble opinion and do not have the stroke

length to utilize more of the jewelers saw blade.

CNC machines (routers) producing mother of pearl and abalone

inlays and inlaid fingerboards and pegheads is definitely the way to go for

production and there are some fine examples of artistically

produced designs

only limited by the programmers artistic ability since

cutters

are now very

small and durable! I certainly don't mean to detract from the many

artists using those machines, but I personally don't like them on pre-war Gibson

inlay designs though. It just doesn't have that variable hand cut look

to the inlays. CNC machines definitely has the precision not found in

hand cut designs. I am sure if Gibson had access to such machines in

pre-war days, they would have used them! No more inlays that I do, the

cash outlay just doesn't justify owning a CNC machine.

A trick in removing Gibson inlays and backing

from pre-war fingerboards is to use vinegar saturating the inlay area and

the vinegar will normally dissolve the binder used in the filler. Try

it and you might be surprised! The trend now days is not to

destroy the original tenor and plectrum necks, of which I don't ever

remember cannibalizing one for inlays.

Above pixs of a few of my Gibson Mastertone banjo

mother of pearl inlay patterns

(master patterns) I cut and had

them photographed and offset printed patterns for cutting and inlaying

purposes. Little digital camera doesn't capture the detail in the cuts

since they are mounted under glass. It was individuals like

myself and many other custom instrument makers that "forced" Gibson

Musical Instruments to reintroduce their old style Mastertone series banjos

due to the huge increase in demand. It only took them about four (4)

decades to get back on the band wagon so to speak.

NOTE: I gave the above master patterns to

David Musselwhite.

NOTE: GIBSON USA takes a firm

and aggressive stance against all makers of counterfeit instruments and

their distribution channels, therefore I would caution anyone against making

a complete Mastertone aka Masterclone of their instruments, present day and

past using the Gibson

logo on the headstock although the early inlay patterns sans the Gibson logo

are subject to public domain.

Pix of some of the Gibson Mastertone Pre-War tenor and

plectrum necks collected over the years of which most were manufactured

prior to 1930 as evidenced by their FON and the quality of the inlays. I counted about 35 at one

time and had an original Pre-War five string

RB3 (late)

neck that Tom Morgan

of Tennessee had cut in half to see how the truss rod worked; at least

that's what Paul Tester of Landover Maryland - deceased related to me of

whom I purchased the neck from. The neck was operational at the time

it was cut in half end to end and I believe had a broken heel that was repaired. The above

1/2

RB3 neck (5th string side) is in the

above pix, 4th from left in the background beside the Hearts & Flowers neck

which has the Mastertone letters inlaid in the peghead! If

memory is correct, the truss rod configuration is opposite from what one

would think, but what makes it work is the entire truss rod is still below

the center line of the neck, therefore the weaker side gives it in to the

force straightening the neck if the neck is bowed. However, the truss

rod doesn't work for a back bowed neck. My entire Gibson pre-war neck

collection was sold to Wayne Peterson in Minneapolis, Minn., but he

said he didn't get the pre-war 1/2 5-string banjo RB3 (late) neck and can't

remember who I sold or traded it to or if I had both halves of the neck at

one time either! CRS disease I guess! The 1/2 neck did

have some of the original inlays still in the headstock and fingerboard at

the time I owned the neck.

Below is a cropped pix showing the 1/2 Gibson pre-war

RB3 neck when I owned it:

Pre-war Gibson banjos for the most part, did not have

the poplar wood backing on peghead inlays since the inlays were approximately

the same thickness as the peghead overlay veneer. However, the

fingerboards did have the poplar wood backing. On my

banjo construction

pages, I detail how Gibson and/or their vendors manufactured the pegheads

and fingerboards. Gibson outsourced about all their production inlay

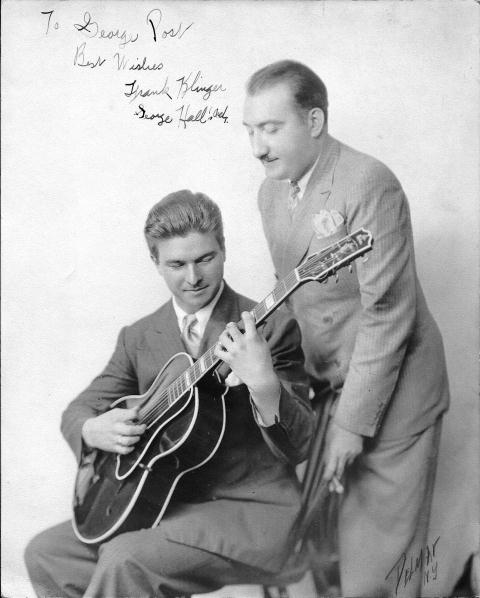

work, but did do some in house inlays per George E. Hall, Gibson employee from

1927 thru 1933.

UPDATE on the RB3 late 1/2 neck cut in half

lengthwise; I talked with Jim Runnels at Huber Banjos today 11-16-11 and Jim

verified that the neck they have is the one pictured above, RB3 late model

leaves and bows and also has the neck heel repairs. There is a link on

the Banjo Hangout that gives a complete history of that RB3 late neck.

Joe Spann sent pixs of the RB3 late 1/2 neck and someone had removed the

peghead overlay cap and replaced it with a much thicker material (without

inlays) and had distorted the true shape of the peghead some. I can't

say for sure it is the same neck, but in all probability, it appears to be one

and the same. Why someone would saw the original headstock veneer off

the 1/2 neck blank and replace it with a regular piece of wood is beyond my

reasoning.

http://www.banjohangout.org/topic/220350

I also talked to Tom Morgan on 11-17-11 and he

remembered the neck very well, however I failed to ask him where he got the

neck from. Tom did state that it did not come from Paul

Champion's banjo. Pix of Tom Morgan below:

Tom Morgan from Dayton, Tenn. is considered

"The Dean of Bluegrass Luthiers" and

through Paul Tester (deceased), I received very valuable information, samples and

specifications of Pre-War wood purflings, bindings, inlay trim,

original neck carved heels for carving patterns, etc.; to have those

specialty items manufactured in West Germany that were not available at the

time, whereas I later offered them through my mail order catalog to

builders.

Tom was decades ahead of the old and new pack of banjo

builders/banjo gurus and certainly is "THE DEAN OF

BLUEGRASS

LUTHIERS"! Take a look at the below links

for additional info:

NOTE: Tom passed away on September 26,

2024

http://lfs.alexanderstreet.com/liner/39a76d2a16f1b32a3e4ce0b34d9cf8e4/FW31072.pdf

DC Bluegrass

Union

Picture of Paul Tester picking his RB5 Wreath Deluxe

arch top banjo with Harold Wilson 1972 or 1973. Photo

courtesy of Harold Wilson.

Note: Wayne Peterson doesn't have any of

those Gibson necks left, however he does have plenty of old catalogs and a

few other odd ball necks and other things of interest for the collector! 10-29-09.

I used the best of Gibson's inlay work in order to get a

master pattern cut for myself. Some of Gibson's inlay work were

horribly cut and most of their inlaid fingerboards and peghead has a

tremendous amount of filler, but I have seen some examples that would be hard

to replicate that were nearly perfect also. The workers at the factory

were on production and got paid extra for anything above their production

quota according to George Hall of Kalamazoo, Michigan - deceased.

There were a few "odd balls" in the above group made by Gibson and had a Bella

Voce with a different fingerboard and have seen and had original necks with

mismatching inlay patterns apparently ordered by the original customer. It appears that Gibson's only consistency was their inconsistency!

I believe my assessment of pre-war Gibson would classify as a true

paradoxical statement.

There is a very noticeable difference in the quality of

Gibson inlays prior to the 1930s and surviving records point that two

different companies provided Gibson with inlaid mother of pearl pegheads and

fingerboards before and after the 1930s. Joe Spann, Research Library

Director is authoring a book on

Pre-War Gibson which will uncover and unlock

a lot of information concerning various facets of Gibson's history and

banjo production!

Above pixs of a custom inlaid Smith and Wesson skinning

knife that I did for myself around 1975. I retired that knife to my

show case in the early 1990s. The

mother of pearl inlays are from a copyrighted pattern of mine titled

“Flaming Claw” and my standard pattern I used on banjos and Dobro

aka resophonic guitars. The inlay work on the knife handle was all

free-hand if I remember correctly due to the curvatures of the handle on all

sides. The above knife, glass display dome and other inlaid and

custom knives were given to our son,

Bill Jr., on 07-08-16.

Specialty items and parts such as the Pre-War Kershner

banjo tailpiece, banjo hook nuts, Pre-War wood purflings

for Gibson Mastertone banjo Granada, #4, #5 Deluxe and Martin

Pre-war wood purflings were made in West Germany for me and the first to

offer those exact reproduction items for sale. I also had F-5 style

bridges made in Germany. There were some close

imitations out there, but none as precise as those I had made. Note:

Pre-War references prior to WWII.

JIM YARBORO NOBLE TOP TENSION BANJO

Jim Yarboro sent me a couple pixs of a banjo he built

in 1986 using one of the Flaming Claw peghead overlays that I cut and

inlaid. I traded Jim a dozen of those inlaid peghead and fingerboards,

(If my memory is correct) that had my copyrighted Flaming Claw

pattern. I currently have patterns 13

& 14 on a banjo and resonator guitar. Jim inlaid a mother of pearl

engraved Noble block where the script Porter would have been. Below is a pix of

the banjo that recently came back to him for a set-up, of which the banjo

was sold by Gruhn Guitars of Nashville, TN to its current owner.

Jim purchased a pre-cut set of the tree of life inlays

and said it took him all night to inlay them. Jim is a top notch

craftsman!

Updated webpage by Bill aka Mickey Porter on 06-22-18.

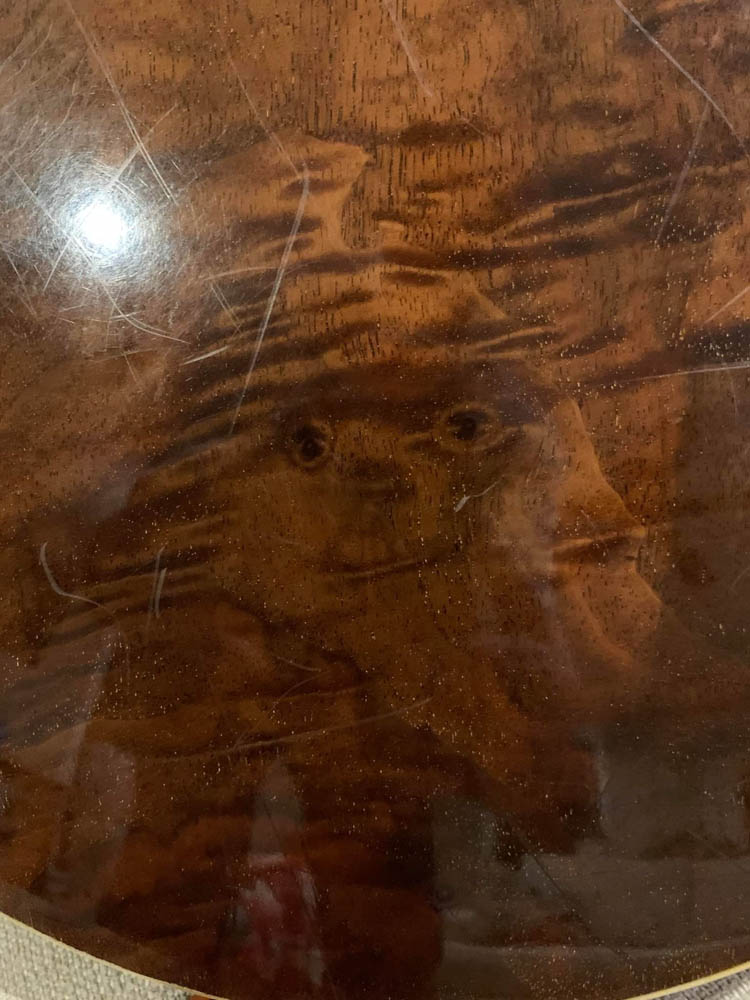

RESONATOR BACK FROM MY PRESS

Below is a pix of the resonator back on the above

banjo. I traded and/or sold Jim a number of resonator backs in curly

maple and figured walnut, but no side walls. Jim stated the resonator

back came from me.

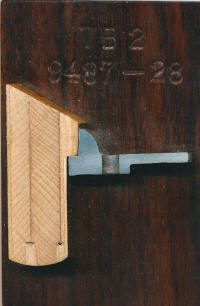

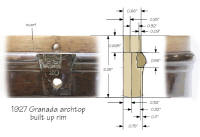

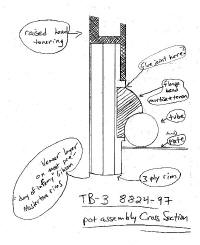

Part of my early banjo research and development

involved having several pre-war Gibson Mastertone banjo tone rings (flat head

and raised head) analyzed

with the then state of the art spectrographic analysis machines to