Eastern Red Cedar 6/4 boards air dried for several years and allowed to

acclimate to the basement humidity which is controlled.

Cedar boards have been ripped to rough thickness and width prior to

milling the radius portion on the lid blanks. About 1/3 or more of the

raw boards will end up in scrap material due to large knots or wrong grain

orientation.

Cedar lids have the radius portion milled, handle portion shaped and

trimmed to final length.

Trimming the 45 degree angles on each corner of lids. It would be

just as easy to power sand the corners and much safer to prevent chip out,

so doing it the "hard way" on this one! Working harder not smarter.

Semi-finished lids. Talk about being frugal...check out the empty

coffee cans...grin if you must...Hey it works for storage! It does not

hurt to have a good supply of lids on hand since some lids sound better with

different call bodies than others even when the lid or call body is processed from the same board.

Guess it is due to the density of the wood and grain orientation. Once

in a while a call body and lid will not sound like it should and thus ends up in

the scrap pile.

Wood marquetry strips (wood purflings) # 4 being added to a "tuned" box call.

If the call does not sound right after initial and secondary hand tuning and

other lids are tried, it

will be scraped before wood purflings are added and wasted in the process.

Simple fixture to hold the box call during the finishing stages and helps

keep track of the sealer and finish coat applications. Currently not

using the "stitch" or Granada wood marquetry...most collectors like

the #4 wood marquetry pattern better.

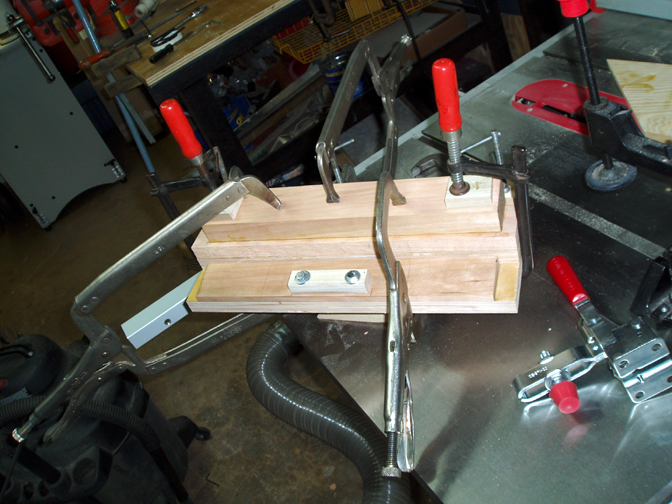

Custom fixture being fabricated.

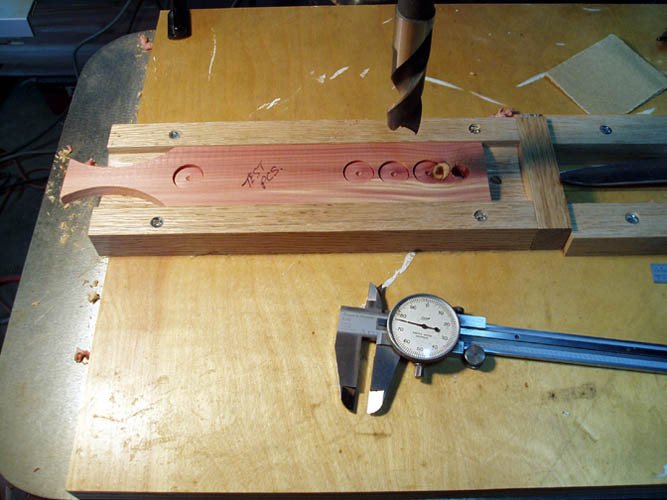

Fixture set-up and test. Every call hand made by me will have

numerous caliper checks along the way, especially the soundboard or side

thickness, depth and width of inside sound chamber. I constantly hit

+- .003 inches of target goal.

Custom commissioned call with strutting turkey inlay in Green abalone

pearl inlaid into Gaboon Ebony insert and then inlaid into the bottom of the

Butternut call. Chisel used to rough out the opening very quickly and

finished with a very small router. The finished call above now

belongs to Jim Yarboro of Gun Barrel City, Texas and he harvested a Rio

Grand long beard with the call. See the

Photo Gallery home page for

the pix and info.

Poplar call blank being routed/carved testing out new sound chamber

design set-up. I call this chamber my Torpedo Nose taper.

The sound chamber is not completed in the above photo. Without proper fixturing and tooling, this is a very difficult sound chamber to execute

without CNC routers/carvers and

I normally hit within a few thousands of an inch on the taper and side wall

thickness. I do this without the usage of CNC routers/carves but with

traditional woodworking techniques, but with accurate fixtures.

Above July 1980 Neil Cost call getting measurements documented. Call is not

owned by me or for sale! I have personally had my micrometers,

calipers and other precision measuring tools on other top call makers

designs as part of research and development constantly adding new data to

assemble bits and pieces in the quest for knowledge. Nell Cost set the

standard for call makers, however many "custom

call makers" simply copy his design; e.g., box call cavity

shape, inlay, checkering patterns and even go as far as to say their calls

are hand hewn trying to give credence to

their call. There was only one Neil Cost and anyone copying his

designs shows no originality whatsoever, however

"Imitation is the highest form of flattery".

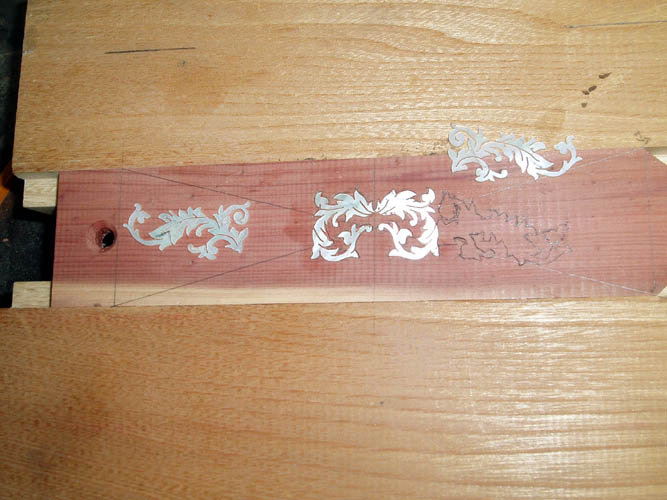

Mother of Pearl oyster shell material .050 inches thick cut with a jewelers

saw blade less than .014 inches in saw blade width into designs suitable for

inlaying into the box call lid and sides using a small router operated

freehand. No jigs or templates used since no two pieces of the inlay

with be exactly the same since they are hand cut by eye following a paper

layout pattern and not with a CNC or laser machine. As you can see

from the pix above, the inlays are delicate and bold, yet pleasing to the eye

with saw blade cut back detail and yet with enough variation to recognize

they are hand cut. It takes time and patience to execute designs of

this type.

You definitely need to be on the State Eye Glasses plan to see and following

the cutting pattern with this fine saw blade!

Above pix of mother of pearl designs being inlaid into a Eastern Red Cedar

lid. There just is no easy shortcuts when inlaying mother of pearl by

hand. The center portion of the design is dry fitted into the hole

that was hand routed out with an extremely small solid carbide router bit.

The right portion of the lid has the scribed pencil lines from the inlay and

ready to begin routing out the cavity for the inlay to rest flush with the

top of the lid. After all inlays are dry fitted they will be glued in

place with a cedar color matching epoxy filler material and will get sanded

after the filler has set a day or two.

This process is very time consuming, expensive and rarely do you see

a custom inlaid turkey box call of this caliber except in the most serious

box call collections. The above call will go into a private collection

when completed.

Click on below thumbnail pixs for a larger screen view of the process:

I have a tutorial on how to cut and inlay mother of pearl located at the

banjo construction

page. I used an air driven small die grinder to route the grooves for

the inlays and a 1/32 inch diameter solid carbide spiral up cut router bit.

The Eastern Red Cedar lid was stained black using alcohol based aniline

based dye and will be sprayed with several coats of clear lacquer.

BILL PORTER'S SHOW CASE CALL

Above lid placed on a figured black walnut call body completed on

06-22-2022. I inlaid the above lid a long time ago and finally got

around to putting it on a call base worthy of the lid. This call will

be for my display case, however I might call an ole long beard in just for

fun and not fire a shot!

The deer antler used in the pix a few paragraphs above, ended up being the handle for a custom

knife located at this

link.

I no longer donate calls to NWTF chapters or support the organization

due to alcoholic bars set up with free drinks as a means to

inebriate potential high dollar spenders and bidders at their banquets.

This is a disgusting and immoral way to conduct business to raise money in my

humble opinion! Also, the usage of

"bar maids" (literally and figuratively) to serve the drinks and assist in the auction is

low class. When you are

of the world, this is a normal protocol.

Web page updated by Bill aka Mickey Porter on 11-26-17.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take this

moment to accept him by Faith into your Life, whereby Salvation will be

attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through faith;

and that not of yourselves: [it is] the gift of God: 9 Not of works, lest

any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for, the

evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by the

word of God.”

Open this

link about faith in the King James Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the Lord

Jesus, and shalt believe in thine heart that God hath raised him from the

dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation, King

James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder of

soul and spirit, and of the joints and marrow, and is a discerner of the

thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of God is

eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory of

God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what doth

the LORD require of thee, but to do justly, and to love mercy, and to walk

humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."

HOME PAGE