LETS GET STATED WITH A PROTOTYPE

I had a piece of 3/4 inch plus width of walnut and ripped it in

half using the table saw yielding two pieces 3/8 inch thick, however the

saw cut wasn't perfect, but will do for testing purposes.

The four pieces above has box joints routed using the above jig and

will route a groove for the bottom using a scrap piece of 3/16 inch

thick Burch plywood. The box joints are slightly proud of the ends

to allow for final sanding.

ROUTED THE GROOVE FOR THE BOTTOM

There was not much room to spare with the slot and will reduce the

height of the next tray where there is a full width box joint at the

bottom of the boards. I believe I made this prototype about an

inch taller than the original serving tray. The slot is 5/32 inch width.

The long sides of the tray has the slot stopped about half way in the

box joint from the end, otherwise you will see the bottom panel.

The router table had a stop installed at each end and the material had

to be lowered onto the spinning router bit, which can be dangerous if

not very careful.

This is the same technique used when putting a bottom in a tray

and/or napkin holder using dovetails.

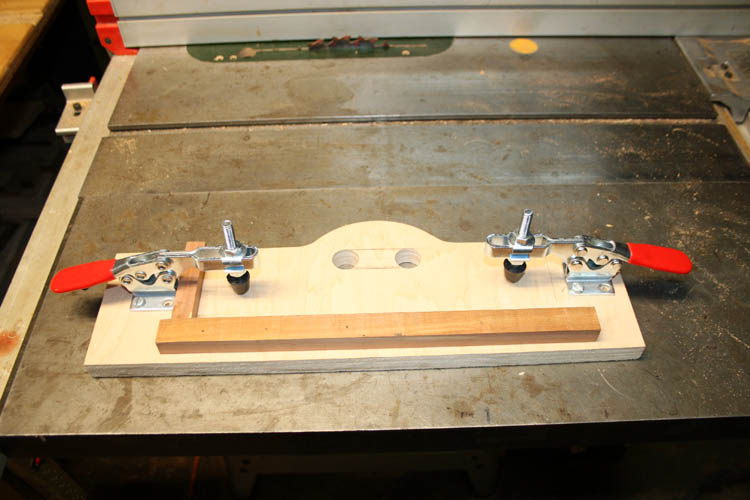

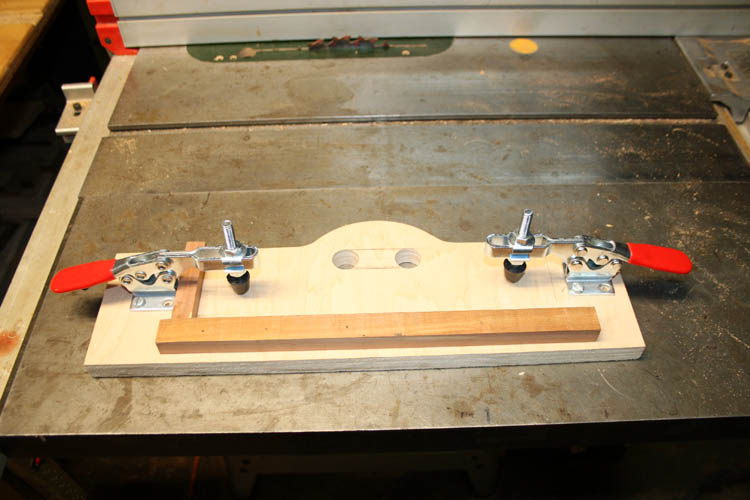

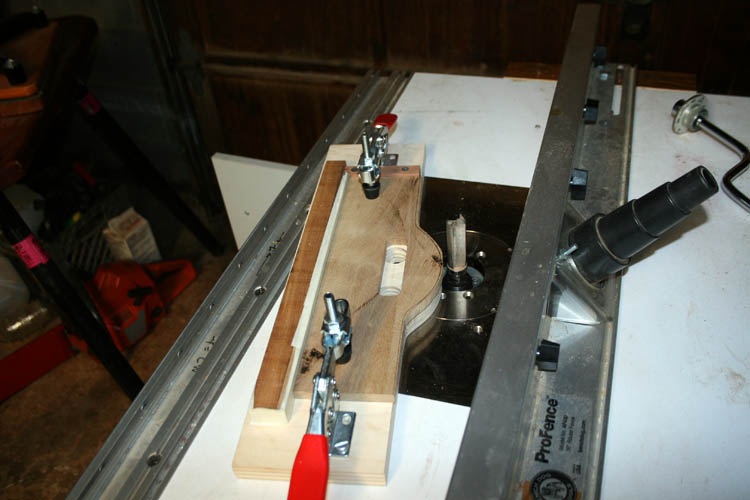

ROUTER JIG FOR TRAY END PIECES

I made a router jig for the table router to profile the ends of the

serving tray. The ends will be cut to length and the curvature rough cut using

the band saw to within an 1/8 inch of the profile and then placed on

this jig. A flush cut profile router bit will be used which has a

bearing that will

follow the curve of the profile pattern jig. To keep from any tear

out, the piece will first be routed starting at the center of the curve

and the jig will be moved into the router bit from the right to the

left. Once that cut is make, the piece will be flipped over and

re-clamped in the jig. Normally, you will feed the material to be

routed from the right to the left.

I used a pair of DeStaCo knock off clamps HH225D which to me works

better than the DeStaCo 225U clamps, plus they are a lot cheaper. This jig is SN 383.

ROUTING THE HANDLE SLOT

I cut the slot in the test serving tray using a forstner drill bit at

each end and then used the jig saw to complete the cuts. However,

this is too slow and required additional sanding and will use a router

plunge bit the appropriate size and my

mortise fixture.

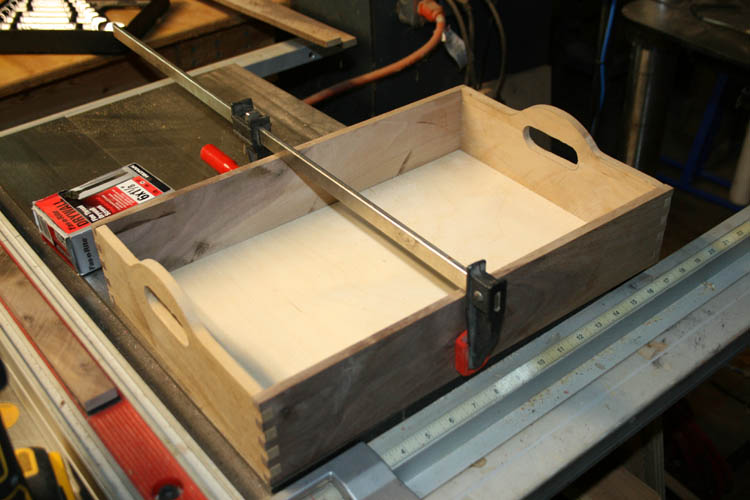

Above first prototype serving tray completed less glue up.

USING MY PAT WARNER DESIGN MORTISE FIXTURE

I didn't do any sequence pixs of cutting the handle holes in the ends of

the serving tray, but will show the

fixture and explain what I did.

The handle slots in the original serving tray were 13/16 inch width and

2 15/16 inch length. I did not have a router bit 13/16 inch in

diameter, therefore I used a 1/2 inch diameter spiral up cut plunge

router bit and

routed an appropriate opening for your fingers.

The mortise fixture will allow you to set the east to west limits needed and

also has stops for the North to South direction of the router. As

evidenced by the above pix, the mortise fixture and router does a

beautiful job requiring little if any sanding!

Close up of the mortise jig and router. The router can slide on

the 3/8 inch stainless steel rods left to right and have the stops set

to give me an approximate 13/16 inch width slot. The opening in

the Plexiglas top of the fixture is 3 inches wide by 6 3/4 inches length

which will allow for any mortise that I might need!

If you are making a mortise the same width as your router bit, you

tighten the two brass screws on the base of the router base which locks

the router in place onto the stainless steel guide rods.

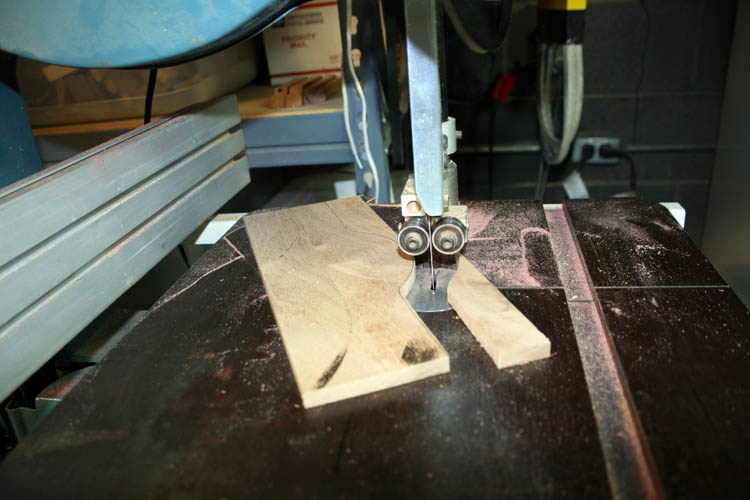

ROUTER JIG FOR END CURVATURE

I used scrap aka unallocated 3/4 inch birch plywood for the pattern

jig to cut the curvature of the handle ends of the serving tray. I

later added a piece of wood and several layers of masking tape to fine

tune it to the exact width that I needed. My goal for the box

joints was to have an equal width box joint at the top and bottom of the

sides, therefore the modification to this jig.

The end pieces were rough cut on the band saw to about 1/8 inches of

the line and then placed on the jig using a pattern bit that has a

bearing that follows the curvature of the pattern jig. The pattern

router bit I used was way too long and have one that is 1 inch in length

and will use that one when I set up to do a series of the serving tray.

End pieces ready to route the curve of the handle.

Ready to route the end pieces.

The pattern fixture aka jig leaves a good finish cut to the curvature

requiring very little if any sanding. I later went back and sanded

the edges of the pattern jig to remove most of the band saw marks left.

I will show the glue up of the serving tray later and will round up

some lumber and plywood for the bottom. I plan to add a thin brass

insert for each handle to give it additional strength, but will no doubt

free hand the route.

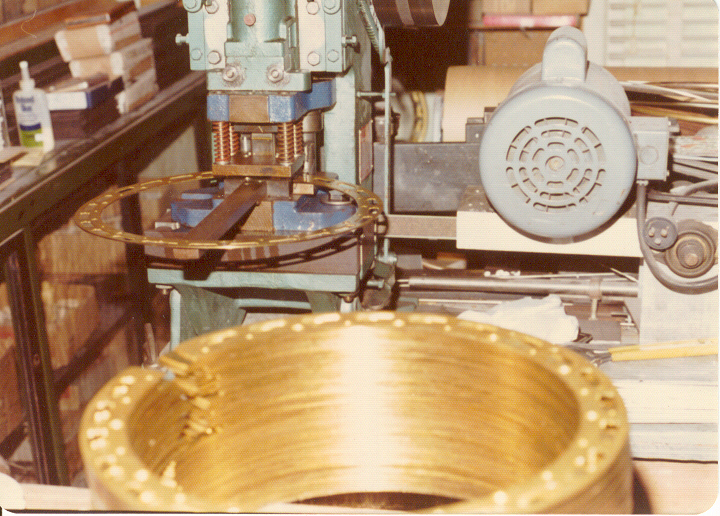

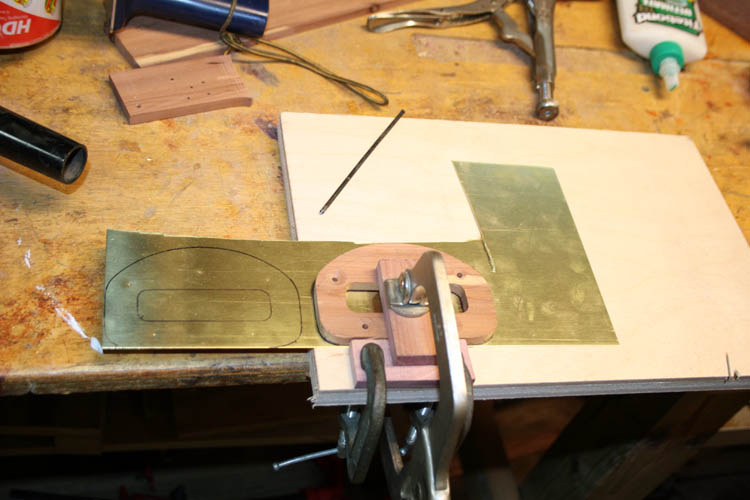

JIG FOR ROUTING .025 BRASS

I am planning on building at lest six (6) or more of the serving

trays, therefore I am thinking about routing the thin .025 inch

thickness brass using my DeWalt 625 3 HP variable speed router using a

pattern and a flush cut pattern router bit. I have never routed

brass or aluminum in the past, however I have used a scroll saw and

jewelers saw blade to cut .062 inch brass which was very laborious to

say the least and have stamped brass using a punch press and die set.

Here is an example:

Below is pix of example where I cut the tone holes in the nickel

plated brass using the scroll saw and jewelers saw blades:

I did some research via YouTube and the internet how to cut brass

using a router and it appears to be doable for sure.

FIXTURE/JIG CONSTRUCTION

I first made an exact wood pattern: one for marking the brass and the

other for the wood pattern to use with the router and a flush cut

pattern router bit.

There will be about 3/16 inch width inside the outer edge (curvature)

of the handle area and the wood pattern was cut to size using the band

saw, table saw, miter saw and final sanding to the edge of the line

traced onto the wood. The center portion was cut out using my Pat

Warner design mortise fixture first while the wood was full length.

Five (5) small countersinked holes were drilled into the pattern for

attaching the brass plate.

Scrap wood was used to fabricate the fixture/jig and above pix the

first stage to make the base plate.

I glued a double layer of the pattern so the bottom of the pattern

flush cut router bit would have clearance since it has a nut on the base

to hold the bear and the carbide cutter in to the shaft of the router

bit.

I rounded up addition scrap wood to extend the length of the

fixture/jig to give plenty of real estate for the large router base.

From this angle (view) you can see the actual pattern is below the

surface of the top base plate to allow for stacking several pieces on

brass to the pattern using flat head screws.

To use the fixture/jig, the brass will first be marked and drilled

using the pattern marking plate. A hole drilled in the center

portion to allow for threading a jig saw blade and cutting the inside

portion where you fingers will go and then cut the outside shape

slightly oversize of the pattern jig. The brass plates will then

be screw to the pattern and routed using the DeWalt 625 variable speed

router with reduced speed around 12K RPM using a flush cut pattern

router bit. This jig is SN 384.

Above with the pattern glued in place to the fixture jig.

There was a good amount of time to make the fixture/jig up to this

point and I certainly do hope it works as intended, grin if you must!

Otherwise, the brass plates will be cut free hand on the scroll saw!

NOTE: After cutting out the brass handle insert with the

scroll saw and a # 6 jewelers saw blade, I decided not to use the above

router jig for the brass.

ROUTER PATTERN JIG FOR THE CUT OUT IN THE HANDLE

If the above jig works ok, I will fabricate a router jig using a

guide bushing to inlay the brass insert into the handle of the serving

tray.

Above is part of the jig making process to route the cut out for the

handle brass insert. The top is a pattern cut, of which I started

to make the cut on the band saw, but switched over to the scroll saw

using a jewelers saw blade. The next portion is the actual route

in a test piece of wood which I had to fine tune the upper jig a few

times to get the bottom pattern to fit in the routed portion.

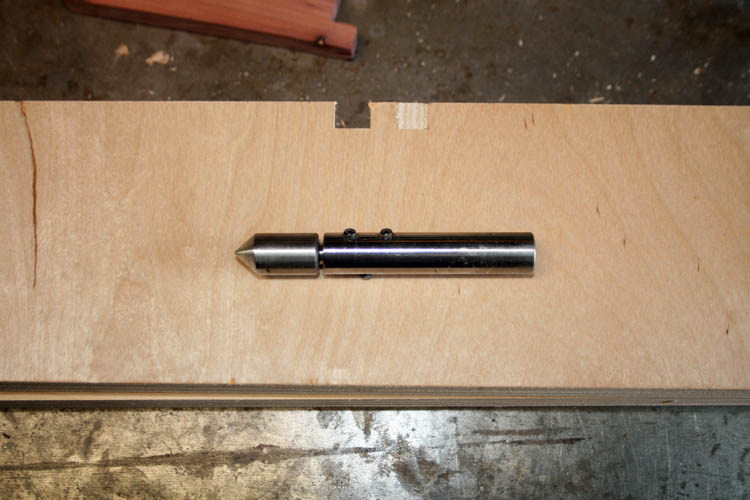

In essence, I used a small DeWalt DWP611PK 1 1/4 HP plunge router with a 3/8 inch outside

diameter guide bushing with a 1/4 inch solid carbide up cut router bit

which means I had to increase the lower pattern size .062 inches all

around. I marked around the lower pattern with a Sharpie marker

and had a thin piece of wood between the pattern and the marker to give

me an approximate .062 inch clearance or increase in the pattern.

Again, it was very laborious; e.g., trial and error. With CNC,

this would be a piece of cake, but have to use what is available in my

woodworking shop.

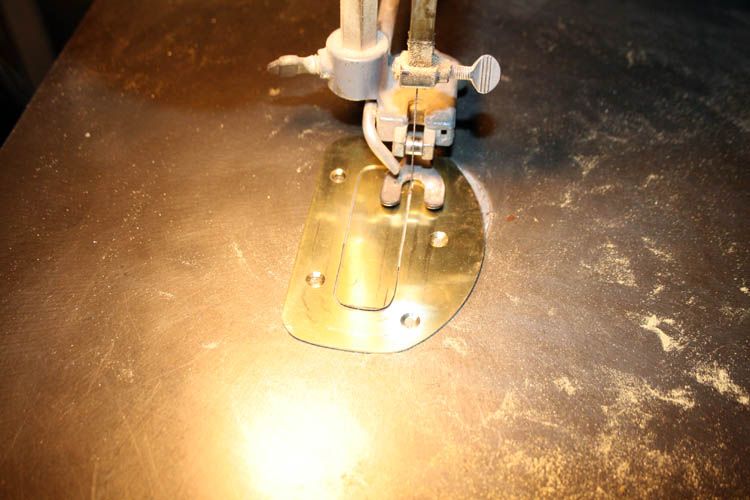

A pix of the pattern inside the jig cut out for the router. It

is not perfect, but close enough! I later glued a small piece of

wood to fill in the gap left by the band saw blade to keep the wood from

opening up any further.

Pix showing the router guide bushing with the exposed 1/4 inch

diameter router bit. The guide bushing will follow the inside cut

out of the wood pattern. As stated, there is .125 inch total

difference between the outside diameter of the guide bushing which is

.375 inches and the .250 inch diameter router bit., which equates to

.0625 inches all around the pattern desired.

A jig to position the end tray member to be pattern routed. I

am figuring this jig out as I go and will no doubt mount this jig onto a

larger piece of Burch plywood to give the small router base more real

estate to work with.

The router pattern will need to be precisely located in position on

top of the serving tray handle end.

BRASS HANDLE INSERT CONSTRUCTION

I "changed horses in the middle of the

stream", so to speak and after cutting one of the brass

plates out with the scroll saw using a # 6 jewelers saw blade, I could

cut freehand to the pattern close enough without having to use the

router jig made for the brass.

In the past, I cut mother of pearl and abalone musical instrument

inlay patterns

and was very accurate with the scroll saw. After cutting the above

brass handle insert, years of experience quickly came back and no need

to route the outside profile of the brass insert.

After cutting a couple of the inserts out, the light bulb came on and

I decided to rough cut the outside profile from the sheet brass which is

6 x 12 inches x .025 inches using my Milwaukee 4.5 inch angle head

grinder with a thin friction cut off wheel which cut the thin brass

easily.

I first marked the pattern onto the brass using a extra fine Sharpie

marker, then used a 1/8 inch diameter center transfer punch and marked

the screw holes. I then went to the small drill press and used a

120 degree countersink bit for the screw holes. I then drilled a

1/8 inch diameter hole inside the cut out where your fingers will go on

the brass/serving tray handle to thread the jewelers saw blade to

complete the cut out.

After the center finger hole was cut out, I then took the brass

handle insert to the 6 x 48 inch belt sander and sanded the outside

diameter to the line marked. This was

"working smarter, not harder" in my humble opinion. I

checked the fit with a test route piece of material.

I was able to get five (5) brass handle inserts from one piece of the

6 x 12 inch .025 inch sheet brass.

I am thinking about building six (6) of the serving trays for family

and one for our neighbors.

On Monday, our Lord willing of course, I will complete the router jig

for the handle brass insert. There is not much room for error in

this jig since the routing jig has to be precisely aligned over the top

of the serving tray handle end which already has the cut out for your

fingers routed into the wood piece. I increased the width of the

router jig pattern and mounted the base to a piece of birch plywood to

give more real estate for the router which has the guide bushing and the

1/4 inch diameter up cut solid carbide flat bottom router bit.

INSTALLING BRASS HANDLE REINFORCEMENT

The brass insert was placed into the cavity excavated aka routed out

and then used a 7/64 inch spring loaded self-centering drill guide, pix

below which works for # 6 wood screws:

I then used a 80 degree tapered countersink drill bit to account for

the taper of the flat head screws, pix below:

ROUTER JIG PATTERN FOR CUT OUT CONTINUED

In the above pix, I have glued additional side material to the router

profile pattern cut out jig which hopefully will allow me to position

the above jig on top (pattern plate) of the base plate that

positions/holds the serving tray ends in place. I will trim the

sides to the desired width.

I also glued in additional strips of wood on the sides of the jig

that is flush aka level with the serving tray end piece that will

contain the brass inlay handle reinforcement that will strengthen the

handle area. I have marked where the brass inlay will be

positioned once routed out.

I screwed a piece of 4 x 4 scrap wood to each end of the above

fixture/jig to elevate the jig off the table and/or circular saw table

where I will clamp the fixture down.

I will have to figure out a hold down method to keep the top router

pattern in place and do have enough material on each side for alignment

pins. I will probably glue a couple more filler strips of wood the

same height as the serving tray end piece to keep it from moving; East

to West. The North to South portion is secured in place with end

stops with a few thousands of an inch clearance.

ROUTER PATTERN PROFILE JIG COMPLETED

The pattern profile was fixed into position over the serving tray end

piece using # 6 drywall screws 1 1/8 inch in length. I used a

tapered pilot and countersink hole drill and drilled in several places

on the outside of the pattern profile to keep the pattern profile jig in

place and flat to the piece to be routed. This jig was more or

less "fly by the seat of your pants"

and figured it out as I went!

There is plenty of real estate surface for the small router to move

on with the additional "wings" added to the original pattern profile jig

I made earlier.

The serving tray end piece is routed for handle brass insert. I

used a chisel to clean the top edges of the piece routed.

This pattern profile router jig is not perfect, but not too shabby

for making the jig freehand without the benefit of a CNC machine.

I am sure there are better ways to construct the profile jig using

intermediate profile jigs using the master pattern to locate from.

This jig is SN 385.

NOTE: I definitely made the router profile pattern jig

the hard way since Whiteside offers a router inlay kit # 9500 which

allows you to make a profile pattern jig using a template, which in my

case would be the wood master pattern used to cut the brass inlay and

you then make a template using their router bushing(s). In the

future, I will purchase the inlay kit for my next inlay project!

I will route the box joints in the end pieces and side of the serving

tray and then route a 5/32 inch width groove in the bottom of the

members for the 1/8 inch thick Birch plywood panel aka bottom.

ROUTING GROOVE FOR THE BOTTOM OF SERVING TRAY

Above stops that control the length of the groove in the handle ends

of the serving tray. As stated earlier, you have to lower the end

piece onto the spinning router bit which can be dangerous destroying

your end piece and could hurt yourself.

Alternate method would use a router on top of the end piece, but you

could easily ruin the piece since there is little margin of error

between the groove which is 5/32 inch width and only 3/8 inch width of

the box joint.

No stops were needed for the sides of the serving tray.

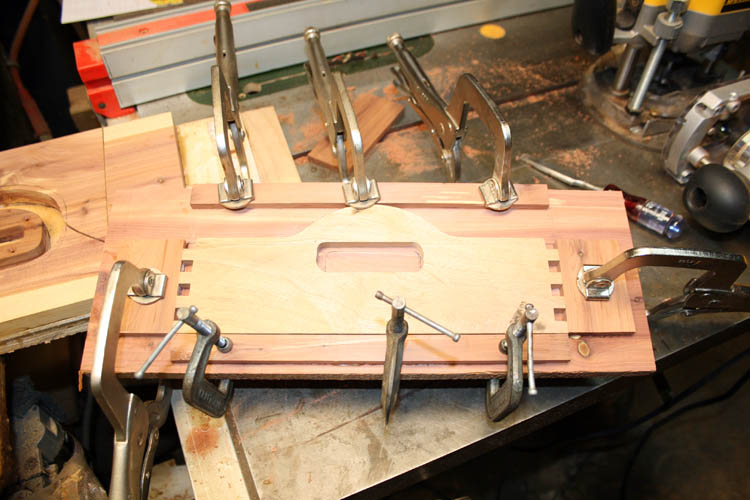

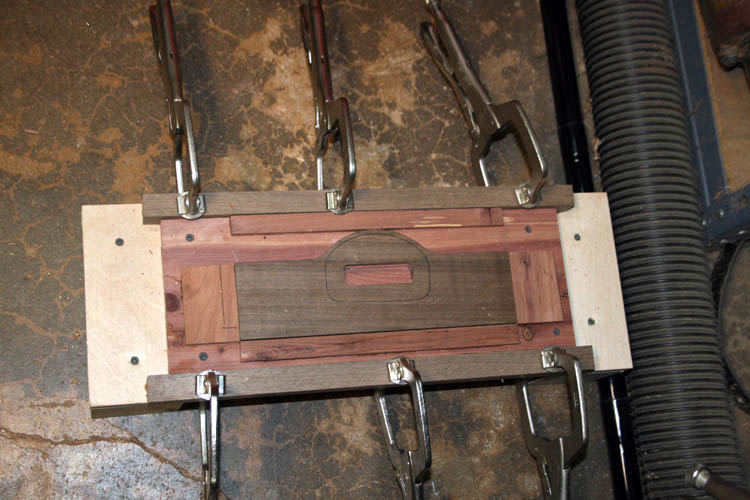

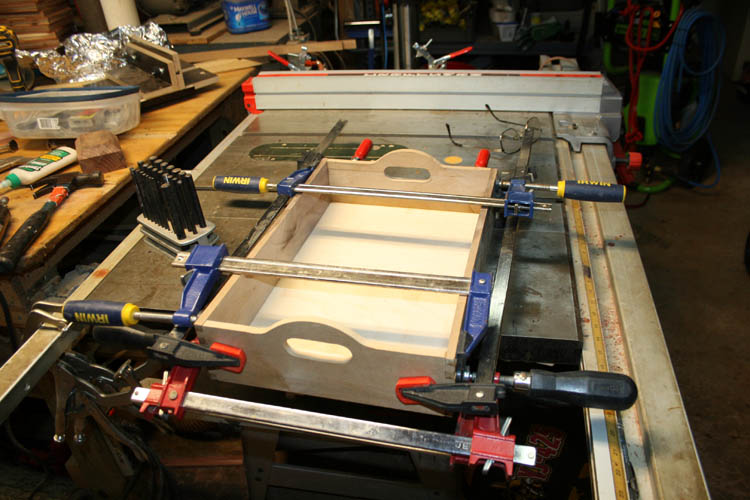

GLUED THE SERVING TRAY TOGETHER

With making only maybe seven (7) +- serving trays, I will not make a

glue-up fixture just for the serving trays, but will use clamps as

above.

One of two serving trays without a brass insert which were my test

trays!

TO COMPLETE THE SERVING TRAY

The serving tray box joints will be sanded flush when glue is dried

overnight, final sanding and inserting and screwing in place the brass

handle inserts. When the weather permits, a few coats of musical

instrument grade lacquer will be sprayed onto the serving tray.

I have an adjustable # 6 drill centering bit to drill pilot holes

into the ends of the serving tray to secure the brass inserts.

When using pattern profile jigs and fixtures, it is imperative that

all your parts to be milled/profiled be as accurate as possible to locate to the jig for

repeatability.

FINISHED PROTOTYPE SERVING TRAY

I sanded the serving tray and installed the handle brass inserts and

then sprayed a couple coats of lacquer on the serving tray. This

prototype serving tray will be SN 386. I have two other test

serving trays to complete which will not have the brass inserts.

I am well pleased with the serving tray. I decided not to stain

the Baltic Burch plywood bottom and I like the contrast between the two

woods. I have mahogany wood ordered to complete additional serving

trays for family members and our closest neighbor, our Lord willing of

course.

STARTED EIGHT ADDITIONAL SERVING TRAYS

I received the mahogany wood ordered and got the ends and sides cut

to dimensions along with cutting the curved portion of the serving tray

end pieces.

Today being 02-23-2024, I started routing the cavity out for the

handle brass inserts. I reworked my router jig by adding

additional shims glued to the sides for a flush fit of the end piece to

prevent torking the upper router profile pattern.

As stated earlier, the end pieces are marked from the profile pattern

and band sawed close to the line and then clamped onto the router

profile jig and using the router table.

The profile router table jig for the handle curve saves a bunch of

time and sanding in my humble opinion.

I was short brass for the handle inserts and ordered a 6 x 12 x .025

inch piece which will give me five (5) units.

PROJECT MOVING ALONG

I glued up two serving trays today (02-26-2024) and test fit the other

six (6) units. I had four end pieces that had the box joints in

the wrong orientation, (my bad) and cut the box joints off and routed

them again which shortened the width of two of the serving trays

approximately one inch. The box joints on a couple were

"tight as two coats of paint"

because I didn't have enough scrap aka unallocated material to adjust

the box joint jig to fine tune it properly.

The above Bessey parallel clamps bar clamps worked good for this project.

I used them on my

custom keepsake boxes, but did not like

them. The Merle band clamps worked much better keeping things at a

right angle.

I sprayed a couple coats of musical grade instrument lacquer on the

serving tray that did not have handle brass inserts (test serving tray).

I will get into my cruise control mode aka retirement mode and glue

up one serving tray each day and do a final sanding on it and install

the brass inserts into the handle ends. When the weather permits,

I will then apply a couple coats of musical instrument grade lacquer.

Cutting the brass handle inserts was the most time consuming and

challenging part of this project.

FINAL SERVING TRAY COMPLETED

I sprayed a couple coats of Deft lacquer on the last serving tray

completed. It rained a day or two and put the project on hold

until today.

This has been another fun woodworking project and I am going to

insert a table of the cost for the 10 serving trays that have the brass

handle reinforcements. I did a couple test serving trays without

brass inserts using scrap aka unallocated wood.

SERVING TRAYS COST