YARD/HOME PROJECTS AND REPAIRS 2022This is

a catch all page for yard projects and the maintenance of yard equipment

such as the lawn tractor, Troy-bilt tiller, home generator, weed trimmer, leaf blower and all home maintenance whether corrective or preventative!

TOMATO PATCH

A couple days ago, the afternoon weather was very pleasant, therefore

I decided to till our little tomato patch area with the antiquated

Troy-Bilt tiller which has a 5 HP Craftsman engine on it. I

checked the oil and gas level and had to add some engine oil to the

engine block and gave the pull starter cord a good pull, however the

started cord was snatched out of my hand and had my right arm sore after

a couple of the same failed attempts to get the engine started.

Last year, the tiller worked ok, but it did have some erratic, not

normal sounds to it and also it would cut out every now and then under

load.

I thought about taking it to our local Lawn tractor service center

being Pinkston's Mower, Inc., but decided to see if I could find out

what the problem was. I typed the problem on the YouTube channel search

engine and there were plenty of videos with the same problem that I was

having and the trouble was a broken flywheel key which I call a shear

pin in the flywheel.

I took the housing (shroud) off the engine which contained the rope pull cord

assembly, removed the screen cover from the clutch assembly, removed the

clutch assembly to access the flywheel and it was obvious that the shear

pin aka flywheel key was broken which causes the engine to be

out-of-time and in this case, when the engine tried to start, yanked

back on the rope starter pull cord with great force.

I went to Pinkston's Mover and purchased three flywheel keys and will

have a couple spare ones. Back in 2018, I replaced a sheared

flywheel key and other parts and have it documented

here. The soil where the

tomato patch is located has some roots and if the tiller tines get in a

serious torque bind, the flywheel key is the built in safety mechanism

to keep from damaging the internal parts of the engine, which is a good

thing.

NOTE: The above Troy-Bilt tiller had at least two prior

owners and was repainted with fresh decals, however the decals have

deteriorated over the years. I plan to remove them and use a magic

marker and/or label maker to refresh my memory on the functions of the levers.....grin if

you must!

I will post a few pixs when I start tilling up the tomato patch

adding some fertilizer, broken up egg shells, sawdust from my

woodworking shop and maybe purchase a few bags of sand to add to the

soil.

TILLED THE TOMATO PATCH

I added sawdust from my woodworking shop

dust collection system and

crushed eggs shells for some natural calcium to the tomato patch soil on

03-02-2022. The tiller fired up without any trouble and right at

the end of finishing the tilling of the soil, I put the tiller in

neutral and put it in reverse, whereas it jerked in reverse pretty hard

and I believe the engine back fired. I wasn't able to start the

engine again after letting it set a while. The flywheel key might

have sheared again since the starter pull cord did snatch back one time

pretty hard. I probably didn't torque

the clutch assembly enough to hold the flywheel solid against the

tapered crankshaft with the flywheel key in place. My right

arm/hand strength is not 100 percent yet from the

broken arm

last year on April 19, 2021.....got to have an excuse right?

It looks like there will be another repair in the future to get in

running again.

REPLACED SHEARED FLYWHEEL KEY

To make a long story short, I replaced the flywheel key which was

sheared in two pieces and the keyway was about 1/2 inch from being

aligned with the flywheel and crankshaft keyway. I torqued the

clutch assembly as tight as I could get it using a large pair of channel

lock pliers. I ordered a clutch wrench where I can use a socket

and torque wrench to get enough torque applied.

Below a few pixs taken during the repair:

I installed the flywheel and flywheel key and then the clutch

assembly. Before I did all that, I used some 600 and 1000 grit

sanding paper to polish the crankshaft straight portion where the inner

clutch assembly shaft spins.

The clutch reverse spins freely without binding and the screen was attached to the clutch assembly.

After the shroud was in place, I choked the carburetor and after two

or three pulls of the starter rope, it fired and moved the choke lever to

the normal run (vertical) position.

When I finish tilling the tomato patch right before planting tomato

plants sometime near the end of April, I plan to take a look at the

starter and see why it is not engaging the toothed flywheel, although

the starter solenoid is activating, the starter is not engaging the

flywheel. I haven't used the starter in several years due to a

dead battery. I jumpered voltage from the John Deere to the

starter solenoid to ascertain if the starter would activate. If I can get the starter and/or solenoid working

properly, I will replace the dead battery.

I have plenty of routine yearly maintenance projects to get started on once

the weather turns and stays much warmer. We have had an unusually

colder winter this year and looking forward to Spring of the year!

Web page published by Bill aka Mickey Porter on 03-01-2022 and

updated on 03-02-2022.

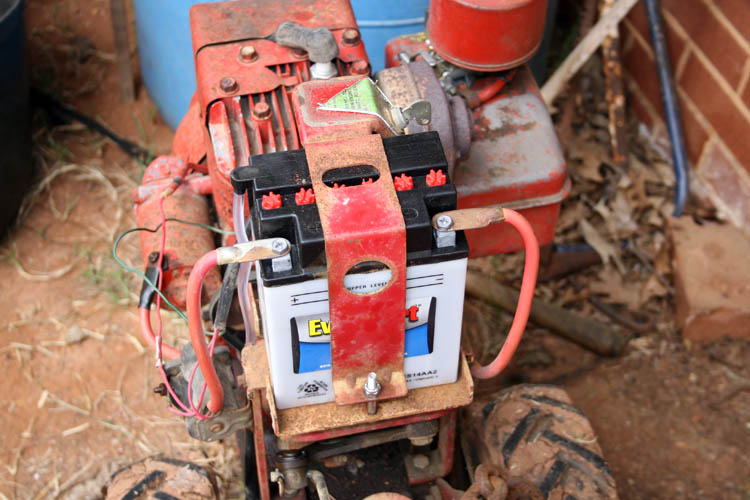

REPLACED TILLER BATTERY

I replaced the tiller battery on 03-30-2022 and the starter turned

over and got the tiller started. I let it run for a while and

checked to the voltage of the battery to see if it was charging, of

which it was. I had to replace the existing battery bracket hold

down bolts with longer ones since the battery was taller than the original

battery. The wiring for the switch and starter solenoid needs a

little TLC and will use a few tie down straps.

NOTE: The above battery came with the electrolytic solution

in a plastic sealed container. The instructions was to fill each

battery cell and then charge the battery. I had to purchase a

battery charger to get this project completed.

Web page updated by Bill aka Mickey Porter on 03-30-2022 and

04-07-2022.

CUT DOWN SHADE TREES NEAR THE TOMATO PATCH

The weather forecast was to be in the high 70s in the afternoon and

got an early start today (03-03-2022) cutting down several trees that

were shading our tomato patch on the West side. I had a fresh

gallon of gas using Stihl oil and non-ethanol gas and added some

chainsaw bar oil to the reservoir. I either had a new chainsaw

chain and/or a freshly sharpened one and it went through the sweet gum

tree like butter leaving some good sized chips denoting the chainsaw was

cutting properly.

A zoomed out image of the fallen sweet gum tree adjacent the tomato

patch. A couple of the smaller trees called

Widow Makers because they are hung up in another

tree and a hazard to try and get them on the ground.

The tomato patch will get plenty of sun light now from the West and

mid day too. I will let the sections of sweet gum tree dry out

some before I start getting them out of the way and let Nature do its

thing!

I definitely have to purchase a cant hook

to roll the log portions over to finish the cut, otherwise the chainsaw

chain will dig into the dirt. How I managed all these years

without one is amazing and has accounted for many chainsaw chain

sharpening(s).

I will come back later and cut the tree stumps down closer to the

ground for eye appeal.

This sweet gum tree I plan to leave as is for now since it is out of

the way. A bonus is future seed balls will now vanish!

We should have a much better tomato crop this season, our Lord

willing of course with the extra sun light reaching the tomato patch.

TOMATO PLANTS IN THE GROUND

I waited until around the 25th of April before I started putting some

tomato plants into the ground and put the last four (4) plants in the

ground today being May 2, 2022. At the moment, I have eighteen

(18) tomato plants in the ground.

This should be enough tomatoes for my bride and myself and everything

goes well, our Lord willing of course!

We had a "frog strangler"

rain last evening and should jump start the plants for sure with what I

call, "Nutrients From The Sky."

I have already given the plants a little Miracle Grow water solution

to help them along.

Above close-ups of the tomato plants. I have three (3) three

gallons size plants, and about eight (8) one gallon size plants if my

memory is correct and the balance is smaller plants. Some of the three and

one gallon plants already had small tomatoes as evidenced by the pixs

above on them with a good amount of blooms as well.

There is a variety of Homestead, Celebrity, German Johnson, Cherokee Purple, Pink

Brandywine and one other variety.

Web page updated by Bill aka Mickey Porter on 05-02-2022.

TOMATO PLANTS UPDATE

We have had several good rains aka "nutrients from the sky" and the

tomato plants are jumping. About all the plants have blooms on

them now.

I will have to start weeding out some grass when the ground dries out.

Web page updated by Bill aka Mickey Porter on 05-24-2022.

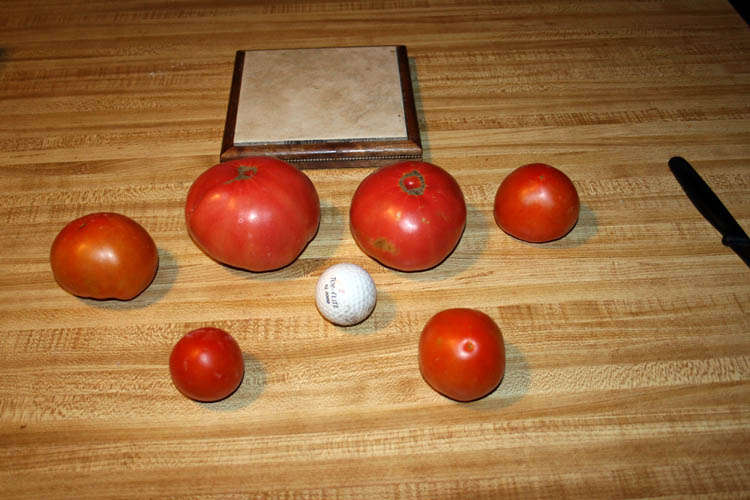

FIRST RIPE TOMATOES

We received our first two ripe tomatoes on 05-30-2022 and my bride

and myself eat them sliced with salt and black pepper. On

05-31-2022, I picked three (3) more tomatoes, two about ripe and one was

ripe. I made my bride a sandwich on 06-01-2022 and it was

definitely wonderful indeed! This is the earliest we have

harvested tomatoes.

Here is pix of the tomatoes harvested on 06-03-2022.

We plan to have a couple BLT sandwiches from the above tomatoes very

soon!

Web page updated by Bill aka Mickey Porter on 06-01-2022 and

06-03-2022.

GERMAN JOHNSON TOMATOES

As of 06-15-2022, I have been getting some tomatoes from our tomato

patch and the German Johnson tomatoes are beginning to ripen.

Below is a pix of a couple of them and I made three (3) thick sliced

tomato sandwiches from the larger one.

The German Johnson tomato had a wonderful taste and texture!

Can you say "beautimous" out

loud?

Web page updated by Bill aka Mickey Porter on 06-16-2022.

HARVESTING SOME TOMATOES

It has been super hot this late Spring and Summer, however we have

continued to get some good tomatoes and enjoyed many sandwiches; e.g.,

BLT, Tomato and Club and enjoyed eating the Cherry tomatoes like

candy...........grin if you must!

I can visualize a good

Club sandwich from the largest German

Johnson tomato. Plants I purchased here in Wadesboro, NC from HW

Little, Co., Inc. did not do well at all, especially the Cherokee Purple

tomato plants.

Web page updated by Bill aka Mickey Porter on 07-05-2022.

CHAINSAW WORK CONTINUES

The temperature the afternoon of 03-04-2022 was 60 degrees and

decided to fire the chainsaw up again. Earlier around mid-morning,

I started dragging some of the laps from the downed sweet gum tree that

stepped off to be approximately 82 feet in length.

I cut the stumps from three (3) of the trees cut yesterday and it

looks much better. I surveyed the two trees that were cut and

lodged into another good size red oak tree, of which I call those type of trees

"Widow Makers" because if you

are not careful in getting them down, you can certainly make your bride

a widow, therefore the name Widow Maker is very applicable!

The tree that was holding the two widow maker trees was leaning in

the right direction and I knew once I started the back cut and the tree

started to fall, I had to get in high gear out of there away from the

two widow maker trees that would come crashing down as well.

Below is a pix of the Widow Maker trees on the ground along with the

large 15 inch diameter Red Oak tree that had them hung up:

Another pix of the widow maker trees and the trees stumped out:

Pix of the stumped out trees and also the large sweet gum tree,

whereas I dragged out the laps cut from the tree.

The

brown/reddish stump in the front center of the pix is a maple tree

that was the corner of a dog lot the prior home owners Paul (deceased) and Opal

Walters owned. I removed the heavy hog wire fence and posts not

too long after we purchased said property in July 1989. The decayed stump had

the fence wire grown into it.

Here is a pix of the stump right after I cut it in February 2019 and

you can see the ends of the fence wire the chainsaw chain cut through.

Yes, I did see sparks flying from the chainsaw.............grin if you

must!

The chainsaw chain definitely got another sharpening before the next

usage!

View of the area below opened up even more now:

I ordered a 60 inch length cant hook from Wood-Mizer, internet pix and when it

arrives, will finish up this project; pix below:

With the extra sunlight able to shine onto the tomato patch, we

should have much better tomatoes this season, our Lord willing of

course.

I asked my friend Robert Webster of Hamlet, NC to contact his

son-in-law and see if he wanted any of the wood for firewood.

Web page updated by Bill aka Mickey Porter on 03-04-2022.

FERTILIZED YARD AND TOMATO PATCH

The weather prognosticators are forecasting rain next week, therefore

I purchased another bag of 10-10-10 fertilizer and spread about 80 lbs

on the front and side yard along with the small tomato patch. The

rain should help dissolve the fertilizer and next month I plan to till

the tomato patch again.

One of our security cameras captured yours truly spreading the

fertilizer on the front side yard hyperlinked

here.

Web page updated by Bill aka Mickey Porter on 03-05-2022.

RECEIVED THE CANT HOOK

I received the cant hook today 03-08-2022 and put it quickly to use.

It is amazing how much leverage you can get with the 5 ft. bar.

I finished all the cuts needed on the bottom side of the logs and the

cant hook rolled over the long section of the sweet gum tree with no

trouble at all. I didn't have to exert much energy and that

is a good thing.....working smarter, not harder!

The cant hook got another workout on a red oak tree. The

circa. 1999 Husqvarna Farm Model 55 chainsaw is cutting real well.

There is a hickory tree to the right of the red oak tree and I cut it

up into manageable lengths too. I plan to get the ole manual log

splitting maul out and split some of the wood for our fire pit and

"weenie" roasts for the Gonzales Grand Kids!

As stated, it will be log splitting time very soon and will get the

balance of the large sweet gum tree out of the way.

Web page updated by Bill aka Mickey Porter on 03-08-2022.

SWEET GUM TREE OUT OF THE WAY

Late yesterday afternoon, I got the balance of the large sweet gum

tree moved out of the way and the rain today has stopped my outside yard

projects, etc. Pix of the tomato patch area below:

The grass and of course the weeds have started growing fast the past

few days with the warmer weather and need to get the lawn tractor

serviced ASAP. As soon as the rainy weather stops, of which

is good for the broadcast fertilizer, I need to split up some of the

hardwood for our fire pit.

Web page updated by Bill aka Mickey Porter on 03-09-2022.

WORKING HARDER NOT SMARTER

Today was overcast and intermittent light misting rain falling with

the temperature in the mid 40s. After getting back from shopping

in Rockingham, NC and putting up dry goods, refrigerated items, etc., I

decided to get the ole log splitting maul out and split up some of the

hardwood for our make shift fire pit for

"weenie roasts" for the Gonzales

Grand Kids.

We have never burned wood for heating our home, therefore I do not own a hydraulic log

splitter, but have managed to split wood the hard way as needed.

Below is pix of the pile of split firewood and I have to take my

time and split a few pieces at a time and then take a rest....grin if

you must:

The log splitting maul seems to be getting heavier with each

additional year of usage, but I am thankful for each and every day that

our Lord allows!

Log splitting - to be continued.

Web page updated by Bill aka Mickey Porter on 03-10-2022.

WORK CONTINUES

With the temperature in the mid to high 40s, I split more firewood

and decided to cut down a dead sweet gum tree on our upper property.

My endurance seems to be getting better having been hindered by

non-physical activities during the Winter. Below are a few pixs taken:

The firewood pile is getting larger and will haul this pile to our

fire pit using a wheel barrow. I am unable to get my truck closer

to the pile due to the rain and wet/soggy back yard and a drainage ditch.

The little Ford Ranger will spin on wet grass....grin if you must!

I believe I can get the lawn tractor very close to the split wood and

use a wagon garden cart attached to the lawn tractor to work a little smarter

not harder getting the wood to the fire pit area.

I will use some exterior plywood to make a temporary bride across the

drainage ditch instead of navigating the sloping incline area below the

tomato patch.

The above sweet gum tree has been dead for some time by the bark

releasing from the tree.

The ole "husky" made quick

work of getting the tree on the ground. I will let nature continue

to process the dead tree.

I will call it a day for the chainsaw and log splitting work,

whereas I have a quart bag of frozen white perch fillets thawing out and

my bride and myself will have a

fish fry late this afternoon.

Web page updated by Bill aka Mickey Porter on 03-11-2022.

BURNED LEAVES - FIRE PIT AREA

It will not be too much longer before we can have

"weenie" roasts for the Gonzales Grand Kids, therefore I raked

up the leaves adjacent the fire pit and set them on fire. We

experienced a light drizzling rain toward the end of the fire burn which

helped freduce the risk of spreading the fire!

Before our next "winy" roast, I will police up the area and rake

additional leaves from the rear white milky quartz rock wall and

probably do another controlled burn. The painted red color wood

adjacent the rock wall is the remnants of a

Santa's sleigh.

Web page updated by Bill aka Mickey Porter on 03-16-2022.

READY FOR A WEENIE ROAST

We planned on having a "weenie" roast for the Gonzales Grand Kids today

(03-26-2022) and I spent most of yesterday getting the area

"policed" up and raked and

hauled many wheel barrow loads of leaves off, etc.

It certainly does look much better now and spend a couple hours this

morning rounding up some dead cedar trees on our property. I put

the ole Husky chainsaw to use along with my regular axe splitting up the

wood for the fire pit.

Web page updated by Bill aka Mickey Porter on 03-26-2022.

LAWN TRACTOR MAINTENANCE

Today 03-22-2022, the mid-day weather was gorgeous with highs in the

lower 70s and a great day to do the annual maintenance on the John Deere

X300 lawn tractor.

What started out to be routine maintenance, ended up being a

corrective maintenance issue. Yesterday after cutting the front,

side and back yard and having the deck in gear while running water into

the port to clean the deck underneath, I noticed an abnormal sound and

the deck was doing more vibrating that usual with the deck blades in

gear.

While removing the right cutting blade, I noticed a good amount of

movement in the spindle and knew that the bearings were gone. I

went to John Deere aka Quality Equipment in Polkton, NC and purchased a

spindle assembly. When you purchase something with John Deere

green on it, your wallet or plastic will definitely know you have been to

John Deere!

I had never taken the cutting deck off the X300 and viewed a couple

videos on YouTube before starting this project which was a valuable help

and resource.

After disengaging the deck from the lawn tractor, I used a DeWalt 20V

cordless impact Drill Driver model number DCF885B which is

variable speed; 0-2,800 RPM to try and loosen the pulley nut which was

7/8 inches, however the nut would not budge. I then took a propane

torch and heated the nut up and after several seconds with the impact

driver/drill chugging along, the nut finally broke loose. It was

then no problem removing the spindle assembly which was held to the deck by

four (4) bolts.

The old spindle assembly is off and the new one ready to be

installed. I definitely didn't blow or wash the leaves from the

upper cutting deck...........my bad!

New spindle installed and ready for the pulley and pulley nut.

With that out of the way, getting the deck back onto the lawn tractor

took some serious effort, but managed to get it done and tested the unit

out and it ran fine without all the noise and excessive vibration.

I should have replaced the other spindle which will go out soon for

sure, but I am going to "milk"

it as long as I can!

After reading a few internet threads, the deck bearings do not last

that long on some of the John Deere models and I am not talking about

the cheaper ones they sell to Lowe's, etc. for resale.

Most of the time you get what you pay for, but I don't think it fits

current John Deere, whereas I believe their quality has diminished over the

decades trying to

stay competitive with other brands which are getting a Lion's share of

the market.

After the spindle replacement, I changed the oil, oil filter, spark

plugs, cleaned the air filter and greased the fittings.

BECAUSE ITS GREEN, DOESN'T MEAN QUALITY AND SERVICE

Just for the record to validate my above heading, I used a Troy-Bilt

lawn tractor which was around 18 HP with a Kohler engine and 36 inch wide cutting deck for

approximately twenty-five (25) years and did not have any major repairs

or issues, other than cross threading the spark plug which had to be

re-tapped/threaded. The deck spindle bearings were still good when I gave it

to our oldest daughter, of which she used it for a few years and I believe

that was about eight (8) years ago.

The only problem with the machine was the carburetor needed cleaning

and the fuel line needed to be blown out!

PLANNED OBSOLESCENCE

After viewing a couple

videos on why many lawn tractor deck spindle

bearings fail within a few years, it was apparent that they were

manufactured to fail. The reason being, there are grease fittings

on most of the spindle assemblies, however the bearings are sealed and

the applied grease never reaches the inside of the bearing raceway.

The only grease in the bearings is the grease applied during the bearing

manufacturing process.

Here is the definition of planned

obsolescence: Planned obsolescence means

manufacturers deliberately designing products to fail prematurely or

become out-of-date, often to sell another product or an upgrade – a

practice that is barred in some countries.

Web page updated by Bill aka Mickey Porter on 03-22-2022.

DECK SPINDLE TEAR DOWN

We had rain last night early morning (03-24-2022) and too wet to do

anything outside and to keep from getting

"antsy", I decided to tear down the X300 deck spindle, whereas at least one bearing was

completely shot.

Yesterday, I attempted to take the spindle apart to access the

bearings, but wasn't able to do it. There are no YouTube videos

showing the tear down of the John Deere spindle, part number

AM137483; finally figured out the top idler spacer needed to come off. It was

apparently fixed solid to the main shaft; i.e., press fit on the shaft.

I soaked the shaft/heavy washer with Kroll oil overnight and this no

doubt helped!

There was about 1/8 inch clearance between the washer and the spindle

housing and took a flat head screwdriver and worked around the diameter

of the housing and it started to move upward and finally got it removed.

I definitely did the above the hard way, whereas all I had to do was

put a nut on the top threaded spindle and tap it with a hammer and the

spindle will start moving out of the spindle housing. You have to

readjust (back out the nut) to give the shaft clearance space, whereas

the spindle will come out the bottom of the spindle housing.

As depicted by the pixs below, the top bearing was totally destroyed

and somewhat dry indicating there was no grease getting to it.

There was some grease inside the spindle housing and the lower bearing

was still in fairly good shape. I did notice that there was no

seal on the bottom bearing facing the spindle cavity and probably why it

did not fail, of which there was adequate grease in the bearing raceway.

NOTE: John Deere sells the above bearings, whereas the

bottom bearing has the top seal removed and the upper bearing has both

seals in place. No amount of grease you pump will get into the top

bearing and as evidenced will prematurely fail!

A closer look at the bearings, of which the top bearing was totally

destroyed aka shot.

I ordered a couple after market bearings for this spindle and will

drill and tap a weep hole in the upper spindle housing and also remove

the seal on the bearings that is facing inside the spindle housing to

allow grease to get to the bearings. I tested the zerk grease

fitting on the top of the shaft and there was grease getting through two small holes on either

side of the main shaft.

As soon as the bearings arrive, will get the deck spindle put back

together and have a spare unit!

REPLACED SPINDLE BEARINGS

I received the spindle bearings today (03-28-2022) and already

drilled and tapped a weep hole in the spindle housing to ascertain that

the cavity will be full of grease.

I installed the spindle bearings without the usage of a press,

whereas I have a small press to install frets into musical instruments,

but it was not large enough, therefore I tapped the bearings into place

with a small hammer with a brass and a hard plastic head. After

the bearings were installed, I filled up the spindle cavity with high

temperature bearing grease. Pixs below:

I removed one of the bearings seals on each bearing and the

bearings without the grease seal will face inward toward the spindle

cavity to allow grease to get to the bearings.

The bearing is slowly tapped into position.

Spindle housing with the bearings and caps in place along with the

weep hole sealed with a 10-24 bolt.

I will give the spindle a test run using my large drill press to

drive the spindle and see if the grease stays in place. There was

some slop between the main shaft and the inner bearing no doubt due to

wear. If it doesn't work, I have enjoyed taking the spindle

housing apart and installing the bearings even though the bearings cost

$ 15.50 for a set of two.

Web page updated by Bill aka Mickey Porter on 03-28-2022.

REPLACED LEFT SPINDLE

The lawn tractor was making a terrible racket when the mowing deck

was engaged and ordered a John Deere deck spindle assembly from one of

John Deere's vendors via EBay which was a few bucks cheaper than the

closest John Deere Dealer in Polkton, NC. The hours on the JD was

approximately 178 hours.

I replaced the worn out spindle assembly and the top bearing was

totally shot and the ball bearing raceway had given way and the ball

bearings had worn grooves into the spindle spacer rendering the spindle

housing unfit for replacing the bearings.

It didn't take but about 30 minutes, guessing at the time since I now

know the short cuts and easy way of removing the deck, etc. and added a

1/2 inch drive pneumatic impact wrench which was a breeze removing the

spindle housing, blade and pulley nut.

I did notice a couple belt flat groove idler pulleys had excessive play in them

and will order replacements and order a new belt since it is showing

some wear, but still working ok.

After replacing the spindle assembly, I cut the grass in the front

and side yard and the lawn tractor was not too loud when the deck was

engaged and no excessive vibration as before.

Web page updated by Bill aka Mickey Porter on 04-16-2022.

REPLACED TWO DECK FLAT IDLER PULLEYS

On May 11, 2022, I replaced the two flat idler pulleys on the

deck. I have on back order the V-Drive deck pulley. When the

V-Drive pulley arrives at the John Deere outlet in Polkton, NC I

will purchase two of the hard plastic deck wheels which are worn badly.

The deck drive belt is in fairly good shape and will

"milk" it a little

longer............grin if you must!

After installing the two flat deck idler pulleys, it was amazing how

quiet the machine sounded with the blades engaged. The total

operating hours for the X300 was 182 hours.

The only thing that didn't need replacing on the 42 inch Edge deck

was the two spindle drive pulleys.

Basically, I will have rebuilt the deck when the V-Drive deck pulley

arrives and the replacement of the worn deck wheels.

To say the least, "I am not impressed

with the reliability of this John Deere X300 42 inch deck."

Web page updated by Bill aka Mickey Porter on 05-11-2022

REPLACED WORN DECK WHEELS

On May 16, 2022, I replaced the two worn deck wheels and noticed that

the shoulder bolts aka axles were worn badly as well and order some

generic shoulder bolts from EBay.

The shoulder bolts I received, the shoulder portion of the bolt was

about 3/32 inch too long and added a washer between the shoulder bolt

and wheel to the deck frame bracket. I had to drill the washer

hole out to 5/8 inch diameter and the wheels were snug without much

wobble and turned freely.

NOTE: While at the John Deere place in Polkton, NC, I

purchased a belt and picked up the v-drive pulley that was on back

order. I will not change the v-drive pulley unless

the v-drive pulley gets real noisy, wobbly, etc. and/or the drive belt

breaks.

Web page updated by Bill aka Mickey Porter on 05-20-2022.

MOVED SPLIT WOOD TO THE FIRE PIT AREA

I pumped up the tires on an old wagon garden cart that has about seen

better days. I used that wagon/cart for many years hauling our yard

Christmas decor

lights, etc. from the basement to the front yard which served

us well.

After finishing the deck spindle tear down, I was still a little

antsy and decided to move the

split firewood to the weenie roast fire pit:

I will leave the firewood in the wagon garden cart for now and put a plastic tarp

over it and let it continue to dry out..

Web page updated by Bill aka Mickey Porter on 03-24-2022.

CHAINSAW MAINTENANCE

The Husqvarna 55 chainsaw has gotten a good workout so far this

season and wasn't running "perfect", therefore changed the spark plug

(Champion RCJ7Y) which was fouled some. I checked the air

filter and it was ok and basically that was all the maintenance needed.

The chainsaw fired up and sounded pretty good and still cutting

excellent. No pixs this time.

Web page updated by Bill aka Mickey Porter on 03-29-2022.

STAINED YARD SWING

The humidity today is 36% and the temperature 65 degrees F. and a

good day to spray a coat of stain on the yard swing. I first wiped

the swing down with with mineral spirits removing any dirt/grime and let

it dry for an hour to two. The yard swing has been resting in the

basement woodworking shop since cold weather last year and had a chance

to dry out and acclimate to the basement humidity, whereas the furnace

keeps the moisture level down.

I had about 2.5 gallons of oil type based stain TWP 100 from

SealandProtect.com

and stirred it up real well and it was still good. I used

the CA Technologies spray gun Lynx LH300 and sprayed a good coat of

stain on the entire swing. Pixs below:

I transferred stain from the 5 gallon container to the 1 gallon

container to make less of a mess filling the quart spray gun cup.

The above CA Technologies spray gun has given me excellent service

over the years.

I will let the swing dry for a couple days before hanging it under

the white oak tree in the front yard.

Hopefully, when the weather gets warmer of the early morning hours, I

will get a chance to use the swing and get some

meditation

in.

Web page updated by Bill aka Mickey Porter on 04-07-2022.

CHECKED OUT THE WEED TRIMMER

I rinsed out the gas tank on Stihl FS 70RC weed trimmer and added

fresh gas to the tank. It fired up ok and after idling a while ran

very good and caught up on some weed trimming. I don't think i

need to replace the spark plug at this time. I used the air hose

to clean any debris from the trimmer housing and it should be good to go

for this grass cutting season.

Web page updated by Bill aka Mickey Porter on 04-01-2022.

APPLIED ORTHO WEEDCLEAR TO THE WILD CLOVER

It seems like the wild clover is trying to take over the front yard

this year in places, therefore I am mixing up a solution of Ortho

Weedclear to kill it and give the grass a chance to grow. Our

weather prognosticators are predicting a high today of eighty-two (82)

degrees and will be an ideal day to spray the Weedclear solution.

I applied approximately 3 gallons of the solution to the yard and

hopefully it will kill the wild clover.

Web page updated by Bill aka Mickey Porter on 04-12-2022.

SPRAY PAINTED THE UGLY DRUM SMOKER

Our ugly drum

smoker needed a fresh coat of spray paint and got the ole 4

inch Milwaukee angle head grinder out and outfitted it with a wire brush

and went to work wire brushing the rust from the ugly drum smoker.

A few days earlier, I burned the inside of the drum out using plenty of

junk mail, newspapers and some small cedar wood robbed from our fire pit

area.

I had a partial can of gloss black spray paint, but the nozzle and/or

tube was clogged up and didn't get much usage out of that can and went

to H. W. Little and purchased a couple cans of Rust-oleum gloss black spray paint.

Below is the finished drum, sans the lid:

Below, the ugly drum smoker getting wire brushed:

Come July 12th, the ugly drum smoker will be ten (10) years old and

don't think I have spray painted it before.

I need to burn the accumulated grease off the underside of the UDS lid and apply of coat of

spray paint to outside. I will probably do that when we have

another weenie roast for the Gonzales Grand Kids!

I have done numerous Boston butts in the ugly drum smoker along with

turkey and chicken leg quarters. The hickory smoke flavor in the meat is

hard to beat and you cannot duplicate the same with a gas

grill...........end of story!

Web page updated by Bill aka Mickey Porter on 04-22-2022.

CHANGED OIL IN AIR COMPRESSOR

With the wet damp weather limiting my outside activities, I changed

the oil in the 6HP 60 gallon single stage air compressor.

The oil level was low and dirty for sure. I can't remember the

last time I changed it and glad I got around to it today.

I also washed the felt air filter out and letting it dry before

putting it back in place.

Web page updated by Bill aka Mickey Porter on 05-26-2022.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."