DUST COLLECTION SYSTEM

Upon setting up my basement woodworking shop prior to manufacturing

turkey

box calls, a dust collection system was a priority being in such close

quarters. The area of the basement for my woodworking shop was

originally a basement garage which also houses the heating and air

plenum duct works and a fuel oil fired furnace.TREE

STANDS MANUFACTURED

My first usage of this space was when I manufactured my own patented

foot climber tree stands;

US Patents

4953662 and

5167298,

of which I initially manufactured them at the

old home place on White

Store Road starting in 1986, whereas I converted a large school bus into

a shop just for manufacturing said tree stands at that

location until

1989 when we purchased our current home.

I had my welding fixtures near the garage door opening to keep from

getting asphyxiated from the mig welding fumes generated from

welding thin wall EMT, (electrical mechanical tubing), galvanized

finish and used

the basement garage for eleven (11) years until the year 2000 for that

purpose.

LAST TREE STANDS MANUFACTURED

In the background, you can see a Di-Acro # 4 Bender. The current

price of that bender is over 6K dollars not counting the tooling cost to

make the bends in 3/4 and 1/2 inch EMT; inflation for sure! There were

twenty-four (24) bends total for this stand including the foot climber

and the seat!

YEAP, GOT ON A RABBIT TRAIL AKA SIDE TRACKED

With the prior history out of the way.......grin if you must, I

converted firearms not being used into cash via our local Village Gun

and Pawn shop and obtained some excellent deals (cash flow) since the

firearms had appreciated greatly in value over the decades/years and purchased the necessary equipment;

e.g., table saw, dust collection system, planer, jointer, compound miter

saw, air compressor, drill press, band saw, router table,

sanding station and many small wood working tools and accessories.

DUST COLLECTION SYSTEM

I installed 4 inch PVC thin wall sewer pipe to run overhead and had the table

saw connected to it via flexible 4 inch dust collection hose. The input

to the Delta 1.5 HP dust collector model 50-760 has two inputs and used one input for

the table saw and the other input for the planer, jointer and router

table. There are three (3) cut-off traps aka blast gates, one at the

table saw, another one on the flexible hose to the planer (to be

installed) and one next

to the PVC line going to the sanding station.

Above wood acclimating to the basement humidity and will start a couple

projects very soon.

Below pix of a straight connection, whereas I removed the blast gate

to install between the tee connection and flexible hose to the planer,

router table and jointer as needed.

In the past, I switched the flexible hose to the planer, jointer

and router table as needed . As stated earlier, space is at a premium and had

to attach the flexible hose between the planer, jointer and router

table. The planer stayed in place and moved the jointer and router

table into position when needed. However, the sanding station was

never attached to the dust collection system and had to manually vacuum

the dust up after usage.

The band saw uses a separate SHOP VAC for dust collection and

used the same SHOP VAC for other areas as needed, however it is

currently dedicated for the band saw only..

The compound miter saw has its own dedicated SHOP VAC.

MORE 4 INCH PVC PIPE INSTALLED

I had just enough 4 inch PVC sewer pipe left over when I installed a

new drain

system for the house front gutters to install above the

garage door abutting the overhead floor joists for a dedicated dust line

to the sanding station. I had to purchase a couple 90 degree

elbows for the thin wall PVC sewer drain line and a fresh container of

all-purpose glue. However, the sanding station was never

attached to the dust collection system and had to manually vacuum the

dust up after usage.

I plan to dismantle the

portable shooting

bench and Sinclair rest, bottom left in the above pix and store it out of the way.

In order to finish this project, I ordered a 4 inch tee connector for

the 4 inch dust collection hose. I have an extra dust collection

trap aka blast gate and will install it to the input of the dust

collection line going to the sanding station when the tee connection

arrives.

TEE CONNECTOR ARRIVED

The tee connector arrived on 01-18-2022 and have it in place with the

blast gate installed ahead of the flexible tubing going to the planer,

jointer and router table, of which I will rotate the hose as necessary.

This should provide a more dust free atmosphere for the basement

woodworking shop, although dust is inevitable!

I also added a more flexible 4 inch dust collection hose that will

rotate between the planer, router table and jointer.

Web page uploaded by Bill aka Mickey Porter on 01-14-2022 and updated

on 01-19-2022.

EMPTIED DUST COLLECTION BAG

On 03-02-2022, I emptied the dust collection bag and applied it to our

tomato patch area. The top cloth bag was taken outside and beat

with a stick trying to get sawdust and chips from the inside and went

over the entire bag with high pressure air hose.

Web page updated by

Bill aka Mickey Porter on 03-05-2022.

WYNN

ENVIRONMENTAL PLEATED CANISTER FILTER

Since the above pix

was taken, I have attempted to clean the bag numerous times with high

pressure hose and just giving the bag a good old fashioned beating with

a flat board, however the efficiency of the dust collection has

diminished and degraded badly over the years and time for an upgrade as

the cloth bag is inhibiting proper air flow.

As evidenced by the above two pixs, the cloth bag is inundated with the

debris from the machines used rendering the dust collection very, very

limited.

I did an internet and YouTube search on 09-16-2024 and there were

several companies that made compatible dust collection canister filters

for the Delta 50-760 dust collector and decided on the Wynn

Environmental Canister 35C222NANO Cartridge Kit recommended by

Dick Wynn which is MERV 15 rated being about 20 percent higher in

price than their competitors, however said kit came with all the

mounting hardware that you need.

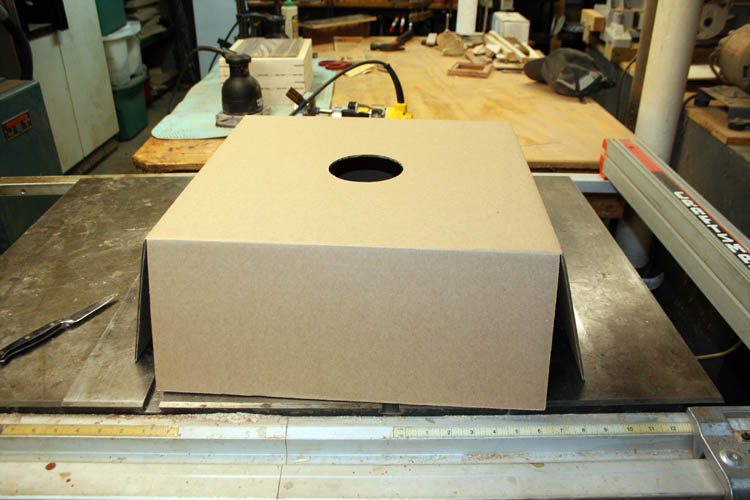

PLEATED CANISTER FILTER ARRIVED AND

INSTALLATION

The pleated canister filter arrived the

afternoon on 09-21-2024 via FedEx and it took probably 25 to 30 minutes

to install the latches, etc. and was definitely in cruise control and

not in a hurry for sure. Retirement has a way of bringing that out

in myself!

The filter was packaged in a good "stout"

box, whereas the filter fit the box like a glove.

By the thickness of the pleated filter, there should be some serious

chip and dust collection from the table saw, planer, router table,

sanding station and the jointer as needed!

Above packing insert on top of the canister.

Pix of the instructions and mounting hardware with a couple collection

bags.

The four mounting angle brackets requires bending them to allow the

straps to function properly per the manufacturers instructions.

Four 1/8 +- inch holes were drilled equally spaced apart approximately

ninety (90) degrees.

There is a clip on the inside of the rim that the sheet metal screw goes

through, however there is plenty of grip between the threads of the

sheet metal screw and the metal rim of the dust collector. I

didn't install the rubber gasket between the angle bracket and the rim;

apparently didn't read the instructions close enough; my bad.

Close-up of the hold down adjustable mechanism.

I checked the suction at one of the hoses and noticed a definite

increase in the air flow and will give it a sure test when I use the

planer again.

Per the manufacturers instruction; to clean filter apply

60 PSI air from the outside of the filter and it blows the dust,

chips, debris, etc. back into the collection bag and filter should last

a lifetime.

Using the shipping box to place the old felt filter into and have

garbage pickup do its thing.

Web page updated by Bill aka Mickey

Porter on 09-21-2024.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."