FULL MORTISE LOCK JIG

I started building a test sample secretary/letter

box and

do not want to install the quadrant hinges and full mortise lock with hand

tools; e.g., chisels and at the least a drill press and/or hand drill and a

small router with edge guides.

I did an internet search and found an excellent reasonably priced quadrant

hinge jig sold by Rockler (Jig It) for using a small plunge router and they

offered several different jig plates for various manufacture's hinges, of

which I purchased one. However, there was not a single full mortise

lock jig available for sale by Rockler or Woodcraft and did locate such a

jig on YouTube, but there was no link to its manufacturer and/or

availability. The blogger failed to respond to my email to ascertain the

availability of the jig he was using. The blogger was simply doing the

video.

One thing I certainly do not like to do is,

"Reinvent the Wheel", if such a product is available and

within my common sense price range...ok, I can be very frugal at

times.....grin if you must!

To reiterate, I do not plan to install the quadrant hinges or a full mortise lock

"free hand." The full mortise

lock jig is on my immediate "to do" list and knew it would be a good

challenge due to what equipment I have. A milling machine, CNC router or drill

mill would make such a project a piece

of cake to manufacture in my humble opinion.

I plan to add a steel plate on the back side of the walnut

base member with a 1/4 inch and 9/64 inch diameter hole as a drill guide for drilling and

creating the key

hole cut out.

I am debating (thinking) about a guide bushing mortise in the jig plate to

mortise the bolt clearance

cavity beneath the strike plate on the lid and it would seal the deal so to

speak. No use stopping at 3rd base when a home run is in sight!

COMPLETED MORTISE JIG

I added another guide bushing mortise to the jig plate to route for the bolt recess beneath the strike

plate and a drill guide to the rear for drilling the two holes for the key

hole slot. I used a total of four (4) E-Z LOC threaded bushings for 1/4 x 20

x 1.25 socket head screws. This jig is SN 73.

Center line of mortise slots for the guide bushing at both ends of the

full mortise lock jig plate. The smaller outboard mortise slot for the

bolt recess under the striker plate (lower right) requires a separate

adjustment of the fence and/or appropriate spacer, of which the spacer will

probably be the way to go.

Tested out the full mortise lock jig and pleased so far!

Very pleased with the final results!

Purple heart drill guide bushing below.

GETTING STARTED

I had some scrap aka unallocated phenolic laminated 1/2 inch thick plywood used for

making jigs and table saw inserts which would be good for making such a full

mortise lock jig. I also had unallocated 12 mm Plexiglas which would

work, but elected to use the phenolic coated plywood instead.

The size of the jig platform is 13 1/8 x 4 1/8 x 1/2 inches and basically

somewhat controlled by my mortise jig since the cut-out opening in the

Plexiglas top is 3 x 6 7/8 inches and have plenty of flexibility in the

longitudinal plane, but limited to the 3 inch width in relationship to the

left guide rail and clamping system, of which I can increase

the width of the mortise slot if ever needed. A plunge router using just edge guides would

be a nightmare to create the mortises for this full mortise lock jig in my

humble opinion, but the experienced can make it happen for sure! The

mortise jig is the way to make it easier and more accurate, again

in my humble opinion!

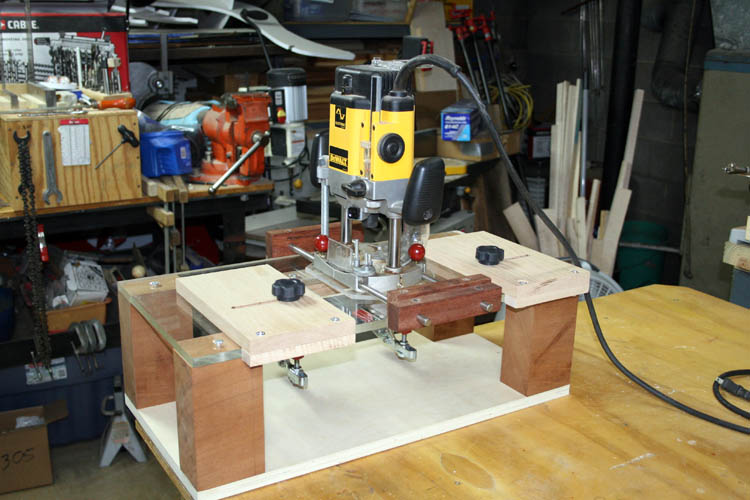

My main equipment for making this jig will be my custom made Pat Warner

design

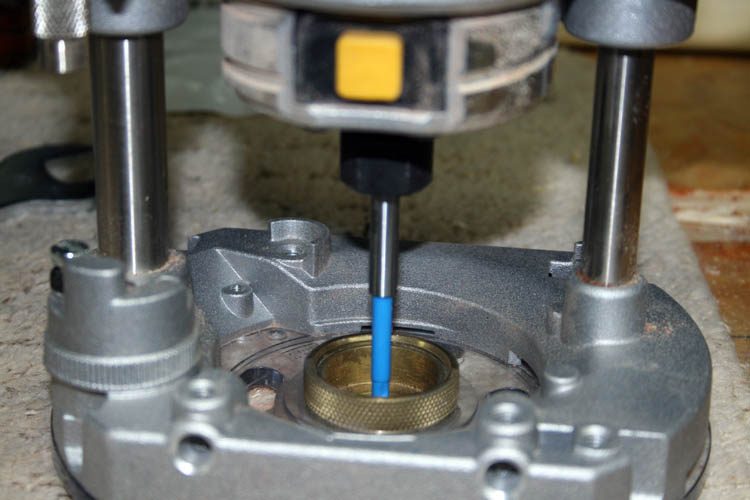

Mortise Jig and a 1/2 inch diameter two flute up-spiral solid carbide router

bit that is four (4) inches in length. This full mortise jig will use a 3/8 inch

diameter router guide bushing and a 3/16 inch diameter solid carbide

up-spiral router bit. I do not have a long enough router bit to

complete the cut-out for the lock body, but have the appropriate length 3/16 inch

diameter carbide tipped flat bottom bit on order from Rocker SKU 56249.

The simple formula for calculating the offset is: (Outside diameter of

guide bush – diameter of cutter) divided by 2. You will notice in some

of the thumbnail pixs, I have the length of the jig plate mortise slot in the test

samples annotated if you plan to build this type of jig.

I used a 1/4 inch diameter solid carbide two flute router bit in the

Mortise jig 3HP router to create

the mortise in the jig plate for the bolt striker mortise and moved the

router lateral on the mortise jig to get the appropriate width of the

mortise slot since the 1/2 inch diameter router bit was to large for the jig

plate bolt mortise.

The above Pat Warner

design mortise jig that I made has really gotten

plenty of usage

and a valuable tool when you want precision mortises. I used a Brown and Sharp dial caliper to verify measurements of the

Rocker full mortise lock SKU 130261 part and here

is a down loadable

.pdf file for this lock.

I used scrap white pine to test the width and length of the mortises

before routing the 1/2 inch thickness phenolic laminated plywood jig material.

THUMBNAIL PIXS

Click on the below thumbnail pixs taken for a larger screen view:

I definitely need to add a fine tune adjustment to my Pat Warner design

mortise jig for the lateral (East to West) router movement on the

stainless steel guide rods. I am currently using a thin strip of wood

on the left hand side of the mortise jig held in position by two small C

clamps. I drilled the left router guide rail and installed an E-Z

LOC threaded bushing for a 1/4 x 20 tpi threaded rod with knob for such

an adjustment, but as the old saying, "When I get around to it".........grin

if you must!

A COUPLE ROOKIE MISTAKES

I had a couple "rookie" mistakes making this jig by not clamping the jig

plate securely enough to the base of the mortise jig Plexiglas member which allowed the jig plate to

shift. I corrected one of the rookie mistakes by gluing in a 1/2 inch

diameter dowel rod to the end of one of the mortises on the jig plate which

was too long because the longitudinal temporary stop on the mortise jig was not

properly engaged

to the router sub-base. Allowed the glue to set and then

re-routed the mortise slot in the jig plate with the temporary longitudinal

stop firmly in place. The other rookie mistake did not affect the accuracy of

the jig plate, cosmetic only.

TWEAKING THE JIG

I am still waiting on a long shank 3/16 inch diameter, flat bottom, two

carbide blades and 1/4 inch diameter shaft in order to route the cavity for

the body of the lock which requires a 1.625 inch deep cavity.

I had a piece of 3/4 inch unallocated cedar that was left over from a

toy

chest that I build for my Grandson

Xander McKnight Gonzales and decided to

use it as a test sample before committing the secretary/letter box and glad

that I did.

It was quickly evident the the mortise for the bolt to travel behind the

striker plate on the lid of the box was too short and had to set the mortise

jig back up to complete the mortise in the jig plate.

Also, the cavity for the body of the lock was a little too close in

tolerance and lengthened the mortise slot in the jig plate and gave both

mortises on the jig plate a test run.

Above is the test pieces for the box and the lid. I didn't take any

serious time setting the depth of the router cavity for both mortises.

The lock bolt travels upward and then to the left to engage the striker

plate cut-out.

Completed mortises in the test pieces and everything worked as it should.

The mortise for the bolt to engage the striker plate looks a little ragged,

but didn't clean off the routed edges from the spiral up-cut router bit.

When the long shank router bit arrives, then the acid test for the full mortise lock jig will get

its first work out.

Web page updated by Bill aka Mickey Porter on 05-31-19.

ROUTING THE BOX PROCEDURES

In usage, the jig will be resting on top of the front of the box and

clamped to the box. A center line and center mark on the box front side will

be the locator for the jig. Once the back walnut fence that is below

the jig is set to have the jig guide bushing mortise centered over the center of the box front

where the selvedge will rest, the fence is locked tight with the set screws

and the jig clamped securely to the box.

The router depth is set for the thickness of the selvedge which is about

.093 inches. Using a small plunge router, DeWalt DWP611PK with 3/8 inch diameter guide

bushing and a 3/16 inch diameter router bit, route the mortise for the selvedge. Remove your clamps.

Slide the jig where the cut-out mortise in the jig for the full mortise

of the lock is centered over the selvedge and set your router depth for the

required depth of the lock being about 1.625 inches. Clamp the jig in

place to prevent any movement which will spoil your routed cavity for the

body of the lock and route the cavity aka mortise using multiple passes

until you reach the required depth. Usually 3/16 to 1/4 inch depth

passes will not load the little 1.25 HP router down or spoil the router bit.

Using a 1/4 inch and 9/64 inch diameter drill bit, drill each hole using

the purple heart drill guide plate which is correctly positioned already for

the lock key way.

You later can free hand chisel or route the distance between the 1/4 inch

diameter hole and the 9/64 inch diameter hole to complete the key access to

the lock. Do not drill through the entire thickness of the box stock.

NOTE: I plan to add a steel plate (drill guide bushing) and

replace the purple heart drill guide bushing plate, but in all probably the purple

heart will last for a very long time....will wait and see on this idea!

ROUTING THE LID PROCEDURES

Remove the jig from the box and position the jig onto the lid. The black

walnut fence should already be correct. Position the center of the

mortise cut-out in the jig plate over the center of where the strike plate will go and secure the jig

with clamps to prevent any jig movement. Set your router depth for the

thickness of the strike plate which is .050 inches. Complete your

routed mortise. Remove the clamps.

Loosen the two set screws and reposition the rear walnut fence, or add an

appropriate thickness filler strip where the smallest

mortise in the jig plate is centered over the strike

plate and clamp the jig in place. Set the router depth to 3/8 inch and route the

mortise for the lock bolt. Remove the jig from the box

lid.

Using a chisel or small router such as a Dremel tool, etc., remove

material between the 1/4 inch diameter hole and the 9/64 inch diameter hole

for the key access. This will be the only free hand operation for the

lock install. The holes are close enough to blend them together using

the 9/64 drill bit.

I used a Dremel and 1/8 inch solid carbide spiral cutter to fine tune the

key hole access.

Routed the mortises for the full mortise lock and the lid striker plate

and lock bolt mortise. I had to rework the drill jig plate for the key

slot and the jig plate was not properly centered to the jig plate. My

first drill holes were to the right of center line, but when corrected, the

escutcheon adequately covered the ragged looking hole which looked like a

giant Warf rat had gnawed the opening.....grin if you must!

I will install the lock and striker plate, but will leave off the

escutcheon; cover and tape the opening when I spray lacquer and drill holes

for the escutcheon pins. I will also mask over the lock selvedge plate

and strike plate also prior to spraying several coats of lacquer.

Striker plate below getting pilot holes drilled for the lock bolt to

engage.

I used a Speedy 5/64 self-centering drill and then drilled the pilot

holes to 3/32 inch which gives about .010 inch grip and more than enough.

It is very easy to strip the soft brass screws even with the 5/64 inch pilot

hole in very hard wood.

In summary, the jig works

well, but with the length of the jig plate for all the mortises presents a

few clamping challenges, but clamping is doable!

The mortise for the lock body cavity needs to be reduced in width a few

thousands where the lock body mortise will not be flush with the selvedge

plate of the lock. At the moment, both the selvedge mortise and the

lock body mortise is .375 +- inches. I will simply add a piece of tape

to the mortise in the jig plate to reduce the lock body cavity mortise

width. The router guide bushing rides against the inside wall of the

mortise on the jig plate and doubt I would ever wear the tape out.

I am seriously thinking about making a Plexiglas 1/4 inch thick template

for the Rockler

Jig It jig mortise system since I already

have my mortises figured out for a 3/8 inch diameter bushing with a 3/16

inch diameter router bit. This will be another challenge due to my

equipment limitations, but I believe I can make it happen by thinking

outside the box so to speak as far as positioning the Plexiglas underneath

my mortise jig.

Web page published by Bill aka Mickey Porter on 05-27-19 and updated on

06-03-19.

REWORKED THE JIG PLATE

I glued a thin strip of maple approximately .030 to the straight side of

the jig plate mortise for the lock body and had to fine tune it by filing and

sanding it down and got an excellent fit using some scrap cedar wood to do

test mortises, etc. I also fine tuned the drill plate for the key

hole too.

Web page updated by Bill aka Mickey Porter on 06-04-19.

COMPLETED SECRETARY/LETTER BOX

Above pix taken under a light box; doesn't' high light the wood color and

grain pattern.

My bride is enjoying the secretary/letter box!

Web page updated by Bill aka Mickey Porter on 06-11-19.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."