XANDER'S TOY BOX AKA BLANKET CHESTOur

youngest daughter Lisa Dianne Gonzales asked last year or earlier if I would

build our youngest Grandson

Xander a toy box of which I agreed to do so. I

started the project in the middle of February 2016 and taking my own time

since I am in the retirement mode and try not to get in too big a hurray,

however time waits for no one!

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep Safety

paramount because hand and power tools can do serious bodily harm and death

if not used properly, therefore these pages are solely for

entertainment purposes only from

a personal liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues

before going any further.

LETS GET STARTED

I researched the internet for some ideas on the design of which there are

numerous types ranging from very simple to some very ornate. I decided

to go with something above just a simple box with a design where it could be

used later on in life to store other things since the toy storage stage will

be quickly outgrown in due time. Another thing I had to consider, was a design

that would allow me to utilize what available equipment and tools that I

currently have and with the small tight quarters of my basement garage woodworking shop

which has a large percentage occupied by storage shelving units, etc, I am

definitely limited in the size of the project!

I also wanted to use something besides birch plywood as the main body of

the box desiring to see some wood grain pattern and went with 3/4 inch pine board glued up panels that were 2 x 4

foot in size and available at our nearest Lowe's in Rockingham, NC. I

have capability to glue up such panels but no use reinventing the wheel on

this one; maybe for using some other wood than pine. I

initially decided to use the same 3/4 inch thick pine board panel for the

lid but after I started to install the top banding and edge trim around the

box, I was a little short on

the width of the panel which I will detail later on. I could have used

the panel with a border but the panel developed a serious bow in it. I went with a

heavier 1 inch thick pine board panel which is probably an overkill on my part

but that is part of my DNA profile. One of my friends Robert Webster

of Hamlet, NC told me that no one could ever accuse me of under building

something. I didn't have a

formal drawing for the toy box but more or less

winged it which will

likely cost

you a few mishaps along the way as I just mentioned earlier and

Murphy's Law

quickly rises to the occasion.

My woodworking shop is barely large enough to handle a 2 x 4 foot box and

my table saw is taxed to try and cut panels any larger than 24 inches in

width of which I

have to use a couple saw horses outside, circular saw and

saw guide

to get a larger panel cut down to a manageable size. The usage of my home

made panel sled for the table saw can then get the panels cut to size and

square. My out feed table doubles as a work

station and I can rip 8 feet length stock up to 24 inches wide which is

near the limit of the table saw adjustable fence.

As noted on my last

woodworking project, I found that most of

the framing squares and tri-squares are not perfectly square unless they are

manufactured by someone like Starrett who makes precision measuring

equipment but it is high dollar....most of the

time, you get what you pay for!

CUTTING THE PANELS TO SIZE AND ASSEMBLY

I started the project off by cutting the 2 x 4 foot glued up pine board panels to size:

I used the above home made impromptu crosscut sled to cut the panels to length

because it was not square and used the rip fence to cut the panel to the width needed. I later

made a much more accurate crosscut sled just for 90 degree crosscuts and

have sleds for forty-five degree

crosscuts and a miter sled.

After the panels were cut to size, the five panels were glued and screwed

together using 1 1/4 inch drywall screws. I should have installed the

bottom panel with it resting on a

ledger board on the sides and ends but there is enough wood

screws and glue to hold it in place along with the corners resting on the

inside portion of the legs which act like a ledger board.

Click on below thumbnails pixs for a larger screen view:

A

Fuller brand combination tapered drill bit and countersink was used to pre-drill the holes to

prevent the wood from splitting since the screws were only 3/8 inch

from the edge of the material. After the box was glued and screwed

together with the aid of some long bar clamps, a handle opening on each end of the

box was cut using a forstner bit and jig saw. The handle openings will

also double as a safety feature

allowing air to circulate into the box in case Xander decides to play inside

the box with the lid closed which could very well easily happen.

LEG CONSTRUCTION

The next order of construction was the legs which were made from clear

pine 2 1/2 inch width boards ripped down to 2 inches and decided to put a

forty-five (45) degree miter on two adjoining sides instead of just abutting

them together which should give a little more eye appeal. The finished

legs attached to the corners of the box will give the illusion of being

solid since the end of the leg will have a solid square glued in place and

later the lower portion of each leg will be tapered using the band saw. Face frames

aka stile and rails will

be added to the box before the legs are attached for the additional layer of

depth perception.

Click on the below thumbnail pixs for a larger screen view:

I thought I was going to have to make a glue up jig for the legs but

remembered a technique that was used by box builder Doug Stowe who authored

Basic Box Making which utilized masking

tape to hold the pieces together for the glue up which works great if your

parts fit together as they should. Each ninety (90) degree portion of

the leg will be also be glued and screwed to each corner of the box with the

screws countersinked and covered with poplar dowel rod inserts. The

usage of the legs on top of the face frames will give one more element of

depth perception for the recessed style panel construction. I am not

concerned with the extra amount of material used on this project.

RECESSED PANELS

Since I do not have router cutters to produce raised panels to dress the

box up, face frames were made using the same material I used for the legs

being 2 1/2 inch width clear pine boards to give some depth perception and

eye appeal to

the box. They were cut to length and

used the

Dowelmax jig

system to install a pair of 3/8 inch dowels into each

stile where it connects to a rail. A

Kreg pocket hole jig would

be the tool of choice for this since it is much faster than the Dowelmax

system and the screw hole pockets would not be seen anyway, whereas joint strength is

not an issue here since the face frames will be glued and screwed to the box.

I plan to add a Kreg pocket hole system to my shop in the near future since

I have a few more projects in mind that could utilize the pocket hole screws.

For strength, reliable test have problem dowels are a much stronger joint

with the mortise and tenon topping the list.

Click on the below thumbnail pixs for a larger screen view:

After the face frame panels were allowed to dry overnight, they were attached to the

box using Titebond II glue, drywall screws and countersunk the screws that would show and

added poplar 3/8 inch diameter dowel plugs to hide the screws.

Click on below thumbnail pixs for a larger screen view:

BOSCH ORBITAL SANDER BIT THE DUST

After the poplar dowels were added over the screws and allowed to dry

overnight, it was time to sand

them down flush using a Bosch 5 inch diameter orbital sander of which the

socket head bolt that secures the pad broke requiring a complete disassembly of the tool

in order to get to where I could drill and remove the broken portion of

the socket head bolt inserted into the end of the motor shaft that drives the pad.

Murphy's Law

never sleeps.

After drilling out the center of the bolt in the end of the motor

armature which came out without having to use an EZ out extractor

tool, there was not a replacement size 7 x 16mm socket head bolt to be

found locally and had to order a replacement on line. Below is a pix

of the broken bolt:

I had to order the part from Utah and ordered the wrong bolt; my bad

since the parts schematic diagram shows the correct parts.....grin if you

must....had to order the correct part and the shipping was about three times

the value of the bolt but things like that happen when you don't pay

attention to detail. Anyway, got the bolt in and put the sander back

together and it worked fine; image that!

LEG INSTALLATION

It was time to install the legs after band sawing the taper on two sides

of each leg.

The legs were glued and screwed in place over the face frames with the drywall screws and the countersunk

screws had poplar dowels added to hide the screw. A top border was added to the

box with forty-five degree miters with an overhang to give a little more

depth perception to the upper portion of the box.

Click on below thumbnail pixs for a larger screen view:

The rear portion of the top border was routed for the piano hinge prior

to gluing and screwing it into place which is flush with the back with no

overhang. I did a mock up test with the

cut-off portion

of the hinge to ascertain the proper depth needed for both the

lid and the box with thumbnail pixs below:

FIRST MAJOR "MISHAP" OF THE PROJECT

After getting the 1 inch thick lid cut to size, I had some scrap walnut and

wanted to place a border around the front and sides, however the walnut was

too short and added a piece of pine in the front center so the border

would be long enough. After getting the front border glued up and

dried overnight, the

front and side pieces went to the router table where a decorative edge was

milled into it. Forty-five degree miters were cut, dowels fitted along

with some # 20 size biscuits. Everything fit like a glove and tried

and do the glue up for the front and sides at one time which was a major

disaster/mistake. Before I could get all the dowels, biscuits, etc., in place,

the Titebond II extended time glue set up, whereas it was impossible to get

the left side border to pull together with the bar clamps and the aid of a hammer. I

had to cut the walnut border from the lid, re-square the lid back up and start

over on another border. I had some 6/4 cedar boards and decided to

use them as I needed 1 inch finished thickness to match the lid thickness.

After getting everything redone; e.g., planed down to thickness, cut to size, border routed, dowels

and biscuits re-cut, it was time for another glue up. This time, I

decided to glue the front up first and let it dry overnight and do the same

thing for each side border which worked out very well. After the lid

border was dry, I installed additional longer dowel rod pieces into the back

of the lid for additional support.

Click on below thumbnail pixs for a larger screen view:

MOLDING TRIM ADDED TO THE PANELS

Two types of standard moldings were used being a

cove molding under the top

band and a base board

cap molding for the panels and base

available from Lowe's and our local H. W. Little, Inc. Hardware. I

used my home made forty-five (45) degree miter

sled on

the table saw and miter saw to cut the

moldings. The molding was installed using 18 gauge wire brad nails driven by a

pneumatic

DeWalt DWFP12233 brad nailer

and Titebond II glue to secure the molding trim in place.

I remember as a young lad, during the summer months my Uncle

Doug Coley

would "hire" my brother and

myself to help him in his masonry construction

business and observed how the finish carpenters cut and applied moldings

and most used a home made

wooden miter box and a few had a much nicer

metal

miter box all powered by a thin hand trim saw. That was

an era when a carpenter carried his tools in a large open style wooden tool

box. Things has really changed since then.

Click on below thumbnail pixs for a larger screen view:

LID HINGE INSTALLATION

The heavy duty steel piano hinge was cut to length earlier and a 82

degree countersink was used to taper the factory punched holes for size # 10 flat head

wood screws to allow the piano hinge to lay fairly flush. As

stated earlier, I already did a mock up test install on a scrap piece

of wood to ascertain the proper depth needed for the hinge and

pre-drilled the holes in the box and the lid using a self-centering 9/64"

Vix bit for # 8, 9 and 10 wood screws.

Click on the below thumbnail pixs for a larger screen view:

The lid was removed after the test installation and everything sanded to

220 grit using a Porter Cable 330

palm sander. I finally had to replace

my 1969 Rockwell Speed Bloc 330 palm sander which is the same exact

model as the Porter-Cable. I definitely got my money's worth out of

that palm sander which was still working but had gotten far too noisy and

too much extra vibration. In the hyperlinked pix circa mid 1070s, my bride has an

awkward hand position on the Rockwell palm sander wanting to

"show case" a ring while she was

sanding a Gibson RB5 Pre-War Banjo Wreath

pattern fingerboard recently cut and inlaid by

yours truly.

RETHINKING THE LID DESIGN

I can't remember why I decided to use only the mitered cedar border on the front

and sides instead of mitering a matching piece for the rear unless strength

was an issue which I don't think it would have been a problem. Like I

said earlier, I have been somewhat "winging it" on this project without a drawing,

blueprint or diagram and it has come along pretty good so far. After

looking at the top of the lid, it just didn't balance out and lacked the eye

catching quality I was looking for and

decided to add a strip of matching cedar inlaid into the back of the lid.

Now I remember why I didn't use walnut for the rear of the lid; I didn't

have enough 1 inch thick walnut to add to the lid......CRS (clean version,

"Can't Remember Sometimes" kicked

in earlier....grin if you must! However, I did have enough cedar but

had already routed the channel for the piano type hinge and pre-drilled the

holes. It is best to

do it right the first time!

Click on below thumbnail pixs for a larger screen view:

I had a piece of the cedar molding long enough and ripped a piece a little

over 3/16 inch thick to fit between the two cedar side pieces at the rear of the

lid. I got a couple routers out and decided to use the smaller 1.5 HP

DeWalt router and used a straight edge as a guide for the router to control

the maximum width of the cut into the top of the lid. I set the router up using a

1.125 inch diameter two fluted carbide tipped cutter which cuts flush on the

bottom. I also set up a scrap piece of material and did a test run on

it to get the router depth adjusted and the straight edge width needed from the edge

of the rear of the lid. Routers work great but most of the time you need some type

of means to control its path whether it is with a guide bearing, guide

bushing, straight edge or fixture which controls and limits the movement of the router.

Those items are like a road map or GPS to the router to get you where you need to be.

Using the plunge router with the edge guide would have required more

set-up time using a longer auxiliary board for the edge guide to ride

against and there would be some clamping issues too and the smaller router

with the board used as an edge guide worked fine.

After the channel was routed, everything went along fine and freehand

routed the end of the channel and finished squaring the corner of the routed channel with a

3/4 inch chisel and mallet. I glued and clamped the cedar board in place and

after drying overnight, I will remove the

clamps and finish sand the cedar insert board. Below pix of the lid:

I like the lid much better now with the pine totally surrounded by the

cedar.

I ordered a pair of

Stabilus 150N Lift-O-Mat Gas Springs for

the lid support since the lid weighs 16 lbs. which are on back-order.

STAINING AND FINISHING

My bride was looking at the pixs taken so far and wanted to know why the wood

molding trim was more gold colored and I told here it was the color/hue or

shade of the pine molding (apparently two different species) which should stain and match the pine cabinet once

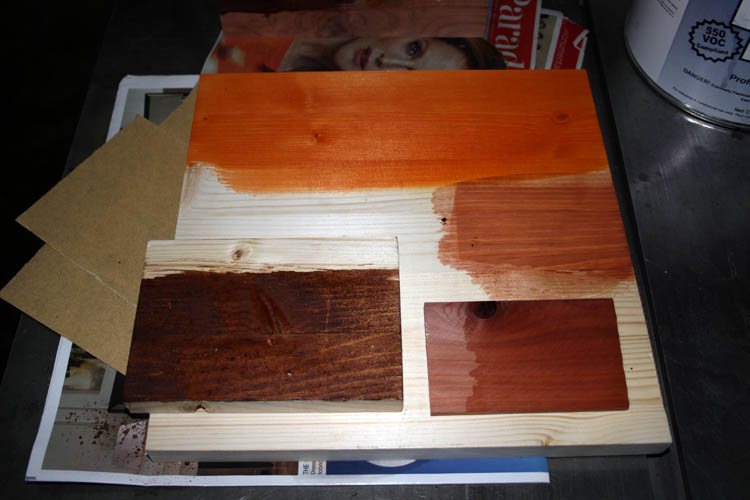

the stain/poly is applied. I am going to test out Min-Wax Polyshade

Chestnut color combination stain and polyurethane on scrap material and see

how it looks. If I don't like it, I will go with a separate stain and

polyurethane finish.

Web published by Bill aka Mickey Porter on 03-05-16.

FINISHING STARTED ON 03-07-16

I tested out the Min-Wax Polyshade and didn't like it. I did a test

panel or two with a couple different alcohol based stains but decided to

finish the toy box with clear musical instrument lacquer to show the natural

grain pattern of both the pine and the cedar. There are three

different species of pine in the box with each having a different hue and

grain pattern which is ok too.

I have left over sanding sealer, lacquer and lacquer reducer from my

banjo construction

project and hope the ole

Lynx L300H CATechnologies HVLP spray gun is still

operational.

I used my summer sausage

drying rack to support the lid and used a four

wheel pull cart for the toy box and applied a coat of sanding sealer to the

lid and the box. They were allowed to dry and lightly buffed with

a Scotch Brite green pad. I do not have an inside spray booth and have

to work with the weather conditions and do my spraying in front of the basement garage

entrance to the shop. The weather was fantastic today with a

light breeze blowing and got a couple coats of lacquer applied. I will

spray a couple more coats of lacquer on tomorrow and let it harden a few

days to a week before buffing it out. All I want is a protective coat

of finish and not going for a musical grade type finish.

Click on thumbnail pixs below for a larger screen view.

Web published by Bill aka Mickey Porter with update on 03-07-16.

SPRAYING LACQUER CONTINUED 03-08-16

Around mid-day, the temperature was in the low 70s with the humidity

around thirty-four (34) percent per a Google check and was time to add a

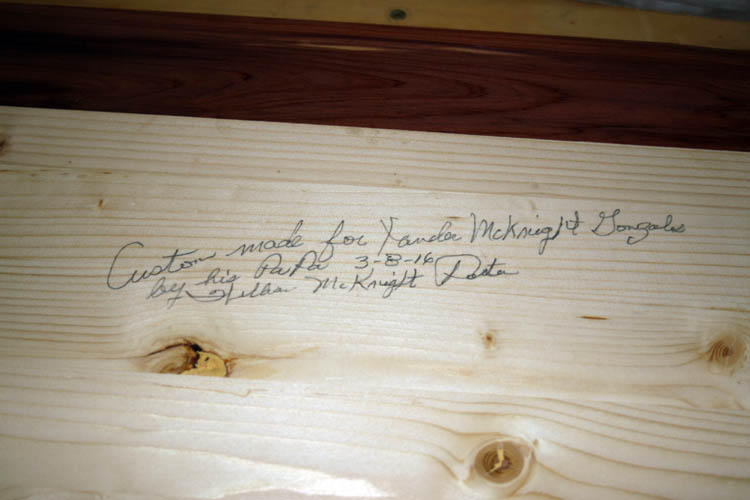

couple of clear coats to the underside of the lid. Our daughter wanted

me to sign and date the box for Xander of which I did prior to spraying on

the first coat; pix below of the inside of the lid:

I applied two coats of lacquer to the lid and one or two coats to the box

and will let it dry before any additional top coats are applied. My

lacquer reducer for the

Mohawk nitrocellulose lacquer was getting

very low and ordered four (4) gallons to keep from having to pay a

surcharge for less than their minimum order standard. I am sure it will get used on my woodworking projects;

besides, it doesn't eat anything......grin if you must! The lacquer is

manufactured in Hickory, NC and Mohawk-Finishing also produce and sell other labeled

musical instrument finishing products as well.

Web published update by Bill aka Mickey Porter on 03-08-16.

WAITING ON THE

Stabilus 150N Lift-O-Mat Gas Springs

The toy box is completed except for lift-O-Mat Gas

Springs. Below pix with the lid installed:

Web published update by Bill aka Mickey Porter on 03-14-16.

XANDER'S BIRTHDAY PARTY

Today is March 20, 2016 and still waiting on the gas springs for the

Xander's toy box aka blanket chest. Xander's birthday is tomorrow and

his Dad has to work so Steve, Lisa, Xander, my bride and myself met at the

Pizza Inn in Rockingham, NC for an early birthday lunch celebration.

After the lunch, we met at our home and Xander got his birthday cake, ice

cream and some birthday gifts. I forgot my camera mode was set for an

outside sunny day setting and the WB setting was incorrect for using in the

auto mode inside but things like that happen, especially more so in the

Senior Citizen mode.....grin if you must!

Click on below thumbnail pixs taken for a larger screen view:

We had a great time and Xander was in over drive this afternoon.

Hopefully, the next picture will be the installation of the lid gas

springs.

Web published update by Bill aka Mickey Porter on 03-20-16.

Stabilus 150N Lift-O-Mat Gas Springs

finally arrived on 04-19-16

The Stabilus gas springs finally arrived and

installed them on 04-20-16 and plan to deliver the toy box aka Blanket chest

tomorrow. The springs works very well even though it might get a

little ones fingers when the lid closes but the force is greatly reduced by the

gas springs, whereas the lid weighs sixteen (16) pounds. I placed a felt pad under one corner to take give some

space between the lid and the chest. As soon as you raise the lid

upward a few inches, the gas springs take over and raises the lid in slow

motion to its maximum opening position which is a little less than 90

degrees. In closing, the springs will slow motion close the lid except

the last few inches which has some force to it which could get a little ones

finger but like I said earlier, the force is greatly reduced.

Below a couple pixs taken:

I am very pleased with the finished toy box and it was another learning

experience. I found out the hard way that

all squares

are not square and one of the ole Marine Corps sayings,

"Adapt and Overcome" and that is

exactly what I did.

I am currently building additional

napkin holder boxes for gifts; might sell a

few and learning new things in the process.

Web published update by Bill aka Mickey Porter on 04-20-16.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."