CHANGING JET 13" PLANER/MOLDER JPM-13CS KNIFES

I purchased a Jet 13" Planer/Molder over seven (7) years ago and a set of

special molding knives to form the radius on my

turkey box call lids.

That planer/molder has gotten a serious workout, not only with turkey box

call lids but some of my projects such as

heirloom boxes,

napkin holders,

serving trays,

hanging porch swing,

banjo construction, etc., of which a good amount of the surface planing was on

hard curly maple wood which takes a toll on dulling the planer knives very

quickly.

Above is an internet stock photo of the Jet 2 in 1 planer/molder.

After looking at what a replacement set of planer knives for the Jet 13"

planer cost, it was definitely cost effective to have them re-sharpened at this

time; at least that was surmised.

I carried the knives to a a facility that specializes in sharpening saw blades of all types

and of course planer knifes. The turn around is around a week.

I did internet searching and found several companies offering replacement

knives for the Jet 13 inch planer/molder and they priced in range from over

100 bucks directly from the Jet distributor to 39.95 for a set of

Titan Knives. There were cheaper

knives, but when the shipping was factored in, the Titan Knives were the

best bang for the buck. I ordered a set of the

Titan Knives from Oella Saw and Tool located in Elliott City, MD and the

knives arrived on 04-12-17, which excellent quick service.

PERSONAL SAFETY AND LIABILITY ISSUES

My goal will be to keep Safety

paramount because hand and power tools can do serious bodily harm and death

if not used properly, therefore these pages are solely for

entertainment purposes only from

a personal liability standpoint. Please read the

Legal Stuff

page for additional information concerning liability issues

before going any further. Safety glasses and hearing protection is a must,

although I do forgo the hearing protection many times; my bad!

SAFETY FIRST - DISCONNECT POWER SOURCE

Safety has to be first, therefore unplug the power cord to the machine.

If directly hard wired, flip the breaker switch to the off position and secure

breaker panel where no one else can flip the breaker switch back to the on

position. This is mandatory in a work environment!

In order to remove the planer knives, there are three (3) hex socket head

cap screws on top of the dust hood dust chute and three Phillips head screws

on the rear of the dust chute.

After removing the three hex socket head cap screws and three Phillips

head screws, the dust cover and chute can be removed by pulling the cover

upward, allowing access to the cutterhead assembly which contains the three

knives, long and short lock bars.

Exposed cutterhead assembly below.

With a marking pen, label each knife on the cutterhead one, two and three

for easy identification. I went ahead and labeled the lock bars for

each knife also.

Loosen all lock bar set screws on knife number one. With the brass

rod that is provided in the tool kit with the machine; using a mallet,

carefully tap on each end of the outside of the set screws for all three

lock bars on knife number one in a downward direction. This loosens the taper fit of the lock

bar causing the lock bar to go downward into the slot of the cutterhead

assembly removing tension against the knife and the side of the cutterhead

slot. Carefully remove knife. Remove lock bars. Clean all

surfaces of the cutterhead, slot, gibs, locking bars, etc. Repeat the

same for knives two and three.

AUXILIARY PLATFORM

The center short 2 inch length lock bar is for special molding of which

the molding cutter knife will be at least 1/8 inch higher than the regular

cutterhead knives and requires a special trough to be made to center the

wood in line with the molding cutter knives. Also, the in-feed and

out-feed rollers have to be re-adjusted when using molding knives.

There is a lot of set-up involved to use the center slot for molding knives

and a dedicated molding machine would be highly desirable. With the

molding knives in place, you are limited to the width of material you can

plane and also you are limited to a 2 inch wide molding cutter which worked

fine for my turkey box call lids since they were a little less than 2 inches

in width. I used the above machine mostly for making turkey box call

lid radius cuts and did many years supply of the lids at one set-up before removing the

special molding knives and trough/auxiliary platform. I currently, use

the planer just for surface planing instead of making box call lid radius

cuts.

Below a pix of the auxiliary wood platform removed from the planer with a Eastern

Red Cedar board that had been planed using the special set of radius knives

in the molding cutterhead.

The little Jet 13 inch planer/molder did a great job cutting the radius

for the turkey box call lids.

Above is pix of the cutterhead assembly with the knives and lock bars

removed.

You repeat the above steps for knives two and three.

Above pix of the lock bars, brass rod, Allen wrench and the adjustment

height tool for the cutterhead knives.

I will post pixs of installing the sharpened knives into the cutterhead

when I receive them back from.

INSTALLING REPLACEMENT KNIVES

I received the reground knives on 04-11-17 and

was not impressed with the

regrind. The knives would definitely not shave any hair off my arm and

only one knife would begin to cut a regular piece of paper. I could

see the knife edges and they were basically a little blunt. Apparently, there

was a two stage grinding done and the second final grind did not come to the

edge of the knife to produce a razor edge, even though around a 40 degree

angle and a little bit of a hollow ground instead of a flat ground was

present on the knives.

Also, I put my calipers on the width of the blades and they varied from .618

to .625 which is not precision grinding in my book. Although this is not a big issue,

since each knife can be adjusted to Jet's standard using the set-up tool

provided with the machine. The regrind was a wasted

$ 16.05 in my humble opinion, therefore I did not install the original Jet reground

knives. I am sure I could sharpen the dull knives on a flat surface

using conventional techniques without any expensive equipment, but will

chalk this one off to experience.

Instead, I installed a replacement set of planer knives manufactured by

Titan Knives and they were razor sharp. Those knives were flat ground

to an excellent smooth finish, whereas the original Jet knives were vertical

ground which will leave a micro serrated edge since they appeared to be

ground to about a rough 100 grit.

Click on the thumbnail pixs below for a larger screen view:

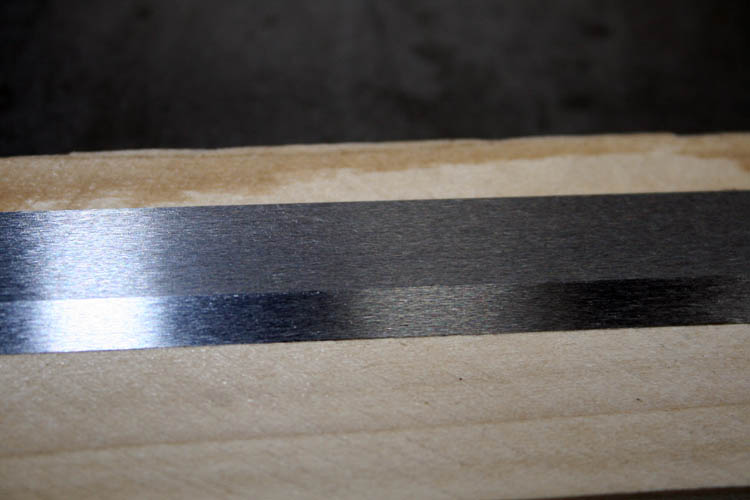

Below is a close-up pix of the back side of one the original Jet knives that

came with the machine. As evidenced by the rough vertical

manufacturing grind lines, the knife edge will be somewhat serrated if

viewed under magnification. The original blades performed pretty good

until they of course got dulled from usage over the years on very hard woods.

The planer hasn't been in much of a production environment as far as

continued usage and the reason the knives lasted as long as they did.

The

Titan Knives are precision made of T1 HSS with a

smooth flat horizontal ground finish on all surfaces of the knifes with the

grind lines running parallel to the length of the knife and to reiterate,

razor sharp.

To install the knives, you place all the lock blocks in the cutterhead

slot along with the spacers for the short molding lock bar for knife # 1. The knife will rest on top

of

a portion of two flat

head Allen head machine screws which are for adjusting the height of the

knives. You

tighten each lock bar to take out the slack and using the height gauge for

the knife; raise or lower the knife blade until it contacts the gauge,

checking the knife height at both ends. You could set up a

dial

indicator gauge and do the same thing with more precision if

desired.

You then tighten all the set screws pulling the tapered lock bars tight

against the knife and the cutterhead slot.

You do this for all three knives. It was a little trouble keeping

the knives flush against the height adjustment machine screws since the

blades wanted to ride upward when tightening the locking bars. I used

a hammer and wood block to tap the knives tight against the machine screws

when the knife would ride up off the flathead machine screws that control

the knife height.

After the knives were installed, the dust chute and dust cover was

installed. I will give the planer a test run before too much longer.

My next woodworking project is a

potato and onion storage bin cabinet for

the kitchen.

IN-FEED & OUT-FEED ROLLER ADJUSTMENTS

While waiting for the cutterhead knives to be re-sharpened, I adjusted

the spring loaded feed rollers. In essence, you want the spring loaded

in-feed and out-feed rollers to be about 1/8 inch downward from the

cutterhead which keeps adequate pressure onto the material you are planing,

allowing the in-feed roller to pull the material into the cutterhead along

with the out-feed roller to keep the material flat against the bed of the planer.

When I first got the machine, I made three set-up blocks, however I could

not locate them and made another set of two blocks only. Below is an archived

pix of the original set-up blocks:

Click on thumbnail pixs below for a larger screen view:

The purpose of the set-up blocks will position the in-feed and out-feed

rollers as stated above in the proper relationship to the cutterhead.

Too little pressure and the board will not be pulled through the machine and

if the feed rollers are too low, it will overload the machine and/or not

allow you to feed the material into the machine.

As a general rule of thumb, the in-feed and out-feed rollers are set 1/8"

below the cutterhead (not the knives). Make certain the power to the

machine is off!

Lower the work table to allow the cutterhead block to slide freely between the

table and the cutterhead. NOTE: Cutterhead may have to be

turned by hand to rotate a knife out of the way....in this case, I already

had the knives removed.

Adjust the table height so the cutterhead block can be inserted between the table and

the cutterhead with minimum resistance.

Remove the cutterhead block. Do not raise or lower the table at this

point. It will affect the final result.

Insert the block labeled "Feed Roller" into the planer opening.

Raise or lower the in-feed roller until it rests on top of the block end to

end. To adjust the in-feed roller, loosen the jam nut on both sides of

the in-feed roller. Turn the threaded bushing counter clockwise to

raise the roller and clockwise to lower the roller. Raise or lower the

roller until it contacts the top of the block equally on both ends of the roller.

Block should be slide in and out with minimum of force.

Repeat the process with the out-feed roller.

PRIOR MAINTENANCE

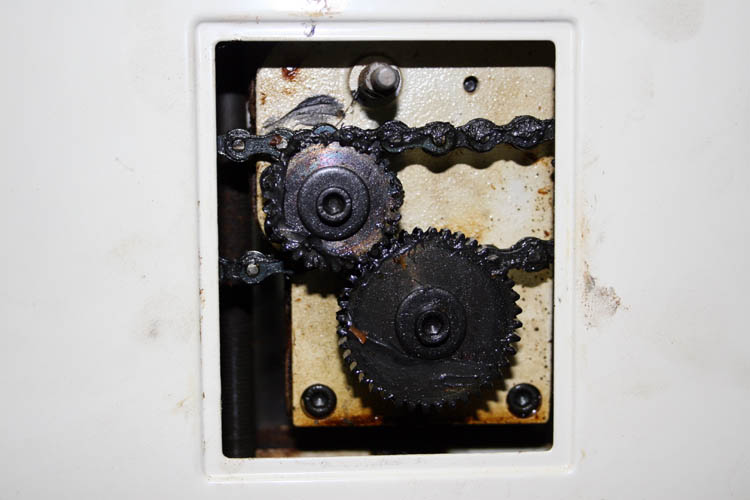

In the years using the above planer/molder, I have experienced only one

equipment malfunction around March 2010 and that was brought about by taking

to deep a cut

off a wide board which had a tapered thickness. Before I could cut the machine power off, the

machine bogged down and one of the two chain drive sprockets broke along

with shearing a keyway or two. Those sprockets appear to be cast

and/or

Metal Injection Molding technology rather

than machined from a billet of steel. It didn't take too long to get

replacement parts on line. I ordered a couple spares of each, since the shipping

was more than what the parts cost or close to the amount anyway.......don't

remember exactly the amount of shipping, but it was very excessive. Shipping

and Handing charges are a big profit for some companies.

Below pix of the spare parts:

Pix below of what the gear feed roller assembly looks like:

Web published by Bill aka Mickey Porter on 04-06-17.

WHAT IS PLANER SNIPE

Those that are senior citizens probably remember about going

snipe

hunting, either holding the bag or participating in the drive. In a

nutshell, an unsuspecting young person and maybe a little on the gullibility

side, would agree to go snipe hunting which was after dark in some remote

location. The idea was to hold a burlap sack in a small creek bed and

the party of several would go upstream and drive or flush the snipe down to

where the person holding the bag would be able to catch him in the burlap

sack. Once the person holding the bag was at the proper location, the

other party would actually leave and not return, leaving that person alone

waiting on the snipe.....grin if you must!

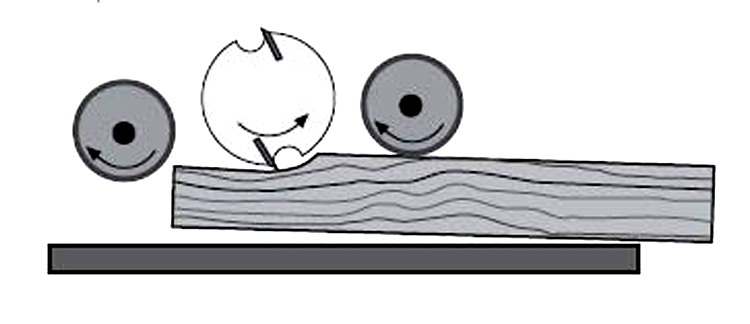

Well, planer snipe is not that kind of snipe, but a malady common to the

usage of a small planer and/or the bench top type of planer which leaves one

or both ends of the planed board a little thinner than the rest of the

board. To some degree, snipe happens on much larger planers too but

not as pronounced. The effect is usually quite subtle, but if you run

your fingers along the board, you can usually feel a slight step.

Shining a light on the board at a low angle also reveals it. Below is a pix screen captured from the internet

showing what snipe looks like:

The principle cause of snipe is the unbalanced pressure exerted by the

rubber rollers, which is normally experienced at both ends of the work

piece. When the work piece is introduced to the planer, the blades

work on the piece while held by only one rubber roller (in-feed) which pulls

the board upward slightly, after which

it is held by two rubber rollers (in-feed and out-feed) and thus equal

pressure at both ends of the work piece. This ensures that a uniform surface

is realized after the nearly invisible groove. In contrast, at the

out-feed, a situation arises when wood is held by only one rubber roller and

hence unbalanced pressure which ultimately results into a planer snipe.

GETTING RIDE OF PLANER SNIPE

It is possible to eliminate or reduce the planer snipe by applying upward

pressure on the end of the board once the in-feed roller contacts the board

holding the work piece firmly on the table during the in- feed and when the

board is about to exit the cutterhead. Alternatively, use a discarded

piece of wood in front of the actual work piece so that it takes the brunt

of snipe at both ends. This method always works, but applying upward pressure

works fine in my humble opinion.

Snipe can be sanded out in most cases, but it is best to eliminate it

altogether. In the past, if snipe was a little too deep to sand out

and there was spare material, I simply cut the end portion off of the

material that had the snipe, but that is a wasteful, when you are frugal and

using "high dollar" wood.

JET PLANER/MOLDER PERFORMANCE

For the money, this has been an excellent 13 inch planer/molder and would

recommend this machine to anyone that needs a planer with a little more

power than the bench top models. It will work in a semi-production

environment for a small shop, but a larger cabinet shop would need a much

larger and more powerful machine. Most of these types of machines are

no longer manufactured in the USA, whereas Delta, Powermatic, DeWalt,

Craftsman, etc. were once manufactured here in the USA and high

quality machines. A Grizzly planer is a comparable machine to the Jet

brand. Most of the time, you get what you pay for!

It is sad, the Cooperate Greed of America has sent many of our

manufacturing jobs to foreign countries for the sake of the all mighty

dollar! See scriptures below.

Web published updates by Bill aka Mickey Porter on 04-09-17 and updated

on 04-12-17.

LEAVING ON A

SPIRITUAL NOTE

If you do not know Jesus Christ as your Lord and Savior, please take

this moment to accept him by Faith into your Life, whereby Salvation

will be attained.

Ephesians 2:8 - 2:9 8 For by grace are ye saved through

faith; and that not of yourselves: [it is] the gift of God: 9 Not of

works, lest any man should boast.

Hebrews 11:1 “Now faith is the substance of things hoped for,

the evidence of things not seen.”

Romans 10:17 “So then faith cometh by hearing, and hearing by

the word of God.”

Open this

link about faith in the King James

Bible.

Romans 10:9 “That if thou shalt confess with thy mouth the

Lord Jesus, and shalt believe in thine heart that God hath raised him

from the dead, thou shalt be saved.”

Open this

link of Bible Verses About Salvation,

King James Version Bible (KJV).

Hebrews 4:12 “For the word of God is quick, and powerful, and

sharper than any two edged sword, piercing even to the dividing asunder

of soul and spirit, and of the joints and marrow, and is a discerner of

the thoughts and intents of the heart.”

Romans 6:23 “For the wages of sin is death; but the gift of

God is eternal life through Jesus Christ our Lord.”

Romans 3:23 “For all have sinned, and come short of the glory

of God;”

Micah 6:8 “He hath shewed thee, O man, what is good; and what

doth the LORD require of thee, but to do justly, and to love mercy, and

to walk humbly with thy God?”

Philippians 4:13 "I can do all things through Christ which

strengtheneth me."