SWITCHING TO CROSSBOW

After pulling back my antiquated 60 pound pull Mathews

Drenalin solo cam

bow a time or two, I decided it was time to either stop bowhunting or start

using a crossbow because of a decline in my strength. It was about all

I could do to break over the cam bow and that was the deciding factor for

considering a crossbow.

I am sure if I practiced enough pulling the Mathews Drenalin bow back, my

shoulder strength would return, but I think I made the right choice.

CROSSBOW HUNTING IN NORTH CAROLINA HISTORY

Crossbows became legal to hunt with on August 1, 2010 here in North

Carolina. Prior to that date, to hunt with a crossbow during archery

season, you had to obtain a special permit requiring a Physician to state

you were unable/physically challenged to use regular archery equipment.

I remember those (can't remember specific names for certain) circa early

1980s, that were not physically

challenged, but to lazy to practice with a regular bow and arrow and

therefore obtained a "handicap permit" to

purchase a crossbow to circumvent the regulations. I also remember one

individual, now deceased that would shoot a deer with a high powered rifle

during archery season and stick an arrow through the bullet hole. One

individual was also fined for using a high power rifle during squirrel

season to hunt deer early, of which the Game Warden didn't buy his outright

lie.

Some of us have to learn the hard way to observe game rules and

regulations and it will reduce the size of your wallet very fast if

doing so. I am

referring to a

personal incident from 1969 and as the ole country boys would

say, "Got broke from sucking eggs"........grin

if you must!

BACK TO THE CROSSBOW

Cocking a crossbow with the standard rope cocking device, you use your

lower back and both arms straightening up and then pulling upward with both arms,

whereas the ball of your foot is inside the stirrup

at the end of the crossbow which is much easier than pulling a cam bow back

in my humble opinion. However, a truly physically challenged person

would have much difficulty with a standard rope cocking device before the

advent of the mechanical wench and lever type cocking devices.

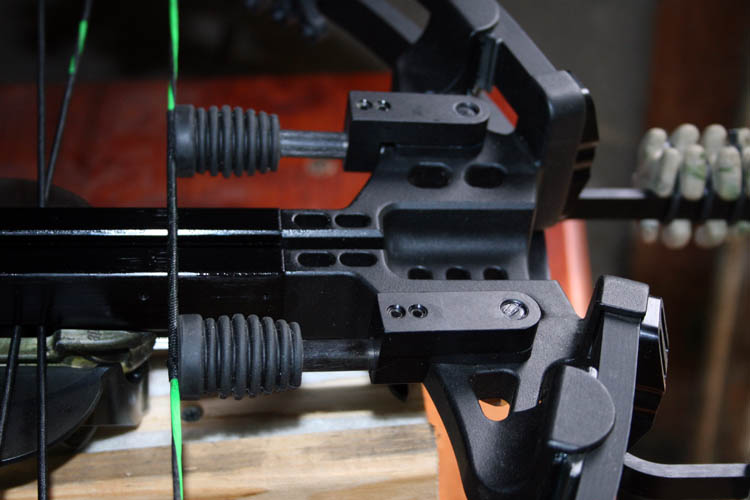

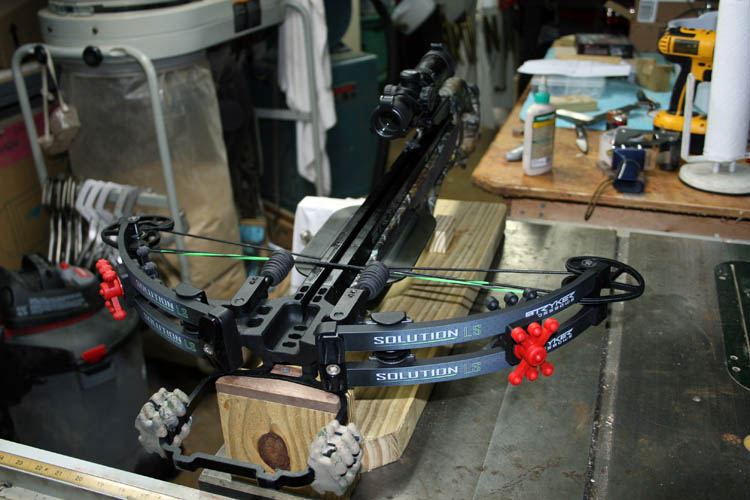

STRYKER STRIKES AGAIN

My friend

John Gaddy who lives in Polkton, NC stopped hunting altogether

the past few years and recently sold his four wheeler and I knew he still

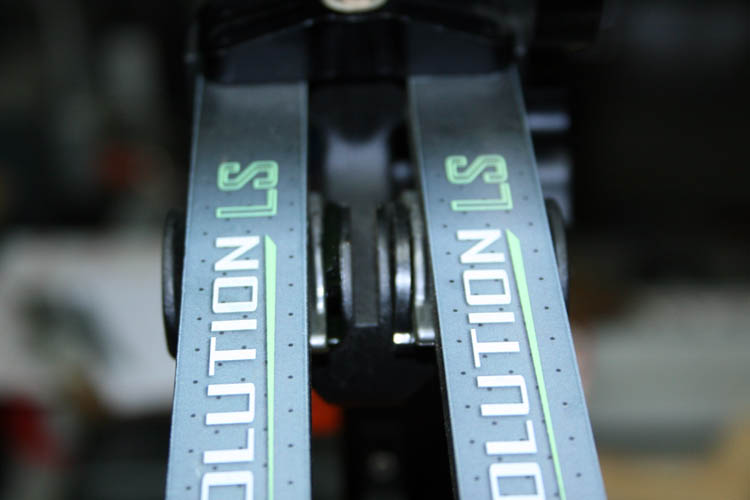

had one crossbow left which was a Stryker Solution LS circa 2014. I contacted

John and he gave me a good deal on the entire package which retailed for

about 1K when he purchased the crossbow.

Big John Gaddy strikes again on 10-17-14 with his Striker Solution LS Crossbow.

Below is a 8

point buck that weighed 221 pounds sporting a rack with 17 inside

spread. Several asked the deer processor was his scales right and he

said they were correct. The buck traveled a good 200 yards before

expiring with a shoulder wound of which Big John was trying to make a heart

shot, but sometimes it just doesn't happen the way we want it. John had

to recruit some help from Jody Brown and ole Jody bird dogged the buck down

which left no blood trail due to the location of the wound. This buck

was harvested at an undisclosed location here in Anson County, NC.......grin if you must!

John has killed several good bucks with the Stryker Solution LS crossbow

and hopefully I can put some venison in the freezer before too much longer

using the crossbow!

I went and looked at the crossbow and it was in mint condition and the deal

was sealed with the exchange of some greenbacks. I shot the crossbow and it was much louder than I am

use to with a regular parallel limb cam bow, but the accuracy was there.

The crossbow speed was rated at 390 feet per second at a 155 pound draw

weight using a 392 grain arrow/broadhead combination, of which I am not

really that concerned about arrow aka bolt speed having killed many deer

with both recurve, round wheel compound and cam bows. Speed doesn't

kill, it is proper broadhead placement to have venison on the table and in the

freezer.......grin if you must!

TARGET FOR THE CROSSBOW

Yesterday, 08-21-2020, I went to Dunham's in Rockingham, NC and purchased

a Morrell's Yellow Jacket crossbow target for field points and a tube of

Excalibur rail lube.

This morning, 08-22-2020, I shot three test bolts at about 19 to 20 yards

with the 125 grain field points since I

plan to use the existing Thunderhead 125 grain 3 blade replaceable blade

broadheads I have. John had one quiver with five (5) of the Rage type

retractable two blade broadheads and a package of three (3) Montec G fixed

blade broadheads all being 100 grains and three quivers total with some

field points. There was also a couple practice Rage type broadheads

with some loose replaceable blade broadhead, of which I don't plan to use.

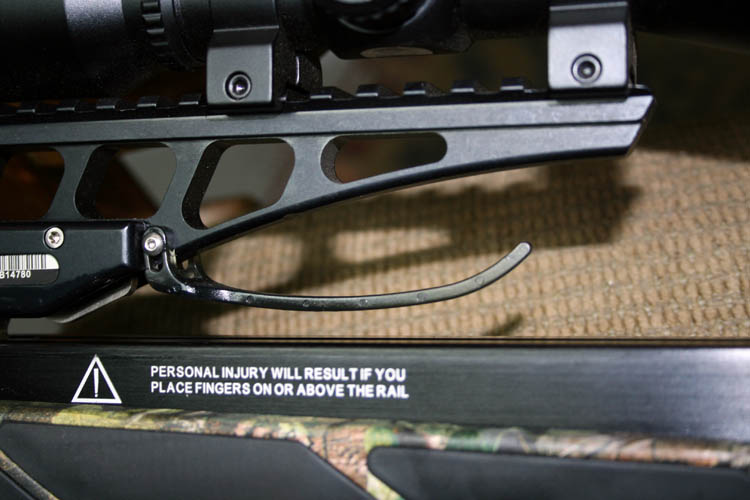

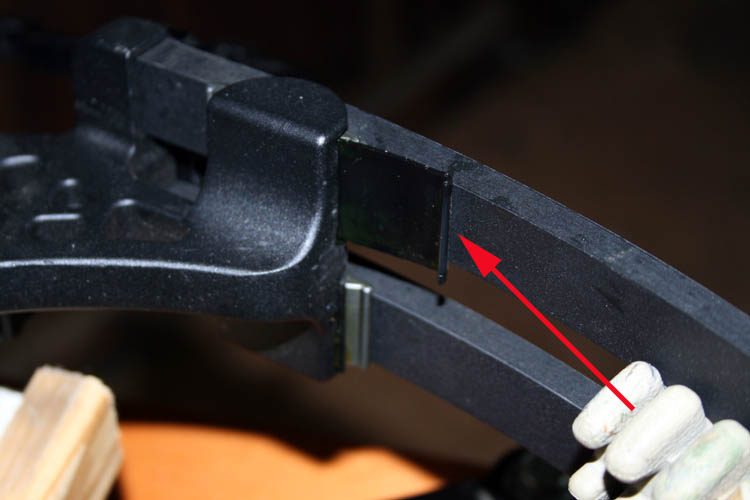

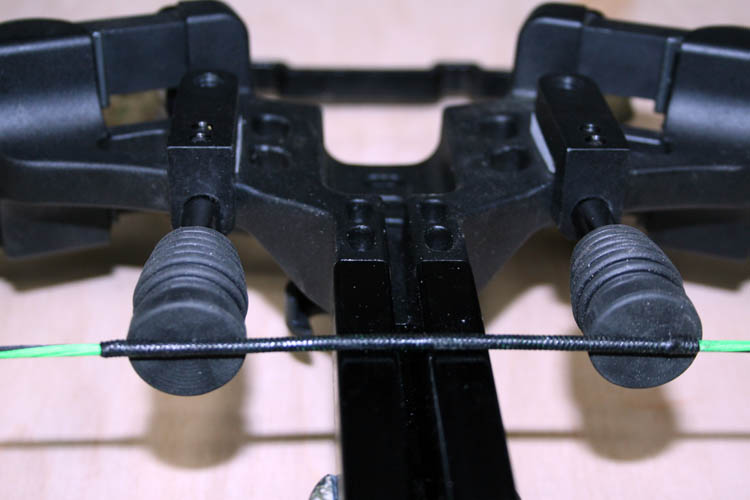

The arrow retention spring type lever that applies downward pressure to the arrow

aka bolt

wasn't touching the bolt and adjusted it where it was making contact with

the bolt which helps keep the bolt aka arrow against the crossbow string and slotted

rails.

The trigger group has an anti-dry fire feature which is a big safety

feature to prevent damage to your crossbow. The crossbow will not fire

without an arrow loaded.

I planned to use my

benchrest and Sinclair forward rest, however the rest

top was to high.

With the top portion of the Sinclair rest removed, I could use it with

the crossbow.

My 20 yard target is down hill, otherwise the forward rest would work.

As stated above, I removed the upper portion of the Sinclair shooting rest from the

shooting bench since it would not go low enough to use with the crossbow and

rested the front of the crossbow on my hand. I plan to build a simple

wood top to fit the crossbow forearm piece and Sinclair shooting rest which

I can adjust up or down as needed, whereas the entire one piece base will

rotate to the right or left as needed, plus up and down. Visit my

benchrest page.

IMPRESSED WITH THE CROSSBOW ACCURACY

The first bolt was a little high and to the left, but definitely would

take a deer's heart out.

I moved the POA of the scope a little to the right and shot a couple more test bolts.

John had the crossbow sighted in a 30 yards using 100 grain field points

and/or broadheads. The heavier field point brought the point of impact

down about right for 20 yards, even though a little high.

The trigger pull is pretty good, but I have been use to the

CZ 452

American .22 caliber target rifle's trigger pull which is between 12 ounces

to 1 pound of trigger pull.

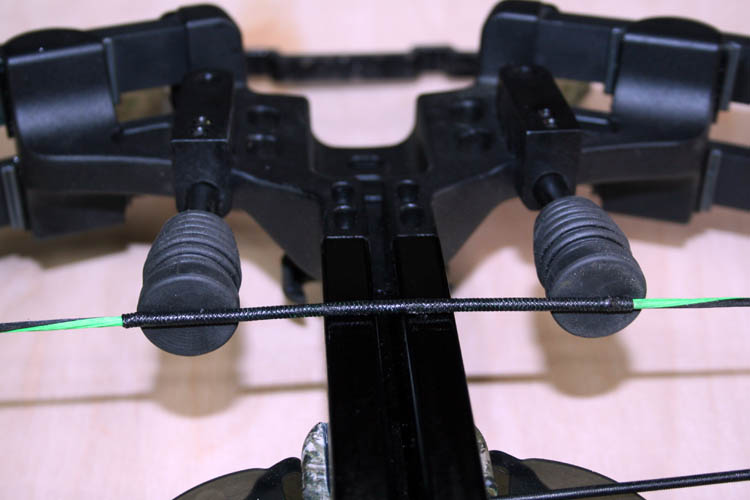

SHORTENED LENGTH OF THE COCKING ROPE

I was having a little difficulty cocking the crossbow with the standard

rope cocking device and figured out it was too long. The length of the

rope was shortened 7.5 inches and will give it a test run when the heavier

crossbow bolts arrive next week.

You can see how much extra rope was shortened up.

With the rope shortened, the hooks will rest on the crossbow string with

some tension on the string and a good place to store the rope cocking device too after the

crossbow has been decocked and/or fired. The rear of the rope cocking

device is anchored into a slot that is in the stock pad. The rope

cocking device with the pulleys, reduces the effort to cock the crossbow by

fifty (50) percent! Ten-X recommends that the hooks are facing up on

the bow string.

I will cut off the excess rope not needed after I field test it.

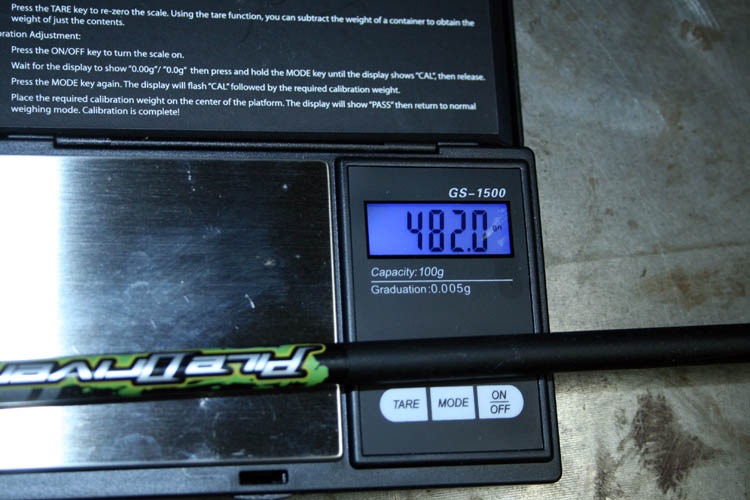

I ordered a six pack of heavier crossbow bolts; Carbon Express Piledriver 20 inches

in length with the half moon nocks which also comes with the universal nock.

With the 125 grain broadhead, the total weight of the bolt should weight

about 467 grains. I will test them with the 125 grain Thunderhead broadheads and hopefully

they will fly as good as the Stryker carbon shafts with the 125 grain field

point.

NOTE: A couple days ago, I got my portable hunting blind in

position and now it is a waiting game to see when the deer start coming to

the broadcast corn and sweet feed.

Web page updated by Bill aka Mickey Porter on 08-22-2020.

HOME MADE FRONT REST SUPPORT

I made a simple wood front rest support for the crossbow fore grip area

which fit onto

the Sinclair rest and still have the necessary adjustments such as elevation

and windage. The

one piece base for the rear bag and front Sinclair

rest also has adjustments for windage and elevation as needed.

I have some heavier spined crossbow bolts arriving and will

field test the forward rest and shoot a couple practice Thunderhead 125

grain 3 blade replaceable broadheads to ascertain how they fly. The

hand rest aka forearm piece on the cross bow is not flat, therefore added a

couple heavy felt type strips to each side of the U shaped channel the

fore end piece rests in to increased the stability.

In all probability, the Lord willing of course, I will make a simple

support to rest the crossbow fore end piece on while in the shooting blind.

I want to remove as many variables as possible to

"hunt smarter, not harder."

Web page updated by Bill aka Mickey Porter on 08-24-2020.

CAMERA TRIPOD REST

I took one of my point and shoot digital camera tripods to the hunting blind to ascertain if it

would be suitable for a rest for the crossbow and it might work.

I used the existing camera mount adapter which is detachable from the

tripod which has a 1/4 x 20 tpi screw and made a place to fit the adapter to

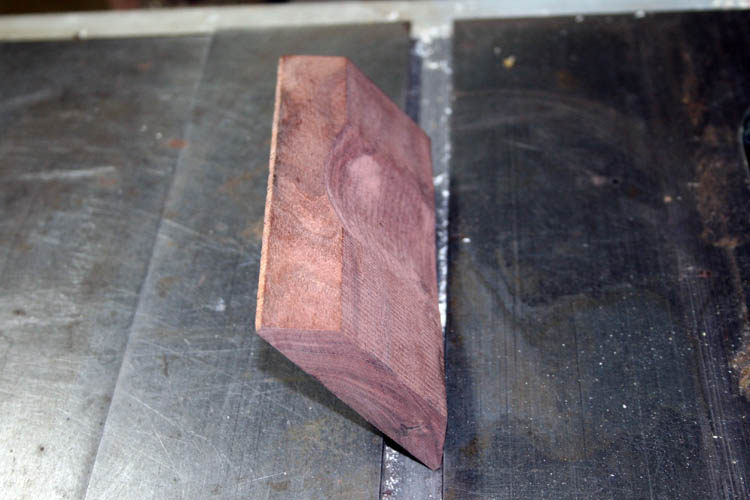

rest the crossbow fore end. I already had a piece of scrap aka

unallocated walnut and cut it six (6) inches in length, drilled and tapped a

1/4 x 20 tpi hole. I then sanded a radius in the center to match the

curvature of the crossbow fore end.

The above tripod is designed for the smaller digital cameras, but worth a

try.

I tested the tripod rest out with the crossbow and it was far too

noisy/squeaky with too much inherent movement and went to plan B.

Some

times we win, sometimes we lose!

FIXED RIGID REST

I screwed a couple scrap pieces of pine 1 x 4 to the elevated seating

platform and attached a cross member (1 x 4) to each upright member.

It was reinforced with another scrap piece of 1 x 4 and it was very stable.

I will later go back and put some camo paint on the front toward the feeding

area. The hanger for my Mathews Drenalin Solo Cam bow was perfect for

the crossbow also.

NOTE: I later went back and spray painted the shooting rest

and bow hanger flat black!

As Hannibal Smith said on the A Team TV show,

"I love it when a plan comes together".....grin if you

must! I have to remember, "Watch out for

the blind X-frame cross members."

Web page updated by Bill aka Mickey Porter on 08-25-2020 and 08-26-2020.

WAITING ON HEAVIER CROSSBOW BOLTS

Still waiting on the crossbow heavier bolts and the tracking provided

stated the shipment would be late. The business is located in Bowdon,

GA and per the tracking was shipped on the 22nd. The shipping was

free, but the early Pony Express was faster than our current USPS mail.

Yes, pun is intended, since Bowdon, GA to Wadesboro, NC via I-85N is 363.7

miles!

I also ordered a dozen NAP 125 grain bullet points for 11/32 diameter

bolts on the 25th and they arrived on the 27th which was excellent.

I have received notices before from Charlotte, NC USPS hub of delayed

shipments with the packages being torn open in shipment and resealed.

I try and stay positive most of the time, but it is hard to do when dealing

with incompetence. Visit this page to get my

drift.

Web page updated by Bill aka Mickey Porter on 08-27-2020.

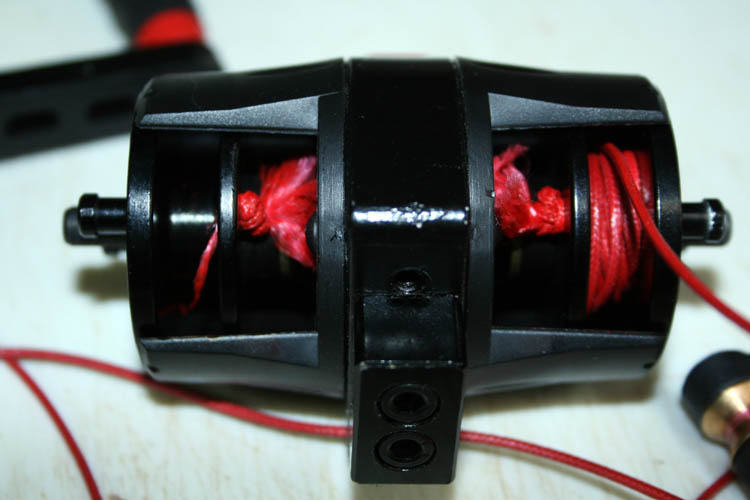

REPLACED STRING SUPPRESSORS AKA STRING STOPS

Yesterday 08-29-2020, I was checking the tightness of all the bolts on

the Stryker Solutions LS crossbow and noticed that one of the string

suppressors aka string stops was badly worn and about cut 1/2 through from

the string, not visible in the pix until you pull on the suppressor.

I am surprised that the string suppressor holders are not bent and/or

broken due to the tremendous shock/energy generated at the end of the

crossbow string travel and coming to a stop.

I went on line and checked out different YouTube videos about the Stryker

Solution LS string

suppressors and most said that the original ones that came with the crossbow was

"junk" and looked for an

alternative. Several stated that the Mathews vertical bow string

suppressors would work on the Stryker, but it was difficult to get them into the

holder due to them being much larger (fatter) and they were certainly correct.

I took a practically brand new set of string suppressors off my Mathews

Drenalin Solo cam bow to make the switch.

One of the Mathews suppressors is longer than the other, but will work

just fine nevertheless.

Compared to the original string suppressor that came with the crossbow, these

Mathews string suppressors look like they are on steroids.....grin if you

must!

Also, the small screws that hold the string suppressor housing in place

to the rail is a #

10 torx screw versus an Allen head bolt. Luckily, I had a set of torx

tools for a 1/4 inch drive ratchet.

I went on line and ordered a replacement set of Mathews string suppressors

for my Mathews bow.

STILL WAITING ON CROSSBOW BOLTS

The crossbow bolts I ordered on the 21st and shipped on the 22nd are

still at the USPS Regional Destination Facility MID CAROLINA-CHARLOTTE NC

DISTRIBUTION CENTER August 28, 2020, 9:39 pm.

NOTE: Crossbow bolts arrived on 08-31-2020.

As soon as those crossbow bolts arrive, I will check how they fly with

the 125 grain Thunderhead 3 blade broadheads. The heavier shaft with

the 125 grain broadhead and the beefier string suppressors should quiet the

crossbow down a good amount. I also have a set of Bowjax crossbow

split limb suppressors on order. YouTube video test showed the Bowjax

suppressors were far superior to the Limb Saver limb savers to dampen limb

vibrations. I want to

try adding a damping system to the foot stirrup to remove some of the noise

and vibration and might try the old Limb Savers attached to the sides of the

stirrup with plastic tie straps.

All of the above things mentioned will slow the crossbow speed down, of

which I am not that concerned with since I shoot mostly 20 yards or less

from my hunting platform and ground blind.

Above pix of the Carbon Express Piledriver arrow with a 125 grain field point.

After this hunting season, I will replace the crossbow cables and string.

Web page updated by Bill aka Mickey Porter on 08-30-2020 and 08-31-2020.

REPLACED STRYKER 3 X 32 SCOPE

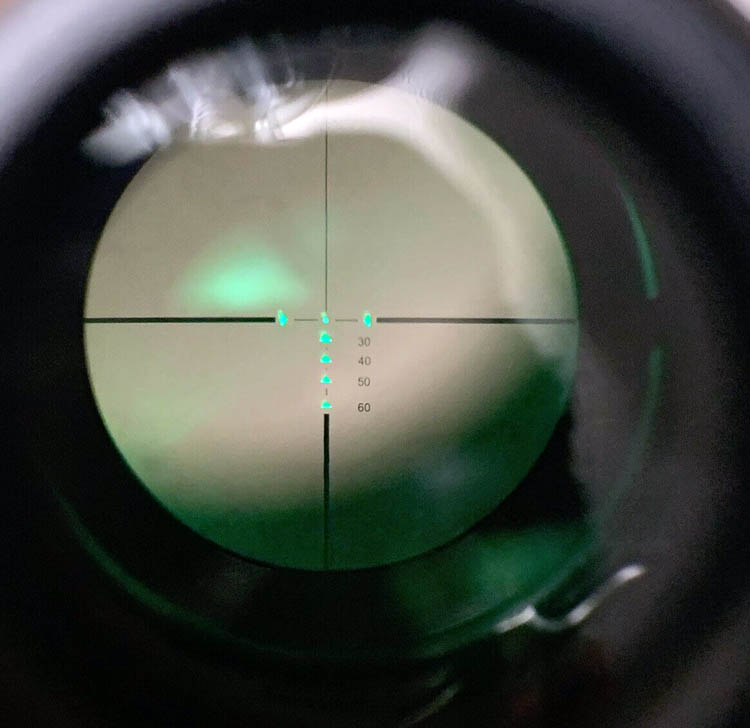

Since I will be hunting mostly from a blind, I decided to replace the

existing scope on the crossbow with one with a rheostat lighted reticle

which gives you the option of either green or red. The scope I ordered

was sold by Excalibur Crossbow model Tact Zone and has a 30MM tube versus

the standard 1 inch diameter tube on most of the crossbow scopes and

variable power from 2.5 to 6X.

It has a speed dial to calibrate your arrow speed aka bolt POI (point

of impact) from 30 yards to

60 yards with the 20 yard setting remaining constant.

I later torqued the metric socket head cap Allen screws to fifteen (15)

inch pounds. My torque tool, The Fat Wrench made by Wheeler didn't come with the metric Allen sockets

and had to round a set up.

RETICLE IMAGE FROM INTERNET

I shot the crossbow a number of times and the Thunderhead 125 grain 3

blade broadheads didn't want to fly as accurate as the field points and

tested out a couple of the practice Rage 2 blade 100 grain practice

broadheads and they flew pretty good, therefore will be using the hunting

100 grain Rage broadheads for hunting since I have five (5) of them in one

of the quivers that came with the crossbow package from John Gaddy.

I sacrificed a Rage 2 blade expandable 2 inch cut 100 grain broadhead and

it flew excellent and will use them to hunt with.

BOW PRESS & TRIVIA

Back in the mid 1980s when we had the

City Lake Archery Club active here

in Wadesboro, NC, I helped do archery equipment set ups for our club members

and earned the nickname Bow Doctor.

Later, Mike Howell, now deceased opened an archery shop at his home here in

Wadesboro, NC and did

repairs, sold bows and accessories. Jim Skipper of Indian Trail who

owned Skips Archery Shop, now deceased helped Mike get started and taught

him how to make custom strings, etc. Jim Skipper and myself did a lot

of "horse trading" over the

decades.

I made a couple custom bow presses back then and still have the last one

I made, however that style of bow press will not work with the parallel limb

bows of today and extreme short axle to axle bows and definitely not a

crossbow.

I used a simple cable and screw type hand held press to work on the above

Drenalin bow.

I thought about how I could modify the above obsolete design bow press for a crossbow,

but it would be more trouble and expense than what it would be worth and

that style of press could easily damage crossbow limbs by not exerting

pressure at the limb tips and not being supported adequately, therefore found an

excellent

crossbow press on line made in Georgia by

Last Chance

Archery.

The closest archery dealers aka repair shops are located in China

Grove and Charlotte, NC and definitely would not drive through Charlotte, NC

to a bow shop, but as a last resort.

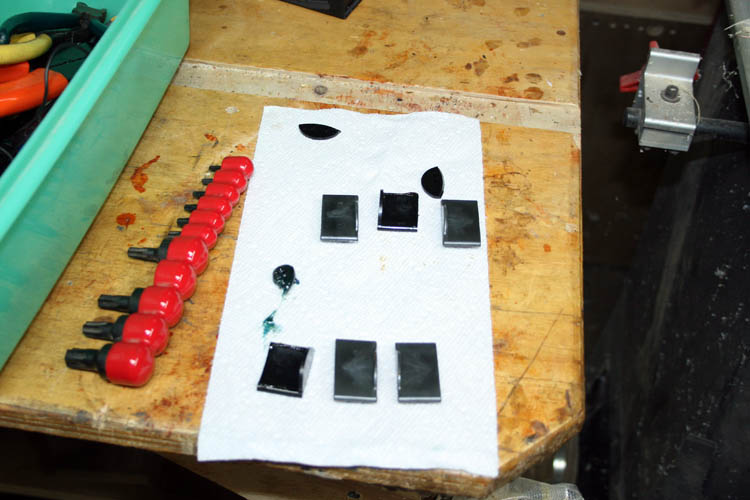

LIMB SADDLE BEARINGS AKA SHIMS

I have a set of cables and string on order from 60X Custom Strings, but will wait until after

hunting season before I change them out. Also, there is a saddle

bearing made from v10 Delrin aka "shim" on the top right and left limb that one end is broken that apparently

helps keep the shim in place and will replace

them at the

same time. The limb "shim" system is the only complaints about this

model bow via the archery crossbow threads and

might be the

Achilles' heel

on this model crossbow. I am waiting on a set of saddle bearings item

code 15322 aka shims

and saddle pivots item code 15321 from the

manufacturer.

In the above pix, the saddle bearing aka shim has the left curved

end broken off allowing the saddle bearing to work its way out between the riser

saddle and saddle pivot. All the saddle bearings are the same length

and as stated, due to the tab broken off on the left end of the upper limb

saddle bearing aka shim has worked

its way almost entirely from between the riser concave pivot and saddle

pivot giving the illusion

that it is longer. The saddle bearing aka shim also has a vertical

half moon portion

on one side that abuts the saddle pivot side which has the same type of half

moon portion.

NOTE: On 09-11-2020, the top saddle bearings aka shims finally worked their way

out. The only reason I can think of them using the saddle bearings aka shims is to

reduce friction. Bethany

Harrold of Pure Archery Group, Customer Service Representative for Bowtech

and other archery companies, etc., has ordered a set of pivots and saddle

bearings for me.

The crossbow wasn't shooting arrows as consistent as it had before the

shims aka saddle bearings started moving out from off the top of the pivots.

After they came out, I adjusted the scope and the bolts were grouping pretty

good at 20 yards.

The above parts in the center of the pix between the limbs are

called pivots and saddle bearings.

Once I take the limbs off the crossbow riser, I will have a much better

understanding what is taking place. The cams are slightly out of time

and will be adjusted (if needed) when I replace the pivots and bearings, cables and string at

the end of this hunting season. See crossbow maintenance below.

Just maybe, I can make it without some major mechanical set-back!

INSTALLED BOWJAX LIMB DAMPENERS

I replaced the Limb Savers with a pair of Bowjax limb dampeners and used

the Limb Savers on the foot stirrup to help control vibrations there.

I changed the orientation of the flexible "legs" to be parallel with the

limbs per manufacturer.

The Bowjax limb dampeners are held in place by a single small bolt and used tie down

straps to secure the Limb Savers to the foot stirrup.

I will replace the saddle bearings, saddle pivots, the cables and string after our archery season. I will

probably install a pair of string silencers too. See Crossbow

Maintenance section below.

TLC MAINTENANCE NEEDED

This crossbow is definitely in need of some TLC

maintenance since it still has the original cables and string and most

manufacturers recommend you change them out every three (3) years or sooner

depending on the number of shots fired and/or any cable/string fraying.

Web page updated by Bill aka Mickey Porter on 09-04-2020.

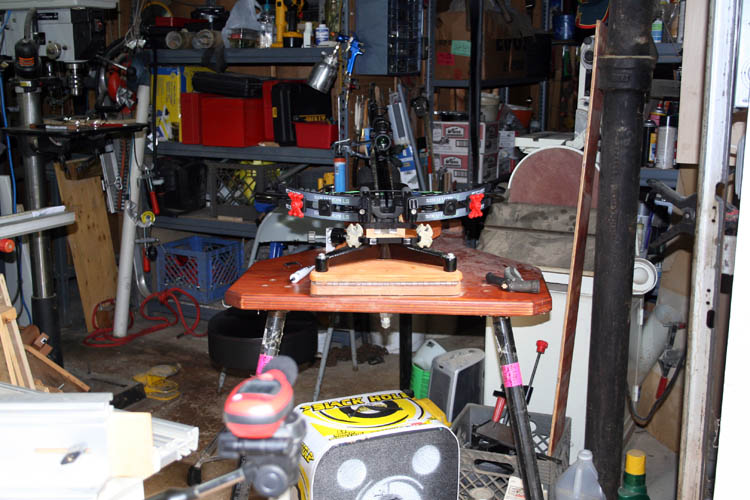

EZ GREEN CROSSBOW PRESS

I received the Last Chance Archery Crossbow Press this morning and gave

it a field test.

I have plenty of Easton 2315 arrows for the Drenalin bow which is no

doubt now retired!

Some serious thought went into the design of the EZ Green series of bow

presses and Last Chance Archery has several US Patents for the same; e.g.,

7,597,094 & 7,644,708 & 8,517,362.

I have just enough room to work on my crossbow for changing cables,

strings, etc.

This definitely is an excellent crossbow press and applies pressure to the limb tips

where it is needed. I mounted the press to my arrow making workbench

with the provided hex head lag bolts and flat washers. The crossbow

press is adjustable from 11 to 32 inches.

VERTICAL CROSSBOW SAFETY SUPPORT

I added a vertical upright safety support to

affix an adjustable strap and/or rope to

attach to the crossbow stock for safety purposes, whereas

Murphy's Law

never sleeps!

To easily access the axles with the roller for the cable, the crossbow

will work best in this position.

In case I get "butter fingers"

while using the press; e.g., putting the crossbow into the press and

removing it, the upright safety support will keep the crossbow from hitting the

floor. I thought about the Clint Eastwood movie,

Hang em High........grin if you must!

This press will remain idle until after archery season unless I get the

plastic limb components in soon, since I probably will not hunt until the

deer start using my feeding station regular and/or the weather gets much

cooler which normally happens around the 1st of October.

Web page updated by Bill aka Mickey Porter on 09-09-2020.

CROSSBOW MAINTENANCE

I received a set of saddle bearings and saddle pivots from Bowtech via

UPS today at no charge, even though the crossbow warranty has expired and I

am not the original owner of said crossbow.

It has been a long time since I have taken a bow completely down to the

bare bones and this is the first crossbow that I have taken the limbs off

and changed the cables and string.

With the Last Chance Archery EZ Green Crossbow Press, it was a breeze to

compress the crossbow although it was a little nerve racking to see the

limbs compressed and then completely relaxed and straight as an arrow so to

speak once I took all the pressure off the limbs. I was more anxious

when I compressed the limbs from the totally relaxed position (straight as

an arrow) with the

cables and string removed. I had to back the press out a good bit to

get the crossbow back in the press vertical fingers........grin if you must.

Crossbow completely relaxed below.

The crossbow reminds me of a Northrop Grumman B-2 aka Stealth Bomber

wings!

I removed one of the E clips from the axle and pressed the axle out far

enough from to expose the round bushing that held one end of

the cable in place on the cam.

If you were just replacing the

cables and string, this is far as you need to go with pressing the crossbow

limbs.

My musical instrument

ShopFox Parrot Vise from Grizzly worked great for positioning the crossbow to take the

limbs from the riser and keep the saddle bearings and pivots in place on the

crossbow riser. I used a # 45 torx with 3/8 inch drive ratchet to

remove the limb bolts.

After taking the limbs off the riser of which the limbs fit the riser

limb pocket like a glove and indexed where each split limb would not move.

With the Bowjax limb dampeners in place on the split limbs, the limbs did

not move around and made it easy to keep everything in the correct position.

This is a pix of the original saddle bearings and saddle pivots in place.

The top limb on each side of the crossbow had the saddle bearings missing

and only a part of the black nylon tab showing on the right limb which is

the bottom limb. The upper limb saddle bearing black half moon tab is

missing from the riser limb pocket as evidenced by the pix.

The above are the saddle pivots and saddle bearings removed from the

limbs and crossbow riser. The saddle pivots are made from MDS nylon and the saddle bearings

made from v10 Delrin that makes contact with the limb pocket concave portion. As stated earlier, this is the area that gives the most

trouble with this model of bow. The saddle pivots probably didn't need

changing, but changed them anyway! Two of the saddle bearings above

are missing the concave portion which worked its way out of the crossbow

riser concave pocket.

There apparently is a tremendous amount of shock/energy transfer to the

saddle bearings and saddle pivots when the crossbow bolt is released due to

the "hatchet" style cams used.

Once I removed the saddle pivots and saddle bearings from one limb pocket

one at a time, I cleaned the pocket and applied some heavy blue bearing grease to the riser

limb concave pockets and both

sides of the v10 Delrin saddle bearings. There was no grease applied to the flat

portion of the MDS nylon saddle pivot that makes contact with each split limb.

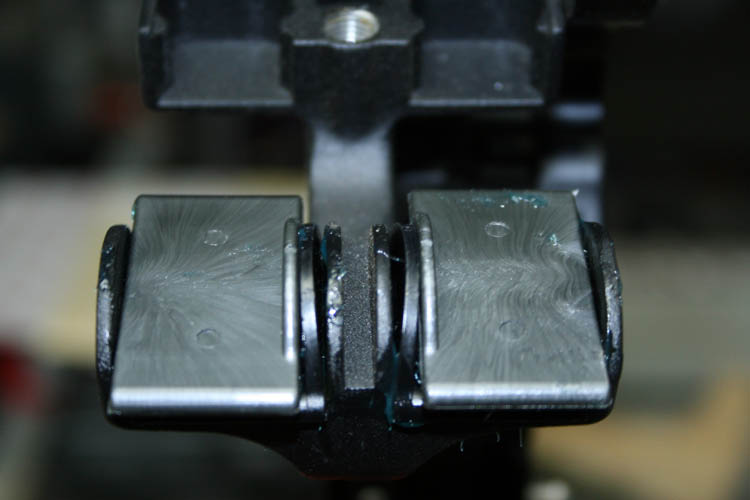

SADDLE BEARING

Below is a close up pix of the v10 Delrin convex saddle bearing which

makes contact with the concave cavity in the crossbow riser. The

overhanging tabs on the end of the saddle bearing helps keep the saddle

bearing in position in the limb concave riser pocket.

Many crossbow technicians think the saddle bearing material composition

is too brittle, while others contribute their breakage to the crossbow limb

bolts backed out about 1/4 turn from the riser. The crossbow limb

bolts were definitely not maxed out against the riser when I checked all the

bolts on the crossbow.

.

.

Below are some pixs to help explain the procedure:

The riser has a concave radius which matches the saddle bearing and saddle pivot

radius.

The v10 Delrin saddle bearing goes on first and then the saddle pivot with the flat

side abutting the limb.

With the saddle pivots and saddle bearings in place, the limbs are ready

to attach to the riser limb pockets.

As evidenced by the above pix, the Delrin (black) saddle bearing half

moon tab is not at a right angle to the base of the saddle bearing as is the

half moon tab on the nylon saddle pivot. This is no doubt a product of

the mold that produced the saddle bearing when it was taken from the mold

and cooled down....that is just my humble opinion. Anyway, this is a

problem with this model bow!

The limbs installed with new saddle pivots and saddle bearings.

INSTALLED NEW CABLES AND STRING

I am glad I took several pictures of the cables and string orientation on

the cams since they are totally reversed as far as their orientation in

reference to a regular cam bow limb, but works exactly the same.

The above pix is the string side of the cam which faces upward on the

crossbow.

CABLE SLIDE

I had more trouble with the cable slide than any other thing. The

cable slide fell down inside the

hollow rail at the front of the crossbow and had to take the crossbow from the

press and coax it out letting gravity do its job.

I used a single stand from an old bow string about the size of dental

floss and tied the cable slide in position prior to installing the cables

and string and then removed the string strand afterward.

The original string had stretched quite a bit and the cables as well.

The axle to axle measurement was right on the money at 19 3/16 - inches with

the new cables and string and

the original ones had stretched to 19 1/2 inches axle to axle. The cam

timing looked pretty good and don't think I will have to do anything to the

cables; e.g., twist to shorten.

The cams do have timing marks stamped onto them and will take a close-up

pix of them later.

I will give the crossbow a test run in the morning to check the bolt

point of aim.

Web page updated by Bill aka Mickey Porter on 09-17-2020.

DEAD SILENT CRANK

Shooting the crossbow is plenty of fun and with that said, you still

exert a lot of energy cocking the crossbow with the provided rope cocking

device. It doesn't take too long; speaking for myself to really feel

the lower back getting worked out pretty good. The next day or two, my

lower back cries out from the "work out" cocking the crossbow.

I went on line and viewed many mechanical cocking devices available and

decided on one made by Killer Instinct called the Dead Silent Crank and

placed an order for one via EBay.

The crank comes with a butt stock plate since the crank has a tenon on

the end that fits into a mortise in the butt stock plate, whereas the crank

can be attached and removed very quickly and is quiet in operation which is

a plus.

I received the dead silent crank this afternoon, 09-17-2020 and

retrofitted it to the stock of the crossbow. The crossbow butt plate

mounting holes are 3.5 inches center to center and the dead silent crank

butt stock plate are 3.25 inches. Also, the dead silent crank butt

plate had a

curvature to it and did some serious grinding with the belt sander to get

it in the ball park. The design of the Stryker stock wasn't feasible

to try and drill new location holes for the 3.250 center to center hole

spacing on the Dead Silent Crank butt plate.

Not the prettiest job, but the retrofit is workable!

The Dead Silent Crank will get a good work out tomorrow, our Lord willing

of course.

Web page updated by Bill aka Mickey Porter 09-17-2020.

DEAD SILENT CRANK USED TO DECOCK THE CROSSBOW

I am mainly using the Dead Silent Crank for decocking the crossbow and it

works great!

Web page updated by Bill aka Mickey Porter on 11-11-2020.

DSC IS A SAFETY HAZARD

On December 3, 2020 the above DSC string hook/roller disengaged from the crossbow string

while letting the crossbow string relax with the curved plastic metal string

hooks striking me in the chest leaving a bright red spot, but no bruise.

It was painful to say the least.

On December 4, 2020 while letting the crossbow string relax, the string

broke on the left plastic and metal string hook/roller with said hook/roller striking me

near the center of my forehead leaving a swollen knot. If the string

hook/roller had hit myself in the eye, I could have easily lost that eye due to the

force and energy of the string hook/roller.

I emailed Killer Instinct via their contact page form, but have not heard

anything from them.

I plan to get my PortaBand saw and cut it into several pieces.

My gut instinct told me that the red braided string was too small and

Murphy's Law

never sleeps.

Web page updated by Bill aka Mickey Porter on 12-08-2020.

DSC PROBLEM SOLVED

I solved the problem with the above Killer Instinct DSC by cutting it up

with my Milwaukee PortaBand saw and will be accident free in the future from

that pile of junk! Killer Instinct is a good name for the DSC and hope

their imported crossbows fare much better!

Web page updated by Bill aka Mickey Porter on 12-10-2020.

TEST FIRED CROSSBOW

I shot two bolts at about 19 to 20 yards and they were almost touching.

The POI was 2 inches low and about 1 inch to the right. I

adjusted the scope and shot one more arrow. It was close enough for

hunting.

I inspected the crossbow and everything looked ok and ready for hunting.

The Dead Silent Crank worked good, and did take some effort to use, but not

as much with the regular rope cocking device.

I later adjusted the scope POA for the bolt to hit the black

bullseye. I checked the POI at 30 yards with the Excalibur

Crossbow model Tact Zone speed dial set at 380 fps and the arrow elevation

was right on and a little to the right of the small black bullseye.

Web page updated by Bill aka Mickey Porter on 09-18-2020 and 09-22-2020.

INSTALLED LIMB SAVER STRING LEECHES

I installed a pair of Limb Saver string leeches, of which I had to relax

the crossbow string in the EZ Green Crossbow Press which was a breeze.

The string leeches go between the center of the string.

I fired three test bolts and one of the string leeches came out and

removed the other one.

I ordered a set of Bowjax string suppressors that the crossbow string

will go through the center of the string suppressor and you will have to

remove your crossbow string in order to thread the crossbow string through

the center of said string suppressor.

As evidenced by this web page, I am having a tremendous amount of fun

"tinkering" with this crossbow!

Web page updated by Bill aka Mickey Porter on 09-19-2020.

STRING SUPPRESSOR STOPS

There are much better string suppressor stops available than the original ones

that came with the crossbow and decided to go with a set manufactured by

Parker that will fit this crossbow with some modifications. The Parker

system is incorporated in several

different crossbow manufacturers including Excalibur and others, of which

the system is a much beefier string suppressor stop.

I have a set on order and will adapt them to the Stryker Solution LS

riser which requires a 1/4 inch thickness spacer to raise the stops where

the string will center the stops and grind/cut the forward rectangular

suppressor holder to match the curvature of the crossbow riser.

I viewed a crossbow thread about a modification using the Parker string

suppressor stops, therefore the modification was much easier than going

about it "cold turkey."

Parker is no longer in business and I had to search EBay to find a set

that would fit the Stryker Solution LS crossbow riser.

Web page updated by Bill aka Mickey Porter on 09-21-2020.

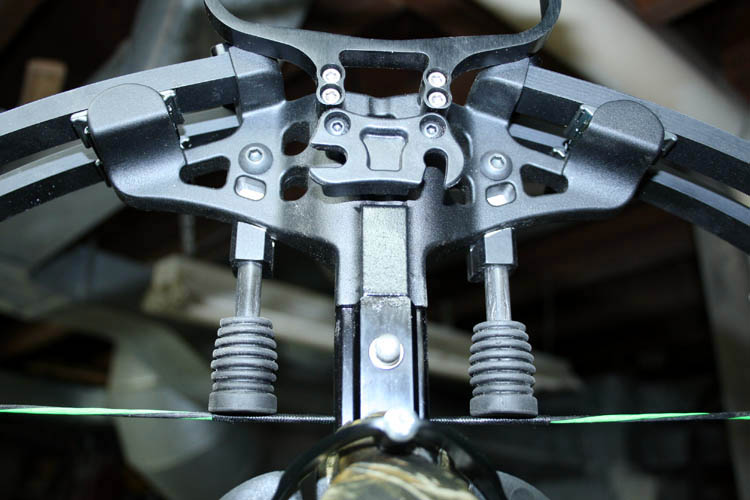

PARKER STRING SUPPRESSOR STOPS

I received the Parker string suppressor stops on 09-26-2020 in the

afternoon and was anxious to retrofit them to the crossbow riser.

I did not do a complete pictorial essay of the modifications, but will describe

what took place.

MODIFICATION IN PROGRESS

Below is a pix of the modification in progress with the brackets that

holds the suppressor stops in place rough ground/filed to fit the crossbow

riser.

The 5/16 x 18 tpi bolts aka button head screws are at least 1/4 inch too short and will purchase a

pair when the auto parts stores are open either Sunday afternoon or Monday.

The spacers were made from a piece of scrap aka unallocated aluminum flat

stock .193 +- inches in thickness and used the band saw, drill

press and belt sander to fabricate them. The string suppressor stop on

the left is about the right length and the one on the right is the original

length that comes with the system. The cutouts aka holes in the

crossbow riser were not round and the inside diameter slightly under the

required 5/16 inch diameter and were drilled/reamed a few thousands of an

inch to accommodate the bolts

provided.

I will final fit the string suppressor stop blocks and the spacers where

the stops are perpendicular to the crossbow string, dissemble and spray a coat of

matte

black on the spacers and the area where material was removed from the string

suppressor stop aluminum block holders.

Above pix before flat black sprayed on the spacers. I have the

string suppressor stops abutting the crossbow string with some tension and

will give it a test after final assembly with the correct length bolts.

The string suppressor composite composition rods are also abutting the

crossbow riser and secured in place with two set screws on each of the

aluminum block holders.

These beefed up string suppressor stops has to reduce the vibration and

sound level much better than the original string suppressor stops that

originally came with the bow, whereas the "acid

test" will be when I shoot the crossbow.

Web paged updated by Bill aka Mickey Porter on 09-27-2020.

FINISHED STRING SUPPRESSOR INSTALL

I could not locate identical button head screws locally to replace the existing

screws and opted to use 5/16 x 18 tpi x 1.5 inches flanged hex head bolts and cut their length to

1.25 inches +-. Also my blue Loctite is very old and purchased a fresh

tube.

The aluminum spacers and modified holders were spray painted yesterday

with matte black Aluma-Hyde II sold by Brownells and this morning coated

the raw ends of the shortened flanged hex head bolts using a Q-tip saturated

with the spray paint.

FIELD TESTED THE CROSSBOW

I shot two bolts at about 19 yards + - and pulled the first arrow and

shot it again and it went into the same hole on the bag target.

As far as the sound level reduction, I really can't say for sure, but

there definitely is a reduction in the

felt crossbow vibration. As stated

earlier, I have been use to shooting a Mathews Drenalin parallel limb solo

cam bow which is super quiet with no hand shock!

I adjusted the scope one (1) click POI to the right.

I shortened the length of the suppressor composite rods a little while still maintaining

good tension on the crossbow string and the string

traveled a good 3/8 inch past the crossbow string at rest, therefore

compressing the suppressors aka dampening devices. As far as the

effect on the bolt speed where the power stroke is reduced some, I don't

have a clue, but I am not really concerned about losing x amount of feet per

second in bolt speed!

I have the length of the suppressors adjusted where they are touching the

suppressor stops with some tension and will do some recon as to what most

recommend as touching or not touching the string. I later found that

everyone has their own opinion with no conclusive evidence to back up their

opinion, therefore will leave them adjusted as is.

I am very well pleased with the modification and install and hopefully

the deer will start visiting my feeding station before too much longer with

some fresh venison

in the freezer.

100 GRAIN VERSUS 150 GRAIN FIELD POINT

At some time in the future, our Lord willing of course, I plan to hunt

with a 150 grain Rage 2 blade TRYPAN hypodermic 2 inch expandable broadhead, however I have several

years supply of 100 grain Rage 2 blade expandable broadheads on hand.

I wanted to see what the difference in the bolt drop at 19 yards would be

comparing the 100 grain field point against the 150 grain field point.

The 150 grain field point drops approximately 1.250 inches lower than the

100 grain field point.

Where I plan to currently crossbow hunt from my shooting blind, twenty

(20) yard shots will be the norm.

I believe the crossbow did sound a tad quieter with the 150 grain field

point and the accuracy is still dead on so to speak. I need to add a

decibel meter to my hobby inventory!

Web page updated by Bill aka Mickey Porter on 09-28-2020.

CROSSBOW SPEED

I wanted to ascertain what the crossbow speed is with the additional

stuff I have added to it; e.g., Bowjax limb dampers and added another set I

placed on the outside of the mounting blocks, of which I ordered a set for a

solid limb versus a split limb, my bad. I also placed the original

LimbSavers that came with the crossbow on the outside of the foot stirrup.

I added the Parker String Suppressor Stops which shortened the string travel

a little effecting the power stroke, but probably less than 1/4 inch.

The Stryker Solution LS is rated at 390 feet per second, 155 lb. draw

weight using a 392 grain bolt with includes 100 grain field point, however I am

using a heavier crossbow bolt, Carbon Express Piledriver that weights 457

grains with a 100 grain field point and rated at 442 grains per the package with

100 grain field point.

I only shot one bolt through the meter with the results below. If I

was serious about the bolt velocity, I would have shot several bolts across

the meter to get an average reading:

As stated earlier, I shot a test bolt at 30 yards and the elevation was

dead on, of which I had the speed dial on the Excalibur Tact Zone scope set

at 380 feet per second; a good lucky guess.

Crossbow bolt speed is not an issue with me due to my hunting conditions

and look forward to my first deer harvest with this crossbow. It has

already proven to be an excellent crossbow, whereas my friend John Gaddy has

harvested several good bucks over 200 pounds.

Web page updated by Bill aka Mickey Porter on 09-29-2020.

PADDED SHOOTING RAIL IN BLIND

I was wanting to obtain a scrap piece of carpet to place on top of the

shooting rail in the ground blind platform and luck was in my favor. I

was visiting the same friend recently that sold me the crossbow and I

observed some good looking carpet someone had thrown beside the road not too

far from his home.

On the return trip, I stopped and cut a piece from the carpet that had

very little wear on it and installed it on the shooting rail.

This will definitely get you in the mood to crossbow hunt for deer!

I tested the rail out with the carpet and it is super quiet and the

optimum height too.

I did see some deer activity on the trail camera around 3:15 A.M. on

09-29-2020 and hopefully the deer will start visiting the broadcast corn and

sweet feed regularly and will be time to sit in the blind.

TARGET AT 41 YARDS

There is one place where deer have crossed between 40 and 41 yards and

wanted to see how the crossbow bolt held up at that distance and further

test the calibration of the Excalibur Tact Zone scope. I shot one

arrow at a foam layer target and it did not stop the bolt and couldn't

really tell where the point of impact was, although I knew from the sound

and target movement, it was a hit. I replaced the foam layer target

with the Yellow Jacket target, however the target was not positioned

perpendicular to my shooting position, my bad. I made a make shift

shooting rest using the foam target sitting on top of my planer and not

super steady, but it worked fine.

I held at the top of the lower right bullseye top black ring and that is

where the bolt impacted about 1 inch to the right. That would take a deer's transmission out

with no problem! The Excalibur Tact Zone illuminated scope speed

setting is very accurate for sure.

Web page updated by Bill aka Mickey Porter on 09-30-2020.

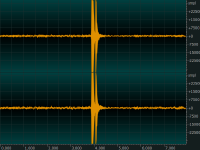

AUDIO RECORDINGS

I set my TASCAM DR-05 audio recorder about 3 feet from the crossbow and

shot a bolt at a 19 yard Yellow Jacket target. You can hear the crossbow discharge

and the bolt impacting the target. The audio editing software program screen

shot shows what you are hearing. To me, the crossbow is very loud and the crossbow

is actually inside the basement garage a foot, therefore the sound

hasn't had time to dissipate, if that is the right word to use. I am

sure it would record a little different if outside. Just

for curiosity, I plan to later do a check with a decibel meter shooting the

crossbow outside and observe the results. My video recorders have long

since bit the dust and maybe in the future will purchase a camera to mount

on the crossbow for some additional fun.

Click on the below icon(s) for the audio file in .mp3 format and screen

shots in .png format:

RECORDER PLACEMENT AT 1 YARD

Click on thumbnail pix for a larger screen view.

Click on thumbnail pix for a larger screen view.

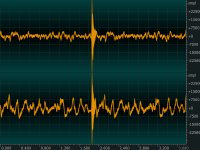

RECORDER PLACEMENT AT 19 YARDS

I shot another test bolt with the recorder placement right behind the

target butt and then isolated the sound only coming from the crossbow and

then isolated the sound impact of the bolt at the target butt documented

below since there was just enough delay to separate the two sounds:

CROSSBOW SOUND AT 19 YARDS

Click on thumbnail pix for a larger screen view.

Click on thumbnail pix for a larger screen view.

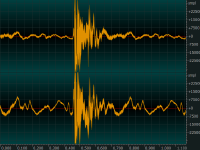

BOLT STRIKING TARGET AT 19 YARDS

Click on thumbnail pix for a larger screen view.

Click on thumbnail pix for a larger screen view.

After hearing the crossbow sound from 19 yards, I don't think I am too

concerned about the noise of the crossbow versus the sound generated at the

crossbow! I was amazed at how loud the bolt impacted the target butt

with the recorder near the target butt!

Sound travels approximately 1100 feet per second at sea level and there

are a few variables, etc., and with the crossbow bolt traveling at 380 feet

per second, a spooked, fully alert deer could move enough (jump the string)

to cause a problem, but at 20 yards or less, I don't think it is much of an

issue if the deer is not fully alert and not looking in your direction.

Yes, I have had an alert deer or two jump the string using a round wheel

compound bow even at 17 yards from a very noisy Bear Brown Bear model bow

and learned over the decades when to take a shot and not to take a shot with

an arrow; e.g., reading the deer's body language.

CROSSBOW WORKSTATION FIXTURE

I was playing around with the crossbow and wanted to decock it instead of

shooting an arrow into the target or shooting a decocking arrow into the

ground and used my bench rest, however the rear elevated sandbag was a

little in the way of the handle of the Dead Silent Crank.

I tested out my Tipton gun vise, but it was too long for the crossbow.

I decided to make a simple workstation that would suffice for decocking

the crossbow and could be used for other things on the crossbow as well.

I used scrap aka unallocated pieces of pine wood and thin walnut to

fabricate the simple fixture just for this particular crossbow. As

stated earlier, I used my ShopFox musical instrument vise, but had a

hankering to do this fixture.

A few splashes of color on the ole Stryker Solution LS.

Fits like a glove.

I will test the fixture out decocking the crossbow, of which I know it

will work excellent since I have already decocked the crossbow using my

benchrest shooting rest with the aid of the Dead Silent Crank. This

fixture will allow you to safely put tension on the crossbow string and

release the trigger of which you have to have a bolt in place, otherwise the

dry fire safety mechanism will not allow you to decock the crossbow.

This procedure is a two handed operation for sure. I definitely will

have the decocking arrow loaded, even though I plan not to have it go

airborne......grin if you must!

I know, it would be much simpler to just fire the decocking bolt into the

ground, but this is my usual MO (modus

operandi), but the crossbow fixture is

multi-purpose.....another grin is in order.

Another reason is, that I do not know how long the v10 Delrin saddle

bearings will hold out, since most threads have the top saddle (black)

bearings going out first. I have probably shot this crossbow more

since I had owned it than the original owner John Gaddy, of which the top

saddle bearings were nearly out of the crossbow riser then!

Retired folks do have time for some fun........grin if you must!

NOTE: The fixture works great decocking the crossbow with

the aid of the Dead Silent Crank! The crossbow is

tighter than two coats of paint

held in the fixture.

Web page updated by Bill aka Mickey Porter on 10-01-2020,10-02-2020 and

10-08-2020.

DEER ACTIVITY

The past three (3) days, the trail camera has a couple different bucks

coming in at dark and one around 8:26 this morning.

On 10-06-2020, while changing out the SD card, I noticed that the camera

lens had some type of spider web substance on the lens and removed it with

my Tee Shirt. I remember sometime back that I left the camera door

open for a few hours during the day when I removed the SD card, therefore

whatever got on the camera lens had all the images as if there was a heavy

fog in the area. I now have spare SD cards dedicated just for this

camera and it should not be a recurring problem.

Web page updated by Bill aka Mickey Porter on 10-06-2020.

Since I meat hunt, both those bucks are shooters as well as any does that

venture into crossbow range................grin if

you must!

Web page updated by Bill aka Mickey Porter on 10-03-2020.

SOUND METER

I set a Triplett SoniChek MC sound meter near my crossbow and recorded

the sound level when the bolt was released. Prior to the test, I added

another set of BowJax Magnum Limb Dampeners to the limbs...there are

three(3) sets of the limb dampeners on the limbs, of which is an overkill

for sure.

The main reason for the extra BowJax Limb Dampeners is to hopefully

extend the life of the Delrin pivot bearings which are known to fail in the

Bowtech Stryker Solution LS crossbow and don't entertain the thoughts of

having to change them out on a yearly basis!

Just for curiosity, I will later send a bolt or two through the Shooting

Chrony meter to see how much if any, the speed was reduced. I am not

really concerned by x amount of speed lost since my shots will be

less than thirty (30) yards with the average around twenty (20) yards from

my hunting blind.

I changed the power of the Excalibur Tact Zone scope setting down to

about 3X hoping that I would get a little better low light capability with

the scope and wanted the wider field of view at 20 yards too. I had it set up around 5X and the field of view at 20 yards

was narrower than I like. I don't think the Excalibur Tact Zone scope

is clear and sharp as the Stryker 3 x 32 that came with the crossbow,

however the lighted reticle is definitely a plus in low light shooting

situations.

Whew, that was some serious rambling getting a little side tracked for

sure and back to the checking the sound of the crossbow.

I believe the accuracy is listed as +3.5 db at 1000 Hz., but don't have a

clue as to accuracy across the frequency spectrum. I only recorded the

sound level of one bolt released. The sound meter reminds me of a

bottle of liquid shoe polish with the sound screen looking like the

applicator....grin if you must!

Above is pix of the set-up. Just enough room to walk around

equipment to equipment!

Like I said earlier, an overkill on the BowJax string dampeners......grin

if you must.

What surprised me was the point of impact of the bolts at 19 yards when I

added the last BowJax string dampeners next to the limb riser pockets.

The first bolt shot was the higher one in the target and the second one was

the last one I shot. Maybe things had to settle down, because the

crossbow was spot on elevation wise before the last BowJax string dampeners

were installed. I don't think it is my shooting error because the

crossbow is rock steady in my benchrest.

I plan to do some further tests with the Triplett sound meter since the

reading from the crossbow shot seemed very low in my humble opinion. I

whistled near the sound meter and it registered 65.7 db which appears to be

correct from what I have read concerning various sound levels that have been

documented. I have to run both our emergency generators and will check

their sound volume.

Web page updated by Bill aka Mickey Porter on 10-09-2020.

TESTING OUT THE SOUND METER

I test run our emergency generators on 10-10-2020 and the larger one

sound level was 104 db. I will check the sound level of the

crossbow again with the Triplett meter more out front of the crossbow and

about the same height for another comparison check.

TESTING CROSSBOW VOLUME AGAIN

I released two (2) 150 grain field tip bolts at a 19 yard target butt and

recorded the sound volume as follows:

The first arrow released with the sound volume above and bolt impact pix

below:

Yesterday, I released a couple 100 grain field point bolts that were

impacting the target high. The first one was higher than the second

bolt release with pixs a couple pixs above.

The second bolt released with the results below:

The second bolt was lower than the first depicted below:

The sound volume of the crossbow released three times average was 60

db. Nevertheless, it sounds loud to me and still not convinced of

the accuracy of the sound meter.

I have three (3) Rage TRYPAN Hypodermic 150 grain 2+ inch cut broadheads

and want to use them, since I will be taking 20 to 30 yard shots from my

ground blind with 20 yards being the normal yardage.

Using the Carbon Express Piledriver bolt, the total weight is 525 grains

which included the LAUNCHPAD

crossbow lighted nock and 150 grain Rage broadhead for some serious penetration.

Web page updated by Bill aka Mickey Porter on 10-10-2020.

RELEASED A FEW MORE BOLTS

I released several crossbow bolts this morning and the first two were in

the black center bullseye. The 3rd and 4th bolt impacted about two

inches to the right. I don't have a clue why they would be moving that

much. I checked all the screws, etc., and nothing was loose. It

could be the Excalibur scope, but my guess would be the upper limb Delrin

(black) saddle bearings are about to break the tab that is facing toward the riser since

there was an equal amount of gap between each end of the Delrin black saddle bearing

when I installed new ones, whereas now the Delrin saddle bearing on both right and left

upper limb are "tighter than two coats of paint" against the riser with some exposed gap

between the Delrin saddle bearings facing the cams.

Some crossbow threads allude that it might be the method you are using to

cock the crossbow with uneven pressure applied to the rope cocking device,

however I make certain that the rope cocking device hooks are against the

rail when I am pulling the crossbow string. I used the Dead Silent

Crank which apparently pulls equal with the same results for bolt # 4.

I will mark the crossbow string from each distance from the rail when at

rest and compare the distance once the crossbow is cocked and ascertain if

there is a discrepancy in my cocking method!

I will release a few more bolts to ascertain if the POI is the

same as when I last "fired" the crossbow. The bolt POI movement

would easily harvest a deer, but I am expecting more consistency than what I

am getting from this crossbow!

UPDATE: I waited an hour or two and released another bolt

and the point of impact (POI) was in the center of the small black bullseye. It

appears after several "shots", the point of impact POI is moving to

the right and upwards a little. I am not going to worry about it until

after hunting season is over and then try and figure out what is causing the

POI to move after a couple of bolts are released.

Web page updated by Bill aka Mickey Porter on 10-12-2020.

UPDATE: I released another test bolt this morning and the

POI was in the small black bullseye. I am planning on hunting on

the 15th and maybe the deer will cooperate a little.

Web page updated by Bill aka Mickey Porter on 10-13-2020.

STRYKER CROSSBOWS BITING THE DUST

I recently emailed Bethany Harrold of Pure Archery Group, Customer

Service Representative for Bowtech and other archery companies, etc., about

the problem with the v10 Delrin saddle bearings and apparently the Stryker

Crossbow division will be a thing of the past once their current inventory

is depleted. I wish I had saved the email for the exact details, but

this is the nutshell version of the email, if I perceived the email

correctly!

This decision was no doubt based on the fact that Bowtech purchased

Excalibur crossbows which has an outstanding reputation in the crossbow

market!

I will try and obtain another set of the v10 Delrin saddle bearings to

keep on hand since this is the main problem with the Stryker Solution LS

crossbow.

Web page updated by Bill aka Mickey Porter on 10-17-2020.

FIRST DEER WITH CROSSBOW

There was no way to get a very good photo since there was mixed sunlight

in the back yard at the hanging tree.

Above spike buck harvested on 10-17-2020 at about 1:56 PM. Short

story here:

https://portercalls.mountainbikebill.com

Web page updated by Bill aka Mickey Porter on 10-17-2020.

ORDERED SPARE SADDLE BEARINGS FROM BOWTECH

I placed an order with Bethany Harrold of Pure Archery Group, Customer

Service Representative for Bowtech and other archery companies, etc. today

via the landline for eight (8) of the v10 Delrin saddle bearings which

should keep the Stryker Solution LS crossbow running until it is time to

hang it up or it blows up!

Web page updated by Bill aka Mickey Porter on 10-20-2020.

NOTE: I received the two sets of v10 Delrin saddle bearings

on October 27, 2020.

Web page updated by Bill aka Mickey Porter on 10-28-2020.

HUNTING SEASON 2020 ENDED EARLY

I was fortunate enough to harvest four (4) deer with the crossbow this

season and still

had two (2) doe tags left, however our freezers in the basement was about

topped off and decided to end the hunting season early on 12-09-2020.

I continue to give God, the Praise, Honor and Glory in all things through

Jesus Christ our Lord and Savior and thankful for each and every day that He

allows!

Web page updated by Bill aka Mickey Porter on 12-10-2020.

RE-INVENTING THE WHEEL

Since using my first crossbow during the 2020 hunting season, I started

looking at some of the threads about crossbows and it appears that crossbows

have the same old problem with regular archery manufacturers promoting the

speed of their crossbows, of which sells crossbows.

With archery experience going back to the late 1970s, I have watched the

progress of archery equipment and it would be scary to know how many

different bows I have owned since getting into archery. I still have

four (4) cam/round wheel compound bows and 2 are wall hangers for sure!

I believe I had thirteen (13)

recurve bows and 1 long bow at one time also,

of which I sold the entire lot to a hunter/collector in SC.

Before hunting with a bow of any type, I purchased a used recurve target

bow complete with arrows and the whole ten yards of equipment, however I

wasn't truly aware of the importance of the dominant eye and the bow was for

a right handed shooter. I shot it pretty good instinctive style even

with a dominant left eye and later sold the entire outfit to who I can't

remember.

With that said, my first compound bow was a Bear round wheel bow with

hanger brackets for the round wheel/cams which was very noisy and slow and

later purchased a Bear Brown Bear model round wheel compound bow which was

fast, but noisy. The riser was not center shot and sent the bow back

to Bear and they replaced it with one that was center shot; e.g., riser was

cut thinner. I do believe I was probably the first to design an

off-set cable guard to isolate

the two cables on the Bear Brown Bear model bow which reduced the noise of

the bow. I harvested my

first deer with that bow, a few more deer

and a Bobcat before switching to PSE equipment.

I remember I had PSE custom build a left hand bow using their Mach6 rise

with a set of Mach5 carbon limbs since they did not make a Mach5 in left

hand model and the price tag on it way back then was 1K dollars.

My point being, seems like ever time there was some new development in

bow technology, I did an upgrade in equipment which can get very expensive.

See my Murphy's Law

short story.

Looking back, the big factor was the lure of increased arrow speed and I

had my share of limb cracking, bow noise, vibration, hand shock and

everything that goes along with increased arrow speed.

All of what I just wrote equally applies to the crossbow.

Manufacturers are pushing the limit to increase the bolt speed which is the

major culprit for crossbow limb failures in my humble opinion. With

the increased speed, individuals will no doubt take much longer shots

resulting in crippling game animals and there are many irresponsible hunters

using all types of weapons with their primary goal of bagging a game animals

with whatever means and action is necessary.

NEWTON'S THIRD LAW

Sir Isaac Newton first presented his three laws of motion in the

"Principia Mathematica Philosophiae Naturalis" in 1686.

His third law states that for every action

(force) in nature there is an equal and opposite reaction.

This definitely applies to the crossbow and shooting too light weight of

a bolt is probably the major cause of crossbow limb failures over time,

other than just poor manufacturing technology. Manufacturers are

recommending too light weight of bolt in order to increase bolt speed in my

humble opinion.

ARCHERY MANUFACTURERS ORGANIZATION

Fred Bear set the standard in the archery industry for

arrow hunting weight (AMO) being a factor of 9:1; e.g., a 60 pound

pull bow at 28 inches should have an arrow weight of 540 grains. I

realize that might not be realistic for crossbows due to the draw weight,

but it should wake up some folks!

As I have stated many, many times over the years and practice what I

preach, "It is arrow placement that brings home

the venison, not arrow speed."

INTERNATIONAL BOWHUNTERS ORGANIZATION

The IBO standard is 5 grains of arrow weight for each pound of bow

pull, therefore a 60 lb. draw weight bow would use a 300 grain arrow.

I have seen videos of hunters using 70 pound pull cam bows with such a light

arrow and about 2/3s of the arrow would be sticking out of the deer as it

ran off, especially if the arrow contacted a shoulder and/or bone.

Arrow speed, but no penetration in my humble opinion.

CURRENT CROSSBOW PRICES

With all the new technology, the perceived crossbow leaders

apparently has added platinum to their rail and riser assemblies since the

price is totally unreal and crazy! There definitely is nothing wrong

in purchasing the "best" if you can afford it, but you can get a 400 fps

crossbow for less than 500 bucks that is fairly reliable and paying 3K dollars or more for a

crossbow that will shoot a bolt 500 fps is insane in my humble opinion!

To reiterate, "It is arrow/bolt placement that brings home

the venison, not arrow/bolt speed."

STUPACRATS

If our Lord tarries long enough and the current 2021

"Stupacrats" in Washington, DC consisting of both

Demoncrats

and Republicans continue to erode our democracy, America might end up

speaking Chinese and having to shoot a

slingshot

or throw rocks for hunting and self-defense.

Open this .PDF

file if you think China is asleep!

Read my quote of

the decade short story and

America's Moral Decay.

Web page updated by Bill aka Mickey Porter on

01-16-2021 and 01-22-2021.

LIQUIDATION OF CAM BOWS AND ACCESSORIES

On April 19, 2021, I broke my right arm

radius bone about

one (1) inch from the wrist which required 2 plates and 8 screws to secure

the crushed bone while it healed and another recent surgery to remove the

top plate and screws to allow the wrist to bend.

Therefore, I decided to sell all my archery

equipment and accessories except that which pertained to the crossbow.

An acquaintance of several decades was contacted and he agreed to purchase

said equipment, accessories and supplies.

Below are pixs of my crossbow corner at the present

time:

I relocated the crossbow press which freed up the workbench area and now

more user friendly.

A fixture was made just for the Bowtech Stryker Solutions LS Crossbow

before I broke my right arm which has a boat winch and can cock and decock the crossbow as desired.

Web page updated by Bill aka Mickey Porter on 07-30-2021.

SADDLE BEARINGS BREAKING AGAIN

On 10-21-2022, I noticed that one of the black Delrin saddle bearings

(bottom right limb) was coming out

of the limb pocket, whereas one end of the saddle bearings tab was

completely broken off which allows the saddle bearing to move out of the

limb pocket. I replaced four (4) sets of Delrin saddle bearings on 09-17-2020

which lasted a little over two years. As stated earlier, those Delrin

saddle bearings breaking is the

Achilles' heel for this bow model. I

checked the crossbow further and noticed that the top left limb Delrin

saddle bearing was broken also.

The broken end of the black Delrin saddle bearing is laying on the riser

above!

The other saddle bearings are about to break as well, whereas one side of

the saddle bearing will work its way against the bow riser and then shear

aka break off and there is no way for the saddle bearing to remain in place.

I will use this crossbow as a back-up as I have a TenPoint Titan De-Cock

crossbow with the ACUdraw crank on order.

Web page updated by Bill aka Mickey Porter on 10-22-2022.

TENPOINT TITAN DE-COCK ACUDRAW CRANK CROSSBOW SAGA

I purchased a TenPoint Titan De-cock ACUdraw crank crossbow from Wyvern

Creations, LLC via the internet on 10-24-2022.

This crossbow was going to replace a 2014

Bowtech Solutions LS model

crossbow (shown below) which has issues with the Delrin bearings, but is

still shootable and have harvested two (2) deer with this crossbow so

far this hunting

season.

Another reason for choosing this crossbow

(TenPoint Titan De-Cock ACUdraw crank), I

needed a simple means to cock and de-cock the crossbow and not having to shoot a

bolt in order to de-cock the crossbow. The Titan M1 crossbow platform had very

good reviews and hoping the same for this model TenPoint crossbow Titan

De-Cock ACUdraw crank,

however

"the jury is still out"

as will be manifested in this short story!

On 10-28-2022, I placed a TenPoint (SDS) String Damping System on

the stock to help prevent excessive noise and vibration. I

also installed a pair of BowJax limb vibration dampeners on the limbs

prior to shooting and sighting the scope in.

ACUDRAW LOCKING UP RIGHT OUT OF THE GATE

I noticed right off that the ACUdraw crank system was giving trouble by

locking up (binding) before I

got the U shaped string claw attached to the crossbow string and it was

difficult to get the claw to release after the crossbow was cocked. I shot maybe a dozen (12) crossbow

bolts within a few days and finally the ACUdraw mechanism locked up and I could

not release the U-Shaped claw from the crossbow string with the crossbow cocked without a lot of trouble and

effort. Finally, the ACUdraw crank retraction power spring broke.

Also, the two stage trigger pull became a single stage trigger pull and

you were pulling against the wall all the time and the trigger pull

poundage to me was excessive. However, I am use to a very light

trigger pull on all my firearms and the Bowtech crossbow I have been

using has a light trigger pull, maybe 3.5 pounds and less than 2 lbs. on

my CZ 452

American .22 caliber rifle.

Also, the cams were not in time, but didn't seem to affect the accuracy.

TENPOINT CUSTOMER SERVICE LACKING

I contacted TenPoint via the contact form on their website and they

later advised that

I take the crossbow to one of their authorized service center dealers

after I had already

made the trip three (3) days earlier. I had earlier tried to contact them

via email, but

did

not get a response. Also, I tried their 330-628-9245

land line and

got no where with their convoluted automated telephone service and never

did get to speak to a live person; e.g. customer service. I was

placed on hold for an extremely long time and finally gave up!

It might be easier to locate someone in the Federal Witness Protection

Program than contact a customer service representative at TenPoint

Crossbow Technologies in my humble opinion!

COPY AND PASTE FROM TENPOINT

LIVE CHAT

William Porter

Fri, 11/11/22 7:32 am

Even your own repair facilities do not have a diagram of the mechanism.

I went to one of your repair shops and they charged me 40 bucks for a

main spring that should be under warranty. I shot the Titan about

12 times and the spring failed.

Also, you folks do not answer emails either.

Your service sucks.

Here is what I did to a 1000 dollar top of the line PSE bow,

circa 1994

Description:

https://portercalls.com/images/PSEMach6WarrantyRepair2.jpg

NOTE: See my

Murphy's Law short story which details

why the above bow ended up in 13 pieces and deposited in the landfill in

2008.

Looks like your Titan might be a candidate.

Have a blessed day.

later,

Bill Porter

Below is a conversation with TenPoint after I received my bow back from

their authorized service center dealer in China Grove, NC

Michelle

Thu, 11/10/22 9:16 pm

If you mean schematics, no. That is proprietary information. If you need

yours repaired, please go to a service center as recommended in our

previous chat.

William M Porter

Thu, 11/10/22 12:45 pm

Zip Code: 28170

Message: Do you have a diagram for the Titan De-Cock ACUdraw crank?

PROPRIETARY INFORMATION

NOTE: I did an internet search at the US Patent Office on

11-12-2022 and found U. S. Patent 11,428,499 B2 pertaining to the

de-cock trigger group which was patented this year (08-30-2022) assignee

Hunter's Specialty Manufacturing, Inc, D/B/A TenPoint Crossbow

Technologies. So much for

proprietary information per TenPoint Michelle!

YOUTUBE VIDEO by BRYAN ZABITSKI - SERVICE & REPAIR MANAGER TenPoint

HOW TO REPLACE THE ACUdraw POWER SPRING TenPoint

CROSSBOWS

The video

is fairly

generic to other models of the ACUdraw

as to how the retention power spring operates and the replacement of

said spring.

TENPOINT AUTHORIZED SERVICE CENTER DEALERS

As eluded to earlier, I contacted one of TenPoint's authorized service

center dealers in China Grove, NC and drove there on

November 7, 2022 which was a 60 mile drive one way and it took about 1.5

hours to make the trip. The repairman, can't remember his name

(maybe the owner) took the ACUdraw mechanism apart and stated that he

had never worked on that

particular model and did not have a spring for it, whereas he would fill

out a warranty repair and order one from TenPoint.

Later that same day, the authorized service center dealer called and stated they found a

spring for the crossbow and had it repaired and the bill was $ 100.00.

I drove to the repair center on the 10th and was waiting at their business

which opened at 10:00 AM.

We tested the crossbow, cocked it and de-cocked it and it did

lock up (bind) one time while

retracting the claw from the crossbow string and

then worked fine. I asked the owner if he charged me for the

retention power spring and stated it wasn't

covered under the warranty. I paid the 107 dollars which included tax and left him a

3 dollar tip. I was charged 40 dollars for the spring, 60 dollars

labor charge and 7 dollars tax. I looked up the cost of the spring

on line and it was a little less than 15 dollars! I think I got

"took to the cleaners" on that for sure.

I asked them about the two-stage trigger pull not working and they did not

address that issue, but said "crossbows normally have a heavier trigger

pull", of which I understand.

It makes me wonder if they placed the original

retraction power spring back onto the spool hub since the end of the

spring was broken at the hub. It would be easy to bend the end of the spring a few

degrees,

drill a hole in the end of it and reuse the retraction power spring.

I contacted Wyvern Creations via email and left them information about

the trouble I was having with the crossbow and he said

"I forwarded this up the ladder at TenPoint

to make sure it does not get buried. Hopefully someone will

contact you."

I am very well pleased with the customer service from Wyvern Creations,

but extremely displeased with TenPoint's apparent no customer service as

far as I am concerned. I have read numerous threads on the

crossbow nation website aka (blog) and I am definitely not alone in my

assessment of the quality of their customer service!

I ordered an Excalibur Tact-100 scope from Wyvern Creations to

replace the TenPoint Pro-View 3 scope that came with this crossbow.

NOTE: On 11-11-2022, I filled out the contact form on TenPoint's

website and requested a RA number to send the crossbow back to

the factory. It is still locking up

intermittently, even though I am following the

instruction manual and pulling the claw out slowly as per the

recommendation of Wyvern Creations and TenPoint.

So far, I have driven approximately 240 miles taking about 6 hours (two

round trips total) to China Grove, NC and the crossbow is still not

functioning properly 100 percent of the time and not to mention spending

107 dollars for said repairs and vehicle gas!

NOTE: On 11-12-2022, I placed the crossbow in a home made

cocking and de-cocking station and test fired the crossbow several times to check the

trigger pull poundage with a digital meter. As fate would have it,

the crossbow cocking mechanism did not lock or hang up while strapped

down in the fixture, but worked as it

should.

I used a Lyman digital trigger pull gauge to ascertain what the trigger pull

was and the readings of the trigger pull was as follows: 7 lbs. 10 ozs.,

and 7 lbs. 7 ozs. for a average of 7 lbs. 8.5 ozs. which is a heavy

trigger pull for me. Also, the two stage trigger pull is not

present, but you are simply "pulling against

the wall" and there is a little creep detected in the

trigger pull. I don't know for sure

if the trigger pull poundage reading I got was accurate since I could